Plastic window structures are considered reliable and airtight. But over time, they also begin to let in cold air. This is especially unpleasant in winter, when precious heat is literally blown out of the apartment. Changing the situation doesn't always require installing a new system. In most cases, it is enough to properly insulate plastic windows. Let's figure out how to do it right.

No. 1. Why do plastic windows need insulation?

In the first few years, well-made and installed plastic windows will certainly be a reliable barrier to cold air, drafts and noise. Over the years, of course, problems can arise, and often the user himself is to blame. If installation is done incorrectly, various defects can make themselves felt in the first season.

The most common reasons for additional thermal insulation of plastic windows:

- installation performed in violation of technology;

- shrinkage of the building, which is especially typical for new buildings;

- wear of rubber insulation. Responsible manufacturers and installers inform the user about the rules for caring for the rubber seal, but few follow the rules and regularly inspect the condition of this structural element. Lack of proper care leads to an accelerated process of thinning and drying of the rubber, the appearance of microcracks in its structure, the result is a decrease in the tightness of the fit to the frame and deterioration of thermal insulation;

- incorrectly installed slopes.

A window of poor quality or with technical characteristics that do not correspond to climatic conditions will also not be able to provide normal thermal insulation, which is why it is so important to be able to choose the right plastic window and immediately decide on a suitable double-glazed window.

Self-adhesive tape

Insulating window structures is a very important process that must be approached very carefully.

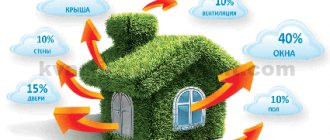

Uninsulated windows often cause drafts, which as a result negatively affect the health of residents.

In addition, window openings become the main bridge of cold, which leads to the loss of a large amount of thermal energy.

Today, the market offers a large selection of modern insulating materials that can reduce heat loss through window units.

All these materials are highly effective and very easy to install. Among all the options, it is worth highlighting self-adhesive tape.

It is made on the basis of foam rubber, polyethylene and polyvinyl chloride. On one side, the material is coated with a sticky compound, which allows it to be fixed in a specific place.

Advantages of self-adhesive insulation

This self-adhesive window insulation has certain advantages.

These include:

- Ability to close cracks, the thickness of which can reach 7 mm;

- High resistance to changes in temperature and air humidity;

- Various colors, which allows you to optimally aesthetically fit the tape into the appearance of the window;

- Relatively low cost;

- Possibility to open the doors.

Thanks to these advantages, this material has gained high popularity and demand among the population.

Disadvantages of the material

Unfortunately, duct tape also has some disadvantages. First of all, it is worth noting its fragility. Most often, it lasts no more than one season.

This means that the insulation needs to be updated annually. Of course, if the doors are rarely opened, then the tape can last two or more seasons.

Despite the fact that such material tolerates temperature changes very well, severe frosts can negatively affect its performance properties.

As a result of exposure to too low temperatures, the adhesive composition may lose its adhesiveness. As a result, this leads to the tape peeling off.

The main disadvantage of such insulation is that it cannot be used on modern window structures. This is due to the fact that it can cause significant harm to the performance characteristics of plastic windows.

No. 2. We identify weak points

To effectively insulate plastic windows, you must first understand where the seal is broken. The only thing you can immediately remove from the list of suspects is the frame: multi-chamber plastic is a good heat insulator, it does not dry out, unlike wood.

Cold air can penetrate through the following structural elements:

- clamping elements that tend to loosen over time;

- a detached glazing bead that holds the glass unit in place;

- worn out seal;

- polyurethane foam, if it was applied in violation of technology;

- windowsill;

- slopes.

A double-glazed window rarely causes a violation of thermal insulation (the exception is its depressurization), but it can also be additionally insulated. “Extra” heat in winter will not hurt.

to identify leaky window - just run your palm along and across the entire structure, and you will feel that there is a decent amount of wind in some places. Some people recommend using a lighter for this purpose. If you light a flame and pass it around the perimeter of the window, maintaining a safe distance, it will tilt in those places where there is even a small draft. Be extremely careful with this method!

As a rule, work on insulating a plastic window can be done with your own hands. The exception is when it is necessary to insulate the slopes from the outside, and the apartment is located above the second floor. You need to be prepared that comprehensive insulation may be needed if several zones of warm air leaks are found, but first things first.

Preparatory stage

First, you need to assess the situation, that is, find out where the draft is coming from - from the frames or from under the window sill? The reason may be an old seal or defective slopes.

To determine the area from which the cold is blowing, just run your palm over the surface of the window frame. If you cannot identify the cause, you can hold a lighted candle near the window block. The flame of a fire is most sensitive to drafts.

- Possible gaps and cracks can be indicated by moisture after the previous rain, which is concentrated in a certain place. When water accumulates in the corner of a window opening, most likely the reason lies in the joints.

- Drafts can occur due to poor sealing. You can do an experiment. A piece of paper is placed in an open window and the frame is closed. If the sheet is easily pulled out, then the seal is weakly pressed against the window frame.

When choosing a method of insulation, you need to clearly understand the purpose for which this is being done? Sometimes, in pursuit of cheapness, a window loses its attractive appearance and the approach to the window is blocked.

It is important to consider the price of materials. Some of them are quite affordable (the sealant costs no more than 200 rubles per can). More durable methods will cost more, but may be a worthy investment in the future.

No. 3. Debugging the clamping mechanism

House shrinkage and weather factors can lead to slight distortion of the window sashes and slight deformation of the sealing rubber. This leads to deterioration of thermal insulation, but in this case, returning the former tightness is a matter of a couple of minutes, however, knowledge of the design of a plastic window and skills in working with tools will be needed.

The clamping mechanism can be adjusted using special eccentrics located along the perimeter of the sashes. To ensure a tighter fit of the sash, the eccentric must be turned clockwise using a 4 mm hex key. Focus on the serif located on each such element. When it is directed towards the street, the pressure is weakened; when it is directed towards the seal, it is strengthened. The video shows everything well.

adjustment of the hinges , which also have their own mechanism responsible for the pressure density, helps to insulate a plastic window Here the regulation is carried out using a hexagon. You should follow a simple rule: if the tongue is pushed out strongly, then the sash fits well. To pull it out, you need to turn the hex counterclockwise if the hinges are on the left, and clockwise if on the right.

Things are even simpler with glazing beads . It is enough to pry off the old, loose glazing bead with a thin spatula, and install a new one in its place, which can be bought from the same company that sold and installed your windows.

After adjustment, check whether the tightness of the structure has improved using your palm or a lighter. If everything is done correctly, but there is still a draft, you will most likely have to change the seal.

How to choose a ribbon

The choice of self-adhesive insulation for windows must be approached very carefully. The tape is made from various materials and can have different profiles. This is worth considering when choosing it.

If you decide to use a rubber band, it is better to choose the softest one. Thanks to this, the insulation will reliably close all the cracks and reduce heat loss from the window structure to a minimum.

As already mentioned, insulation can have a different profile. When solving this issue, it is worth paying attention to the nature of the cracks.

If the gaps between the frame and the sash are straight, you can use rectangular profile insulation. It can be used to seal cracks up to 4 mm thick.

In other cases, the optimal solution would be materials with profiles of various shapes that resemble letters of the Latin alphabet.

For example, material with an “O” profile allows you to hide uneven cracks, the thickness of which can reach 7 mm.

When choosing insulation, special attention should be paid to the expiration date.

If it has expired, the adhesive properties of the tape have decreased significantly. As a result, this can lead to it quickly peeling off from the window.

No. 4. Replacing the seal

Ideally, a rubber seal can last quite a long time, but for this to happen, certain conditions must be met. According to the operating rules for plastic windows, the seal must be regularly lubricated with special substances, but which of us does this? So it turns out that after 5 years the rubber dries out and begins to let in the cold breeze from the street. The problem may be in the seal, which is located under the glass, or in what is located along the contour of the sash. Replacing the seal in a plastic window is not so difficult as it is responsible. If you doubt your skills, it is better to call a specialist.

Procedure for replacing the window seal:

- removing the bead;

- dismantling the lining and glass unit;

- dismantling a worn seal;

- installing a new seal through the groove. It is better to cut the tape in advance, which is 3-5 cm longer than the required length. The new seal is placed in its proper place, while acting as carefully as possible and without straining the material. The excess is carefully cut off. If desired, and for guarantee, the seal can be additionally fixed with adhesive;

- installation of double-glazed windows, linings and glazing beads. Glazing beads are fragile parts, so they must be removed and installed with extreme caution so as not to break them. Otherwise you will have to buy new ones.

The seal, which is located along the contour of the sash, may also need replacement . In this case, it is better to remove the sash. First, the decorative overlays are removed from the hinges, and then the pin is pulled out of the hinge using a mounting handle or screwdriver. All that remains is to carefully remove the sash, and only then it is very easy to remove the old seal from it. It is better to start installing a new seal from the top of the sash, gently pressing it, but not stretching it. It is better to secure the beginning and end of the sealing tape with glue. All! All that remains is to hang the sash back: you can install the pin with your bare hands, and then return the decorative trim to its place. The video shows and describes everything very well.

Self-adhesive insulation

Insulation materials are divided into adhesive, groove and self-adhesive.

The easiest way to install is self-adhesive. It can be foam rubber, rubber, made of polyethylene foam or PVC. There is insulation for plastic windows in black, white and brown. The material is quite durable and allows you to seal cracks up to seven millimeters wide.

When choosing self-adhesive insulation for windows, be sure to look at the expiration date. If you buy rubber or plastic insulation, it is better to take a softer one.

Foam or polyethylene (tubular or rectangular) is suitable for sealing gaps up to four millimeters, provided that the gaps are fairly level. Otherwise, you need to pay attention to the brand: up to three millimeters, profile C, E, K is suitable, up to five - P, V, up to seven - B, O.

More on the topic Thermal film for windows

To seal not very wide cracks, you can use a rubber seal; for uneven and wide cracks, it is better to choose silicone, it is more flexible.

No. 5. Window sill insulation

The installation of a plastic window is often associated with significant damage, which is especially significant in the area between the wall and the window sill. Some installers fill the cracks with cement and construction debris. No comments here. It is better, of course, when the space under the window sill is filled with polyurethane foam, but this option is not ideal. Over time, the foam can shrink or even dry out, forming decent gaps through which cold air enters the house.

To insulate a plastic window, you will have to get rid of the old foam and fill in new one. Keep in mind that it tends to expand as it hardens. After complete hardening, the excess is cut off; some builders recommend additionally filling small cracks with silicone sealant. This is followed by plastering work and the application of decorative coating.

If possible, the window sill area can be additionally insulated from the outside. Polyurethane foam is also used for this, but sometimes polystyrene foam is also used. Everything is plastered on top using a mesh and finished off.

Foam rubber

Foam rubber insulation for windows (foam rubber tapes) was used to seal windows for the winter long before the production of insulation was put into production.

The advantages of this material are known to everyone: it is easily compressed (and, as a result, installed), does not injure the surface of the frame, this method is cheap and simple.

There are also disadvantages: foam rubber for insulating windows is not the best choice; even with very good compression, air still leaks through the pores, and it is also not very durable - foam rubber comes off relatively easily.

The second problem can be partly solved by modern rubber-based adhesives. To solve the first part of the cracks (especially in hard-to-reach places), it is advisable to fill them with silicone or acrylic sealant before installing the insulation.

No. 6. Insulation of slopes

Today, often when installing plastic windows, slopes are additionally installed, smooth, beautiful, made of dense plastic. It often happens that there is a large crack between the decorative strip and the wall, which perfectly allows cold and wind into the apartment, therefore, to improve the thermal insulation of plastic windows, it is recommended to insulate the slopes from the inside or outside.

The procedure is as follows:

- dismantling unnecessary parts of polyurethane foam;

- if the surface is very uneven, you can plaster it;

- treating the slope with a primer, you can use antibacterial compounds to prevent the development of mold;

- A fragment corresponding to the slope is cut out of foam plastic. To make it stick to the surface better, you can slightly scratch it on the back side. All that remains is to apply assembly glue and press firmly to the surface of the slope; to guarantee, you can install several dowels;

- All that remains is to mount the corner, putty the surface and secure the casing.

Ethylene propylene synthetic rubber

EPDM, a compound of ethylene and propylene rubber (soft porous rubber seal), is most often used in the manufacture of self-adhesive seals, because the material is quite ergonomic and does not deteriorate when exposed to constant loads, which is especially important and necessary for windows and doors.

A special advantage is that rubber is a non-toxic coating that is environmentally friendly for people and the environment. It does not form mold, rot, insects, termites and other pests.

Very wear-resistant. Absorbs shocks, maintaining the durability of structures. Adheres to any surface, used for metal doors and even gates, hatches and cabinets, for industrial purposes - on electrical equipment and ventilation systems.

What should I do before installation?

If you want to ensure that when installing a self-adhesive seal on doors and windows there are no problems leading to its subsequent deformation or dismantling, be sure to follow the pre-installation procedure, namely:

- clean the surface from dust and dirt, wipe the surface with alcohol or acetone and dry thoroughly; visually mark the places where the seal will be glued and the places of contact (on the frame, sash, door or door frame);

- prepare the required length of the seal in advance; remove the protective layer gradually and press firmly to the base; after 2 hours, the glue finally sets to the base, drying occurs in temperature conditions from +5-40 degrees Celsius.

Source: vhod.guru/otdelka/uteplenie/samokleyuschiesya-uplotniteli-dlya-dverey-i-okon.html

New window or repair of the old one?

The issue regarding windows in the house is decided depending on the circumstances, different for everyone. In one case, the output is a completely renovated window unit, painted and sealed. In the second there is a plastic window. All other things being equal, given that the cost is approximately the same, not everyone prefers a new double-glazed window. The reasons are different for everyone, but reviews of the results of repairing old windows are only positive.

Materials and tools

To insulate a PVC structure you may need:

- construction knife;

- soap solution;

- spray;

- rubber spatula;

- clean napkin or sponge;

- polymer panels (polyurethane foam, polystyrene foam, penoplex);

- panel adhesive;

- self-tapping screws;

- mushroom dowels;

- putty knife;

- double sided tape;

- reinforcing mesh;

- heat reflective film;

- perforator;

- sandwich panels;

- construction (or regular) hair dryer;

- vapor barrier film;

- plaster;

- sandpaper;

- screwdriver;

- PVC corners;

- set of screwdrivers and hexagons;

- water-repellent film;

- rubber compressor;

- silicone sealant.

Which ones are better?

The means for insulating windows from those described above in terms of efficiency and availability are ranked in the top as follows:

| Place | Means | Manufacturer | Price |

| 1. | Self-adhesive seal | Novotex | 260 |

| 2. | Self-adhesive foam | PEAK | 190 |

| 3. | Construction putty | Der Master | 100 |

| 4. | Masking tape | Polyal | 110 |

| 5. | Heat-saving film | LLumar | 500 |

| 6. | Silicone based sealant | Makroflex | 700 |

| 7. | Paraffin | Promexport | 60 |

| 8. | Paper tape/paper/newspaper | Knauf | 50 |

Technology of work execution

It is worth noting that milling work can be done with your own hands using hand tools. After all, the groove for installing the seal is required to be very small. Let's take a closer look and analyze step by step the progress of such work:

- First of all, it is necessary to repair wooden frames. This includes: removal of old paint, fungi and mold, puttying and painting of window sashes.

- You can also replace and adjust fittings: window latches and handles.

- At this stage, if necessary, you can replace the glass or treat loose areas with silicone sealant.

- Now the window sashes must be removed for further cutting of grooves. If installation is carried out in cold weather, during this time you can curtain the window opening with thick material.

- Then, using a hand tool, a groove is cut around the entire perimeter of the sash, the depth of which should be at least 5 mm and the width no more than 3 mm. This is regulated by using the appropriate cutter.

- Now the tail of the seal must be inserted into the cut groove and rolled with a special roller for secure fastening. In this case, it is necessary to perform reciprocating movements so that the seal does not stretch too much.

Advice! If you don’t have the desire or ability to do milling work, you can greatly simplify the installation of the seal yourself. To do this, you can use a construction stapler or good glue. True, the effect of this installation method will be somewhat worse and such a seal will last only 4–5 years, after which repairs will be required.

Difficulties and errors

When insulating plastic structures, the following problems may arise:

- The biggest difficulty may arise when insulating PVC windows with polymer boards (expanded polystyrene or analogues) if the room is located above the second floor. Processing external walls or slopes in this case is not possible without the use of special equipment (truck crane or climbing equipment) and specialists in high-rise work.

- Finding the right seal, as well as its incorrect installation.

- When gluing the film, wool, dust or debris may get underneath it, which can cause unevenness and bubbles to appear during shrinkage.

- Some types of protective films have low strength, which is why it can tear when smoothed.

- If the fittings are adjusted incorrectly, the window may not close, and the rubber bands, hinges or locking mechanism may be damaged.

New product on the construction market

The relative novelty of the repair work raises doubts among many who decide to replace the window - the financial side of the issue allows you to significantly save on installing new windows, but will the cheaper method be worth it? Experts confidently state the difficulty of performing this type of dismantling on their own. Not everyone can make a selection along the sash, creating a groove for the seal. But having examined the process in detail, it seems possible to perform it yourself if you have the tools and materials.

Waterproofing windows from outside

The installation seam is most susceptible to the harmful influences of the external environment from the street side. Therefore, even if you do not use special insulating agents, you need to at least plaster or cover the external slopes with panels. Installing windows according to GOST involves the use of either tape materials or water-based sealant.

Waterproofing tape

For exterior work, two types of sealing materials are most often used - PSUL and waterproofing diffuse tape.

- PSUL. Pre-compressed sealing tape is visually very similar to foam rubber, in most cases it is dark gray in color. An adhesive mixture is applied to one of the edges of the tape, covered with paper film.

The sealant is produced twisted into reels (wide products in rolls), which are unwound immediately before installation on the block, otherwise the sealant will become unsuitable for use. One of the features of PSUL is its expansion in cross section, which makes it possible to fill all the irregularities between the block and the opening. The tape does not allow water to pass into the seam and allows it to evaporate from it. - Diffuse vapor-permeable tape. Most often it is used in combination with PSUL to insulate the lower part of the window block at the installation site of the drip profile.

If the design of the opening does not allow the use of pre-compressed materials, a diffuse vapor-permeable tape can be installed along the entire outer perimeter of the glazing.

Its characteristics are similar to PSUL - it also well insulates the seam from external moisture and promotes the removal of internal moisture. The main differences are in the installation method and maintaining the shape after pasting, which does not allow filling in uneven areas in the opening.

Both types of waterproofing are compatible with almost all finishing materials and can be used to seal any seams.

Basics of the method

Swiss technology, carried out independently, allows, with minimal investment and a set of materials, to make the window frame airtight, and the running parts to close and open well. Dismantling work takes place in any temperature regime, so even in winter it is not problematic to obtain a high-quality window.

This type of repair got its name thanks to the materials. The finishing uses Swedish sealant , which has a number of positive qualities. This material has a tubular structure and is made of silicone, which allows it to be resistant even to sudden temperature changes. The temperature range that the Swedish seal can withstand is from 50 °C below zero to + 80 °C. Moreover, the material is highly resistant to moisture and dirt, and has a long service life - manufacturers promise from 15 to 20 years without repeated dismantling.

In order not to make a mistake and choose a seal that is suitable specifically for your case, you need to familiarize yourself with the markings. The diameter of the tube and its structure can be different, so the dimensions should be adjusted to the groove in which the tube will fit:

- E – groove 2-3.5 mm;

- P – groove 3-5 mm;

- D – groove 3-7 mm.

Execution Sequence

To obtain the highest quality window, you must strictly adhere to the step-by-step operating algorithm. Every owner may not have a set of tools at hand, but hardware stores often offer tool rentals, which can also be used.

Required tool set:

- Roller walker for laying insulation;

- Milling tool for preparing grooves;

- Screwdriver.

To begin with, dismantling work is carried out. To do this, the running elements are removed from their hinges and the frames are untwisted. In some cases, it may be necessary to dismantle the glass. The removed frame is processed, cleaning it from dirt, dust, and removing old paint. The presence of small cracks that do not go deep into the frame can be eliminated with putty. It is necessary to fill the gap that has been cleared of small dirt particles with a layer of putty, then leveling and wiping the layer flush with the surface of the frame. When the frame is in proper shape, a kind of double-glazed window with an additional layer .

A sealing tape is attached to the inside of the sash and sealed tightly. This technique will create a tight press. Silicone sealant is applied at the connecting junction of the frame and glass so as to completely fill the gap. Outdated glazing beads should be replaced with new ones. By adjusting the pressure, gaps are eliminated between the sash and the frame. Then comes the installation of the seal.

Using a milling tool, prepare a groove with an angle of 45°, performing the operation along the entire perimeter of the frame. The chips are removed from the finished groove and the surface is thoroughly cleaned. A tubular seal, selected according to the size of the grooves, is installed in the finished groove . To do this, from the corner of the frame, the edge of the seal is placed into the opening and gradually driven in with a roller walker.

Thus, the double-glazed window assembled using Swedish technology is ready. The inside of the sashes is dried with a hairdryer, and the finished frames are mounted in place and adjusted.

Description of technology

This insulation method is based on the use of modern tubular seals, similar to those used for plastic profiles. Such seals are produced by the Swiss company Eurostrip, hence the name of the method.

Using a router or other tool, cut a shallow groove in the window sash with your own hands. Such a groove is made along the entire perimeter of all sashes that need to be insulated. The seal has a special raised spike, which is inserted into the groove and fixed in it. Using this method has its advantages:

- The most important aspect is the fact that the vents, and, if necessary, the sashes of wooden windows can now be opened for ventilation at any time without any problems. After all, after installation, the need to seal the cracks with tape completely disappears.

- A high-quality seal is not afraid of temperature changes - it is made from frost-resistant materials.

- In addition, this material is resistant to various stains, and when making repairs, it can even be painted along with the frames.

- The manufacturer provides a guarantee for a certified product - up to 20 years of impeccable service.

- The material from which the seals are made is absolutely environmentally friendly and complies with all sanitary standards of our legislation.

- By installing such a seal, you can forget about such a problem as repairing wooden windows for several years.

Advice! This technology is applicable not only for wooden frames, but also for plastic or aluminum profiles, which are used for do-it-yourself glazing.

Types of seals

Several types of Eurostrip seals are supplied to the domestic market. Let's briefly look at each of them:

- Thermoplastic elastomer (TEP). This type has the lowest price, for which it pays for low frost resistance and fear of staining. Therefore, its use is very limited.

- The rubber seal (EPDM) has good mechanical strength. The disadvantage is the rather high rigidity of the material, which does not allow it to completely follow all the bends of the frames. It is recommended for use on glazed balconies, where frames are rarely repaired, since such material should not be coated with paint - it will crack.

- Silicone seals have the highest performance properties. This material is elastic and soft, compresses well without losing its shape. The most expensive type of seals, but they are worth the money.

Please note: PVC doors to the balcony

Choosing the right option

One of the main points that you should pay attention to when choosing a sealant is its shelf life.

Products with an expired or nearing expiration date may peel off from the surface over time, or may not provide proper sealing at all. In order to check the quality, it is enough to bend the material and evaluate how quickly and accurately it restores its original shape.

When choosing a self-adhesive rubber seal, it is best to opt for softer models. If there is sufficient softness, the material will be able to replicate to a greater extent all possible surface irregularities, thereby eliminating any draft.

Frame repair cost

The average cost of insulating and fitting a window is about 3,000 rubles. This figure takes into account dismantling work with the sashes, making grooves and filling with sealant, often silicone, if necessary, adjusting the sashes, sealing the glass, the sash opening - if the binding is paired.

Furniture work is paid above this amount. If necessary, for an additional fee, craftsmen will carry out a complete repair of the window frame.

In the case of framed windows in the manner of “Stalinist” windows, only the inner sash is insulated, leaving the outer one in its original state. When ordering insulation and an external sash, the price doubles.

Please note: Adjusting plastic balcony doors yourself with video instructions

The price list of organizations providing such services also includes a cost for coloring, which averages 5-6 thousand rubles.

Based on all the data, a complete dismantling will cost the same as a double-glazed window with two chambers, a window sill, mosquito netting, bevels and ebb.

Average price for services

The cost of various types of insulation depends on the material, as well as the complexity of the work (for example, high-rise).

Average prices for some types of work:

- replacement of seal – 150 rubles/linear meter (l.m);

- sealing seams with silicone – 250 r/m;

- adjustment of fittings – 150 RUR/window;

- external insulation with polystyrene foam – 400 rubles/meter.