| Place | Name | Characteristics in the rating |

| Top 10 best mineral wool manufacturers |

| 1 | ROCKWOOL | Best quality and practicality |

| 2 | KNAUF | Most popular company |

| 3 | ISOVER Saint-Gobain | The best combination of price and quality. Durability |

| 4 | IZOVOL | The highest level of fire safety |

| 5 | URSA | High-tech equipment |

| 6 | TECHNONICOL | Better rigidity. Withstands heavy loads |

| 7 | BELTEP | High wear resistance |

| 8 | PAROC | Practicality and reliability |

| 9 | Isoroc | Universal characteristics |

| 10 | Thermolife | Good sound insulation |

It is impossible to imagine the arrangement of any room without heat-insulating materials for walls and floors. Mineral wool is one of the most effective types of inorganic fiber insulation. Thanks to the air contained in its spaces, heat is retained. The product is made from glass or rocks. The best features help keep cold air out of your home. Therefore, today it is the most popular and durable product.

There are many manufacturers on the modern market that successfully and efficiently produce mineral wool, which is suitable for any geometry. Thanks to the flexibility of the material, builders create sealed seams. The insulation is quite fire-resistant, which allows you to be sure of safety. In addition, during operation it does not emit toxins. We invite you to familiarize yourself with the leading brands in this field to evaluate the experience of each of them.

Shape: additional layers

Today, mineral insulation is produced with a thickness of 2-25 cm in a variety of shapes, on which the area of application depends. And the greatest variety is found in mineral slabs:

- Slabs with an additional bitumen layer , which serves as the basis for the roofing sheet.

- Plates covered with polymer film or fiberglass . They are used for “dry” insulation and for sandwich-type construction. Thanks to fiberglass, such slabs are protected from moisture, wind and fibers being blown out of them. In addition, working with such slabs is much more convenient.

- Variable cross-section slabs that create a roof slope and allow rainwater to drain easily.

- Lamellar slabs , which are distinguished by an unusual arrangement of fibers, which are no longer randomly located, but are laid strictly perpendicular to the surface of the slab. Such slabs are more elastic and are indispensable for insulating curved surfaces, because have significantly greater tensile strength.

- Two-layer slabs for “wet” external insulation. Here the top layer is more rigid and protects the slab from deformation during installation. Thanks to this, a fairly flat and hard surface is created for the subsequent reinforcing layer and plaster. And the more elastic part of the slab is designed to fit tightly to the wall and provide thermal insulation. To prevent the sides from being confused, they are marked.

- Plates with aluminum foil . This foil is additionally reinforced with fiberglass, which also acts as a vapor barrier and is excellent for insulating a residential attic.

Plenty of choice, isn't it?

Consumer choice

In private construction, approximately 80% of the purchased insulation is basalt and stone mineral wool, which have universal quality characteristics. Slag and fiberglass wool are used more often in enterprises for thermal insulation of specific objects.

Reliable thermal insulation

In practice, which mineral wool is best for insulation needs to be decided taking into account a specific building, room, structure. When making design decisions, specialists calculate in advance what density of mineral wool is best to choose and how to use the material correctly.

Errors most often occur not because of the quality of the insulation, but because of its improper use. It is recommended to carefully study information from the manufacturer about the characteristics and properties of mineral wool, and features of use.

Knauf produces everything!

Photo: www.dostavkasmesi.ru

Knauf is a manufacturer that has proven more than once that it can provide the construction market with the best offers. Thermal insulation is no exception. Knauf offers good quality mineral wool based on basalt fiber, as well as glass fiber composition. The first option is widely used for technical insulation, in construction and in the production of complex equipment. Fiberglass insulation is produced for specialized purposes (TEPLOKnauf), as evidenced by its names:

- HEATWALL;

- HEAT stove;

- WARM roofing;

- Acoustic partition;

- HEATROLL.

Most of the mineral wool sold by the manufacturer belongs to the Knauf Insulation series. There are no toxic phenol-formaldehyde resins used in the production of this product. The Knauf Insulation and TEPLOKnauf thermal insulation lines are intended for the construction of residential buildings by individuals and construction organizations.

Disadvantage : high price

Rating : 9.9 points out of 10

Reviews : “You rarely hear a bad word about Knauf. This means that the material is truly excellent.”

What is better to buy: roll or slab

Roll and sheet form

The answer to this question must be sought based on the type of structure that is insulated. For vertical surfaces, sheet material that does not slide down is more suitable. To insulate floors, pipes, and other horizontal sections, use a roll that is easily rolled out, takes the desired shape, enveloping the base.

The composition of both types of canvases is absolutely the same, especially if they are products from the same brand. A rolled copy creates fewer cracks and joints; it is used more economically due to less waste.

But it is thinner and less dense. On vertical surfaces it needs to be fixed, and sometimes the slabs are simply enough to be tightly inserted into the sheathing.

Material calculation

Differences in the dimensions of mineral wool elements can mislead you. Professionals try to save working time. The price of a mistake is the same for everyone - budget overruns and loss of time.

To perform calculations, use an online calculator. It will take into account all the necessary quantities, parameters and conditions.

A small reminder on using the calculator:

- Please note that not all Russian settlements are represented in the list of cities. Therefore, try to choose options that are minimally distant from the location of your home. This is important because this parameter determines the average winter temperatures;

- all numerical values (thickness) are displayed in millimeters. Just in case: 1 m is 100 cm or 1000 mm;

- We recommend looking at the detailed characteristics of insulation on the manufacturers’ websites. There you will also find recommended prices for this type of product;

- All calculations are approximate, so it would not be superfluous to add 10% to the results obtained.

Having obtained the thickness of the thermal insulation as a result of calculations and knowing the area of the walls, it is easy to calculate the volume of insulation. We hope this is helpful.

Which mineral wool is best to buy?

Depending on the material of manufacture, mineral wool can be fiberglass or stone. Each type has its own advantages and disadvantages, which will be discussed below.

When choosing insulation, it is important to consider the following characteristics:

- Thermal conductivity coefficient - the lower it is, the better insulating abilities the material has.

- The degree of vapor permeability, allowing the insulation to allow vapor to pass out and not retain the lag;

- Fire resistance – reflects the fire safety of mineral wool.

The purpose of the material also matters. Today, manufacturers produce universal mineral wool, as well as insulation materials separately for roofing, interior work, facades and rooms with high humidity.

Mineral insulation is sold in rolls and sheets. Which option to choose does not really matter, since mineral wool can be laid even from scraps, which does not reduce its characteristics. It's just a matter of convenience.

Recommendations: 10 Best Heating Cables

11 best underlays for laminate flooring

12 best mats for heated floors

About the use of insulation

The general category of insulation, obtained by dividing the raw material into fibers, is usually called mineral wool.

The widespread use of inorganic insulators is associated with high heat and sound insulation properties:

- construction of engineering communications;

- to protect industrial equipment;

- in the field of construction.

Insulation of the roof of a building

The main advantages of mineral wool:

- There are completely no organic elements in the structure of the product, which allows the service life to be unlimited;

- does not burn - class NG, NPB 244-97;

- the material belongs to breathable insulation - the fibrous structure allows excess moisture vapor to pass through, air circulation is maintained;

- does not decompose or mold;

- does not attract insects and rodents;

- tolerates temperature fluctuations and exposure to aggressive environments.

Mineral wool is used in interior decoration in accordance with building codes (SNiP) and codes of practice. The vapor permeability of the material is especially important for insulation and sound insulation of wooden and stone structures. High performance properties of the best types of mineral wool and reasonable price are the main factors for consumer choice. v

What is it used for?

Floor insulation

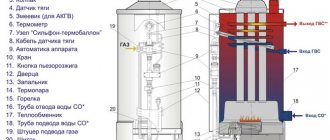

Mineral wool is a convenient material for insulating internal and external walls, roofs, floors, attics and utility unheated rooms. The raw material is resistant to high temperatures, so it is used for fire protection, insulation of boilers, furnaces and pipelines. It is used for protection by structures with heating up to +700°C!

The substance is used to insulate industrial systems: pipelines, tanks, instruments and machines. It is actively used in the construction, oil and gas, and petrochemical industries. It is an advanced soundproofing component in various acoustic structures.

TechnoNIKOL is a reliable Russian brand

This is an exclusively Russian brand that has 53 factories in 7 countries. Among them are Germany and Great Britain, Italy and Lithuania. Official representative offices are located in 18 countries. The company's training centers are also located there. TechnoNIKOL has its own Research Centers for the development of new technologies for heat and sound insulation. The products of this concern are very popular due to competitive prices and are sold in 95 countries.

TechnoNIKOL general building thermal insulation based on stone wool

An inexpensive way to perform thermal insulation on any construction site is with materials based on stone wool with a universal purpose. At TechnoNIKOL such products are represented by the BAZALIT series. All brands can be mounted horizontally or vertically.

- BAZALIT L-30 - has a density of 25-35 kg/m3 and a thermal conductivity of 0.032 W/(m*K) at an outside temperature of 10 degrees. Well suited for a base layer followed by cover.

- BASALIT L-50 - denser slabs (36-50 kg/m3), designed for installation in any spatial position. Particularly good for the bottom layer when insulating floors and interfloor ceilings.

- BASALIT L-75 is the most dense material based on stone wool with an indicator of 51-75 kg/m3. Vapor permeability of 0.5 mg/(m.h.Pa) allows its use in the middle layer on walls with light masonry.

TechnoNIKOL stone wool for insulation of all types of roofs

For all types of roofing, the TechnoNIKOL company has developed a line of TECHNORUF insulation materials. The TECHNORUF N EXTRA brand is produced in the form of a basalt slab with a density of 90-110 kg/m3 and can withstand pressure up to 3000 kg per 1 m2. It is optimal for arranging a sloping roof. TECHNORUF N PROF is next in class and has a density of 110-130 kg/m3. With a deformation of 10%, it is capable of carrying a load of up to 4000 kg per square meter, which is also not bad for insulating a roof of complex shape.

TECHNORUF V PROF is designed for all types of flat roofs. It has a pronounced hydrophobic effect. It can act as the top durable layer in three-layer structures. Its density is 175-205 kg/m3, and its strength can withstand up to 8000 kg of pressure per m2. To quickly create a slope on a flat roof for precipitation, use TECHNOROOF WEDGE 4.2%, which automatically forms a slope contour. At the same time, cotton wool itself effectively combats cold retention and has a thermal conductivity index of 0.038 W/(m*K).

TechnoNIKOL TECHNORUF N EXTRA.

TechnoNIKOL stone wool for insulation of ventilated facades

For ventilated facades, the manufacturer offers a whole line of basalt wool from the TECHNOVENT series. TECHNOVENT EXTRA brand is quite suitable as a base layer or in combination with another insulator. Its breathability is 35 m*s*Pa.

There is another type of this material - this is TECHNOVENT N PROF, the air permeability of which is 80 m*s*Pa. The insulation is intended for use in industrial and civil construction during new construction and reconstruction of buildings and structures for various purposes as an inner layer with two-layer thermal insulation in curtain wall systems with an air gap.

TechnoNIKOL stone wool for insulating a wet facade

TECHNOFAS EXTRA insulation, designed to retain a thick layer of plaster, is well suited for wet facades. The density of the slab is 80-100 kg/m3, and the thickness is from 50 to 150 mm.

When a thin layer of plaster is planned, you can save money and choose TECHNOFAS EFFECT, which, with a smaller cross-section, has an increased density of 125-137 kg/m3, which will provide the required strength. TECHNOFAS DECOR is produced for insulating facades on balconies and loggias, therefore it has an increased tensile strength of 25 kPa.

TechnoNIKOL TECHNOFAS EXTRA.

Is mineral wool dangerous for health?

This is what phenol-formaldehyde resin looks like when frozen

Many have heard the common myth that mineral wool is harmful to health due to the phenol-formaldehyde resin it contains. In large quantities, this substance becomes carcinogenic. On this basis, many studies and risk assessments for humans have been carried out.

As a result, the following conclusions were made:

- The resin content in the insulation is 4 times less than the maximum permissible norm

- After heat treatment, the resins acquire a solid form. They do not evaporate into the air, which means they are not dangerous

- All patented mineral wool brands have test certificates

- People encounter phenol-formaldehyde compounds every day. For example, a billiard ball is made entirely of this resin. It is added to the chipboard from which furniture is made, to carpets, and plastic dishes.

Buy insulation only from trusted suppliers who can provide test reports and hygiene certificates.