In order for the bathhouse to be hot and retain heat for a long time, an integrated approach to insulation is required; many articles are devoted to this, for example, how to insulate walls from the inside and outside, whether it is necessary to use foil, how to insulate the ceiling and the floor, what materials are preferable to use for the ceiling part . If you describe everything at once, you will end up with too much material, from which it will be difficult to assimilate the necessary information.

Therefore, we have prepared a separate article in which we will consider different insulation for walls inside a bathhouse. The section about all insulation materials is here.

Types and characteristics of materials with foil

There is a large selection of foil insulation on sale. They all differ in their properties and application features.

Universal insulator based on polyethylene foam

This product is sold in rolls, and the layer thickness can vary from 2–10 mm , and the polyethylene is foil-coated on one or both sides.

There is also a self-adhesive version on sale, that is, on one side there is an adhesive layer with a protective film. This polyethylene insulation is used for finishing walls, ceilings, floors and ventilation systems. With its help, you can equip a heated floor, organize thermal insulation of baths and a finishing base for linoleum. Moreover, this material is used to create shoe insoles.

Today, the most common types of foil polyethylene on sale are penofol, isolon and ecofol . The cost of the roll directly depends on the thickness.

Foiled mineral wool

This material is foiled on only one side. The products are produced in the form of rolls or slabs. In this case, the layer thickness is 5–10 cm. Fiberglass or basalt wool can be used for production.

It is worth noting the limited use of such insulation, since mineral wool can negatively affect human health. Accordingly, such foil insulation is used in non-residential premises , as well as for exterior decoration. Due to its properties, the product is suitable for thermal insulation of interfloor ceilings, walls and baths.

Expanded polystyrene insulation

This material is recognized as a durable thermoplastic. Its production is possible by fusing polystyrene granules. Expanded polystyrene itself is used in places with high humidity and significant mechanical stress. This is explained by the fact that polystyrene, which is pre-foiled, is not afraid of rotting, mold and mildew. It retains its characteristics at temperatures from -180˚C to +180˚C. Accordingly, the material can be used to insulate underfloor heating.

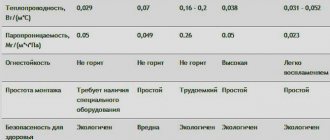

What materials to choose for insulating the walls of a bathhouse from the inside?

Bath insulation on walls with foil

Well suited for baths, because... performs several functions at once (hydro- and vapor protection, heat-insulating properties). There are several types depending on the foil material:

- with a layer of foil;

- with aluminum coating;

- with a layer of aluminum foil.

Regular foil can be subject to corrosion, and aluminum must be protected from excessive overheating, otherwise it can damage the finishing materials.

See also: What types of foil for baths are there, what kind of insulation with foil is used and why does it have opponents?

Classic mineral wool

When heated (and this process is always typical for a bath), this material begins to release phenol-formaldehyde resins, which act as a binder in mineral wool. The negative impact of these resins on human health has been proven.

Basalt wool

It is low cost, fireproof, and easy to install. It can be classified as an environmentally friendly material; in addition, basalt wool has good sound insulation. The disadvantages include the tendency to shrink (over time the layer will become thinner) and the fact that it becomes dusty during installation.

Foam glass

Foam glass would be an ideal option, if not for its high cost and heavy weight. It is absolutely harmless and safe, not susceptible to shrinkage, insects and rodents. It is a fireproof material. It must be installed together with a vapor barrier, otherwise the walls will be damaged by fungus, mold, etc. The difficulty of installation lies in the fact that if the installation technology is violated, there is a high chance of destruction of the material.

Useful video

Watch a video about the advantages of this modern material:

Peat blocks

They are crushed peat, which is formed into blocks of various sizes and shapes. Combines heat and sound insulating properties. It has bacteriological properties and is not subject to burning or rotting. It is considered an environmentally friendly and breathable material.

A small disadvantage is that this option is not very common and at the moment there are quite a few companies producing it.

Ecowool

Thanks to the flame retardants included in the composition, it is classified as a fireproof material. And cellulose gives the right to classify it as an environmentally friendly material. The difficulty is that the most effective method of application is “wet”, and it requires certain skills and specialized equipment. In addition, ecowool is very hygroscopic and is not suitable for use in a bathhouse.

Foil polyurethane foam

Another insulation for a bath on the walls with foil.

It is one of the most modern materials, has an aluminum coating on one or both sides, and performs shielding and waterproofing functions. A slight difficulty seems to be that specialized glue is not always able to hold the sheets on the walls, and breaking through the material is contraindicated. Otherwise, the heat-insulating layer will be destroyed.

Polystyrene foam and polystyrene foam

We strongly recommend excluding these materials from the list of suitable insulation materials, because when heated (more than 60 degrees) it begins to release harmful substances. And then the healing procedure takes on the opposite character.

So, we have comprehensively examined the topic of insulation for bathhouses on the walls from the inside. The choice of insulation materials is huge and many of them are suitable for use in bathhouses and steam rooms without danger of harm to human health. In addition to industrially produced materials, do not forget about natural insulation materials, for example, mixtures with clay.

The most important thing is to correctly install all the elements of the “pie”, not forgetting about ventilation gaps and the use of steam and water protection. And it’s worth completing the work on the internal insulation of the bathhouse with finishing materials that can be coated with special compounds or oils to maintain a beautiful appearance. In this case, you will get an excellent bathhouse in which it will always be pleasant to steam.

Scope of application

Foil insulation has not yet come into full use, however, they are beginning to be used more and more often in the construction and renovation of premises that are exposed to various kinds of high temperatures and high humidity.

It is also often used for protection against certain weather conditions. In addition to applications in the private sector, foil insulation materials are actively used for insulation in the industrial sector.

Here are the main examples of using this insulation:

- Insulation of baths and saunas. Due to its high insulation, strength and durability, the material is ideal for insulating such places.

- Insulation or insulation of pipes. Quite often in winter, water in some private houses may freeze, which is why all residents of a private house may lose water supply. Especially for this purpose, the pipes are insulated with foil insulation, since it does not let cold into the pipe for a long time and does not release heat from the pipe.

- Insulation of balconies. Here this material has proven itself to be an excellent means of saving heat from blowing out (relevant for residents of multi-storey buildings). Even if there is a strong cold wind outside, and you live on the 20th floor, the foil insulation will not allow the wind to “blow” heat from the balcony.

- Insulation of private houses or parts thereof. Again, this is very important for residents of regions with cold climates, where cold winds constantly rage.

Features of using foil thermal insulation

According to the recommendations of the current standard for thermal protection of buildings (SP 23-101-2004), external placement of a thermal insulation layer in two-layer walls is recommended. But this does not apply to foil insulation, since the relative position of the layers should prevent the structure from getting wet and not interfere with normal moisture transfer. And if there is a vapor barrier (foil) outside, drying of the main facade material will be blocked.

At the same time, the standard allows for internal insulation if a layer of continuous and durable vapor barrier is installed on the side of the room. And this exception is completely suitable for foil insulation. They also use internal insulation of the walls of hangars, warehouses and other buildings that are made of corrugated sheets.

The use of reflective thermal insulation is advisable in the following cases:

- When arranging the walls of frame houses. In this case, the wall is considered as a single-layer structure with thin-walled shells, which combines load-bearing and thermal insulation functions. And here, instead of the usual film vapor barrier, an additional layer of foil insulation is used.

- When insulating balconies. The design of the balcony fencing is similar to the wall of a frame house.

- When insulating a loggia.

- When insulating the roof of a used attic or attic.

- When insulating attic walls. In this case, their design completely coincides with the structure of frame walls.

- When insulating a bath or sauna. Internal insulation with foil materials significantly reduces the time it takes to warm up the room and saves energy resources during operation.

Types of foil insulation

The difference between materials is related to the purpose and insulation used. If each of them has foil, then that’s where the similarities end. There are 4 types of products:

- Foil penofol;

- Mineral wool with foil;

- Expanded polystyrene;

- Basalt wool.

Foil penofol

Such insulation with foil has different names, for example, folgoizol, polyethylene foam or isolon. This product is most different from its analogues. Sold in rolls. Insulation – foamed polyethylene (crosslinked or uncrosslinked). The thickness is small - from 3 to 10 mm. As a result, the material can be rolled, bent and shaped into any shape. This is a good foil thermal insulation for pipes. The aluminum layer can be on one side or the other. There are variations with a self-adhesive base. The price is affordable.

There are variations on sale with a reinforcing layer in the form of fiberglass. Moisture absorption ranges from 0.35 to 0.7%. The layer is non-vapor permeable, the indicators are 0.001 mg/m*K. The scope of use is wide. We carry out insulation of walls from the inside with isolon, creation of warm floors (underlayment for parquet, laminate, linoleum), use in a split system, for wrapping pipes.

Foiled mineral wool

Like regular mineral wool, it is produced in the form of rigid slabs or in rolls. This is a good combination option, since cotton wool is afraid of moisture and loses its characteristics when wet. A layer of foil eliminates this disadvantage.

Otherwise, the characteristics are the same as those of mineral wool. These are excellent sound and heat insulation properties, environmental friendliness, and long service life. The foil layer is only on the outside. Maximum thickness – 100 mm. Due to its protection from elevated temperatures, it is used for places where heat resistance is required. Namely: near fireplaces, installation of chimneys, baths and steam rooms. Good foil insulation for pipes.

Styrofoam

The classic option: cheap but practical. It is a hard foam plastic that is heat resistant. The grains are tightly fused. Foil on one side. Sold in slab form. Most often used for arranging heated floors.

These special floor insulation materials have markings for the cable system inside. This simplifies installation work.

Density – from 30 to 50 kg/cm3. Thickness from 20 to 50 mm. Not afraid of moisture, dampness, temperature changes. Withstands pressure, does not rot or rust.

Basalt insulation

Ideal for use in very aggressive conditions. Remains in its original form even with temperature changes from -200 to 700 ℃. The best way to insulate and protect gas stations and other structures.

Important! To insulate a wall, floor or ceiling, you will need insulation no less than 50 mm thick. Therefore, mineral wool with a foil layer or basalt wool is most often used for walls.

Thermal insulation of various structural elements

In frame house construction, it is advisable to use reflective insulation for thermal insulation of the floor. It is better to install “breathable” mineral wool on the walls without a foil layer, otherwise air exchange into the room will be difficult. The technology for fastening materials depends on the scope of its application: inside the house, insulation of the roof, floor or pipelines.

Wall insulation with Penofol or Penoflex

The difference between the materials is the thermal insulation backing. In Penofol it is foamed polyethylene foam, and in Penoflex it is extruded polystyrene foam. The technical characteristics and methods of their installation are similar.

Useful: Unusual frame houses: types and technologies

Sequence of work:

- According to the size of the purchased insulation (roll width), install a wooden frame on the walls. The slats are secured with dowels, the maximum distance is 1 m.

- Cut Penofol - cut into pieces, the length of which corresponds to the height of the room with allowances of 8-10 cm on each side.

- Apply the rolled material to the wall, straighten it and attach it to the wooden slats with a construction stapler. Penofol should not hang down or be excessively stretched.

- Place a sheathing of bars about 2 cm thick on top of the insulation. This will provide the required ventilated gap.

Such thermal insulation is perfect for walls in a country house , glassed-in balcony, utility room or building for keeping animals.

Thermal insulation of the roof with three-layer insulation

Thin roll insulation for a roof is not enough. Penofol is best used in combination with mineral wool; an alternative option is thermal insulation with foil mats made of basalt wool.

Instructions for performing work on installing insulation with two metallized layers:

- Lay waterproofing on top of the rafters horizontally. The canvases are attached with an overlap in the direction from bottom to top.

- Press the hydraulic barrier to the beams with counter-lattice strips. Next, you need to fill them with horizontal bars of the main sheathing. The roofing will be installed on top.

- Attach planks 50-60 cm thick to the rafters on the inside, installation step 60 cm.

- “Shoot” three-layer penofol to the formed frame, cover the seams with aluminum tape.

When attaching the inner lining, it is necessary to provide an air pocket. Ceilings are also insulated using a similar principle.

If Penofol is installed in pairs with additional insulation, for example, mineral wool, then one metallized layer is sufficient.

Insulation technology

When working with foil materials, you should adhere to a technology that is different from the methods of laying conventional thermal protection.

Which side to lay

Taking into account that the purpose of the foil layer is to reflect thermal waves, it becomes clear which side to lay the material on - the metallized side to the heat source . When installing mats on an outside wall, for example under siding, the foil should also face outward to prevent cold air masses from penetrating into the house.

Outside

To organize work on insulating external walls, you will need:

- Attach the slatted frame to the façade. The distance between adjacent slats should correspond to the width of the insulation minus 3-5 mm.

- The foil material is glued to the wall surface between the frame slats.

- After completing the insulation, it is necessary to cover the entire insulated surface with a reinforcing mesh.

- The final finishing with plaster, clapboard or siding is carried out using a fixed mesh.

From the inside

When installing the material indoors, the procedure is as follows:

- Vapor barrier material is attached to the walls using a furniture stapler.

- The next step is to fill the slatted frame, intended to form the base for finishing. The span between the slats should be 3-5 mm less than the width of the insulation.

- Insulation is glued into the resulting cells.

- The finishing finishing material is attached to the slatted frame, while a ventilation gap of 5 mm should remain between the inside of the finishing material and the thermal insulation.

Insulation for a bathhouse on the walls from the inside: is it necessary?

Thermal insulation of bathhouse walls from the inside can be classified as a controversial issue.

Doubts arise from our traditions: classic log baths were never insulated inside. All insulation work was carried out outside: caulking and sometimes finishing with boards or clapboard. The emergence of modern heat-insulating and building materials gave impetus to the development of this direction. Therefore, if you decide to build a bathhouse not from wood (logs or timber), be sure to read the further information .

Why is it better to use insulation for walls inside a bathhouse?

First of all, this is justified by the fact that steam and waterproof materials are used together with heat-insulating materials. This integrated approach guarantees the achievement of several goals at once:

- increasing the service life of the bath (by reducing the risk of rotting as a result of waterlogging);

- reduction of fuel consumption for heating the bath and heat loss;

- the bath’s ability to retain internal heat increases.

Application

Foil insulator can be used everywhere:

- for thermal insulation of ventilation air ducts, wells, wells;

- lining of pipelines (water supply, gas outlet, heating, etc.);

- for the purpose of reflecting heat emanating from heating radiators and other devices;

- when installing heated floors;

- to reduce heat loss in the room (installation on walls, floors, roofs).

It is advisable to use foil material when insulating the attic, roof ceiling and other internal surfaces of the building. The insulator operates in bathhouses, steam rooms, garages and other outbuildings. It is used for brooders and incubators and is used in crop production for growing seedlings.

The scope of application of foil insulation can be called unlimited due to its high performance qualities.

When choosing, it is recommended to take into account not only its cost, but also the following factors:

- All types of foil insulation have excellent noise-absorbing qualities, vapor and waterproofing properties.

- To reduce heat loss through the floor, preference should be given to a base made of solid polystyrene foam blocks.

- When finishing a bath/sauna, glass wool material is often used.

- A self-adhesive insulator will help create a reflective effect from radiators and batteries.

What insulation and why is it better to choose?

In order to understand which insulation is better to choose, you need to understand the scope of application of each type, which is what we will do now.

Rolled self-adhesive foil insulation made of polyethylene foam is used for installation: on the floor, as additional thermal insulation in the construction of an individual home. In multi-apartment premises this is the main insulation. It performs the function of waterproofing and is used as a substrate for laying linoleum and parquet; walls and ceilings. Particularly common in confined spaces of balconies and loggias. Thin insulation does not affect the usable area; roof. Used as an independent material, or together with other insulation materials; bath. They are used to preserve heat, because polyethylene foam copes with this task perfectly. It is not used in the steam room. At high temperatures, the self-adhesive material may become deformed.

On a note! Polyethylene foam has become widely known precisely as a material with heat-reflecting properties. It is often placed behind heating appliances, which allows you to save on heating costs.

Self-adhesive foil insulation made of polystyrene foam is able to regulate heat flow. And this is its main purpose.

Insulation is used:

- in housing construction;

- agriculture, it is used to insulate calf barns and incubators;

- in car repair and maintenance;

- shoe industry for the production of warm insoles.

The use of foil wool is mandatory for thermal insulation of baths, steam rooms, and saunas. It also serves as a thermal insulator for boilers, boilers, and pipelines.

So how to choose from all the variety? It is worth paying attention to the following:

- Before purchasing, consider the dimensions and type of room;

- do not ignore the thermal conductivity coefficient of the insulating material (the lower it is, the better);

- rationally weigh all the pros and cons of the selected heat insulator, relying on an unbiased assessment and opinion of experts.

Advantages of insulating material with foil

Foil insulation has many advantages that other materials often lack. It is these “advantages” that make insulation with foil stand out against the background of a wide variety of insulation products:

- Increased ability to reflect heat. Foil is a wonderful reflector that can repel about 95% of thermal radiation, keeping the house warm and keeping the heat out. By the way, it is for this reason that protective suits for firefighters are made from foil insulation.

- Waterproofing. Foil is a hydrophobic material that repels moisture.

- Ease of use. Foil insulation has a cellular structure, due to which it not only insulates well, but is also easy to install.

- Isolation from external influences. Foil insulation does not allow wind and moisture to pass through, does not freeze in winter and does not dry out in the hot season.

- Noise absorption - the use of insulation with foil allows you to achieve silence in the room and significantly reduce the amount of noise coming from outside.

- Health safety and environmental friendliness. Foil has no harmful effects on the human body, does not emit potentially hazardous substances and does not harm the environment.

- Durability. Reflecting all external influences, the foil can serve for a long time without any signs of rust, rotting or corrosion.

- Elasticity. The foil material can be easily given any desired shape.

General installation rules

In order for thermal insulation to be as effective as possible, you need to know how to properly apply and install insulation with foil. Primary requirements:

- Place the reflective surface towards the room. Failure to comply with the norm will negate the main advantage of foil insulation.

- Joining the panels closely - any gaps will lead to the appearance of cold bridges. Thin rolled materials can be laid with an overlap of 5-7 cm. The joint lines must be glued with foil tape.

- Aluminum is a good conductor of current. All wiring in contact with the insulation must be placed in corrugated plastic tubes.

- A gap must be provided between the finishing and the insulation. When installing insulation with double-sided foil, an air pocket is also left on the side of the outer wall.

- The use of self-adhesive insulation is permissible without additional fasteners. However, when finishing large vertical and inclined areas, it is better to pinpoint the material with staples.

Technology and installation methods

Using insulation with foil requires studying the properties of the material and the characteristics of the place that will be sheathed. Before installation, you must prepare the following tools and materials:

- the insulation itself in the required quantity;

- several rolls of construction tape;

- nails;

- hammer;

- construction stapler;

- protective clothing and gloves.

Installation of foil insulation on walls

The insulation is installed on a previously prepared surface. It is cleaned of old finishes, dirt and dust. This will help the adhesive to better adhere to the wall or floor. Experts also recommend using antiseptic treatment.

Thermal insulation of walls outside

External thermal insulation of walls is most preferable, because allows for better heat retention. If it is impossible to do it, then installation is done from the inside. For such work, it is recommended to use foiled mineral wool. In addition to basic materials and tools, you need to purchase a construction gun, a brush, windproof film and dowels.

External insulation is a so-called “layer cake”. The internal part consists directly of a heat insulator. The scheme of work is as follows.

- A metal profile sheathing is installed.

- It is attached to the wall using dowels.

- Thermal insulation boards are inserted into the sheathing. They are attached using glue applied pointwise throughout the entire canvas.

- Additionally, the insulation can be secured with dowels.

- Use a sanding brush to level the surface.

- A protective film is attached to the insulation layer using a stapler or nails.

Internal wall insulation

Insulation of the premises is carried out when there are no other options for installing thermal insulation. The walls are freed from wallpaper and other coverings. If the material was old, then the surface is treated with an antiseptic.

If insulation with self-adhesive insulation is used, then lathing is not required. In another option, it is necessary to build a frame. The insulator is placed in its cavity. Secure the material with nails or a stapler. The joints between the panels are closed with aluminum tape. To create an air gap, wooden slats are installed, onto which the finishing is then attached. Internal installation requires compliance with certain rules:

- the insulator is laid close to each other so that there are no gaps;

- if the material is covered with foil on both sides, you need to make two air pockets - from the outer wall to the finish;

- sheets of rolled insulation are not attached to each other overlapping each other.

When insulating the entire room, work begins with the ceiling, then moves on to the walls. The floor is insulated last.

Laying foil insulation on walls is not difficult, but if you have doubts about its implementation, it is better to invite specialists. The quality of installation will determine the preservation of heat and comfort in the house.

Which side should you put the insulation with foil on?

We'll tell you how to properly lay foil insulation. Since its production technology requires two layers, you need to understand which side is best to lay it on. The universal material should be laid so that the foil is on the outside. Thanks to the metal, all the benefits of insulation appear on a shiny surface, otherwise the heat will not linger inside.

It must be remembered that during the work it is necessary to leave an air gap between the insulation and the finishing, and do not attach the finishing material too tightly to the foil.

To insulate a room from the inside, it is enough to follow simple rules and act in stages.

Step by step guide:

- If the sheets have an adhesive layer applied, it is easier to glue them directly to the wall.

- A method of attaching rolled insulation without special glue is using a stapler.

- If the slab is attached, we make lathing. The slats are stuffed to create a layer of air.

- Then we attach the insulator to the cells, then secure it using dowels.

- Construction tape will help seal cracks in the wall.

- The insulation must be laid closely, eliminating every gap.

- Self-adhesive polyethylene foam is secured additionally.

Rules for installing insulation for external walls

Let's move on to how to properly lay penofol on the outside walls of a house. Any construction forum will show many different photos and tips on this topic.

Penofol is the most popular material for do-it-yourself home insulation. Its technical merits were appreciated by everyone who lives in Moscow and other cities. After making a comparison, you will understand that this is the best thermal insulator. Thermal insulation isolon is used in a wide variety of areas, and everyone can get a warm home.

From the outside, 2-3 layers of thermal insulation must be attached to the concrete wall - expanded polystyrene, mineral wool or self-adhesive penofol, since good sound insulation should be obtained. If the insulation is not covered with glue, you need to select and buy glue in advance.

- Once you've chosen the polystyrene foam, clean the wall and prime the area. It is better to use starting strips for this - this allows you to do the correct pasting.

- We glue the insulation to the concrete (the use of special solutions is important here). Use the solution only according to the instructions.

- Press the insulation firmly against the frame or base of the wall.

- We make joints in the corners.

If you plan to lay mineral wool insulation:

- The first stage is laying mineral wool on the facade.

- We fasten with self-tapping screws or using wide fasteners.

- We lay two layers of insulation end to end.

- We fix it with a protective film.

Insulation of the under-roof space

When insulating your home, you should not skimp on quality materials. Izolon (penofol) has important advantages. There are drawbacks, or rather, there is only one – the price is not too low.

This type of thermal insulation is an excellent material and is a good option for protecting your home from the cold. The main thing is to remember that the house needs to be insulated on both sides: internal and external.

How to attach penofol to the wall of the attic floor? There are no big differences in insulation technology, the principle is approximately the same. The main thing is to take care of quality.

Having arranged the under-roof space correctly, you will be sure that:

- Heat loss will be minimal.

- No moisture will get inside.

- Vapors will be released outside.

The roofing pie, consisting of seven layers, copes with its tasks perfectly. It includes interior finishing, followed by layers of vapor barrier, thermal insulation, and waterproofing. A separate space is also allocated for ventilation. Then they install a counter-lattice, a grate and “cover” the pie with a roofing covering.

Each layer is needed to perform specific functions, and none of them can be skipped or installed incorrectly.

Using foil insulation, you will make the under-roof space warm and cozy. It works great at protecting your home from the cold.

How to attach insulation to a basement floor inside a house

The leader in choice of thermal insulation for internal basement floors is penofol. It retains warm air well indoors and has its advantages:

- Environmentally friendly

- Not flammable

- Has good vapor permeability

- With a high level of sound insulation.

Any construction reference book will show that the thickness of thermal insulation should be within 15 cm, and in areas with cold winters - up to 20 cm. But the final calculation, of course, will depend on sanitary standards and regulations.

The base is the upper part of the foundation, which rises about half a meter from the ground. This structure also serves as a support for the ceiling of the first floor.

Horizontal waterproofing is installed on the ground floor. It prevents moisture from entering the basement floor. Expanded polystyrene is usually used to insulate basement structures. It repels water well and retains heat.

Beginners often ask the question of how to glue penofol and expanded polystyrene to the basement floor inside the house. Choose glue or mastic without a solvent; hot bitumen mastic will not work either.

Popular brands and prices

Buying foil insulation is not difficult. But before this, making the right choice in favor of one or another heat insulator is not an easy task. We decided to help you decide and have selected a list of the most popular and sought-after manufacturers of various types of foil insulation.

Foil polyethylene foam is produced by many companies:

- "Izolon". Product cost from 75 rubles per 1 m2 with a thickness of 2mm and from 105 rubles per 1 m2 with a thickness of 3mm;

- "Penofol". Sold from 65 rub./1m2 with a thickness of 3 mm and up to 455 rub./m2 with a thickness of 20 mm;

- "Ecofol". Price range 36 (2mm) – 70 (10mm) rubles per square meter;

- Foiled polyethylene foam is also produced: “Isoflex”, “Jermaflex” and “Folgoizol”.

Expanded polystyrene with foil. Foil foam from Penoplex, Knauf, TechnoNIKOL is popular. Price 1 cubic meter m depends on the thickness of the base. On average, the cost is in the range of 2.0 - 9.0 thousand rubles.

Foil glass wool. Material 50 mm thick can be purchased for 130 -140 rubles/m2. More expensive analogues are produced by “Rockwool”, “Knauf”, “PAROC”.

Foil-coated basalt wool is produced by TechnoNIKOL, Rockwool and PAROC. The price starts from 4 thousand rubles. per square.

How to lay it correctly

Self-adhesive foil insulation requires the use of special installation technology. We'll tell you about it.

Which side should the insulation be placed on the structure to be insulated?

When insulating rooms, foil insulation is laid with foil to the top. If the foil is positioned the other way around, then the heat wave will not be reflected into the room. When carrying out external work, the installation process looks the same as for internal work. Therefore, when describing the technology, we will not make such a distinction.

Floor insulation

When installing foil insulation on the floor, the so-called “floating screed” and “floating floor” technology is used.

To install the screed you need:

- free the ceiling from old concrete if it crumbles or breaks off;

- prime the surface;

- carry out waterproofing.

If the material does not have self-adhesive foil, it must be lubricated with special glue to form the future base. Before using the contact adhesive for penofol, you need to pause for up to 40 seconds for polymerization to occur. After this time, you should glue the surface of the insulation and smooth it with your hands.

Thin-walled (up to 3 mm) “penofol” is laid with an overlap, and a thick (10 mm) seal is glued without a gap. The joint is connected with tape. The insulation is secured with reinforcing fiberglass mesh, after which the screed is poured.

Under "warm floor"

When preparing a “warm floor”, the heating element is placed in the middle of the screed. The work follows the same sequence as when installing a “floating screed”.

For infrared film, a thin (3mm) heat insulator is attached at the base of the surface. A heating element is placed on top, and then plywood. This screed option requires ALP material.

Experts recommend making sure to ground the foil. If the film breaks down, people may be electrocuted, since metallized elements conduct current well.

Wall mounting

To insulate walls, you need to purchase self-adhesive foil insulation with a fiberglass or polypropylene base. Such insulation is attached to the surface using glue or by preliminary installation of the sheathing. The seam, as in previous cases, is connected with tape, and the remaining gaps are finally foamed. After installing the thermal insulation material, there is no need to make additional vapor barrier, since foil copes with this function perfectly.

Ceiling insulation

Thermal insulation work is carried out with isolon type B (covered with foil on both sides) or C (self-adhesive). Its thickness should be more than 5 mm.

The foil insulation is fixed with glue and/or special dowel nails. On top of it, the ceiling can be finished with any desired material. This could be: plastering, installation of gypsum boards or suspended ceilings.

Thermal insulation of the bath

The work is carried out using rolled glass wool of small thickness. First, the insulation is installed on the ceiling, and then on the walls.

The step-by-step process looks something like this:

- the sheathing is being installed;

- then the insulation is laid into the cellular frame;

- then the joints are taped;

- Finally, the frame is strengthened using counter-lattice.

Roof insulation

Thermal insulation of the roof is carried out, as a rule, using foil mats made of mineral fibers. The work is carried out in the following order:

- the cracks are sealed with tow and blown with foam;

- the sheathing is fixed to the board covering;

- a B-class vapor barrier film is secured with glue or a construction stapler;

- they stuff the strips onto the rafters;

- lay mineral wool;

- The joints are taped.