How does electric ignition work in a column?

The electric ignition unit can operate from different power sources - from batteries or electricity. Geysers with this type of inclusion are called “Automatic”.

The ignition unit requires two thick 1.5 W batteries to operate. To ensure they last for a long time, it is recommended to install high-capacity LR20 alkaloid batteries.

Design and malfunctions of a gas water heater with piezo ignition

Gas water heaters are household bestsellers

The disadvantage of electric ignition using batteries is the need to constantly replace them. You should always have a supply of batteries so that you can quickly replace them.

Columns are rarely equipped with electric ignition from a hydraulic turbine. A hydraulic turbine generates an electric current as fluid passes through it. Water enters the element when the hot water tap is opened. This type of device is much more convenient than one powered by batteries, since it does not require constant replacement. However, the downside is the need for good water pressure - at least 0.3 bar.

How to determine power

First of all, you need to decide on the power or performance of the gas water heater. These are two interrelated characteristics that simply reflect different characteristics of the unit. Performance is how many liters of water a column can heat per minute, and power is how much heat it can release. Some manufacturers indicate power, others indicate performance, so you need to understand exactly what you need.

Let's first figure out what kind of performance you need from your geyser. This depends on the number of consumers who need to be provided with warm water. There are consumption standards for different types of equipment:

- kitchen sink, washbasin - 4 l/min;

- shower - 7-10 l/min.

The higher the power, the larger the size

If you have a kitchen sink, shower and washbasin connected to hot water, so that all three points work simultaneously and the water temperature does not drop, you need a capacity of 4 + 4 + 10 = 18 l/min. This is a lot, the price tag will be substantial. If you think about it, you will realize that all three devices are almost never turned on at the same time. There are situations when the shower and one of the taps work together. To provide them with hot water, the capacity must be 14 l/min. This is a little more modest, but quite enough for a comfortable stay. Look for the found value in the technical specifications; it should not be less.

Now let's look at power. Gas water heaters can allocate from 6 kW to 40 kW of heat for heating water. Here the division is:

- a gas water heater with a capacity of up to 19 kW is suitable for heating water for one water collection point;

- for two points the power should be from 20 kW to 28 kW;

- three require more than 29 kW.

Now, you can definitely say which geyser is better in terms of power in relation to your needs.

Reasons why electric ignition may not work

In some cases, instantaneous water heater users are unable to turn on their device. What could be the reason why the electric ignition of a gas water heater does not work? There are many answers to this question:

- If water or gas is turned off, you should check their availability in the centralized mains.

- The batteries are low and require replacement.

- If the gas or water filter (if equipped) is clogged, you need to inspect them and, if necessary, clean them or replace them with new ones.

- Insufficient water pressure (this especially negatively affects columns with turbine electric ignition). If the water barely flows, then the pressure is not enough for the device to turn on. More often this problem occurs in rural areas or in old houses.

- The water temperature set on the column is too low - you should check what temperature indicator is set.

- The coaxial chimney fan has failed.

- There is no draft in the chimney and the draft sensor blocks the operation of the column. In this case, it is necessary to check the chimney for blockages or backdraft. It happens that the wind blows into the chimney and extinguishes the burner.

- There is not enough fresh air flow - you should check the functionality of the ventilation and open the window.

- The heat exchanger is heavily clogged with scale and limescale. This can cause low water pressure and lead to the column not turning on. The problem is solved by cleaning the circuit. There are special cleaning products for this.

Lights up and goes out immediately after turning on the water supply

Reason #1. Low pressure – insufficient water pressure in front of the device. Eliminate the reasons that reduce the water pressure in the supply network. Clean the dirt in the hoses, rinse the filter element with running water, and replace the mixer screens.

Reason #2. Loss of elasticity of the membrane - mainly for domestic speakers. The membrane of the water unit breaks or breaks, or the plate of the water unit breaks. It is necessary to disassemble the water unit and replace the membrane or plate.

Reason #3. Mixing pressures (pressure drops) - to obtain the desired temperature, use the water flow regulator on the front panel. Adjusting the flow by mixing hot and cold water at the outlet of the water heater is prohibited.

Reason #4. Weak draft, soot - the system for discharging combustion products into the chimney is faulty. Clean the chimney and ventilation duct. Check the integrity of the reflector and breaker. The draft is checked with a burning match, bring the fire to the window in the column, the flame should be drawn in.

Electric ignition for a gas water heater

Present in fully automatic boilers. The operating principle of an instantaneous gas water heater with electric ignition eliminates the need for a constantly burning wick. The main burner ignites immediately. The source of electricity is a 220 W household network, batteries or a hydrogenerator built inside.

Automatic electronic ignition of the gas water heater occurs when the hot water tap is opened. After closing the DHW point, the burner goes out on its own.

Reasons for the lack of flame in boilers with automatic ignition and ways to eliminate them

The ignition unit is damaged

The photo shows the electrical part of the Ariston turbocharged boiler.

To determine the condition of the ignition unit, you can use an electronic tester in ohmmeter mode. The probes are connected to the output of the ignition electrode contacts (or to the electrodes themselves) located on the block. The unit is operational if the tester readings are within the range of 650 - 750 Ohms.

Checking the automatic ignition unit of the Ariston boiler.

In a damaged unit, the tester will detect an open circuit (1 will be displayed on the display) or a short circuit (0 will be displayed). The identified faulty part is replaced with a similar one.

Flame control electrode dirty

During the combustion of fuel, soot is formed, which gets on the working surface of the electrode and disrupts its proper operation. Clean the surface of the electrode with fine-grain sandpaper. If it doesn't help:

- move the temperature control knob to the heating off position;

- wait until the circulation pump and smoke exhauster turn off;

- on the instrument panel, press the switch off button;

- unplug from the socket and turn 180 degrees the plug of the device;

- insert the plug back into the socket;

- turn on the boiler.

Smooth shutdown of heating equipment extends its service life.

The operation of the flame control unit, due to its operating principle, depends on the phasing of the supply network (phase and zero connection points). Therefore, rephasing helps him restore the sensitivity of the gas ions.

Low mains voltage

The ignition unit and electronic gas valve may not work properly due to insufficient voltage in the network. To maintain a stable level of supply voltage, it is advisable to connect the boiler through a voltage stabilizer. It will provide protection for the electronic elements of the gas boiler during power surges.

Gas valve malfunction

The valve may be blocked by debris that has entered through the gas burners. In the device, the inductance coil designed to control the valve position may burn out. To check it, on a completely de-energized boiler, an ohmmeter is connected to the terminals. The coil is considered working when the reading is 80 - 90 Ohms.

Checking the gas valve coil.

To clean the gas regulator, the side part of the housing is unscrewed where the valve is located. Garbage is removed and his work area is cleaned.

Reassemble in reverse order. Often, to assemble a gas regulator, fasteners with a common head profile are used: an asterisk with a pin. To work with such hardware, you need to purchase a screwdriver with a blade of the required size and profile or sharpen a screwdriver with a flat tip.

What is a column flame ionization sensor

- ionization electrode;

- photosensor.

The principle of operation is based on the fact that during the combustion process in gas columns, flame ionization or the production of ion current is created. The amount of energy is directly proportional to the intensity of combustion. Incorrect gas-air mixture ratio, dust settling, and extinguishing of the main burner lead to the sensor triggering. By blocking the gas supply, gas leakage is prevented when the burner goes out spontaneously.

How to light a column correctly

Ignition is carried out as follows:

- the gas supply button is pressed;

- after 10-15 seconds, the piezoelectric element key is pressed or a burning match is brought up (depending on the type of ignition);

- the wick ignites;

- After another 20 seconds, the gas supply button is released.

A geyser with electric ignition turns on independently when the hot water tap is opened. Switching on should be silent. Popping noises and prolonged operation of the spark generator unit indicate a malfunction.

Burner, combustion chamber, chimney

Heating of water in a gas water heater occurs due to the heat released during gas combustion. The combustion itself occurs in the burner, and it is “packed” into the combustion chamber. Unburnt gases that remain in the chamber are discharged through the chimney. Let's take a closer look at all these devices.

Burner - main unit

Burner

The heat source in the gas water heater is a gas burner. There are three types: single-stage, two-stage, modulated. The first two types are almost never seen lately - they do not allow maintaining a given temperature, so there is no point in considering them - all columns have a modulating burner.

This is what a gas burner for a water heater looks like when installed

Modulating burners can be controlled manually - with a special handle mounted on the body - or through a microprocessor that maintains a given water temperature. Burners are made mainly of galvanized steel, since this material is optimal for performing the assigned tasks. It is inexpensive, durable, has a high melting point, and can withstand frequent heating.

Types of combustion chamber and chimney

Combustion chambers in geysers are of two types - open and closed. Their name reflects the essence:

- closed (turbocharged, fan) is a metal box into which a burner is inserted with a socket at the top for installing a chimney;

- open (atmospheric) - this is actually the entire body of the column, since there is no isolated space, just a burner is installed in a certain place, on top there is a lid with a socket to which the chimney is connected.

Different types of combustion chambers require different chimneys. In an open chamber, air is taken from the room, therefore an effective ventilation system, normal air flow and an atmospheric chimney exiting into the ventilation duct are necessary. The closed chamber is equipped with a coaxial chimney (two pipes of different diameters inserted into one another), which is led through the wall to the street. In this case, combustion products are removed forcibly, using a fan, through the inner pipe, and oxygen flows directly to the burner through the outer pipe.

Open and closed combustion chambers at gas water heaters require the installation of a different type of chimney

A gas water heater with a closed combustion chamber operates more stably under normal conditions, but it has disadvantages. In winter, the chimney can become overgrown with frost, causing the heater to go out (it is extinguished by an automatic system that controls the removal of combustion products). The second point is that with a strong side wind, the air flow can blow out the flame. The gas supply is turned off by the same automatic system, but the situation is unpleasant. The third circumstance is that not all city authorities allow holes in the walls of houses and the insertion of pipes.

So in this case, it is difficult to say exactly which geyser is better - it depends on many factors.

Why the ignition may not work

Electric ignition is considered one of the most vulnerable elements of a gas boiler, since it is the one that most often fails than other components. The causes of failure may be errors made during operation of the device, wear of parts or mechanical damage.

Having discovered that the ignition is not working, first of all you need to make sure that it is connected to the electrical network and that there is voltage in it.

If everything is fine with the power supply, but the device still does not function, the reason may be a faulty power supply or button, or a damaged wire. To diagnose a breakdown, you will need a tester; it allows you to check for conductivity.

What happens when the water starts

So, the structure of the column is more or less clear, but how does the column work in principle? And it works by launching a whole chain of processes.

First, water flows pass through the “frog”, then a draft is created in its chamber. Under the influence of high pressure, the elastic membrane bends and pushes the plate, which pushes the water unit of the gas column, which then pushes the gas rod.

After this, the pusher connected to the rod ceases to hold the microswitch plate, and it closes the circuit, thus releasing power to the gas water heater control unit.

In addition, as a result of the above process, the spring bellows is pressed out. valve, removing the plate that closes the channel, and freeing it (gas) free passage to the manifold.

Having received power, the solenoid valve of the column opens without interfering with the gas flow through the spring valve to the manifold.

At the same time, the control unit transmits a small impulse to the candle, which is necessary to form a spark that ignites the burner flame. In this case, the flame is controlled by a separate ionization sensor. If within six to seven seconds there is no signal from the sensor and the burner does not ignite, the electronic module shuts off the gas supply.

This is necessary for safety reasons to avoid gas leakage. If ignition was successful, the sensor will signal to turn off the candle. If the burner goes out after ignition, the sensor also immediately blocks the passage of gas through the solenoid valve of the column.

Work when the water is turned off

The design and operating principle of a flow-through heater depend on the automation of the heating process. After all, a water heater is a heating device. But what happens when the water supply stops? Here's what: the pressure inside the “frog” comes into balance. All the elements fall one after another, like dominoes.

The elastic membrane returns from its bent position to its normal position, thereby returning the plate connected to the pusher. The rod, returning to its normal position, in turn returns the mechanical valve to shut off the gas. The rod also returns the pusher to the mode of pressing the microswitch plate, as a result of which the electrical circuit is broken and the power to the control unit is cut off again. The solenoid valve, no longer powered by anything else, also closes.

This is how another chain of processes occurs, the opposite of what happened when the water was turned on. You can check the status of the column simply by looking at the LCD display. The image below shows the components of the device necessary to turn off the water heating process.

Conclusions and useful video on the topic

You can learn how to independently repair the piezo ignition of one gas burner from the following video:

How to restore the operation of electric ignition on two gas burners is explained in detail in this video:

A breakdown of the piezo ignition of a gas stove today is not a disaster, because with all the necessary knowledge, now anyone can repair the device on their own. The main condition is to carry out diagnostics of all elements of the electric ignition system to correctly identify the breakdown.

If you have already had to independently repair the electric ignition of a gas stove, then please share your experience with our readers and tell us what nuances you should pay attention to during the repair process. In a special block after the article, you can leave a comment telling your story of successfully restoring the operation of the piezo ignition of a gas stove.

How to ignite the device

After the device has been installed, the gas water heater is started for the first time. First of all, open the water and gas supply taps. Then, the column is turned on, presented in three ways.

Manually

This method was used in older type columns. You can start the gas water heater only with matches. Fireplace matches are considered the best option for ignition.

In this case, the following actions are performed:

- Open the tap on the water pipe related to the column;

- Turn the gas supply valve;

- The wick is lit with matches;

- The fuel supply valve is turned and the water temperature is adjusted using a special lever.

lighting is not difficult. Switching off is done exactly the opposite. First of all, you need to turn off the wick, turn off the gas, and then turn off the water.

It is worth working with the old type samples very carefully. Otherwise, an explosion, device failure, or gas leak will occur.

Using piezo ignition

A semi-automatic device with no batteries, having mechanical switches in the form of handles. To ignite it, you need to get a spark.

The following manipulations are performed:

- Open the fuel transfer;

- Clamp the solenoid valve for twenty seconds to obtain a decent amount of gas for the flame;

- Press the piezo ignition key;

- As soon as the wick lights up, set the required indicators on the temperature regulator.

How to properly light a Bosch gas water heater:

- The water and gas supply tap turns;

- The regulator is set to the “on” position;

- The pointer is placed on “piezo ignition”;

- As soon as the contacts work, a spark will appear;

- The start button is not released until the flame flares up; as soon as this happens, the desired power is set.

The wick is in working condition all the time. As soon as the mixer opens, the column begins to heat up. To turn off the wick, set the regulator to “Off”.

In addition to the advantages, this type of speaker also has disadvantages. These include decent fuel consumption with constant wick operation. If the piezo ignition is broken, then the device is ignited using matches.

Automatically

In this way, new models of geysers are set on fire, namely Bosch, Ariston and Beretta. There is a compartment for batteries. To carry out the work, open the gas supply valve, and for the device to start working, open the mixer. A spark comes from the batteries and the device lights up.

Switching on is carried out in the presence of a water turbine. As soon as the mixer is opened, the water begins to turn the turbine, which turns on the electricity in the burner. The only drawback is that at low pressure in the line, the turbine will not turn on or will heat up weakly.

Problems with gas speakers

The geyser is a device that can fail. More serious problems can only be corrected by a specialist, but most cases can be corrected by an ordinary person.

More often, a device malfunction manifests itself as follows:

- Not turning on the gas water heater. It is necessary to check the batteries; they may need to be replaced. The service life of electrical elements is designed for 6 months to a maximum of a year.

- The geyser does not heat the water completely or partially. The water node contains a membrane. This element is vulnerable; its defect may stop responding to deterioration or increased pressure in the water supply system. The membrane may be cracked, clogged, or have a salt coating. Due to defects, it does not stretch under water pressure, so the gas water heater valve partially opens or does not open at all. If there is a suspicion that the membrane is faulty, it is necessary to clean the water unit by checking the element. First you need to shut off the gas supply to the gas unit.

- Contamination of elements inside the device. Soot and dust can damage the geyser. By removing the instrument panel (Figure 7), freeing access to the structural elements, they can be cleaned with a vacuum cleaner.

- Burner extinguishment. Lack of draft and clogged ventilation leads to the extinguishing of the gas water heater burner. Modern devices are designed with sensors to alert about such a malfunction (cessation of gas supply and traction). Having removed the plug and cleared out unwanted accumulations, the chimney channel is checked. Having lit the matches, they bring it to the canal. During normal operation of the chimney, the match should not go out; the flame should be tilted towards the channel. Then we can confidently say that the chimney is clean. If the flame goes out, you will have to clean the entire chimney.

Rice.

7 Device without an external casing Correct and safe operation of the device, no repair of the gas water heater, requires annual scheduled maintenance by specialists.

Why is electric ignition needed?

Housewives note the convenience of this small detail, since a spark for arson is always at hand.

Auto-ignition, first of all, was developed in order to significantly simplify the ignition of fire and, at the same time, increase the safety of gas stoves. In addition, such a system significantly speeds up the ignition process itself, which, together with other advantages of electric ignition, is especially important for people who spend a lot of time at the stove.

In addition to convenience, there is no risk of getting burned, as is the case with using matches.

Execution of work

Shut off the gas supply to the column.

We remove the handle of the limit valve and disassemble the body of the gas water heater. We described how to do this in the article “Master class: annual prevention of a gas water heater.”

Using a flat-head screwdriver, unscrew the two screws securing the flange with the limiter.

We take out the flange along with the bushing and two springs.

Note: The second spring is located inside the bronze bushing.

Using wrench No. 10, turn the tap plug.

We take out the plug along with the washer.

Use a rag to wipe the surface of the cork. If the grease has dried, it can be removed with gasoline or alcohol. Using a rag, we clean the inner surface of the valve body, the flange cavity and the bushing from old grease.

Apply a thin layer of gas lubricant to the entire surface of the plug.

We install the plug into the faucet body with the large hole facing up. The correct operation of the blocking valve depends on its initial position.

Apply a thick layer of grease to the bushing.

We install the bushing into the flange so that the bump on the bushing fits into the groove on the flange.

Install the spring into the bushing.

We put the washer on the plug rod with the rolled side towards itself.

We install a large spring and press it with a flange, while aligning the groove of the sleeve with the slots on the plug rod. To do this, we adjust the position of the bushing in the flange, turning it a little until it hits.

We install the flange with the slot to the left. Press it evenly with two screws.

We put on the faucet handle and check the smooth operation.

Turning on the device

The first step is to install the batteries. To do this, open the battery compartment and install them, observing the polarity. Then you need to open the cold water and gas valves. Open the hot liquid tap on the nearest faucet.

At the moment when the liquid flows through the water unit, a spark ignition occurs and, thanks to this, the burner ignites. If it is turned on for the first time or after a long period of inactivity, air may accumulate in the gas line; in order to remove it, you will need to open the mixer several times, hold it for a minute, and then close it.

If the burner ignites, you need to turn the water pressure adjustment lever (located on the right) to the right, this will make it possible to turn on the Vektor JSD 20 device when the liquid pressure in the system has decreased.

Advantages and disadvantages

@Homeasking.com

Many users cannot give up the habit of using matches. Therefore, they purchase outdated models, thinking that the electric ignition function adds cost to the device. In fact, this appliance skill will cost you nothing.

Using the stove becomes convenient; you don’t have to buy a supply of matches or frantically search for a reliable lighter that can work for a long period. The function protects against the possibility of getting burned. If you have previously used an electric stove, it will be difficult to refuse automatic ignition.

The only disadvantage is the inability to use the task when the lights are off. Therefore, make sure that you still have a tool for igniting a gas stove at home.

Lights up and goes out immediately

The reasons for this problem are:

- Weak traction. The chimney needs cleaning. If there is poor ventilation in the kitchen, then you need to open the windows or install a ventilation valve on the window frame.

- The ignition button is pressed poorly. It needs to be held for 20 to 30 seconds.

- The sensor that removes combustion products does not work. This can be found out using a multimeter. If the sensor is working, there will be a sign on the screen indicating infinity.

- Mixing streams. You need to set the regulator to a constant normal temperature.

- High pressure in models with low power. Set water parameters as indicated in the instructions.

- Systematic switching off of the overheating sensor. Solution: replacing it.

- Adjust the igniter. Disconnect the electrode from the igniter so that the spark is in the central part of the burner. Inspect and test the tube connections for leaks.

If ignition is delayed, clean the burner. There is a high probability that soot and soot have accumulated in it. The problem may also lie in the microswitch.

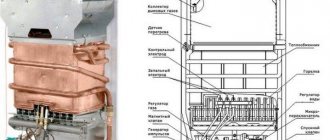

Unit design

Gas water heaters, regardless of the manufacturer, have similar components, the presence of which may differ slightly between different models. For example, we can consider the construction of the Neva gas water heater.

Device structure from the outside

The diagram of the gas water heater is shown in the figure below.

Gas water heater diagram

The front part and sides of the water heater are covered with a metal casing (1). There is an observation window (2) on the facade of the device for visual monitoring of the operation of the unit. Under the window there are regulators: a knob that regulates gas flow (3) and a water flow regulator (4). Between the handles there is an LCD display (5), which displays the temperature of the water supplied to the consumer.

At the very bottom of the device there are pipes for water supply and outlet, as well as for gas supply. On the right side of the water heater there is a pipe (6), to which cold water from the water supply is connected, and on the left, a pipe (7) is connected to drain the heated liquid. Next to it, but a little closer to the center, there is a pipe (8). A hose is connected to it, connecting the dispenser to the gas main, and in some situations, to a gas cylinder. At the very top of the water heater, there is a flange (9) for connecting the gas outlet pipe (chimney).

All elements of the unit are fixed to a metal base (10), which serves as the rear wall of the device. It has 2 holes for hanging the unit on the wall using brackets.

The new Astra gas water heater model has a similar design.

Internal structure of the unit

Now let's look at how the geyser works from the inside, with the outer casing removed. As mentioned above, pipes numbered 6, 7 and 8 are intended for connecting cold water, discharging heated water and connecting gas.

The water block of the unit (12) is connected to the water supply pipe (6). A rod (13) comes out of the water block, on which a handle is attached to adjust the water pressure. Below is a cylindrical part (14), which has a notch on the walls. It functions as a plug that can be removed to drain liquid from the device if repairs are required. The plug also has a safety valve that opens when there is excess pressure in the water supply.

In the center of the unit there is an electronic control unit (16). Wires are routed from it in different directions, going to various elements of the unit and sensors.

Column structure from the inside

On the left, symmetrically to the water block, there is a gas block (17). Both modules are assembled in such a way that they represent a single structure. From it, like from the water one, comes a rod (18) to adjust the gas supply. In the middle between the gas pipe and the control valve there is a valve (19) (electromagnetic).

There is also a microswitch (15) on the gas block, which is pressed by a special pusher when it is turned off. Above you can see the manifold (20), connected to the gas block using a pipe fitted with flanges. The manifold is attached to the body using 2 screws (21). The nozzles are located at the rear of the manifold. Through them, gas is supplied to the burner (22), which has 10 rows. A pair of elements are attached to the front of the collector, similar in appearance, but performing different roles. On the right is the spark plug (23), which ignites the burners, and on the left is the flame sensor (24).

Above the collector there is a copper heat exchanger (25). It just gives off the heat obtained from the combustion of gas to the water passing through it. A water unit (26) is connected to the heat exchanger on the right, and a pipe for discharging heated water (27) is connected to the left side. The heat exchange module is attached to the unit body using 2 screws (28). There are 2 sensors installed on the pipe for discharging heated water. The top one (29) protects the water heater from overheating, and the one below (30) serves as a thermometer. Wires go from it to the LCD display mounted on the casing of the unit.

At the top of the apparatus there is a device for removing waste combustion products (31). Thanks to a system of jumpers of different shapes, the flow of hot exhaust gases is directed towards the chimney channel. A draft sensor (32) is installed on the left, which is connected to the overheating sensor (29) via an electrical circuit. At the bottom of the water heater body there is a block (34) for 2 power elements (batteries). To fasten the outer casing of the device, there are places for screwing in screws (33) on both sides of the housing.

The diagram of the internal structure of the Oasis geyser is no different from the one shown above, except for the presence of a “winter-summer” switch on the front panel. It is designed to turn off half of the operating burners in the summer to save gas.

You may be interested in: how to repair a gas water heater.

Features of the location of the well on the site

To obtain high-quality water, the correct choice of location for the well is very important. To select the location of the water supply source, the following criteria have been developed:

In addition, the well must fully meet the water needs, not interfere with neighbors and travel, and not affect nearby wells.

The simplest option is one well for inspection, which allows you to control the connection of the water supply to the house at the entrance to the building. The maximum distance between water supply wells is 15 meters. If a change in direction is required for the installation of pipelines, a special well is built. At turning points, it is necessary to carefully interface the pipelines to avoid blockages in these problem areas.

The distances from the well to the site objects must be at least:

- well - compost pit - 50 meters;

- well - toilet - 30 meters.

For drinking water from a well, distances from sources of pollution must be strictly observed. All standards are carefully spelled out in SNiP, which takes into account not only objects on your site, but also on the site of your neighbors.