Glass wool or stone wool has been used for a long time; this is a fairly old method of insulating a house, and yet it is used in real time and in almost all construction companies.

The effectiveness of mineral glass wool can be said to be partially irreplaceable. This thermal insulation material can not only insulate large rooms and houses, but also small apartments. [contents] But not only glass wool can be used in thermal insulation, but also alternated with any other material; this will increase sound insulation and heat retention.

The low cost of glass wool has always attracted a large number of buyers because it is cheap and of high quality. Do not forget that glass wool, like many other insulating materials, has favorable and unfavorable sides.

Glass wool cannot replace the complete thermal insulation of your apartment home. But the positive qualities of this material are much greater than the disadvantages.

Glass wool production

Glass wool production occurs in several stages.

- At the first stage, 80% glass and 20% lime, sand, soda and ethibor are loaded.

- All this is connected and placed in the heating compartment.

- The composition is heated in an oven to a temperature of 1400 degrees.

- To achieve fine threads, the composition is strictly controlled

Subsequently, the composition is stretched along a conveyor and treated with polymer aerosols, which help to stretch the threads and join them into a carpet.

After this, the temperature in the chamber rises to 250 degrees, at which point the fibers begin to harden and the remaining aerosol evaporates. After these steps, the cotton wool is left to cool.

The main mistakes when insulating a roof

Actions that can negate all your work and expenses:

- incorrect selection of the thickness of the thermal insulation material can lead to wasting extra money or the lack of the desired result;

- ignoring ventilation will create excess moisture and condensation in the room, which will lead to damage to the coating and rafter system;

- By neglecting the steam and water barrier, you can get a negative result in the form of condensing moisture, which will be absorbed into the heat insulator, violating its properties.

Almost all private households located in most regions of the country roof insulation from the inside Therefore, such events should not be postponed “for later”. It is better to carry out thermal insulation at the construction stage of the building. Properly organized roof insulation is the key to comfortable living in the house and a noticeable reduction in energy costs.

Characteristics of glass wool

Glass wool has a number of inherent qualities

- The thickness of the glass wool layer can be from 3 to 15 cm.

- The length of one glass fiber can be from 10cm to 30cm.

- Due to the length of the fibers, the strength and elasticity of the material is improved.

- Vibration resistant.

- The thermal conductivity of glass wool ranges from 0.030 to 0.052 W.

- Able to withstand heating up to 450 degrees.

Fiberglass is used on a wide variety of objects for the purpose of thermal insulation. This could be a residential building, a heating main, industrial tanks and buildings that need to be protected from fire.

The type of building, or rather the location of the surface in space, does not play a special role. Glass wool can be insulated as horizontal, vertical or even surfaces located at different angles.

Types of glass wool products

- Soft mats;

- Soft, semi-soft and hard sheets with non-natural connecting components. Semi-soft and hard sheets withstand heavy loads well;

- Sheets with increased rigidity and glass felt lining also protect against gusts of wind.

Fastening long glass wool slabs can be done in two ways: tongue and groove. It is these two methods of fixation that perfectly fix the sheet without any gaps and are considered very effective.

Fastening a tongue and groove is a connection of two parts of a sheet, or rather, fixing a protrusion into a groove of the second sheet. Toe fastening is the joining of two sheets of glass wool using the tongue and groove technique.

- In production, finished fiberglass is rolled into a roll for ease of use and transportation. This does not affect the quality of the fiber in any way.

- After unpacking, the fiber quickly straightens and takes on the desired volume.

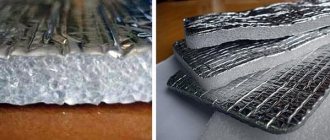

- For greater ease of use and preservation of the material's value, glass wool is additionally reinforced with a layer of cashmere.

- It also does not allow steam to penetrate through the fibers. This layer looks like foil.

There are a number of companies that produce fiberglass with an additional layer of cashmere: Ursa, Knauf, Isover, Neman.

Types of roof according to attic parameters: “cold” and “warm”

Conventionally, roof insulation in the construction world is divided into attic, when the roof slopes are insulated, and attic, when the ceiling is thermally insulated.

Like this? We can say that attics also have their own attic - this is a ventilation gap between the internal insulation and the laid roofing. The fact is that heat, according to all the laws of physics, always rises and seeks its release into the atmosphere. It passes through both the insulation and the vapor barrier, and together with water vapor. And here the external air is pulled in at the eaves plumb, which passes to the ridge and along the way picks up both vapors and excess heat. Through aerators or the same ridge, all this is safely removed and does not cause any problems.

Those. in an ordinary, unused roof, the attic occupies the entire space from the ridge to the attic floor, and in the attic, the attic is just a small space under the slopes between the insulation and the roofing. And in insulating both, the type of roof has its own approach, which we will now study.

Health effects of fiberglass

In 1997, studies were conducted in Europe on the effects of mineral wool on human health. The criteria by which they examined mineral wool were: fiber size, the presence of oxides and alkali metals in the composition.

Mineral wool should have been classified into the second or third hazard class. The second class of hazard involves the presence of irritating substances and the presence of dangerous irritants. The third class of hazard means that the availability of data on the composition does not allow a thorough verification of the harmfulness of the product.

Only in 2001, the result of a study of mineral wool on the analysis of carcinogenic substances was presented to the public. It was classified in the third class, that is, not causing diseases in the human body.

Precautionary measures

When working with glass fiber you need to be very careful. You need to wear overalls made of fairly dense material. Prevent small pieces of fiberglass from coming into contact with your skin. No exposed skin is allowed. The eyes and respiratory tract also need to be protected. Wear goggles and a respirator.

During operation, the fiberglass breaks and small, sharp glass particles are formed; when they come into contact with the skin, they cause itching. Getting them into the respiratory tract is extremely dangerous. Once fiberglass debris gets on your clothing, it will be nearly impossible to remove.

If contact with glass wool particles does occur, you must do the following:

- Do not scratch areas of the skin that have come into contact with the fiberglass.

- If particles of fiber get on your hair, carefully shake them off and close your eyes. After which the head is lowered into the bathtub or a deep cup, shaking the neck to shake off the residue from the hair.

- Then take the spirit under a strong stream of cold water. Hot perfume is categorically excluded, as it expands the pores.

- If fibers get into your eyes, they should also be rinsed with water. Then contact an ophthalmologist.

- If fragments of fiberglass get into the respiratory tract and cause difficulty breathing, you should immediately go to the hospital.

It is better to throw away the clothes you worked in. Even washing several times will not help remove fiberglass from clothing.

Expanded clay

It is used when arranging flat slopes. Expanded clay is a bulk type of insulation. It is placed either on the floor slabs or on the outer surface of the roof. The heat insulator is sealed and covered with a screed, and the required slope of the slope must be observed to ensure the removal of precipitation.

When using expanded clay, the loads on both the foundation of the building and the roofing structures increase significantly. This nuance should be taken into account when drawing up design documentation for a private house. The quality of such thermal insulation depends on compliance with insulation technology.

Pros and cons of glass wool

Like all building materials, glass wool has a number of advantages and disadvantages. One of the main advantages of glass wool is its affordable price, flexibility and poor thermal conductivity.

- Glass wool can be used to insulate a wide variety of buildings.

- Due to its flexibility, it can take any shape.

- Glass wool is not only a good heat insulator, but also a sound insulator.

The disadvantages of fiberglass include the fact that it loses its thermal conductivity properties when in contact with moisture. It is almost impossible to dry fiberglass. The problem can only be eliminated by replacing the old coating with a new one.

The insulation also shrinks. The installation process is also dangerous and quite difficult and requires technical training.

Mineral wool for the roof of a private house

When choosing how to insulate the roof from the inside of a private house, many people prefer mineral wool. It is used for insulation of flat and pitched roofs. This material with a fibrous structure is produced from rock melts. On the building materials market, mineral wool is sold in the form of mats (slabs) and rolled products. When making a choice, you should take into account its thickness and density.

Among the advantages of mineral wool:

- high degree of thermal insulation;

- non-flammability;

- environmental cleanliness;

- stability of parameters;

- easy installation;

- affordable price;

- soundproofing;

- absence of rodents and microorganisms.

Sufficiently rigid mineral fiber slabs are used for external insulation of flat roofing structures. Mineral wool with a lower thickness and density is used to insulate pitched roofs.

Insulation using this material requires the installation of hydro- and vapor barriers and ventilation gaps. These layers prevent moisture from collecting in the insulation. Otherwise, the thermal insulation qualities of mineral wool are reduced, and rotting processes begin in the rafter system.

Choice of glass wool

There are various brands of glass wool on the shelves of construction stores. We'll tell you which glass wool to choose and help you choose the best glass wool for insulation.

If your task is to insulate the floor, you need to pay attention to the type of room. If you want to insulate the floor in the bathroom or kitchen, glass wool is not suitable for these purposes. It is best used as floor insulation in bedrooms.

Glass wool mats are used as insulation for walls. I install them in pre-prepared cells, which are 1 cm smaller than the size of the cotton wool. Due to this, reliable fixation is achieved.

When choosing glass wool as insulation, pay attention to the following manufacturers:

- Insulation ISOVER Warm Walls Strong 1000x610x50 mm 10 pieces (6.1 m2 / 0.305 m3)

- Stone wool Rockwool Light Butts 1000x600x50 mm 10 pcs

- Insulation TeploKnauf cottage 1230x610x50 mm 12 sq.m (16 plates)

- Insulation Technolight Extra 1200x600x50 mm

- Basalt insulation Isobel 1000x600x50 mm (6 sq.m., 0.3 m3, 10 pcs)