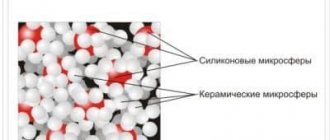

Thermal insulating liquid material produced by KORUND, based on its physical properties and consistency, is very similar to ordinary white paint that is used to paint standard surfaces. Thermal insulation CORUND has only positive reviews. All this is due to the fact that the material consists of a high-quality acrylic binder component, ultra-thin ceramic microspheres with a composition of rarefied air and a specially developed composition of fixatives and catalysts.

In the production of such materials, special additives are also used that completely eliminate the occurrence of corrosion and fungal accumulations in conditions of high humidity. Thanks to this composition, liquid thermal insulation CORUND (read reviews on our website) is flexible, soft, light and stretchable.

After application, the insulation forms an elastic polymer sheathing that has unique properties compared to traditional heat insulators.

The new generation material has already proven its reliability as a temperature preservation component. In addition, CORUND thermal insulation has technical characteristics favorable for combating corrosion and the appearance of condensation on cold surfaces.

Features of liquid thermal insulation

Initially, the composition was developed for the space industry, but later builders became interested in it.

This new material differs from conventional insulation in the method of application. It is distributed over the surface using a brush, spray or roller. Liquid thermal insulation, reviews of which are contained in the article, should be a layer approximately 1 mm thick.

After application, the composition polymerizes and forms a film with energy-saving characteristics.

Types of materials CORUND

Thermal insulation products of the KORUND company have several varieties:

- CORUND ANTIKOR

A universal material applied directly to rusty surfaces. Before application, you just need to walk over the surface with a regular wire brush to remove the dry layer of rust.

The insulation has an additional anti-corrosion property. Thanks to this, the cost of preparing the surfaces to be treated is significantly reduced.

- CORUND CLASSIC

The heat insulator is an ultra-thin material with good thermophysical properties. During transportation, the liquid composition of the insulation is practically not divided into fractions.

- CORUND FACADE

This type of material is applied in layers (thickness from 1 mm), so it subsequently looks like high-quality facade paint. FACADE heat-insulating paint also has only positive reviews from customers. This ultra-thin liquid heat insulator is used for concrete surfaces.

FACADE paint also received excellent reviews in combination with ANTIKOR paint.

Well-known manufacturers of liquid thermal insulation and reviews of their products

Today in stores you can find thermal insulation compounds of different brands. The most famous of them: “Corundum”, “Magnitherm”, “Astratek”, “Bronya” and “Akterm”.

All these compositions differ in manufacturer and area of application. Liquid thermal insulation, reviews of specific brands of which will be presented below, can be used for building facades, roofing materials or pipes. The convenience of its use also lies in the fact that it can easily be used to cover small parts of devices, handles and valves on equipment.

Description and features of Corundum production

Liquid heat insulator Corundum is a mixture of acrylic binder and ceramic microspheres with thin walls that contain rarefied air. Acrylic binder is made using fixatives and catalysts.

Microspheres have a size in the range of 0.01-0.5 millimeters. Also, various additives are additionally introduced into the product, which are designed to enhance its certain qualities. This balanced composition gives the material lightness, elasticity, flexibility and stretchability. In addition, Corundum has excellent adhesive ability.

The consistency of liquid ceramic heat insulator is similar to ordinary paint. Essentially, it is a white suspension, which, after polymerization, forms an elastic and durable polymer coating.

Unlike conventional thermal insulation materials, Corundum not only protects a building or any other structure well from heat loss, but also prevents metal surfaces from rusting.

Initially, such ceramic heat-protective coatings were created by order of NASA for use on spacecraft. After some time, it was possible to adapt these compositions to “earthly” needs. Corundum is the trade name of a product developed by Russian scientists. This heat insulator has all the necessary certificates confirming its quality.

Liquid thermal insulation “Corundum”: reviews and application features

Such thermal insulation is in demand among buyers, this is explained by its ease of use. To apply the material you do not have to buy additional devices. A roller, brush or spray will be enough.

The process of distributing material over the surface requires extreme care from the performer. It is better to form the required heat-protective layer 1 mm thick in 2-3 approaches. Each stage is carried out approximately 24 hours apart.

The service life of the coating depends on the accuracy of following all instructions. This indicator is also influenced by the condition of the surface on which the composition is applied. For example, liquid insulation “Corundum Anticor” should be distributed only over metal that is well cleaned of rust. This can be done with a special brush.

Liquid thermal insulation “Corundum”, reviews of which are almost always positive, is produced with a special composition for application in the cold season. It is worth considering that there should be no ice or snow on the working surface at this time.

According to reviews from owners of private houses, Corundum perfectly protects basement pipes. If applied correctly and the technology is followed, even after several years no defects are observed on the treated metal.

The high speed and ease of application of the Corundum composition gives it an advantage over similar rolled materials. This also reduces the labor intensity of the work.

It is important to purchase products only from authorized dealers, since only the original composition has all the listed properties.

Specifications and Benefits

Since CORUND thermal insulation (you can read reviews on our website) can completely merge with the surface and fill almost all micropores, the concentration of the material in the polymerized state is 80%.

The main technical indicators of heat-insulating paint (reviews) are as follows:

- does not collapse under the influence of ultraviolet radiation;

- the application method is similar to paint;

- has a thermal barrier effect;

- does not allow moisture to pass through and is not exposed to saline aqueous solutions;

- protects the surface from moisture, temperature differences and precipitation;

- does not support combustion (at a temperature of 800°C the material undergoes decomposition with the release of nitrogen and carbon oxides, at a temperature of 260°C the material simply begins to char);

- CORUND thermal insulation also exhibits technical characteristics in terms of environmental friendliness of the product (does not contain harmful organic compounds);

- 1 mm of thermal insulation layer is comparable to 50 mm of rolled insulation.

The main advantage of heat-insulating paint CORUND: characteristics, heating temperature.

You can work with liquid heat-insulating paint without additional ventilation. Compared to other thermal insulation materials (rough and hard), liquid paints are applied much faster and easier.

In addition, a thin liquid layer of insulation is much lighter in weight than, for example, a thick-walled material.

See more on this topic on our website:

- ISOVOL as insulation - technical characteristics and reviews ISOVOL insulation is one of the recent discoveries in the market for modern generation building materials. ISOVOL insulation, the technical characteristics of which indicate high thermal insulation performance, is intended for…

- PAROC insulation - technical characteristics and reviews about insulation. Production facilities of the PAROC brand are available in Sweden, Finland, Lithuania and Poland. Official representative offices from which you can purchase PAROC insulation (technical characteristics and properties are…

- Isorok insulation - reviews and technical characteristics of insulation The ISOROK company produces a large list of thermal insulation materials intended for use in a wide variety of places in buildings and structures (in walls, ventilation shafts, various floors, roofing, pipelines...

- Extruded polystyrene foam - reviews and technical characteristics of PENOPLEX Extruded polystyrene foam is a very popular product in the building materials market. The qualities and properties of this material are recognized as truly unique, as they make it possible to lighten the building structure...

- ISOBEL insulation technical characteristics and reviews from home owners ISOBEL insulation is a new productive material that is produced using innovative technologies using the latest foreign-made equipment. It is created on the basis of mountain basalt rocks. ISOBEL insulation,…

Liquid thermal insulation "Magniterm": reviews and characteristics

There are several types of Magniterm composition on the market. Liquid thermal insulation, reviews of which will be below, is produced for building facades, balconies, floors and basements.

Magniterm Nord deserves detailed consideration. This composition can be used from - 30 to + 80°C. The resins that make up the heat insulator create a thin layer on the surface that allows steam particles to pass through. Moisture does not pass through Magniterm Nord.

Before applying thermal insulation, you need to carefully prepare the surface, that is, clean it of loose areas, oil stains and metal chips. It is advisable to cover everything with a layer of acrylic primer for concrete.

It is worth keeping in mind that before use it is necessary to dilute Magniterm. Liquid thermal insulation, reviews of which are not always positive precisely because this stage of work was carried out incorrectly, is diluted only with high-quality non-toxic liquids. Otherwise, the smell may cause intoxication among residents.

Criterias of choice

When choosing thermal insulation paint, you need to take into account its characteristics and the types of intended work. Much depends on the object of application and its location, as well as the type of surface. It would be useful to study the most frequently offered manufacturers on the market and get acquainted with the opinions of buyers about their products.

For example, for work carried out outside, you need to pay special attention to water resistance and the ability of the mixture not to lose its properties in both cold and hot weather. For interior finishing work, paint that does not emit harmful substances is required.

For painting pipes, thermal materials with maximum heat resistance are used.

It is also necessary to calculate the most accurate amount of mixture that will be required for the job. First of all, it depends on the area on which you plan to apply thermal paint. The surface of the object plays an important role. Overruns when working with wood, concrete and brick can be up to 10 percent, and with metal products – up to 6 percent.

It is necessary to consider how thick the paint will be applied, as well as the number of layers. For different materials, manufacturers recommend using different layer thicknesses, for example, 1.5 millimeters of the mixture is enough for concrete, 2 millimeters for wood, but brick, metal, expanded clay concrete need to be covered with a layer of 2.5 millimeters.

Customer reviews about liquid thermal insulation "Astratek"

Liquid thermal insulation "Astratek", reviews of which will be presented below, is intended for thermal insulation of facades, concrete floors, gas pipelines, sewerage, roofing and metal structures. Work with it can be carried out in a wide temperature range from - 60 to + 250°C.

This is a fairly new material, so buyers do not yet have reliable information about its environmental safety. Manufacturers claim that Astratek does not harm human health. Some buyers doubt this.

Liquid thermal insulation “Astratek”, reviews of which speak of the ease of its application, provides 100% adhesion to the material. After distribution over the surface, it does not weigh down the structure, especially for metal elements.

"Astratek" is a liquid ceramic thermal insulation. Reviews about it left by customers contain information that the liquid also protects against corrosion, condensation and mold.

For information

Liquid thermal insulation Corundum is a mixture based on an acrylic binder and ceramic microspheres, which have thin walls and contain rarefied air inside. Acrylic binders are created using substances from the group of catalysts and fixatives.

Microspheres have sizes up to 0.5 mm. In addition, it contains various additives, so if Corundum is chosen, the facade will be processed very efficiently, since such additives enhance certain qualities of the product. The composition is completely balanced, so the material is elastic, light and stretchable. In addition, the Corundum coating has good adhesion.

The consistency of the substance resembles simple paint. This is a whitish suspension. The material not only has thermal insulation properties, but is also able to protect metal parts from corrosion.

In addition, Corundum is a thermal insulation that has many other advantages:

- Keeps warm well. It has been established that 1 mm of such paint is comparable in its ability to conserve heat with 5 cm of roll-type insulation (for example, mineral wool). The reviews are very good.

- It is easy to apply the substance to surfaces. The paint must be applied using conventional tools. You can use a spray gun, roller, or brush. The product does not emit harmful compounds, so respiratory protection is not required.

- If Corundum is chosen, the facade will be protected from various damages due to the influence of aggressive environmental factors. For example, metal will not rust. Wood does not dry out or rot. The brick, concrete layer and plaster do not crumble and cracks do not appear on them.

- If Corundum is applied, the facade will not be destroyed due to the influence of rodents, insects, bacteria and other pests. The surface does not rot. Mold does not form either.

- The insulating layer is lightweight. If Corundum is chosen, the facade will not have additional load, as if other insulation materials were used, for which it is necessary to install additional special retaining structures. Due to the light weight of the layer, Corundum can be applied even to fragile surfaces.

- There are no seams. Thanks to this, there will be no cold spots. The thermal insulation layer will be seamless, so the cold will definitely not be able to penetrate into the room.

- Durability. It is enough to apply the product only once, and you will not need to replace such a layer for a long time.

- The use of the material is also associated with its environmental friendliness. Over a long period of operation, such a layer does not emit harmful components. The product can even be used in homes where people who are prone to allergies live.

- Neither the area of the room nor its geometry is affected, which is taken into account when using bulky structures. Corundum will not affect the dimensions and shape of the building.

- Can be used as a finishing material. Special components from the group of pigments are added to this paint, so it is also used as a decorative coating.

Liquid thermal insulation “Armor”: reviews and recommendations for use

Among all brands of liquid thermal insulation, Bronya is the most popular. This is due to the availability of the material at cost and a wide range of products. At official dealers you can find varieties for processing facades, metal structures and other types of surfaces. Every buyer will find a suitable option.

Reviews from home owners about this type of thermal insulation are most often positive. Negative opinions about the coating usually arise because it was applied incorrectly by the builders.

Manufacturers recommend applying ultra-thin insulation with a soft natural bristle brush or airless sprayer. You should definitely check with the company’s regional representative about the preferred brand of the latter.

How good is Corundum as a heat insulator?

As practice shows, condensation on the surface and excess humidity really disappear. In addition, there is a very real chance to completely eliminate mold and rotting of walls, for example. However, if you do it in a good way, and not “for show,” then one layer will not be enough - it is better to apply at least three.

With this approach, the temperature in the room should rise by one and a half degrees. It turns out that some more significant, noticeable improvements can only appear when many layers are applied, but this is no longer practical from a purely financial perspective. At significant expense, it is already easier to make a facade from mineral wool.

This concludes the review of the insulation (or rather thermal insulator) “Corundum” and now, probably, it is easier to draw objective conclusions and make a decision to purchase it.

Recommendations for use and customer reviews of Akterm liquid thermal insulation

The scope of application of Akterm liquid thermal insulation is quite wide. It can be used for thermal protection of roofs, ceilings, floors, walls, foundations, pipelines, water storage tanks and many other needs. A separate type of material has been developed for each type of surface.

Akterm liquid thermal insulation, reviews of which can be found on many websites and forums, is easy to apply. Buyers say the coating works best when applied in several thin layers. Those who like to do their own repairs also note the almost complete absence of odor from the composition, which makes it easier to carry out work indoors.

Thus, liquid thermal insulation, reviews of different brands of which were presented in the article, can be used for various surfaces. When choosing it, you need to pay attention to the markings. Compositions for facade work are prohibited from being used indoors. For places with high humidity, you can choose specialized liquids.

Application instructions

Before you start applying Corundum paint, you need to choose the right material. You should not buy products from unverified sellers. The manufacturer is the Russian company Fullerene. In addition, there is a network of distributors. Be sure to pay attention to the condition of the paint. It should take the form of a suspension of paste-like consistency with a whitish tint. Traditional packaging is a plastic bucket. It can be of different volumes. The label must contain information about the manufacturer.

As for the cost of Corund paint, it differs depending on the type of material and the place where sales are made. For example, in Russia the cost of the Classic modification for 100 ml is approximately 34 rubles. Anticor coating can be purchased for 450 rubles per 1 liter. Corundum costs from 400 rubles per 1 liter, and Corundum Winter – from 550 rubles.

To apply thermal paint, you need to stock up on the appropriate painting tools. This can be a spray gun, roller or brush. It is best to apply paint using the first option, since it not only reduces the consumption of the substance, but also makes the coating better.

The thickness of one layer of paint should be approximately 0.4 mm. The next layers should be applied only after the previous layer has dried. If you use a brush or roller, the average product consumption is approximately 500 ml per 1 m².

Here is the algorithm of actions:

- Pour the liquid into a large container and stir well until it has a uniform consistency. To do this, you can use a special drill with a suitable tip. Experts advise setting the machine to medium speed so that the structure of the ceramic microspheres does not deteriorate during mixing.

- Clean the surface to which paint will then be applied. Pre-treat with degreasing compounds. To do this, you can use a special solvent. If the surface is metal, then the rust should be removed.

- Allow the surface to dry completely before applying paint. The first layer should be minimal in thickness, since it is a primer.

- When using a roller or spray gun, you need to carefully handle joints and other places where there is no access. You'll have to use a brush.

- It is recommended to do no more than 3 layers of paint for optimal results.

- It will take about a day to dry completely. If you paint warm pipes, the paint will dry even faster.

Thermal paint Corundum will look beautiful, so it can be used not only as thermal insulation, but also as a finishing coating.

Ceramic insulation technology

It is necessary to apply ultra-thin thermal insulation Corundum to a previously prepared surface, regardless of the modification of the composition. The basic rules that should be followed before starting paint insulation include the following:

- If ceramic insulation is intended for wall treatment, the working surface should be cleaned of dust and dirt, and existing gaps and chips should be expanded and filled with cement mortar.

- Before painting thermal insulation on concrete slabs, they should be cleaned of “cement laitance”.

- It is also necessary to treat the wall with an abrasive wheel, sandblasting machine or a stiff metal brush.

- If you plan to treat a metal surface, it must be dust-free and degreased (substances recommended by the manufacturer - Solv-Ur, Solvent). To paint objects made of non-ferrous metal, it is necessary to remove the gloss and apply primer VL-02 or VL-023.

- It is also worth considering that it is necessary to dilute ceramic thermal paint immediately before applying it to the wall.

It is also worth considering that in some modifications of the composition it is necessary to add water before starting work, so you need to carefully study the manufacturer’s instructions. The volume of liquid depends on the purpose of thermal insulation; in any case, the required proportions are indicated on the packaging of the composition.

The technique of applying ultra-thin thermal insulation Corundum is carried out in three ways:

- using air spray devices;

- airless spray method;

- manually - using a roller or brush.

The manufacturer recommends applying the composition in three layers, and the consumption should be 1 m/m2. When working on thermal insulation, this composition does not require additional ventilation in the room, nor the use of special personal protective equipment.

To guarantee the effectiveness of the result, it is important to strictly follow the manufacturer’s instructions and fully adhere to the recommendations indicated on the packaging

Date: September 25, 2022