In addition to decorative finishing of the house, attention should be paid to the insulation of external walls. Thermal insulation is needed not only for a private home, but also for a summer house, cottage or garage. You need to start with choosing insulation. This material should reliably retain heat inside the building, increase comfort and provide protection for the external walls of the building from various influences. To decide which is the best insulation for the facade, you should familiarize yourself with all the options. It will be much easier to choose the best type if you study the advantages and disadvantages of each variety. Today we will talk in detail about the best way to insulate a facade.

Insulate the facade of a house: what is better to use

Which insulation to choose for the facade? This question is often asked by property owners who plan to insulate external walls. It is worth choosing an external insulator; it is the one that can reliably protect the walls from freezing. There are different types of insulation: external and internal. But with internal thermal insulation, the outer side is deprived of protection before the “dew point”. In this case, the facade will be exposed to wind and low temperatures. Therefore, experts recommend installing insulation on the outside of the building to protect it from the cold. Thanks to this technology, fungus and mold will not grow in the room. You can choose insulation yourself, taking into account the material from which the walls of the house are built. There are various options for insulators, which can be purchased at any hardware store.

The concept of “dew point”

If it is necessary to insulate the walls of a house internally, it is important to provide a layer of vapor-permeable material on the side of the room. If it is not there, then warm air in contact with the wall will lead to the formation of condensation. Droplets of water entering the insulation can lead to a decrease in its thermal insulation characteristics and even cause irreversible damage to the material. This will be due to the “dew point”.

“Dew point” is the temperature regime of the air at which the steam it contains reaches maximum saturation and begins to condense into water.

The “dew point” must be outside the room, and this can only be done with insulation from the outside. With this approach, the temperature of the insulation and the environment is equalized. Thanks to this, the “dew point” moves directly to the edge of the thermal insulation. The surface of the walls of the house and the insulation remain dry, which means they are not subject to premature destruction.

Which insulation to choose for the facade of houses made of different materials

To choose insulation for the facade, you first need to understand what material the building is built from:

- Mineral wool. An excellent option for buildings made of sip panels, wood and all types of heat blocks. Mineral wool is also used to insulate brick houses.

- Foam insulation can be used for thermal insulation of buildings made of sip panels, concrete and thermal blocks.

- Polyurethane foam. The best option for concrete.

- Glass wool. Suitable for insulating external walls of brick and wooden houses.

- Penoplex. It is often used for insulating brick houses, as well as buildings built from ceramic blocks.

Since insulation materials are different and differ in their own characteristics, it is better to entrust the choice to a professional craftsman. A professional knows exactly which insulator is needed for a particular structure.

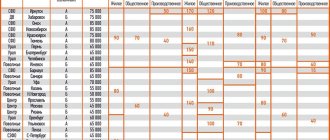

Calculation of insulator thickness

To determine the thickness of insulation for a home, you can use special Internet resources where you can find online calculators for calculations. Please note: the resulting number can only be an estimate. Things to consider:

- Thickness of external walls.

- The level of their heat resistance.

- Specific climate in a given area.

- Temperatures for each season.

- Features of thermal conductivity of insulation.

Knowing this information, you can calculate the required thickness of the insulation material. You can make the calculations yourself or seek advice from a specialist who will insulate your facade.

Types of external facade insulation

How to insulate the facade of a house? The choice of insulators is wide and varied. Manufacturers provide detailed information about their products, so you can make your own choice. Insulating materials are available in various forms. The difference will be in the installation method, the need to use additional fasteners and cost. Insulation materials are even available in liquid form. To apply it to walls, builders use special equipment. Such work can only be performed by experienced, specially trained craftsmen. Below we will consider the best insulation for the facade of a house.

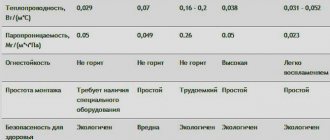

Polyurethane foam

One of the best insulation materials for facades. It is created on the basis of polyurethanes. Provides an optimal level of thermal insulation and has a long service life. If you work with polyurethane foam correctly, its service life will be about forty years. The material does not require any additional fasteners; lathing is also not required. If you don’t know what kind of insulation to buy for a ventilated facade, you can give preference to polyurethane foam.

Ecowool

What kind of insulation is needed for the facade to provide warmth and comfort inside the premises? You can choose ecowool, which consists of cellulose fibers and has the following positive qualities:

- This is an environmentally friendly material.

- Has low thermal conductivity.

- Provides sound insulation.

- Economical.

- Affordable price.

- Simple and quick installation.

- No seams on the coating.

In addition to its advantages, the insulator also has some disadvantages:

- Exposure to combustion.

- Low vapor permeability.

- You will need special equipment for the job.

- If moisture gets on ecowool, it will shrink.

Glass wool

Quite often glass wool slabs or mats are used as an insulator. This type of material is not rigid, has sufficient flexibility and is light in weight. Glass wool is created from fibers and is a type of mineral wool. It is made from glass, and waste from the glass industry is also used for production. In recent years, the popularity of glass wool has declined sharply as it has been replaced by more practical insulators. The disadvantage of this material is that during operation, microscopic particles of fiberglass fly into the air and can lead to irritation.

Basalt wool

Basalt or stone wool is more often used for insulating facades. Available in the form of slabs of various sizes. It does not have such low thermal conductivity as polystyrene foam, but it stands out among other insulators in that it is not subject to combustion. It is a breathable material. In addition to this, other advantages can be highlighted:

- Provides sound insulation.

- Features a long service life.

- Shows resistance to moisture.

- Fungus and mold do not grow on basalt wool.

- Allows you to quickly perform installation work.

- Resistant to temperature fluctuations.

Compared to glass wool, this insulator is much safer and more modern.

How foam blocks and thermal insulation panels are used for insulation

Foam blocks are produced in the form of facing slabs, which are laid according to the principle of brickwork to prevent the appearance of cold bridges. The foam block is glued directly to the load-bearing wall, and the adhesive mixture acts as an additional waterproofing layer.

For better grip, umbrella dowels are additionally used. Foam and gas blocks are lightweight, which makes them easier to install. Due to the fact that the concrete mixture foams during production, the material can freeze and lose strength. Therefore, it is best used with a moisture-resistant finish. It is not recommended to use foam blocks to insulate facades under plaster.

Decorative panels are a set consisting of insulation and a decorative layer. The basis of the panels is polystyrene foam (penoplex), and the decorative layer is plaster or brickwork. Installed using a special adhesive solution. The main advantage is speed and ease of installation.

In this case, there is no need to additionally insulate the facade with plaster, because the decorative layer is applied in advance at the factory. The panels look attractive and retain heat well. The only downside is that the sheets peel off from the surface, especially if you use the wrong glue. If you use dowel umbrellas for better adhesion, the appearance of the facade will deteriorate. The cost of the panels is about 3,000 rubles/m² excluding installation.

Decorative panels consist of insulation and a decorative layer

Popular methods of insulating facades

Modern builders use various methods of external wall insulation. Each method has its pros and cons. The “wet facade” technology has become a very popular method, what is its specificity:

- The wall is pre-cleaned and prepared.

- The next step is to apply a layer of glue of a maximum of three centimeters.

- Laying insulation.

- Applying another adhesive layer.

- Installation of reinforcing mesh.

- Applying plaster.

- Primer.

- Coloring.

Installation of an insulator under plaster is suitable for all types of mineral wool and foam plastic.

Work execution technologies

How to insulate a house from the outside? Two methods are used for this. Both can be used for almost any insulation material. The type of heat insulator has almost no effect on the technology. But you need to take into account certain recommendations from the manufacturer. For example, as is the case with mineral wool, when a ventilation gap is required.

There are two technologies:

- insulation of facades using the wet method;

- dry method, when a decorative coating is used, fixed to the frame.

Wet facade

This method has a relatively low cost and puts less load on the foundations of the building. But it is important to note that a decorative coating cannot guarantee reliable protection against mechanical stress .

In this case, the insulation of external walls is covered with a layer of plaster. Its thickness is usually 40 mm. To ensure strength, a reinforcing mesh (fiberglass or metal mesh) is used.

The wet method of thermal insulation involves covering the walls with decorative plaster

Insulation and finishing of the facade of the house are carried out in the following order:

- cleaning the wall from dirt, leveling defects, treating the surface with a primer;

- fixing vapor barrier material if necessary (for foam plastic and mineral wool);

- installation of insulation boards with an adhesive composition (irrelevant for ecowool, it is simply sprayed onto the surface);

- additional fixation using plastic dowels;

- applying an adhesive solution to the surface of the insulation;

- mesh reinforcement;

- applying an adhesive primer after the glue has dried;

- plastering the surface.

How to insulate the facade of a wooden house with mineral wool? Only the wet method is suitable here. For other materials, you can choose one of two options.

It is better to choose fiberglass mesh as a reinforcing layer.

Finishing and insulating the facade of a house using this technology has one important drawback: over time, the plaster may begin to fall off. This is especially true if the external insulation of facades was carried out using metal mesh. It is recommended to choose a more expensive but modern fiberglass one.

Dry method

Insulation and finishing of facades in this case requires the presence of facing material. The most commonly used materials are siding, lining, composite panels, etc. Insulating houses from the outside with your own hands will require constructing a frame for fastening the cladding. The step-by-step instructions are as follows:

- Cleaning the surface from dirt, leveling large defects.

- Attaching a vapor barrier material, if needed.

- Installation of a frame for insulation from wooden blocks or boards. When using a metal profile, the racks are installed after fixing the material for insulating the walls from the outside. At this stage, you only need to provide brackets for mounting the racks.

- The next stage is attaching the heat insulator with glue. From below you need to provide a starting profile, which will serve as a support for the first row. After the adhesive composition has dried, the facade insulation is additionally fixed with plastic mushroom dowels with your own hands.

- Waterproofing and wind protection should be fixed on top of mineral wool or polystyrene foam. For these purposes, it is recommended to choose a modern vapor diffusion hydro-windproof membrane. How to attach it correctly? The membrane or film is fixed to a construction stapler. The joints are made with an overlap of at least 10 cm and taped.

- After completing all the steps, you can begin installing the cladding. How to finish the facade in each specific case should be indicated in the manufacturer's instructions.

The dry method of thermal insulation of walls involves the use of cladding and the installation of a ventilation gap.

You can insulate walls using the dry method in almost any weather . This makes this option stand out from the previous one. Deciding how best to insulate a home depends on the type of finish chosen.

Heavy systems

The key feature of this technology is the need to use additional fasteners. In this case, dowels are used rather than glue. The insulation material is fixed not with glue, but with a disc dowel and anchors. Further steps will be the same as with the “wet facade” technology. This technique makes it possible to make the walls of a building stronger and more resistant to external influences.

When designing a ventilated facade, a certain thickness of insulation is selected. Ventilated facades are very popular in our country. It is better to entrust the installation of a ventilated curtain façade to professionals. Any material can serve as decorative cladding after the insulator layer has been installed.

Importance of the procedure

For many building owners, facade insulation is of great importance. This procedure allows you to minimize heat loss. Its proper implementation allows you to solve the following problems:

- The heat created in the rooms does not leave the building.

- The cost of heating the facility is reduced.

- The sound insulation characteristics of the building are noticeably improved.

- All barriers that prevent the escape of condensate that has arisen on the facade walls are removed.

The diagram shows why it is so important to insulate your home.

These points often push the owners of buildings with non-insulated facades to carry out insulation work. In order to get the desired result, it is necessary to choose the right material and not violate the technology of facade insulation of the house.

You can see examples of reasonable insulation of the facade of a private house in this video: