SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

During the construction of a house, you should consider such a facade, thanks to which the microclimate in the house will be improved, and the supporting frame will be well protected from external forces. If the building is built from easily freezing materials, then insulating the exterior of the house façade is a mandatory task that reduces heating costs, especially in winter. In summer, properly selected insulation will prevent strong heating of the air inside the home.

Insulation of the building facade from the outside helps normalize the microclimate inside the house

Calculation of insulation thickness

It is mistakenly believed that the thickness of the insulation is a constant value and is, for example, 100 mm; this is a misconception. From an engineering point of view, the thickness of the insulation layer is a calculated value and depends on the region of construction, the design of the building walls, the type of material, the number of cold days per year, and many other factors.

To determine the thickness, you need to perform a thermal calculation in accordance with the requirements of SP 50.13330.2012 “Thermal protection of buildings” . Competent engineering calculation of the thickness of the insulation will save money and at the same time achieve maximum insulation.

A set of measures to reduce heat loss:

- Installation of energy-saving ventilation;

- Roof insulation;

- Insulate the facade and slopes of openings;

- Installation of energy-saving windows and doors;

- Heated floor installation.

Use a thermal calculator to correctly calculate the thickness of the insulation.

Installation of sheathing

Lathing for external insulation is necessary when attaching siding as an external wall finish . With vertical siding, the sheathing is attached horizontally, and vice versa: with horizontal siding - vertically.

The sheathing can be made from wooden beams or their metal profile.

Lathing made of beams

Before you start lathing, you need to prepare the beams: treat them with an antifungal agent.

The following steps are followed:

- saw off the beam of the required size;

- secure the brackets around the entire perimeter with self-tapping screws according to preliminary markings;

- secure the timber as guides along the right and left sides of the wall;

- If there is no thermal insulation, then the beam must be attached to the wall by drilling holes for dowels and securing it with self-tapping screws.

Perform lathing along the entire wall; if necessary, level the surface, use special mounting wedges.

Lathing made of beams

Profile lathing

The metal profile should be secured using hangers and brackets.

Installation of metal sheathing:

- fix the profile on the right side of the wall and on the left so that there is at least 100 mm from the corner to the guide;

- According to the markings, drill holes for dowels and attach brackets along the entire wall;

- if thermal insulation is installed, then the insulation boards are pinned onto the brackets;

- lay a vapor barrier in the same way as insulation;

- install metal profiles along the edges of the wall;

- Use a thread to set the height of the profile and secure the profile along the entire wall;

- between the elements, fasten stiffening ribs from the remains of the profile.

NOTE!

It is better to choose metal profiles for siding with curved edges.

It is best to use a good quality aluminum profile.

Profile lathing

Dew point shift diagram

There are several options for placing insulation relative to the wall: inside, outside, between walls. The main thing to start from is the dew point. Let's look at all the options.

The dew point is the temperature at which water vapor in the air reaches saturation and begins to condense. The dew point at 100% air humidity and the actual air temperature are the same.

Based on current trends, insulating the exterior of a house’s facade is an excellent option for preserving heat. In this case, the dew point falls on the insulation, which means there will be dry walls inside. Otherwise, the outside of the wall will freeze, and the internal areas will become wet and moldy. This process is shown more clearly in the figure.

Safety precautions when working

When working with different types of mineral wool, the same safety rules are followed:

- Availability of protective clothing.

- Be sure to wear a respirator and goggles.

This is due to the fact that the fine-fiber structure of the material is easily destroyed, especially if the insulation needs to be trimmed. When microparticles enter the respiratory tract, they cause irritation (itching, coughing and even inflammatory processes) in the mucous membranes and skin. Therefore, they work with such thermal insulation very carefully.

Having become familiar with the advantages of mineral wool in different ways of installing it, we can say that it is in no way inferior to modern insulation materials.

Internal insulation

This method has a number of significant disadvantages. It should be resorted to only if it is not possible to implement an external method.

Flaws:

- Reducing the usable volume of the room.

- Cold bridges in places where interfloor ceilings adjoin (to eliminate them, treatment of floors and ceilings is required).

- Premature destruction of walls due to condensation of moisture in them and their freezing at negative outdoor temperatures.

- Additionally, the organization of good ventilation of the premises;

Advantages:

- – ability to carry out work in any weather

- – easy access to walls without the use of industrial climbers, construction scaffolding, or façade lifts.

In order to prevent the formation of mold and mildew on the inner surface of the walls, deterioration of the indoor microclimate, and also to avoid dampness in the house, it is necessary to use heat-insulating materials with a low vapor permeability coefficient:

expanded polystyrene with a density of 35 kg/m3 or more (the denser the better);

extruded polystyrene foam (ESSP);

polyurethane foam with closed cells.

It is unacceptable to insulate walls from the inside with mineral wool. This material has higher vapor permeability than concrete, brick, block walls, and also has a high water absorption value.

All this leads to the accumulation of mineral wool moisture and deterioration of its thermal insulation properties, the appearance of harmful microorganisms, dampness and unpleasant odor in the room, and premature destruction of thermal insulation.

Why do you need a counter-lattice?

Lathing and counter-lattice are concepts that are often confused. The lathing is necessary for attaching covering elements to it.

The counter-lattice is attached perpendicular to the sheathing and performs the function of ventilation and at the same time secures the water barrier.

Counter battens must be installed in the walls on the sheathing or on the rafters.

The walls of houses equipped with counter-lattice are called ventilated.

With a ventilated facade, the properties of the cake materials are preserved and the formation of moisture and mold is prevented.

Choosing insulation for house walls

Mineral wool

Mineral wool is an insulation material that consists of inorganic fibers of natural or synthetic origin. Stone (basalt) wool is used in ventilated facades.

Experts mainly use mineral wool slabs when constructing suspended ventilated facades, as well as for thermal insulation of multi-storey buildings using the “wet facade” technology due to the resistance of stone wool to mechanical stress and its non-flammability (flammability group NG according to GOST 30244-94).

Due to the high values of vapor permeability and moisture saturation, this material cannot be used in foundations, plinths, internal walls and other areas subject to regular exposure to moisture.

Expanded polystyrene

This is a new type of polystyrene foam containing styrene and its derivatives. Due to its relatively low price and high performance properties, expanded polystyrene (foam) is widely used in the construction of small-story facades. It is also often used for internal and inter-wall insulation of walls, and for the manufacture of external decorative elements.

Material flammability group G1 according to GOST 30244-94. When insulating a house with expanded polystyrene (foam) to ensure fire protection, installers must take a number of measures:

- along the outer perimeter of window and door openings, make edgings of non-combustible mineral wool slabs with a width of at least 150 mm;

- install fireproof cutouts made of non-combustible mineral wool slabs at the level of the upper slopes of openings along the entire length of the building façade, on each floor, but at least 4 m in height, with a width of at least 150 mm.

Expanded polystyrene is a fragile material. Due to low compressive and bending strength, it is not used in areas subject to mechanical stress. We also do not recommend using it on foundations or in basements. Despite the low moisture saturation rates, the material still has technological pores and is hygroscopic.

Extruded polystyrene foam

Extruded polystyrene foam (EPS), like polystyrene foam, is made from polystyrene, but using a completely different technology.

As a result, the technical characteristics of this material are significantly better compared to polystyrene foam:

- the moisture saturation rate is 10 times less (0.4% versus 4% when in water for 30 days);

- thermal conductivity is 15% less (0.031 W/(m*K) versus 0.036 W/(m*K);

- bending resistance and compressive strength are 5 times higher;

- vapor permeability is 3 times less (0.015 mg/(m*h*Pa) versus 0.05 mg/(m*h*Pa);

- practically does not shrink;

- the flammability class is the same (G1 according to GOST 30244-94).

Expanded polystyrene does not allow steam to pass through, so in suspended systems it is used only for insulating the basement floors of buildings. It is also used as insulation for the plaster facade of a house.

Polyurethane foam (PPU)

Polyurethane foam is a thermal insulation material that is applied by spraying.

Depending on the density, there are soft polyurethane foam (density 8-20 kg/m3) and hard polyurethane foam (density 45-60 kg/m3).

Soft polyurethane foam is elastic and has an open-cell structure. In terms of thermal conductivity, vapor permeability and moisture saturation, it is comparable to mineral wool. Due to its high cost, low mechanical resistance and high hygroscopicity, this material is practically not used in the construction industry.

Rigid polyurethane foam has a closed-cell structure and is currently the most advanced material. It should be chosen due to the following advantages:

- 0.020-0.028 W/(m*K) (this is the lowest value among similar materials);

- is a good waterproofing material due to its low hygroscopicity;

- good adhesion to concrete, metal, wood, plasterboard surfaces, brickwork;

- absence of seams, joints, cold bridges, cracks;

- speed of installation;

- easy to apply on surfaces of complex geometric shapes;

- term

Among the disadvantages of this option it should be noted:

- expensive application equipment;

- highly qualified operator is required;

- high cost (turnkey price for spraying a layer 50 mm thick starts from 1,100 rubles/m2).

Flammability group G1 according to GOST 30244-94.

Types of thermal insulation, their advantages and disadvantages

Among the many insulation materials, those that are most suitable in terms of their physical characteristics and heat-insulating properties predominate.

What is the best way to perform external insulation? The main types of wall insulation intended for external thermal insulation are:

- expanded polystyrene (good thermal insulator, resistant to deformation, waterproof, but poor vapor permeability, risk of damage by rodents, toxic when burned);

- penoplex (low water resistance, durability, resistance to temperature changes, but is vapor-tight, susceptible to rodents);

- polyurethane foam (durable, low thermal conductivity, durability, resistance to temperature changes, no seams during application, however, it can create pressure in the cracks of the building, susceptible to ultraviolet radiation, low fire safety during application);

- mineral wool (an excellent heat insulator, sound insulator, non-flammable, durable, but during installation it emits harmful formaldehyde);

- liquid thermal insulation (waterproofing, sound insulation, environmental friendliness, durability, no seams, not affected by mold, rodents, however, shrinks when applied, which can provoke peeling, recommended for combined insulation);

- glass wool (thermal insulation, sound insulation, not affected by mold, rodents, fire safety, moisture resistance, non-toxic, but due to the fragility of the fibers requires additional protection);

- fiberboard (thermal insulation, sound insulation, environmental friendliness, fire resistance, durability, but despite all the positive properties it is short-lived, not recommended for rooms with high humidity: baths, saunas);

- cork material (light, durable, non-flammable, environmentally friendly, heat insulator, sound insulator, but quite expensive). In addition, there are other materials, but they are less popular.

Choice of insulation

Insulation of external walls with mineral wool

| Name | Price |

| Thermal calculation | For free |

| Geodetic survey | 20 rub/m2 |

| Design work | 70 rub/m2 |

| Installation/dismantling of frame scaffolding | 120 rub/m2 |

| Marking walls for brackets | 50 rub/m2 |

| Installation of brackets | 150 rub/m2 |

| Attaching extension cords | 100 rub/m2 |

| Installation of the first layer of insulation | 200 rub/m2 |

| Installation of the second layer of insulation | 100 rub/m2 |

| Installation of guides | 200 rub/m2 |

| Fastening the facing layer | 600 rub/m2 |

| Construction of a subsystem for a parapet cover | 500 rub/m2 |

| Installation of parapet sill | 400 rub/m. |

| Installation of ebbs, slopes, drips | 350 rub/m. |

Comparison of insulating materials depending on operating conditions

All materials used for thermal insulation of buildings outside have their pros and cons. One of the important indicators is price, which is well reflected in Table 5.

However, parameters such as resistance to moisture, flammability and toxicity should also be taken into account (according to GOST standards 12.1.044-89).

Table 5. Comparison of performance of thermal insulating materials.

| Material type | Coefficient of thermal conductivity | Density (specific gravity) | Flammability | Toxicity | Price*, euro per cubic meter |

| Plant and animal fibers (flax, cotton, hemp, hemp, cellulose, sheep) | 0,035…0,04 | 15…40 (up to 70 for cellulose) | G4 | T3, T3 | 15…40, up to 250 for flax fiber mats |

| Wood, wood fiber, cork | 0,039…0,2 | 110…700 | G4 | T3, T3 | 100…150 and more |

| Fiberglass and mineral (stone) wool | 0,035…0,038 | 15…80 | NG, G1 | Non-toxic | 30…60 |

| Expanded polystyrene | 0,035 | 15…40 | G3, G4 | T3, T4 | 25…80 |

| Polyurethane foam (including polyurethane foam) | 0,03 | 25…35 | G3, G4 | T3, T4 | 220…350 |

| Styrofoam | 0,035…0,05 | 15…35 | G3, G4 | T3, T4 | 25…40 |

*Prices are given for the Moscow region as of January 2022 and are indicative

Thus, based on the above comparative characteristics, we can conclude: stone wool is optimal in terms of price/performance ratio, especially with a high fire threat and in a humid climate.

For those who care most about the ecology of their home, materials based on plant fibers are suitable, but they will require very high-quality waterproofing, are fire hazardous and are not very easy to install.

If the thickness of the insulation is critical, it is worth choosing polyurethane foam in the form of foam, but in this case the costs will be significant.

Turnkey ventilated facade

| Service | 50mm, rub/m2 | 100mm, rub/m2 |

| — Metal siding | 3000 | 3110 |

| — Porcelain tiles | 3330 | 3440 |

| — Fiber cement panels | 3460 | 3570 |

| — Metal cassettes | 3700 | 3810 |

| — Composite panels | 3805 | 3915 |

Full price list here.

Ecowool

Refers to liquid insulation. It is made from cellulose. The composition includes lignin, it gives the insulation stickiness when moistened. This is an environmentally friendly material, does not ignite for a long time, does not rot, and has excellent heat and sound insulation properties. Liquid insulation materials make it possible to form a monolithic surface without joints and insulate large areas in the shortest possible time. To “blow out” a house with ecowool, you need special equipment. Therefore, such material can become problematic for those who plan to insulate the facade with their own hands.

Insulation using “Wet facade” technology

| Name | 50mm, rub/m2 | 100mm | 150mm |

| Wet facade "turnkey" with the thickness of the thermal insulation layer | 2340 | 2560 | 2780 |

| Service | Price |

| Priming the wall surface | 75 RUR/m2 |

| Attaching insulation to an adhesive mixture | 125 RUR/m2 |

| Mechanical fastening of thermal insulation boards | 75 RUR/m2 |

| Reinforced layer arrangement | 300 rub/m2 |

| Application of quartz primer | 90 rub/m2 |

| Application of decorative plaster | 400 rub/m2 |

| Priming the decorative layer | 75 RUR/m2 |

| Painting the decorative layer | 150 rub/m2 |

| Insulation of slopes | 200 rub/m. |

| Slope reinforcement | 200 rub/m. |

| Finishing of slopes | 250 rub/m. |

| Installation of ebb and flow drips | 350 rub/m. |

Doweling

Move to top

After the glue has dried, the slabs are additionally secured with disc-shaped dowels. It is recommended to use dowels with a metal or fiberglass core. Disc-type dowels with a plastic rod do not always allow for reliable fastening. A metal nail must have a plastic head used as a thermal break. The cap (umbrella) of the dowel should be recessed into the insulation by 3-5 mm. The number of disc dowels is usually no more than 5-7 pieces per 1 square meter. Star arrangement (one dowel in the center, the rest closer to the edges).

The installation sites of the dowels are leveled with an adhesive composition, after which the facade is ready for the installation of the reinforcing layer.

Polyurethane foam

Refers to a type of plastic. Suitable for any surface, low vapor permeability. It fits tightly to any structure, due to this, tightness is created.

There is no fungus on it, it does not deform, and is resistant to any influences. Doesn't make noise. However, the procedure for applying such material will require certain equipment. This will make its price higher, which can also become a limiting factor when purchasing.

Mineral wool boards and windproof membrane

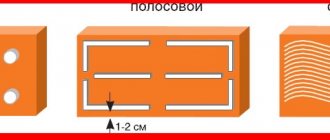

To insulate a house with a ventilated facade, it is recommended to use semi-rigid mineral wool slabs with a density of at least 60 - 80 kg/m3.

Less dense slabs or roll insulation on vertical surfaces may settle and shrink over time.

The thickness of thermal insulation for insulating the walls of a house is determined by calculation, based on the need to ensure the value of the heat transfer resistance of the wall is not less than the standard. For design reasons, it is recommended to make the total thickness of the insulation no more than 150-180 mm. (inner layer 100 mm.

plus outer - 50

mm

).

Mineral wool insulation is a highly breathable material. The air flow, which is constantly present in the ventilated gap and intensifies in the presence of wind, easily penetrates the insulation and carries away a certain amount of heat

.

In addition, the air flow captures and carries away particles of insulation, gradually eroding it and clogging everything around

mineral wool dust.

To protect the insulation from the wind, it is covered with a special windproof film - a membrane. The membrane must be made of a material with high vapor permeability

to allow water vapor to escape from the wall and insulation.

In addition, the membrane protects the insulation from moisture in the event that snow or raindrops penetrate through the gaps in the façade cladding from the outside.

The windproof film is attached to the sheathing bars using staples with a stapler so that it is adjacent to the insulation. A ventilated gap must remain between the film and the cladding. The joint of the film panels is placed with an overlap on the sheathing bar.

The lower the density of mineral wool products, the more sensitive they are to the effects of wind. Special mineral wool slabs with a hardened surface are produced that do not require protection from the wind.

. You can also abandon the windproof membrane if you use high-density mineral wool slabs, more than 80 kg/m3, for the outer layer. But such plates are more expensive.

Material requirements

The best materials for insulation should have a number of properties:

- Shrinkage should be minimal, and there should be no deformation of the insulation due to sunlight or temperature changes. It must be resistant to various influences;

- Long service life;

- It is better to choose one that will not be attractive to rodents and insects;

- It is better if it is easy to install and does not require the purchase of special tools. If you can do the installation yourself without special skills and preparation, this will be the best option;

- It should also not be flammable;

- Don't forget about environmental friendliness;

- It must be vapor-permeable so that the indoor microclimate remains at the same level;

- The lower the ability to conduct air, the better. The room will retain heat longer. It should be noted that real conditions often do not coincide with laboratory conditions, so when purchasing, leave a reserve and remember that these indicators are conditional; in real-life operation they may not coincide;

Look at the density. The higher it is, the heavier the material. And this can put a significant load on the foundation and supporting structures, especially if the layer is thick.