One of the main tasks solved during design - reducing heat loss - is implemented in different ways. Despite the multiplicity of methods, the most effective is considered to be the competent organization of thermal insulation using finishing materials of the “insulation” category. The market offers a large selection of relevant products, so there are no problems with purchasing them, especially since the cost of samples is quite reasonable. However, according to experts, preference should be given to products made from natural raw materials. One of them, Izovol insulation, will be discussed in the article.

Only a professional can understand the terminology applied to various insulation materials, especially if their names are similar. In our case, these are Izovol and Isobel. If you carefully review all the descriptions of materials available on the Internet, you can come to the conclusion that there is practically no difference, since their main characteristics are for the most part identical. And still?

Firstly, Izovol is a brand of a Russian company that supplies the market with insulation materials of several modifications, but on a common basis. Secondly, Isobel is just one of them, which is more often used for thermal insulation of various floors (partitions), as well as to increase the level of noise protection, since the density of the material is lower. Plus, insulation with this name is not only more resistant to thermal influences, but also to open fire. Therefore, there is no fundamental, significant difference between the Isovol and Isobel brands. When purchasing, you should only pay attention to the characteristic that is the most important for thermal insulation, based on the specifics of the installation of a particular sample.

Insulation for sandwich panels

The group includes five types of materials, let’s get acquainted with them.

| Name | Dimensions, LxWxT | Thermal conductivity, measured in W/(m*k) | Vapor permeability |

| SS-105 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,037 | 0,3 |

| SS-110 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,037 | 0,3 |

| SK-120 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,036 | 0,3 |

| SK-130 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,036 | 0,3 |

| SK-140 | 120x60-62.7-100-101x10.2-12.2-15.1 centimeters | 0,037 | 0,3 |

So we looked at what Izovol insulation is. The range is simply huge, all products are of high quality and have excellent characteristics, and they are relatively inexpensive. In other words, an excellent combination of price + quality. That's all, good luck with your work and have a warm winter!

We also advise you to thoroughly familiarize yourself with the thematic video material below.

Video - How to insulate a balcony with Izovol thermal insulation

Insulation Tehnoruf

Previously, we talked about the main advantages of the Tekhnoruf material, its areas of application and prices, in addition to this article we advise you to read this information, see details here

Areas of use of Izovol heat insulator

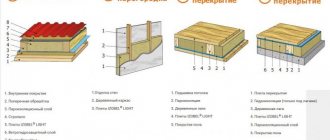

The described type of insulation is widely used not only in private, but also in industrial construction. And it’s not surprising, because basalt wool is the best option for the following structures.

- Facades of buildings with one or several floors (including under “wet” plaster).

- Pipelines, ventilation channels.

- Joists in the floor and, if the mineral wool used is characterized by increased density, under a concrete screed.

- Industrial equipment, various types of production lines.

- Pediments and attics (in this case, insulation can be done both from the inside and outside).

- Garages, verandas, agricultural facilities.

- Roofs (pitched and straight).

- Ceilings and walls (material is laid from the inside).

Reviews about Isobel insulation

Isobel is an economical insulation material.

If the insulation is used for its intended purpose, then there are no complaints from users. So, Isobel is perfect for insulating horizontal floors. In this case, the density of the material is not of key importance, since the thermal insulation is not affected by high mechanical loads. The only thing that can be a problem is the accumulation of moisture in the thermal insulation, but this is not caused by the quality of the insulation, but by improper installation of the vapor barrier. The same problem is encountered when insulating a roof with mineral wool. If you position the vapor barrier and waterproofing incorrectly or forget to leave a ventilation gap, the insulation will be wet.

Negative reviews about Izobel thermal insulation can be found from those who have used the material to insulate walls. The complaints are caused by shrinkage, which is inevitable when soft fiber insulation is installed incorrectly. What to do to prevent Isobel from shrinking:

- install horizontal support bars every 2-3 meters;

- glue each slab to the wall;

- fasten the slabs with mushroom dowels.

And remember the requirements for insulation density for different types of work. For example, only material with a density of 55 kg/m is suitable for walls. cube or more. When using lighter materials, you need to resort to one of the above methods to prevent shrinkage during operation.

The main advantages of Izovol insulation

There are many advantages, let’s briefly consider the main ones.

- The material is made from high quality gabbro-basalt rock.

- Another advantage is the production technology, which distinguishes Izovol from its competitors. The bottom line is this: stone wool is not melted in blast furnaces - gas is used for the melt, due to which the quality of the final material increases significantly. Special units transform the molten mass (and its consistency resembles liquid lava) into basalt threads, from which, in turn, insulation slabs are created.

- As for the chemical and physical properties of the material, they allow it to be used not only for insulation, but also for fire insulation.

- In this regard, Izovol can be used in those structures and buildings that have many elements made of wood. This significantly increases the degree of fire safety, since the described insulation is also fireproof.

- Basalt wool “survives” even the direct impact of a flame without any problems; it does not deform even at 800 degrees.

- Another advantage of insulation is its durability. The service life is at least fifty years.

- It is also resistant to various types of chemically aggressive environments, rodents, harmful bacteria, atmospheric conditions, and the material has excellent mechanical strength.

- In addition to its direct purpose, Izovol insulation can also be used for sound insulation. This is explained by the fact that the slabs, as noted above, consist of basalt threads arranged randomly. Because of this, sound penetrating into the material is reflected a large number of times and eventually attenuates. After all, water, as is known, conducts heat well, therefore, its presence in the thermal insulating layer is extremely undesirable.

- Moisture resistant. The use of special additives allows the material to retain its original properties at high levels of humidity, and also to absorb up to 1 percent (when compared with the volume of insulation) of liquid.

- Affordable price (we'll talk about this in more detail a little later).

- Good vapor permeability, thanks to which moisture from the room evaporates freely, while the structure itself remains dry.

- Finally, the material has excellent thermal insulation characteristics. Its thermal conductivity averages 0.033-0.039 W/μ, thanks to which (at least according to user reviews) walls, roofs or ceilings can be effectively insulated even with a relatively small thickness of the material.

Note! Izolon, as we found out, is made exclusively from natural raw materials, so it is absolutely safe for health. It can be used to perform internal thermal insulation in hospitals, kindergartens and schools.

Paroc insulation

Previously, we talked about the prices, areas of application and technical characteristics of Paroc insulation; in addition to this article, we advise you to read this information, see details here

Technical thermal insulation

This group is not as numerous as the one described above - it includes only five different versions of mineral wool. Product parameters can be found in the table below. By the way, they are all produced in the form of cylinders.

| Name | Operating temperature, degrees | Thermal conductivity, measured in W/(m*k) | Acidity | Density, kilograms per cubic meter |

| 50 | -180 to +650 | 0,034-0,078 | 2,0 | 50 |

| 80 | -180 to +650 | 0,034-0,078 | 2,0 | 80 |

| 100 | -180 to +650 | 0,034-0,078 | 2,0 | 100 |

| 120 | -180 to +650 | 0,034-0,078 | 2,0 | 120 |

There is also technical insulation made in the form of mats. The dimensions of such mats (WxD) are 100x4-10 centimeters, density varies between 40 and 80 kilograms, thermal conductivity - from 0.034 to 0.093, operating temperature range - from -180 to +570 degrees.

How to make Isobel insulation

In green packaging, the mineral wool density is 25 kg/m. cube

Isobel is a basalt fiber insulation material. To obtain such fiber, rock (frozen magma) mined from dormant volcanoes is delivered to a processing plant where it is crushed into small pieces. Then the resulting placer is melted at a temperature of over 1 thousand degrees, resulting in a liquid mass.

To obtain fibers from molten magma, a strong air flow is directed at it. The material seems to be sprayed, and when the fibers land in a special container, they no longer stick together. To make Isobel slabs, basalt fibers are treated with an adhesive composition and sent to a molding machine, where the material is given the required dimensions. Also, the molding machine compresses the mineral wool to a set level, in our case it is 25 or 35 kg/m. cube

The last stage is checking the insulation by a technical control body for compliance with the established characteristics and packaging the thermal insulation in polyethylene. Unlike glass wool, basalt fiber is packaged in its original form, that is, not compressed. Advantages of Isobel insulation:

- produced in the Russian Federation;

- is cheap;

- does not contain blast furnace slag and coke.

It should be noted that phenol-formaldehyde is added to the adhesive composition for basalt fiber.

In its pure form it is a toxic substance, but as part of insulation it does not pose any danger. In addition, phenol-formaldehyde is contained in all plastic products, cabinet furniture and other materials that surround us in everyday life. Claims that mineral wool is dangerous to health are too exaggerated. If you want absolutely ecological thermal insulation without any impurities, then use expanded clay to insulate the floor, walls and ceiling.

To reduce heat loss, thermal insulation of pipelines with mineral wool in rolls or cylinders is necessary.

Read about which mineral wool is best for the attic in this article.

Fire retardant materials

This group is even less numerous than the previous one. To be more precise, this includes only one type of insulated material being described - this is F-150.

Here are the main characteristics of the insulation:

- dimensions (LxWxT) – 100x60x3-18 centimeters;

- tensile strength – 20 kPa;

- compressive strength (if the material is deformed by ten percent) – 6 kPa;

- humidity – no more than 0.5 percent.

Well, it remains to deal with the last group.