City residents no longer consider their summer cottage only a source of garden produce, for which they spend the summer season growing there, but also an excellent place for a comfortable and, what is important, all-season recreation. Therefore, the question arises about what kind of insulation for walls inside a country house is best to use in order to ensure the desired temperature conditions during the cold season.

This problem is relevant, first of all, for those summer residents who initially built their houses only as temporary housing for the summer season, but owners of permanent buildings who did not take care of the thermal insulation of the building at one time are also interested in it. Of course, the best option is external insulation, but, unfortunately, its use is not always possible, for example, if the house is built of wood or labor-intensive and costly work on finishing the facade has already been completed.

In addition, external insulation is more expensive and is a more labor-intensive process. Therefore, in order to reduce heat loss, insulation inside the house is most often chosen for the dacha, which must be carried out in compliance with all standards for installing the material, as well as the correct choice of the latter.

There is a similar article on this topic - How to prepare a brick house for winter: insulation from the outside and from the inside.

Characteristics of thermal insulation materials for internal wall insulation

If you plan to insulate the walls inside the house , then you will first need to buy material for this, the choice of which should be approached very responsibly. The price criterion, of course, is always one of the main factors influencing the choice, but it should not be taken into account in the first place, especially taking into account the fact that thermal insulation work is carried out for a long term, ranging from 20 to 50, and sometimes more years .

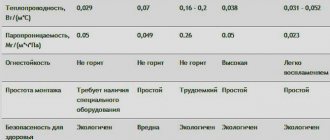

There are objective criteria, taking into account which you need to choose insulation, and among them are the following:

- thermal conductivity - the lower this indicator, the more effectively the thermal insulation material will resist the transfer of heat from the house in winter and the better it will keep cool in summer;

- environmental friendliness - this factor is important, since the dacha, although it is a place for temporary residence, is classified as a residential property;

- vapor permeability - this indicator determines the extent to which the insulation is capable of removing various vapors outside without accumulating them, as this is fraught with the appearance and spread of mold on the walls in the room;

- moisture resistance affects the durability of the material, since some, when saturated, lose their thermal insulation characteristics. For a country house with non-permanent residence, there is a danger of condensation forming, which can cause rapid destruction of the insulation;

- fire resistance and fire safety - the importance of this criterion is beyond doubt, but in some cases it is allowed to use materials that are potentially flammable, but have the ability to self-extinguish;

- soundproofing and noise-absorbing characteristics - in this case they are not decisive, but, for example, if the house is located near the road or if the neighbors happen to be music lovers, then this parameter takes on a different weight;

- resistance to maintaining the original shapes and sizes of the material is important from the point of view that when the material caking, bare areas may appear, which turn into cold bridges, which can reduce all insulation efforts to zero. When purchasing material, it is important to choose products designed for vertical thermal insulation;

- service life - the choice should be given to materials with a long service life, during which they retain all their performance characteristics. On average, the service life of good insulation is 20 years or more; for example, for mineral wool or expanded polystyrene it is close to 50 years.

When choosing a material, it is important to take into account that some of them may be attractive to rodents and insects, which can quickly destroy the entire thermal insulation layer.

Thermal insulating paint

Paint for insulating walls inside is a relatively new insulating material.

It is a special coating consisting of miniature ceramic and silicone balls filled with vacuum, as well as a latex-acrylic mixture that acts as a binder.

Thanks to the vacuum present inside the balls, heat-insulating paint applied to the inside of the walls acts like a thermos, retaining heat for a long time.

Thermal insulation paint has many undeniable advantages compared to other materials:

- possibility of use in the most difficult to reach places;

- Convenience and ease of application (using a spray gun, brush or roller);

- resistance to rotting and ignition;

- absence of harmful fumes;

- excellent adhesion to various types of surfaces - concrete, metal, plastic, etc.;

- Apply in a thin layer without weighing it down.

CAREFULLY!

Before using this coating thermal insulation, it is necessary to thoroughly degrease and dry the surface.

Thermal insulation paint

Basic criteria for choosing thermal insulation material

When choosing internal thermal insulation, it is necessary to take into account purely practical factors, namely the thickness of the material, weight, installation method and variability in the choice of finishes.

Thickness is of decisive importance if the area of the premises is small, since their use will lead to a noticeable reduction in the size of the room. For example, on each side of the perimeter it is necessary to sacrifice an average of 5 to 10 cm along with the finishing, which leads to a loss of up to 2 m2, and sometimes more usable area.

The large weight of the insulation creates an additional load on the supporting structures of the house, which will have to be especially taken into account if the work is carried out in a country house of the so-called “light construction”.

As a rule, it has a weak foundation, and the material for the walls is not particularly strong or thick.

The installation method also needs to be taken into account, since the installation of many insulation is carried out with the manufacture of lathing, the installation of which increases the budget for the upcoming work, and also leads to an increase in the thermal insulation layer.

This criterion is also related to the choice of decorative materials for finishing - preferably insulation materials that allow the use of a larger number of facing materials or, for example, that provide the possibility of wallpapering without special preliminary preparation.

How does the choice of insulation depend on the material of the walls of the house and the climatic region?

The effectiveness of using one or another type of insulation also depends on what material the house is built from: for wooden log houses, for example, the main criteria will be fire safety and vapor permeability. In addition, if you plan to carry out insulation work yourself, you need to take into account the complexity of its implementation, as well as the need to use specialized equipment.

It is also necessary to take into account the climatic region in which the house is built: for harsh conditions, preference should be given to materials with low thermal conductivity and high density.

In such cases, you can use the multi-layer technique. For example, for this, not one, but two layers of insulation are laid, while the top one is installed with the seams offset to prevent the appearance of cold bridges.

You can choose one type of material, but it is preferable to use two different ones. Despite the cumbersome design, with correct calculations and accuracy in choosing the thickness of materials, it is even possible to save internal space.

The most common, gross and invisible mistake in wall insulation. Video:

Foam glass

This is a durable insulation, the density of which ranges from 110 to 200 kg/m³. It is made by foaming molten glass. The insulation can also be used as sound insulation. The thermal conductivity of foam glass is – 0.04 – 0.08 W/m×°C. Foam glass is highly moisture resistant and almost unaffected by weather conditions. Foam glass is a completely environmentally friendly material that is not capable of releasing toxic substances into the air. This insulation has no restrictions on service life.

Some rules for carrying out thermal insulation work at the dacha

Of course, the price of the material also influences the choice of the type or brand of insulation, but, in addition, it should be taken into account that materials for its installation will also be required, the cost of which can significantly offset the economic benefit of purchasing a cheaper insulator.

Installation of thermal insulation material can be done in different ways, but insulating a house from the inside is best done using special adhesive compositions intended for this type of work, as well as fastening elements: dowels, including umbrella dowels, self-tapping screws and even nails.

But in some cases, this set will not be enough and it will be necessary to construct a sheathing, which not only serves as a basis for laying insulation, but also acts as a ventilation gap to allow condensate to evaporate. In such cases, the use of a vapor barrier film is also required, which simultaneously serves to protect the thermal insulation material from getting wet and to freely drain condensate.

Laying a diffuse vapor barrier film can be done both between the insulation and the outer layer of finishing, and additionally between the outer wall and the heat-insulating material.

The choice of method is determined by the material from which the walls of the house are built, as well as the type of insulation itself.

In some cases, protection from moisture is required not only for the latter, but also for the walls themselves, which may begin to collapse as a result of constant exposure to moisture. This factor is especially important when thermally insulating wooden houses and especially if the walls are insulated from the inside with penoplex - a material with low thermal conductivity, which allows the use of products of small thickness, but with almost zero vapor permeability, which in a particular case can be dangerous for a log house.

Prevention of problems associated with the formation of cold bridges

During work, it is important to correctly lay the thermal insulation material, without allowing even a millimeter of bare wall - neglecting this rule will lead to the formation of cold bridges through which heat will freely flow out and cold air in, and in addition, such places become areas where Condensation actively forms, and then mold appears.

The formation of cold bridges can also be caused by fastening elements, and this is especially noticeable in the example of wooden houses, for which the use of metal parts is undesirable.

If possible, it is recommended to use wooden elements that have the same thermal conductivity, and if it is necessary to use metal ones, insulate the latter, for example, with wooden or plastic parts, as well as with the use of thermal insulation materials.

Construction dew point

In contrast to the official understanding of this term, the construction dew point refers to the physical point of condensation of water. In fact, this is the meeting point of heated air from the room and cold air from the street. When thermal insulation is located on the outside of the wall, the construction dew point is located in the heat insulator, since the wall material is heated by the room and the warm air passing through the insulation encounters the cold there. In order to minimize the effects of moisture condensation, a ventilated gap is provided between the house and the insulator.

It is worth noting that in addition to the “dew point”, temperature bridges or “cold bridges” can also cause unpleasant consequences. They occur in places where there is no air gap between the external thermal insulation and the wall. The “dew point” in such places shifts deeper into the thickness, as a result of which local freezing or dampness is possible at the site of temperature bridges.

Insulation materials for thermal insulation of a cottage from the inside

To insulate a dacha, you can use various types of thermal insulation materials, differing in the composition of the raw materials used for their manufacture, technical characteristics, sizes and shapes.

Based on the type of raw materials used for production, thermal insulation materials are divided into products from:

- mineral wool;

- glass wool;

- ecowool, the raw material for which is cellulose;

- expanded polystyrene;

- polyurethane and penoizol.

At the same time, materials based on mineral wool, glass wool can be made in the form of slabs or rolls, ecowool is represented by slabs, as well as a scattering of compressed fibers, although this option is used less often for walls, as it requires special technology.

Expanded polystyrene insulation is presented in the form of foam boards and extruded polystyrene foam, and polyurethane-based insulation is a sprayed material, for the application of which special equipment is used.

How to attach penoplex to the wall? Video:

Foam plastic and penoplex

Both types of material are made from polystyrene foam, but there are some differences between them.

Polystyrene foam is 98% air, lightweight and environmentally friendly . Its main disadvantages are rapid flammability and fragility.

Penoplex is more dense, elastic and durable. It is not subject to rotting and is less flammable.

Foam plastic and penoplex

When should you use foil wall insulation?

To insulate a dacha from the inside, in some cases it becomes especially important to use thin materials, but with a high thermal insulation ability. One of these can be considered penofol, one side of which has a foil surface.

With equal thickness to other insulation, its efficiency is 50-80% higher, which makes it possible to use materials with a minimum thickness for thermal insulation, thus maintaining the size of the usable area in the room.

Such insulation with foil is made of foamed polyethylene with a reflective layer applied to it, which should “look” towards the room during installation.

Installation is not difficult and is carried out using glue and/or dowels, but it requires obligatory maintenance of the gap between the insulation and the layer of external finishing, as well as effective ventilation in the room.

The main obstacle to its use in dachas is the rather high price of the material and the need to perform additional work. But this material has undeniable advantages, among which we should highlight:

- moisture resistance;

- possibility of use in a wide temperature range, therefore, more often than for finishing residential premises, foil penofol is used in baths and saunas;

- high efficiency, including due to reflectivity;

- excellent heat, steam and waterproofing characteristics, thanks to which it is possible to create a stable microclimate in the room for which it is used as insulation, which, in turn, can significantly reduce heating costs.

Warm plaster

Insulating plaster, characterized by excellent thermal insulation properties and ease of use, is increasingly in demand. It is made from perlite and foam glass . The second option is more preferable for interior work.

It is based on unsorted foam glass granules, due to which this plaster has a number of positive features:

- excellent heat and steam conductivity;

- environmental friendliness;

- durability and strength;

- fire resistance;

- sanitizing properties.

Plaster

Advantages of insulation based on mineral wool

Thermal insulation materials obtained from basalt rocks are very diverse, but all of them are an almost ideal choice as insulation.

An important advantage is the large variety of types: the products are produced in the form of plates and rolls, and also the fact that they have a clearly defined functional purpose. This allows you to most accurately select a material for thermal insulation with the most suitable characteristics both in terms of thermal conductivity and thickness, weight and dimensions.

Among the main technical and operational characteristics it should be noted:

- environmental friendliness of the insulation, since natural raw materials are used for its production;

- strength;

- fire safety and high fire resistance, which even allows the material to be used as a fire cutter;

- caking resistance and elasticity;

- moisture resistance, but at the same time the material should not be saturated with water due to its high hygroscopicity - as a result, the thermal insulation properties are lost, which are restored after the insulation dries, but not always in full.

To thermally insulate a country house from the inside, it is better to use rolled wall insulation , which, with a small thickness, can be laid without sheathing; in all other cases, the manufacture of a base is required.

In most cases, installation involves installing a ventilation gap and using vapor-permeable films.

One of the disadvantages of using this insulation should be considered the high price, although, taking into account the service life of 50 years or more, this factor is not critical.

In the construction market, mineral wool insulation is represented by many brands, among which KNAUF, TECHNONICOL and ROCKWOOL have won particular trust from consumers and builders.

Polystyrene foam and polystyrene foam

Foam plastic is traditionally considered one of the most popular materials for insulation, and rightly so, since it has low thermal conductivity and low cost, but it also has important drawbacks that make its use in residential premises undesirable.

It is not strong enough, vapor-tight, and, most importantly, it is a flammable product with a high release of toxic substances.

For wooden houses it is the worst choice, but is quite acceptable for brick walls, although it is still better to use it for exterior decoration as a layer of “wet facade” and with an additional device of fire cutters made of mineral wool between the ceilings, near window and door openings .

But, taking into account the high thermal insulation characteristics of styrene materials, manufacturers for internal insulation offer another material of this group with fundamentally different performance characteristics - expanded polystyrene.

It has:

- low thermal conductivity;

- high density, due to which the effectiveness of the material at the same thickness as foam is doubled;

- sufficient strength;

- ability to maintain shape and size throughout its entire service life;

- moisture resistance.

Although this material is not fire-resistant, it has the ability to self-extinguish when ignited, which makes it relatively safe, but at the same time it becomes a source of toxic fumes. The disadvantage is vapor permeability, as well as poor adhesive ability, due to which fastening must be done using metal elements, which can cause the formation of cold bridges.

One of the popular brands of extruded polystyrene foam should be called “Penoplex”, represented by several series of products that have a clear functional purpose.

To insulate a dacha from the inside, you should buy material from the Penomplex C series (the letter C in the marking means “Wall”) or Penoplex Comfort, developed specifically for low-rise residential construction. An important advantage of these products is the treatment of products with fire retardants, due to which the insulation becomes resistant to fire.

Expanded polystyrene

Expanded polystyrene is a gas-filled material produced in the form of granular slabs.

It is often used for internal wall insulation, although, according to professionals, it is more preferable for external decoration.

The advantages of this material include durability, environmental friendliness, light weight, moisture resistance and high thermal insulation properties.

However, it is not without its drawbacks - in particular, such as the lack of fire resistance and the need to use additional fasteners (adhesives or dowels).

How to properly insulate a room with your own hands?

Having decided on the insulation and purchased all the necessary consumables and tools, you can begin the work itself.

Interior work should be carried out at an outdoor temperature of at least -20°C and low indoor air humidity. If no one can influence the first parameter, then changing the second is easy. You can turn on the heater, fireplace, or stove to dry the walls thoroughly. If there are only small damp areas, then they can be dried with a hair dryer at a temperature of 200°C.

After drying, you need to move on to cleaning. All garbage, dust, old plaster, wallpaper, paint, etc. must be removed.

For these purposes the following are used:

- spatula,

- hammer,

- pick,

- hammer drill,

- bowl with water.

As a result, the base should be clean and prepared for the next stage.

Particular attention should be paid to the wall if it has been affected by fungus or mold. Simply washing it off with water may work, but this is only at first glance.

The spores of these bacteria remain in the pores of the brick and after a while they will again “bloom” in lush color

Therefore, it is important to apply an antiseptic or bactericidal solution to the affected surface.

After the wall has completely dried, it needs to be primed. Some people believe that the purpose of the primer is to clean the surface, so they naively decide to replace it with ordinary water in order to save money.

But the purpose of the primer is not just to clean the surface from dust, but to fill all the small pores of the brick and ensure better adhesion of the subsequent material to the wall. Conclusion - water to clean dust, primer to increase adhesion.

The wall is primed once, or twice (if necessary), but then you must wait until the first layer has completely dried.

The surface is ready for installation of insulation

Polyurethane foam is sprayed onto the wall with a compressor, and mineral wool is placed in the gaps of the frame sheathing. Penofol is mounted on the wall using glue, and the seams between the strips are sealed with special tape.

After the insulation has dried, you can apply plaster to it or install drywall (on mineral wool).

Insulation and soundproofing of brick walls from the inside, video instructions:

Expanded clay

Expanded clay is a relatively cheap and yet effective insulation material that can be used to increase the thermal insulation of floors. Expanded clay is not flammable and does not emit harmful substances when used. Burnt expanded clay is a relatively moisture-resistant material. It has excellent soundproofing qualities. The recommended laying layer when forming an insulating cake is 25 cm. This is its only obvious drawback.