Home » Building a house » Headings » Heating

Alexander Korovaev 10/16/2019

4217 Views

Did you know that with the help of the simplest induction hob you can fully heat a room of more than 30 m²? If not, then you should read this article and find out how to make simple induction heating at home.

Advantages, disadvantages of heating elements of boilers

Advantages:

- Compactness. The device can be placed without worrying about the installation location.

- Availability.

- Ease of installation. Installation takes several hours.

- Devices can be adjusted. A suitable temperature can be set.

Flaws:

The equipment is subject to frequent breakdowns. The heating element is a heating element (thermal electric heater). The main part is the tube. It may break if exposed to heat.

Design

The electrical appliance is not resistant to scale formation. If hard water is used as a coolant, the device becomes coated. The heat transmission capacity decreases, the temperature readings set on the sensor will differ from the real ones.

The equipment does not have many disadvantages; they are mainly related to the peculiarities of its operation. If you monitor the condition and use only soft, settled water, errors can be leveled out.

Otherwise, it’s a decent option for heating your home. You can heat small rooms and large rooms.

Is it true that induction heaters are energy saving?

Economical

This type of boiler is achieved only

by an initial head start of 5-15 minutes in heating speed.

And then, in comparison with heating elements.

Because the most economical among electric heating systems is “warm floor”. All arguments about 99 or even 100% efficiency are deceit

and rely on mass illiteracy. All electric heaters have the same efficiency.

And the statement that part of the heat from the system is dissipated without reaching the coolant is equally true for both heating elements and induction boilers. Considering the high cost of the boiler and the mandatory additional equipment for the induction system for a separate amount, saving 30-50% on electricity is nothing more than a legend and a sales trick.

Durability.

Like everything in the world, the core is also subject to destruction, but it will do this, unlike the heating element, much longer - about

30 years

.

The remaining components also have a good margin of safety. Manufacturers provide a 10-year warranty on the service of the induction boiler, and they do not lie. If it is equipped with high-quality European electronic controllers

, it will easily last

up to 30-40 years.

Photo 2. Induction boiler connected to a closed heating system. Additionally equipped with a controller, expansion tank and pump.

Taking into account the above, the owner of an induction boiler will find savings compared to a heating element only in the long term - after five years of use

system. But compared to the initial installation costs, it may not be significant.

Design features and device

The chamber for storing fuel in any long-burning boiler is impressive in size. This parameter directly affects the burnout time of the fuel filler. Currently, there are two successfully competing technologies implemented in TT boilers: we are talking about Buleryan and Stropuva devices. The high cost and complexity of making a drawing of a long-burning boiler with your own hands poses certain obstacles to the spread of the last of them in our country. In contrast, the Buleryan method is widely used by craftsmen for independently organizing heating of country houses.

The drawing of a long-burning solid fuel boiler Buleryan consists of the following components:

- A metal case covering the internal chambers.

- Lower chamber for burning fuel.

- Upper chamber for gas combustion.

- Doors for storing firewood. It is located in the upper part of the structure due to the large size of the lower compartment for storing the resource.

- Smoke pipe. It is located at the top of the boiler and is connected to the chimney.

- Ash chamber. It is located at the bottom of the boiler and is intended for cleaning it.

There is also another interesting detail. As you know, in conventional furnaces the function of the ash pan is performed by the ash pan: it is through it that the air necessary for combustion flows. In the case of Buleryan, the ash compartment is made completely sealed: the air supply channel here is the upper air chamber. To regulate the oxygen supply, there is a damper at the top of this chamber. As combustion progresses, the wood in the firebox gradually settles, which causes the distributor to lower. This ensures a continuous supply of fresh air.

The design of a long-burning solid fuel boiler is as follows:

- Firebox. The main structural element of any boiler or furnace. Designed to burn fuel in it.

- Gas afterburning section. Here the gases coming from the furnace burn out.

- Ash pit. Compartment for collecting ash. It needs regular cleaning.

- Chimney. A channel for discharging combustion products outside the home.

Coolant circulation

The boiler is simple in design; various types of circulation can be used - with natural movement of the coolant, a circulation pump.

Circulation pump

Some heater models have circulation pumps installed. They help disperse coolant through the heating system. The circulation pump used in the heating system reduces the load on boiler equipment, and the energy consumption of the equipment is reduced several times.

The versatility of boiler heating elements

You can use different types of coolant:

- Tap water, but the device is more vulnerable to scale formation. Plain, untreated water carries debris that causes breakdowns.

- Distilled water. Scale formation is excluded, the liquid does not contain heavy metal salts and does not contribute to the formation of deposits. No debris from entering. Coolant promotes longer operation.

- Antifreeze. Suitable for cottages, private houses. It is used in premises where the owners do not live permanently. In the absence of owners, in order to prevent freezing, the systems are filled with antifreeze.

Distilled water, antifreeze

Pros and cons of an induction electric boiler

Minuses

induction boiler:

- While it is true that such a boiler is environmentally friendly and does not emit exhaust into the environment, it spreads an electromagnetic field throughout the home. People, animals, and technology react to it.

- Safe only conditionally.

If a coolant leak occurs, the electromagnetic field will not turn off automatically, the core will continue to heat up until the housing melts, and this will happen

in just a couple of seconds.

Therefore, complex and reliable automatic control, which turns off the power supply in case of leaks, is very important for such a boiler. It's expensive. And for the sake of economy, domestic models of induction heaters most often use cheap Chinese models. - It costs almost 2 times more than a heating element.

At the same time, its declared efficiency is clearly overestimated and will pay for itself for a long time. - In terms of rationality and economy, it is seriously inferior to gas and solid fuel heating systems.

Advantages:

- Some models have the option of remote control using an electronic programmer via a GSM channel.

It really can be convenient to set the temperature

to 8-10 °C

while people are away from the house, leaving for a week, without worrying about the home freezing. - There are no intermediate technical inspections

, replacement of heating elements and other

maintenance and repair work.

Is the induction heating method really effective and reliable?

Before you buy or start making an induction boiler, it is worth understanding how effective this heating method is. In specialized shopping centers you can hear only positive characteristics of systems operating on this principle from sales consultants. However, not everything they say is 100% true. And these heating units have their own so-called “pitfalls”.

Sellers operate with a whole list of theses, trying to increase sales of boilers operating on the induction principle:

- For example, it is a common statement that the operating principle of these devices is an innovative development.

In reality, this is not true, since electromagnetic induction was discovered back in 1831 by the English experimental physicist Michael Faraday. In the second half of the twentieth century, induction systems were successfully used in the metallurgical industry.

From this we can conclude that these devices can hardly be classified as innovative technologies. However, this also has its own “plus”, since such a system has already been time-tested and proven to be effective.

- The next important quality that sellers focus on is the cost-effectiveness of using an induction boiler. It is usually stated that this type of unit consumes 25-30% less energy than other electric heaters. Can we agree with this?

Prices for induction heating boilers

induction heating boiler

Probably not, though. Any electric heater consumes electricity according to its power specified by the manufacturer in the technical data sheet. That is, to generate one kilowatt of heat, in the most ideal case (at 100 percent efficiency), the device needs to consume a kilowatt of electricity. Moreover, even with the above parameters, the efficiency of the unit may be lower, since much also depends on the specific operating conditions of the boiler.

Induction boilers, largely due to the “reactive” energy generation based on the principle of self-induction, have high efficiency rates tending to 100%. But you still shouldn’t expect some kind of “fabulous” savings from them.

The time it takes to heat the coolant to the desired temperature depends on the power and efficiency of the heating element. It must be said that part of the expended energy, one way or another, is wasted, since the materials from which the device parts are made have non-zero resistance. However, heat loss from the operation of an induction boiler does not go “down the chimney”, but remains in the room where the device is installed, which is often their obvious advantage.

So, the conclusion suggests itself is that it is unlikely that you will be able to save any serious money on electricity when using an induction boiler. But their efficiency and heating speed are really high.

- Despite the approximate service life specified in the data sheet, established by the manufacturer (not to be confused with the warranty!), sellers assure that the induction heating boiler will last at least 25 years. It is necessary to agree that this information is reliable if the electronic control unit is made of high quality. The unit includes semiconductor elements, which can still fail. As a rule, manufacturers provide a ten-year warranty on the components of the electronic unit. However, quite often they work perfectly for 25–30, or even more years.

But in the boiler itself, by and large, there is simply nothing to break. Thus, the primary winding, usually made of copper, has a large margin of safety and will last a long time if it is properly cooled (and this is ensured by coolant circulation).

The core rod or the material of the internal channels, of course, will begin to deteriorate over time, since it will be constantly adversely affected by the aggressive environment of the coolant, as well as by alternating cooling and heating. However, for it to become completely unsuitable for use, more than a dozen years must pass.

Considering the design of a boiler operating using an induction circuit, we can conclude that it is much more reliable and durable than heating devices that use heating elements as heating elements.

Prices for heating boilers

boiler

- Another quality that is a plus for an induction heating device is its silent operation - supposedly this distinguishes it favorably from other heating units. The question arises, is this so?

But here, exactly the opposite is true. Yes, electric heating units operate silently, since during their operation no acoustic vibrations are created and no mechanical components are used. However, it is during the operation of the induction device that low-frequency vibrations can be clearly felt, which can irritate people with acute hearing. This negative phenomenon is minimized in vortex-type boilers, in which the supply voltage to the primary coil is first converted to high frequency.

In addition, if a low-quality circulation pump is installed in the system, it can also become a source of mild annoying noise. But this already applies to all heating systems, regardless of the type of boiler. But the modern range of pumps makes it possible to purchase a completely silent model.

- The buyer can evaluate the compactness of the boiler visually. We can say that this unit consists of a piece of pipe of a certain length, which does not take up much space, unlike other heating devices. True, the mass of an induction boiler is usually quite impressive, which means that reliable brackets will be required.

Induction boilers are usually very compact.

And they are often even placed in “batteries”, putting into operation, as needed, only the number of devices required under given operating conditions. However, do not forget that space will be required for the accompanying elements of the system, as well as the wiring of circuits and the installation of collectors, if required by the circuit. If it is necessary to heat a fairly large area of the house, then several induction devices are often installed, and the entire system will require a lot of space.

- The statement that boilers of this type are completely safe, and that this quality of boilers is more pronounced than that of their heating element counterparts, is incorrect. The operating safety of these two types of heating devices is approximately the same, and depends on the correct connection and the performance of the systems designed to protect them from extreme situations.

For example, if a coolant leak occurs in an induction device, and the electromagnetic field does not turn off in time, and heating of the internal core continues, then the housing and fastenings can melt literally in a matter of minutes. Therefore, when purchasing a device or designing it yourself, you need to pay attention to the automatic shutdown of the unit in the event of an emergency.

Induction boilers are reliable and efficient devices that do not take up much space, but their advantages are often significantly exaggerated

As you can see from the information presented above, induction boilers, just like other heating units, have their own shortcomings, and they are not unique devices that allow you to pay mere pennies for heating. However, their effectiveness is beyond doubt. And yet, thanks to the compact size of the boiler, it can be placed in an apartment, for example, in a niche, so that it will be almost invisible.

Manufacturers

- Galan boilers are popular. Equipment made in Russia. Components are used that are supplied from abroad. The devices are automatically controlled and accessible.

- "Nevsky". Used in closed heating systems. The necessary temperature parameters are automatically set, the device provides comfortable conditions. When the set temperature is reached, the device turns off until it cools down slightly. The boiler has a reliable assembly and components.

- Imported manufacturer Dakon (Czech Republic). There are about 30 models of units with heaters from Dakon. Models with additional equipment are possible - circulation pump, expansion tank.

- Kospel boiler (Poland). Used in single-circuit heating systems.

Boiler piping diagram

Before connecting the equipment, you need a wiring diagram for an electric heating boiler at home. The main thing in this scheme is the availability of power supply. It is calculated depending on the intended heat supply system (two or single circuit) and the power of the boiler apparatus. It must be said that the connection diagram for an electric heating boiler is somewhat similar to the installation of gas appliances. But it has a number of differences.

It is important to remember some points that affect the quality and reliability of heating equipment in order to avoid frequent breakdowns during operation. It must be said that piping an electric heating boiler means connecting it to the heat supply system

For this, special elements are used. When piping, it is necessary to take into account the method of circulation of the coolant along the circuit. The electric boiler must be mounted at the lowest point of the structure. This is necessary in order to ensure maximum heating of all radiators. The discharge pipe should be located above the batteries at a minimum height

It must be said that piping an electric heating boiler means connecting it to the heat supply system. For this, special elements are used. When piping, it is necessary to take into account the method of circulation of the coolant along the circuit. The electric boiler must be mounted at the lowest point of the structure. This is necessary in order to ensure maximum heating of all radiators. The discharge pipe should be located above the batteries at a minimum height.

To install the heating element, you just need to screw it into the thread. To make the joint airtight, you should use gaskets made of heat-resistant rubber. The pressure gauge and thermometer are also quite easy to install. It is better to connect the heating element to the power supply through a separate machine in the distribution panel. Finally, the installation should be tested for faults. To do this, the heating circuit must be filled with water and the heating element must be turned on.

Thus, having developed drawings for an electric heating boiler with your own hands, having prepared all the necessary tools and materials, you can easily make a reliable heating unit. As a result, effective heating of a private home will be achieved with minimal financial expenditure.

- How to fill water into an open and closed heating system?

- Popular floor-standing gas boiler made in Russia

- How to properly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes for malfunctions

Recommended reading

Do-it-yourself heating boiler: necessary drawings and product features Homemade solid fuel heating boilers: step-by-step assembly instructions and features How to make an induction boiler with your own hands? DIY heating boiler

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement will result in legal liability. Contacts

Operating principle of an inverter boiler

Traditional electrical equipment operates on the principle of transferring energy directly to the coolant through heating elements. At the same time, if the device is equipped with heating elements, then, therefore, you need to prepare a place for heating water.

Heating elements are also highly susceptible to corrosion, so they must be protected from irreversible processes.

Inverter equipment operates on the basis of electromagnetic induction. The current itself is generated due to an alternating magnetic field. For this purpose, it is necessary to convert direct mains current into alternating current. An inverter, which can operate both from the mains and from batteries, copes with this task perfectly.

There are two types of circuits in an inverter boiler:

- Magnetic, allowing you to generate an alternating magnetic field.

- A heat exchanger that helps heat the coolant.

With appropriate supply of alternating electricity, the coil begins to form a magnetic field. This helps to heat the liquid in the system and further transfer it through the pipes.

Induction heating system diagram

Application

Heating based on eddy currents created by electromagnetic fields can find its application in:

- heating a residential property, house, bathhouse, garage, industrial or administrative building;

- in the hot water supply system;

- heating of buildings and structures that have certain requirements for heat sources (for safety).

DIY induction heating boiler

At home, the heater can be made from a welding inverter or transformer.

Boiler made from a welding inverter

Before proceeding directly to assembly, you need to stock up on the following materials:

- Stainless steel wire with a diameter of 5-7 mm;

- A piece of plastic heat-resistant pipe, approximately 500 mm long, with an outer diameter of no more than 50 mm and a wall thickness of at least 5 mm;

- Expanded or woven stainless steel mesh with a window no larger than 4x4 mm. The size of the mesh should completely cover the cross-section of the plastic pipe and provide the possibility of reliable fastening;

- Enameled copper wire with a diameter of 1.2-1.5 mm. To wind the coil you will need approximately 5m;

- Two adapters for connecting the boiler to the heating main;

- Welding inverter, allowing smooth adjustment of current strength.

Once all the necessary components are prepared, you can begin to assemble the induction boiler. Assembly consists of several stages:

1. Stainless steel wire is cut into pieces 5-6 cm long in the amount necessary to completely fill the pipe.

2. One side of the pipe is covered with a mesh, after which the wire sections are filled in and the other side is sealed. The internal cavity of the pipe is completely filled, and the presence of a fencing mesh on both sides prevents pieces of wire from getting into the pipelines of the heating system.

3. 90-100 turns of copper wire are wound onto the filled pipe. During the winding process, it is necessary to ensure uniformity and the same distance between the turns. The entire coil should be equidistant from both ends of the pipe.

4. Adapters are hermetically installed at the ends of the pipe, and a tie-in is made into the existing heating main.

5. Both coil terminals are connected to the welding inverter.

6. The heating circuit installed in this way is filled with coolant, after which the system is ready for operation.

It is strictly prohibited to connect the device to the electrical network until the system is completely filled with coolant.

7. Using the inverter, the required temperature regime is set.

This DIY induction device design can effectively heat an area of 50–60 m2. If the heated area is larger, or additional power is required for autonomous hot water supply, there is a second option.

Induction boiler using a transformer

When using a transformer, the role of the heating element is played by the body of the device, inside which the coolant circulates. To manufacture the unit, in addition to welding skills, you will need:

- Two metal pipes placed one inside the other in such a way that a cavity is formed between them.

- Two flat rings for sealing ends;

- Welding inverter;

- Three-phase transformer;

- Metal pipes for inlet and outlet pipes.

1. At some distance from the ends, pipes are welded into the hollow cylinder to ensure coolant circulation.

2. By winding copper wire around the body, the primary winding is formed;

3. To slow down cooling and reduce the dissipation of thermal energy, the product is placed in a special housing, and the resulting cavity is filled with heat-resistant heat-insulating material.

Security

To prevent accidents, when installing homemade induction boilers intended for heating a private home, you must adhere to several rules:

- When connecting the product to the heating system, the distance from the wall must be at least 30 cm, and from the floor and ceiling at least 80 cm;

- Devices can only be installed in closed circuits with forced coolant circulation;

- A pressure gauge and a safety valve should be installed on the outlet pipe.

The use of the phenomenon of electromagnetic induction in the manufacture of heating boilers makes it possible to significantly reduce the dimensions of products, ensure high productivity and long service life of the equipment.

Important notes on installation and use of the boiler

Homemade induction boilers are extremely easy to assemble, install and operate. However, before you start using this kind of heater, you need to know a few important rules, namely:

a homemade induction heating installation is intended for use only in closed-type heating systems, in which air circulation is ensured by a pump;

Closed heating system

the wiring of heating systems that will work in conjunction with the boiler in question must be made of plastic or propylene pipes;

Plastic pipes for heating

To prevent the occurrence of various kinds of troubles, install the heater not close to the nearest surface, but at some distance - at least 30 cm from the walls and 80-90 cm from the ceiling and floor.

It is strongly recommended to equip the boiler pipe with a blast valve. Through this simple device, you can, if necessary, rid the system of excess air, normalizing pressure and ensuring optimal operating conditions.

Explosion check valve

Thus, using inexpensive materials and simple tools, you can assemble a complete installation for efficient space heating and water heating. Follow the instructions, remember the special recommendations, and very soon you will be able to enjoy warmth in your own home.

Measures to maintain boiler efficiency

Induction boiler

It is necessary to ensure high-quality thermal insulation of the premises. The heating system must be properly designed and installed by a highly qualified specialist. In order to ensure high-quality heating of the room, it is necessary to choose the right automation kit. Automation can be installed electronic or mechanical. Mechanical automation is equipped with a reliable control device, but it is not able to maintain accurate power indicators. Mechanical automation is more beneficial for use in industrial, non-residential, warehouse, and garages.

In a heating system built according to the rules, the induction boiler starts at low power, warms up, and gradually increases the power to the nominal value. Modern automation ensures that the optimal temperature in the room is maintained with an error of ± 0.2 °C.

Selection of induction boiler power

If you need to heat a building with an area of 150 square meters. meters and a ceiling height of 3 m, the heated area should be calculated. To do this, we multiply the area of the building (in our case 150 m2) by the height of the ceilings - 3 m. We get a heated area of 450 square meters.

One kilowatt of an induction boiler is designed for 13 m2, which means that the calculated area will be enough to heat a 16 kW boiler.

This calculation will be correct only if thermal insulation work is carried out before heating the structure.

Let's summarize the above. An induction boiler is used for heating residential buildings and industrial facilities. The boiler is compatible with many heating systems. Suitable for autonomous heating and in combination with other heating sources. The device is stable in operation. Consumes the same amount of energy regardless of the service life of the device.

It has a long service life and does not require replacement of components or off-season maintenance. Virtually no scale formation. The disadvantages include the inability to completely clean the boiler of scale and deposits. Since the device cannot be disassembled, it can only be washed with special chemicals. The control unit should also be carefully protected from overheating.

The presence of modern automation will save up to 30% of resources. In residential premises it is advisable to use electronic automation. It will allow you to smoothly regulate the power of the device, turn the device on and off if necessary, and maintain the desired temperature. Using remote control of electronic automation settings will make the control process comfortable for the user.

Video: induction boiler VIN

Autonomous heating in a private home is a very complex and important task that can be solved by using electric boilers. Currently, there are not only models with heating elements, but also more economical products - electrode and induction. An induction electric boiler is very popular due to its high efficiency and, accordingly, less energy consumed to heat the room. Let's take a closer look at the capabilities of induction boiler equipment, its advantages and disadvantages.

The main options for modern electric boilers

There is more than one design option for a boiler for electric heating. The simplest is the built-in heating element

It is necessary to pay attention to the pipe where the heating element is mounted. It must be of the removable category; as for the diameter, it is better if it is larger than other similar elements

A removable pipe is required to carry out repair work if the heating element fails. In addition, a pipe that has a built-in heating element can be classified as a special compact boiler. It is worth noting that this system has high efficiency indicators.

Important! For this reason, it is recommended to avoid all unnecessary expenses, but to achieve the use of the entire system by all possible means. You can simply make a small, free-standing boiler

Equipment of this type can be made from a special steel pipe. Here, the smaller the boiler, the more efficiently it will carry out its work. There is no need to heat excess water and, accordingly, waste a large amount of kilowatts of energy.

To effectively heat a relatively small house of two or three rooms, it is enough to take a pipe element whose diameter is 220 mm, and the length should be only half a meter.

The pipe must be hermetically sealed on both sides with special steel caps. In this case, it is necessary to make a special hole in the upper element, which will be intended for connecting the outlet pipe. This pipe will transport hot water to the installed radiators. In the lower element of the constructed boiler, exactly the same hole is made on one of its sides, then a pipe will be connected there, but with cool water.

For such a design, you can use a heating element with power parameters of 1 kW. It provides heating from a standard 220 Volt network. As for the heating element itself, it can be quickly installed in the lid of the new boiler located below or on one of the sides. The main thing is that this is the side located on the other side of the pipe; cold water usually enters it.

Important! An electric boiler of this type is able to operate around the clock. If you install additional automatic equipment in its design, you can easily maintain the required temperature conditions

By the way, it is usually set using a special regulator.

Installation of a regulator is mandatory, since it is the one that can effectively protect the equipment from overheating. In addition, mounted automation provides an optimal opportunity to save material resources on the total amount of energy consumed.

Vortex Induction Heater

A vortex induction heater (VIN) is a type of induction cooker. It consists of a coil, a magnetic core and a heat exchanger. Alternating current flowing through the coil creates an alternating magnetic field. If a conductive material is placed in this field, it will heat up. The main advantage of VIN is that the inductor temperature does not exceed 140 degrees C. In addition, the alternating magnetic field counteracts the formation of scale. Unlike a vortex heat generator, the operating principle of a VIN fits into the laws of physics. The efficiency of a vortex induction heater is close to 100%, which gives it the right to use in heating systems and other liquid heating systems. However, what do the sellers of vortex induction heaters promise us? And this is where miracles begin. They promise savings of up to 50% compared to conventional heating elements. That is, either the efficiency of the heating element is 50%, or the efficiency of the VIN is 200%. Let's try to figure it out. Your humble servant was not lazy and called several companies selling vortex induction heaters. The most important question that was asked was: what advantage will I get by paying quite a lot of money for this device? Here are the answers I received:

We have a lot of sales and everyone is happy

Fantastic reliability and durability

Savings up to 50% compared to heating elements

No noise

Well, you can argue with the first and second statements. Regarding noise, heating elements do not make noise either. But, with savings, this is interesting. It turns out (according to sellers), the formation of scale on the heating element reduces its efficiency. Accordingly, the efficiency of VIN is due to its constant efficiency compared to heating elements. But excuse me, how does scale reduce the efficiency of heating elements? Let's remember the law of conservation of energy. Let's say we supplied 1 kW of electrical power to the heating element. Accordingly, we should receive 1 kW of thermal energy. If we receive less heat, then the remaining energy must be released in some other form. I don’t remember that heating elements in water glowed or emitted, say, electromagnetic waves. Undoubtedly, scale reduces the heat transfer of the heating element, but this does not in any way affect its efficiency. With a decrease in heat transfer, the temperature of the heating element itself increases, and, consequently, its electrical resistance increases. As the electrical resistance increases, the power consumed by this heating element decreases. In fact, the change in temperature and power consumption is so small that the average user won't even notice it. Will the kettle boil in a minute or in a minute and 5 seconds - does it matter? At the same time, the amount of electricity required to heat a kettle of water will remain unchanged. However, VIN sellers are trying to turn the situation upside down and talk about a decrease in efficiency.

Thus, VIN can be an alternative to heating elements, but it will not provide any savings. There are no miracles. And as for “fantastic reliability”, for the money that VIN costs, you can buy several electric boilers and arrange a backup. Reliability will be several times higher.

Strengths and weaknesses

The large dimensions and difficulty of making a drawing of a long-burning solid fuel boiler with your own hands makes it favorable to use such devices only in large cottages. As for small dachas, it is recommended to choose more economical options for them.

The main advantages of long-burning TT boilers are:

- High efficiency (about 95%)

- Autonomous heating.

- Economical.

- Reliability and durability.

- High efficiency.

- Availability of fuel.

- Environmentally friendly.

- Wide choice of fuel (coal, firewood, sawdust, pallets).

There are also disadvantages:

- Large dimensions.

- The need to equip a separate boiler room.

- Complex design of a long-burning wood-burning boiler.

- Need for constant maintenance.

Advantages of homemade units:

- Cheapness.

- Versatility in terms of fuel used.

- Possibility of subsequent modifications to increase efficiency and add power.

The most difficult thing is to make the structure cylindrical: for this you need to use a rolling machine. If you don't have one, there is an option with old propane tanks. Any pipe of a suitable cross-section will also work: the thickness of the metal walls must be at least 5 mm. In villages they are accustomed to being content with small brick stoves, which demonstrate good efficiency in heating one-story houses and cottages. If you need to heat a large cottage, then in this case you will need a large supply of fuel. In addition, large temperature changes cannot be avoided as you move away from the stove, and caring for it is much more difficult than a solid fuel boiler.

Operating principle of an induction boiler

Induction heating is carried out using the energy of an alternating magnetic field, which the heated object absorbs and converts into heat. Therefore, this is the heating of products made of conductive materials. To convert electrical energy into heat, you must have three components:

- alternating current (standard electrical network 220V, 50Hz);

- inductor, i.e. multi-turn cylindrical coil (usually copper);

- a core made of any ferromagnetic material (a material to which a magnet sticks, usually metal).

Diagram of an induction boiler

Now we will step by step consider the principle of operation of induction heating:

- Alternating electric current passing through the inductor creates a magnetic field around the coil;

- The magnetic field creates Foucault eddy currents on the surface of the core, which heat the workpiece under the influence of Joule heat (Joule-Lenz law);

- Heat from the heated core is transferred to the coolant surrounding it due to the thermal conductivity of the material.

Scheme of induction heating of coolant

To put it simply, this is a step-down transformer that is installed in a pipe.

Thus, electrical energy is transferred only to the core, without the use of contacts, and the heated core (steel pipe) is still in contact with the coolant. And yes, particles can also settle on the surface of the core and impair heat transfer. Marketers often talk about cavitation (oscillation) of the core and, therefore, difficult formation of “scale”. In practice, it will be difficult to verify this, and is this the most important advantage? The steel core has sufficient surface area for effective heat removal even in the presence of deposits.

The video demonstrates the operating principle of a hot water induction heat generator. Many scammers and ignoramuses sell such devices to gullible customers under the guise of CE heaters.

Main structural elements

In general, an electric boiler consists of the following components:

- Heat exchanger: This is a reservoir connected to the heating system in which the working medium flowing through it receives thermal energy.

- Heater: An element in a heat exchanger in which electrical energy is converted into thermal energy through resistance.

- Electrical circuit: a set of parts due to which electric current appears in the heater.

- Automation unit: monitors the temperature of the coolant using sensors and, if necessary, turns on or off the electric boiler.

All of the above is placed in a steel box with thermal insulation - the housing.

What is induction heating

The work is based on the phenomenon of electromagnetic induction

. An electromagnetic field is created inside the boiler, which heats the ferromagnetic core. It is this that transfers heat to the water in the system instead of the usual heating element.

When sellers and manufacturers of VINs (vortex induction heaters)

they talk about its efficiency, they mean the rate of heating of the element and the transfer of heat into the system.

If the heating element heats the water in the heating system, at best, after 20

, or even

30-40 minutes

, then the induction element

is 10-15 minutes faster.

Important! In induction heating, the choice of coolant is quite wide: it can be not only water, but also oil, ethylene glycol and any antifreeze.

Operating principle and design of an induction electric boiler

Similar to a transformer.

The induction current generator consists of primary and secondary short-circuited windings. The primary winding converts electrical energy into eddy current, and the secondary winding serves as the body of the inductor.

The following example will explain the operation of an induction heater even more simply:

- A coil is wound onto a pipe made of dielectric material (non-conductive).

- A core made of martensitic or ferritic steel (ferromagnetic) is placed inside.

- The coil, when exposed to electricity, creates a magnetic field.

- The magnetic field heats the core ( up to 750 °C

). - The core heats the water passing through the pipe.

Reference.

Despite the fact that an induction boiler can quickly heat a large amount of coolant, and the phenomenon of induction itself creates convection movement of the coolant in the system, in order to heat a two-story house without problems,

you need to install a pump in the system.

Most often, an induction boiler is quite compact, not too tall ( 40 cm

), but a weighty (

up to 23-30 kg

) wide tube-cylinder. Therefore, to prevent it from collapsing, it is placed on strong additional fastenings. Sometimes, to enhance the effect, a welded section of several such balloon-shaped boiler pipes is used.

Photo 1. Induction boiler connected to the heating circuit. It is a small cylinder.

Cabinet- shaped designs are less common

.

But in any case, an induction boiler consists of:

- Housing

consisting of dielectric metal. - Electrical insulating layer.

Ferromagnetic

core thickness up to 7 mm

).- Temperature sensor

in the boiler body. - The inlet and outlet pipes

are connected to the system of pipes and radiators. - Automatic switches

(in the control panel). - Thermostat

(electronics in the control panel).

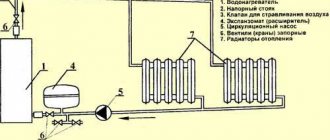

And this is what a heating system might look like, where:

Coolant circulation pump- Heating batteries.

- Induction boiler.

- Diaphragm expansion tank

(for pressure regulation). - Control panel cabinet.

- Shut-off ball valve.

Attention! An induction boiler is only suitable for a closed heating circuit.

A practical guide to making your own

Before installing the equipment, you must carefully prepare: make or order drawings and diagrams, make the necessary calculations, select a location for installation, stock up on materials and tools.

Although ready-made drawings can theoretically be used, in most cases they will have to be redone, since each home craftsman will use the materials that he has.

Production of a boiler based on heating element

It is better to make an electric boiler for heating a house with your own hands based on the technology of a tubular electric heater. This is due to the simplicity of the design. Even a person without relevant experience can do it. This device can be used to heat both large and small rooms. It can be installed in a garage, bathhouse or small room. In addition, for its operation it will require voltage from a regular network.

You can make a 220 V electric heating boiler with your own hands from steel pipes for the body and pipes, metal sheets and several heating elements. If you plan to install one heating element, then a pipe with a diameter of 10 cm is sufficient, and if two or more, then 13-15 cm. The body must be at least half a meter longer than the heating element.

Required tools and materials

A boiler with a power of 2.4 kW requires few materials. It will provide heat to the house as an additional equipment. To work you need to prepare:

- A steel pipe with a diameter of 120 mm and a length of 65 cm.

- Steel sheets 4 mm thick and 1.5 × 1.5 m in size.

- Two heating elements of 1.2 kW each.

- Thermostat.

- Safety valves.

All materials can be purchased in specialized stores. If you install a purchased boiler, then the components must be included with it. Some elements can be made independently from available materials, but a thermostat must be purchased in any case. You also need to prepare a number of tools:

- Grinding machine.

- Welding machine.

- Drill and set of drills.

- Ruler and marker.

- Set of screwdrivers and keys.

Step-by-step instruction

You can make a boiler for a private home yourself using the production instructions. All actions must be performed in the following sequence:

- Heat exchanger production. To do this, you need to burn a 1-inch hole in a pipe with a diameter of 120 mm. It is better to do it with a gas torch, or, in extreme cases, with an electrode.

- The hole made is cleaned using a grinder. Next, you need to weld the pillars to the hole.

- A metal plate 5 mm thick is used for the bottom of the boiler. It will close the device from below and serve as a flange for the heating element.

- At the very bottom of the pipe, stacks are welded in, which drain excess water from the system.

- A stud must be welded to the boiler body. Grounding will be connected to it.

- The upper part is closed with a round plate with a diameter of 120 mm.

- The tightness of the structure can be checked by lowering it into water. All pipes are pre-closed with polypropylene.

- Next, you need to install the thermostat and faucet, and then connect the device to the water supply system.

- At the final stage, the heating elements turn on and test the operation of the system.

This design has its drawbacks. The main one is the impossibility of replacing the heating element. To do this, you need to cut off the top cover and dismantle the structure. To avoid such consequences, it is necessary to install removable heating elements like those installed in boilers.

To protect against corrosion, the boiler is treated with a special substance. After this, it must be primed and painted. But it is better to do these steps separately for each element before installing the boiler.

Although a self-assembled heating system has a number of disadvantages, its efficiency and ease of use make it popular among users

However, we must not forget about extreme caution during installation and operation, since electricity requires special attention. After starting up the equipment, it is necessary to monitor the process of its operation and carry out preventive maintenance in a timely manner.

Types of induction boilers

Shell boiler

The operating principle of all induction boilers is the same. They differ only in design. There are 4 types - shell devices, with volumetric and tubular heat exchangers, as well as inverter ones.

Shell boiler

The design of such a device has a cylinder-shaped casing. An inductor is placed in it. Heat exchange occurs inside and outside. The liquid enters the pipe, passes through the heat exchanger, heats up and passes into the heating circuit.

The production of enclosure devices in Russia is carried out by the INERA brand, also known as SAV.

Boiler with volumetric heat exchanger

The second name of the models is inductive-conductive. It has a cylindrical body made of metal, in which a coil with a ferromagnetic rod is located. It performs the functions of a heat exchanger.

Boiler with tubular heat exchanger

These are classic induction boilers, in which the heat exchanger is made in the form of a set of pipes. They go around the coil. They are considered the first type of such devices to appear on the market.

Boiler with inverter

In heaters with an inverter, direct current from the battery is converted into high-frequency alternating current. The resulting current then passes to the inductor. This solution makes it possible to obtain eddy currents that generate heat in the event of a power outage.

Characteristics of an induction boiler for home heating

The efficiency level reaches 99% and is maintained consistently high during operation. It has an operating current frequency of 50 Hz with minimal interference in the network. All energy used from the network is used to generate heat.

Therefore, when switching to this heating method, operating costs are reduced by 30%.

Boilers are produced with a power of 2.5-500 kW. The boiler has maximum protection against scale. The boiler design completely lacks detachable connections, due to which the likelihood of leakage is noticeably reduced.

Induction boiler connection diagram

The boiler design contains no elements that may be subject to mechanical wear, since it does not use moving parts or devices. Induction heating is compatible with the use of various heat transfer fluids: water, oil and antifreeze. No technological preparation is required to use these liquids. A separate room is not required to install the boiler. Compatible with various heating systems.

Completely autonomous. Does not require preventive maintenance during non-operational periods. There is no need to attract highly qualified employees to perform installation and maintenance work. The service life of an induction heater for heating buildings is at least 30 years.

This type of heater has a high degree of electrical and fire safety, since the heating element and the inductor have no electrical connection with each other. If the heater operates in a heating and hot water supply system, its limit temperature can exceed the coolant temperature by up to 10-30°C.

There are no electrical contacts in the high temperature zone. The exception is 2 - 6 leads of a heat-resistant cable, which are sufficiently remote from the heating area and do not require any measures to ensure high-quality electrical contact. The operation of induction heating technology with industrial frequency current makes it possible to use an induction boiler as efficiently as possible in various industries.

The induction boiler is silent in operation and economical to use, it has positive reviews

The efficiency of the boiler is ensured by:

- — lower heating inertia;

- — use of modern automation;

- — use of modern radiators (cast iron ones increase energy consumption).

- — reliability and long service life due to the simplicity of the design.

Another option

To make it you will need a plastic pipe with a diameter of 63 mm and a length of 50 cm, steel wire with a diameter of 3 mm, a copper conductor with a cross section of 2.5 mm2 and a length of 11 meters.

- The steel wire is cut into 7 cm pieces. It is placed in a piece of plastic pipe.

- Two adapters for a 1″ threaded connection are soldered into the pipe. Coarse filters are screwed on both sides through 1″ nipples.

- Parallel strips of PCB are glued to the surface of the tube.

- Turns of copper conductor are laid on them. The distance between them should be the same. After this, they are filled with epoxy resin.

- The product is mounted in a heating system pipe and connected to a high-frequency voltage source.

The number of turns, as well as the length of the conductor, will have to be selected experimentally, since the length and capacity of the system is different for everyone. The steel wire, heating up from inductive currents, will give off temperature to the water that will pass through the pipe. This option cannot be used as a stand-alone device, but it will be an excellent addition to the main source, which will allow you to save on coolant consumption.

Advantages and disadvantages of plastic pipe boilers

Advantages of induction boilers:

- The water in the heating system heats up twice as fast and has double heating.

- Inertia is much less than when using gas or other fuel boilers.

- Magnetic induction prevents scale formation.

- Quiet operation.

- There is no need for cleaning and maintenance of the boiler.

Like any phenomenon or design, induction boilers also have their disadvantages:

- Before use, you must make sure that the core is completely filled with water and that the water level should not drop during operation, otherwise the plastic will simply melt.

- The boiler can only be used in a closed forced heating system.

- High cost of industrial designs.

The boiler power must provide the proper level of heating in the room. The most acceptable formula: 1 kW per 10 m 2.

An induction boiler is an excellent alternative to other heating devices. If you have the opportunity to make it at home, the skills to work with tools and assemble equipment, and the ability to install heating equipment, then you can make such a device yourself. If you are not confident in yourself, then it is better to buy a ready-made boiler and invite specialists to install it.

Watch the video that shows how you can make an induction electric boiler yourself:

https://youtube.com/watch?v=F6yIXht5gks

This video shows the process of making a boiler for an induction cooker:

Comparison of induction and heating element boilers with the same power

For comparison, two models of the same power will be taken - 25 kW.

The price of induction is 85 thousand. The price of heating element is 46 thousand. Prices are indicated for the period 2022.

In order for the induction device to be put into operation, it is equipped with the following elements:

Induction heater

- Pump.

- Flow sensor.

- Spirotop, pressure gauge, safety valve.

- Electrical panel.

- Temperature sensor.

- Shut-off ball valves.

- The weight of the complete structure is 80 kg.

Compared to a heating element boiler:

Equipment

- Weighs 40 kg less.

- The electronics are located inside. The advantage eliminates the need for an additional electrical panel.

- Automatic power selection and temperature maintenance are possible. An induction device is not capable of this. The setting is done manually. Affects the maximum power consumption of the heating element boiler.

A flaw when switching boiler equipment will cause the light to blink.

Contactors built into induction devices are powerful; when switching, loud pops will be heard.

When compared with a heating element device, it has a small contactor, the operation of which will not cause irritation and is almost inaudible.

- The unit is equipped with thermal protection. Makes sure that the system does not overheat or cool.

- You can see a sensor that detects low water pressure. Essential for leak detection. For induction devices, heating of the heater core is observed, which will lead to complete breakdown of the device.

Main types of induction boilers

Before buying an induction electric heating boiler for your home, you need to choose which type is most suitable.

There are two varieties on sale - induction boilers SAV and vortex boilers (VIN), which have characteristic differences.

Induction heating boilers SAV

Boilers of this type do not require the use of an inverter. A network voltage of 50 hertz is supplied to the winding (inductor). The secondary winding in the form of a system of metal pipes of the heat exchanger is very quickly heated by Foucault currents. The heated coolant moves in the circuit forcibly using a circulation pump. Boilers are produced for voltages of 220V and 380V. A 2.5 kW boiler heats a room up to 30 m2, and you can buy an induction electric heating boiler complete with a control and automation unit for about 30 thousand rubles.

Induction boilers VIN (vortex)

These are new generation induction boilers; their operation requires an inverter - a frequency converter for the electrical network. This technical solution made it possible to make the device compact and lighter than SAV-type boilers. The heat exchanger is made of ferromagnetic material, and the magnetic core and secondary winding are not only the heat exchanger, but also the boiler body.

A VIN type boiler with a power of 3 kW can provide heat to 40 m2.

The kit includes an automation unit, a pump and a circulation pump, so the highest price for an electric induction heating boiler is about 38 thousand rubles.

Advantages and disadvantages of such equipment

When deciding on the type of heating devices, you first need to find their strengths and weaknesses. The obvious advantages of induction boilers include the following qualities:

Induction cooker

- High efficiency, reaching 98%;

- Reducing heating costs up to 30%;

- Equipment reliability due to the absence of heating elements;

- Increased degree of electrical and fire safety;

- Possibility of using any type of coolant;

- Large range of obtained parameters;

- No scale;

- Reliability and trouble-free operation for a long time.

The main disadvantages of such devices, limiting their use, have always been too high a price, large size and weight, as well as difficulty of adjustment. Recently, induction devices have become more compact, and they can be made accessible by DIY assembly.