In some circumstances, you can use heat-insulating paint to insulate your home. It helps you save not only financially, but also spends less materials to complete the job. But there are nuances to using such solutions, which are better to learn about in advance. Then it’s easier to make the right decisions when choosing insulation like paint.

Liquid insulation: efficiency for all occasions

The Russian climate means that even in the southern regions it is not customary to abandon thermal insulation. Most often, preference is given to materials such as drywall, expanded polystyrene, and mineral wool. But each has limitations on its use in practice and features. Thermal insulation paint is one of the available alternatives. It not only protects from any temperature, but also helps save money.

These types of paints have the following properties:

- Preventing condensation;

- Prevention of corrosive deposits on metal;

- Mold is excluded;

- Coatings with increased fire resistance;

- Heat retention.

Heat conservation is especially important if autonomous heating is used. The compositions are safe for people, because they do not contain substances harmful to human health. It is not surprising that the popularity of the compositions is increasing every day. They extend the service life of any products and structures to which they are applied.

Fireproof heat-insulating paint for walls is used to protect against all kinds of negative environmental factors. They will not provide complete sound insulation, but they also differ in noise-absorbing characteristics.

Paints extend the service life of any products and structures to which they are applied.

Surface preparation

Before applying heat-insulating paint, the surface is cleaned, primed and dried. For larger volumes, a high-pressure airless sprayer is usually used. Other special devices for applying conventional paint can damage the microspheres - they will break on the surface, which will affect the thermal insulation properties of the material. In addition, insulating paint has a fairly thick consistency, which can make it difficult to spray. For small volumes, ordinary tools are suitable - a brush, spatula or roller.

Thermal insulating paint for walls: composition and scope of application

Thermal insulating paints include a dispersion of several components:

- Different types of additives;

- Liquid;

- Resins with acrylic.

Example of various additives:

- Fiberglass;

- Perlite;

- Glass balls with vacuum;

- Foam glass.

The material has the appearance of a thick mass, in a gray or white shade. Brushes and rollers are used when distributing compositions over small surfaces. For larger areas, spraying devices are suitable.

Conserving heat and maintaining the strength of the coating are the main goals for which all components are used. Heat-saving paint lasts up to 15-20 years if everything is done correctly from the very beginning.

The compositions are equally used for work inside and outside. This wall insulation paint can easily be used to cover different facades. For restoration coatings, mixtures also help achieve a certain effect.

Conserving heat and maintaining the strength of the coating are the main goals for which all components are used.

Another area of application is the decoration of walls inside residential premises. Here are just some examples:

- Basements;

- Boiler rooms;

- Reservoirs;

- Industrial equipment;

- Various types of pipes;

- Engineering communications, which will not be difficult to insulate.

The mixture goes well with different surfaces - brick, concrete, stone and metal. Application is in a thick layer of at least 4 mm. The load on the foundation increases, so it is important to pay attention to preliminary calculations. But the result of application is no worse than that of analogues. Sometimes thermal paints for walls are used in conjunction with other types of insulation.

The mixture goes well with different surfaces - brick, concrete, stone and metal.

Description of the composition, its components

The innovative material is designed to interact with a surface that releases heat and loses it completely. Insulating materials of the previous generation are aimed at retaining heat, eliminating cold bridges. Thermal insulating paint is endowed with heat-reflecting quality. This means that the heat remains, does not go away, and 70% of it comes back. A similar effect is created due to the vacuum environment inside the filler. Infrared waves in a vacuum environment increase speed by 1000 times. This leads to the fact that only 30% is lost, 70% comes back after being reflected. This operating principle of KM allows you to effectively insulate facades, walls, roofs, and other surfaces of housing construction.

Important: heat loss is reduced by up to 40%. Despite the fact that the coating repels water and moisture, the base does not stop breathing.

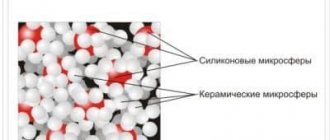

Thermal insulation paints consist of:

- water-acrylic mixture is the binding base. The component affects the uniform distribution of the coating and the adhesion of the insulation to the base;

- microscopic ceramic granules that are filled with gas - fillers. A high level of thermal insulation of the material is created thanks to them;

- silicone, rubber, other elements - additional components. They are responsible for the elasticity of the coating and its water resistance.

When the applied CM dries, vacuum voids occupy 75-80%. Material 2-4 mm is applied. This replaces the use of insulation in its traditional form. Visually, the composition is as thick as homemade sour cream. The base color of the paste composition is white or gray. It is recommended to spray it. Then the coating will lie evenly.

The protective layer of the innovative material will last 12-40 years. It tolerates temperatures from -70°C to +260°C.

Functional Features

Thermal insulation material is capable of performing the following functions:

- Environmental friendliness. They remain safe for others due to the absence of emissions containing harmful substances. Equally applicable inside and outside;

- Heat saving. Thanks to the use of paints, it is easy to save on heating and water supply;

- Strengthening. Thermal insulation paint helps to extend service life;

- Protection. This is especially true for cold weather. There is also no need to be afraid of corrosion, the appearance of fungus and mold.

Thanks to the use of paints, it is easy to save on heating and water supply.

Famous brands

You can purchase heat paint at any hardware store. Well-known brands on sale:

| Brand | Types of CM | Performance indicators | Area of use | Price |

| Korund, Russia | Classic | Container – can 3, 10 kg or 20 l. For indoor and outdoor work, tolerates -60°C to +250°C. | Cooling of contents in heating pipes, steam pipelines; reduction of heat loss – facades, external walls; heat preservation - walls inside the house, train stations, airports; mold protection – bathroom, ceiling | 10 l – 5,700 rub. |

| Anticorrosive | Even metal with rust is covered. Its traces are removed with a brush and can be painted. | 10 l – 6,500 rub. | ||

| Winter | You can work at -10°C. Insulation outdoors in winter is allowed. | 10 l – 6300 rub. | ||

| Facade | A minimum 1 mm layer with high vapor permeability and water resistance is applied to the facade. | 10 l – 6,000 rub. | ||

| Environmentally friendly Astratek, Russia | Station wagon | Quality is preserved after 5 freezing cycles. Density is regulated by water. Tolerates -60°C to +260°C. | For thermal insulation of walls on the street side inside housing construction. | 10 l – 107 dollars |

| Metal | KM's base color is grey. Permissible operating mode -60°C to +200°C. | Protection against metal corrosion; it covers the roof. | 10 l – 6,700 rub. | |

| Facade | The base color is white, can be tinted. Apply with a spatula or spray. The material is vapor permeable and water-repellent. | Heat loss insulation layer on the façade | 10 l – 7,050 rub. | |

| Liquid ceramic coating – KM Bronya | Classic | Prevention of corrosion, condensation, and UV rays from the sun. The coating increases the service life of the object. | Stopping heat loss on heating system and water supply pipes, chimneys. | 10 l – 4,200 rub. |

| Anticorrosive | A composition with anti-corrosion properties adheres to rust. | Heat insulation on the surface of the metal base. | 10 – 5,200 rub. | |

| Winter | Components: acrylic polymers and tiny foam glass granules, the layer is not afraid of frost. The material can be worked at -35°C. | 10 l – 3,900 rub. | ||

| Facade | A covering layer with a high vapor permeability value is applied at 1 mm. | The facade of the house is saved from microorganisms and fungus. | 10 l – 4,200 rub. |

Main advantages

Some of the positive properties have already been described earlier, but there are other features:

- A very thin layer of heat-protective paint on metal and other materials that does not change the dimensions;

- No requirements for skills and equipment, which simplifies application;

- Environmental friendliness;

- Surfaces free of mold and condensation;

- Fire resistance;

- Low weight. This property is especially important when used for facades of buildings and pipelines;

- Resistance to ultraviolet rays;

- Full protection from mechanical loads;

- Rust and corrosion certainly do not appear on metal surfaces;

- Long service life;

- Reliable heat retention.

High consumption and high cost become the only drawbacks for the materials, but in further operation everything pays off.

Rust and corrosion definitely do not appear on metal surfaces.

Types of liquid thermal insulation

Thermal conductivity is considered to be one of the most important factors for classification. But there are other criteria by which compounds are divided into types.

- With a water base. Such materials have no odors and do not emit harmful substances into the air. Heat-retaining paints, suitable for heating systems;

- With acrylates as a base. Also safe varieties. With additives in the form of ceramic granules in most cases. The versatility of the compositions is ensured by combination with any surfaces. This applies to both metal and mineral components.

Some highlight conventional insulating paints and foam varieties of compositions. An example of the latter option is polyurethane foam or polyurethane foam in liquid form. A separate classification exists according to the scope of application.

Thermal conductivity is considered to be one of the most important factors for classification.

Classification of thermal compositions

The classification of the dye is carried out in two directions.

Two types according to manufacturing method:

- water CM - covers the pipes of the heating system, does not contain toxins;

- Acrylic-based CM is universal and interacts with many materials.

Three types depending on the place of application:

- universal CM - walls inside rooms and on the street side, ceiling, floor are covered;

- energy-saving façade paint – the moisture resistance indicator is high and allows the material to be used for painting the surface outside;

- heat-insulating paint for pipes - protects water and gas pipelines, pipes of ventilation and air conditioning systems.

How to choose and use heat-insulating paint correctly

You need to take into account some parameters in advance in order to make the right decisions:

- Surface area and processing method. Material consumption increases when it is applied with a roller or brush. Spray guns and sprayers ensure uniform distribution over the surface. But such equipment is not necessary if the owner works with small areas;

- The purpose for which thermal insulation paint is applied. For example, which surface is subject to mandatory treatment - bricks and wood, metals or concrete. Depending on this, a variety with suitable properties is selected - fire resistance, prevention of corrosion processes with fire resistance, and so on. The composition must exclude toxic substances when working inside;

- Color. It is largely related to the purpose and scope of application.

Spray guns and sprayers ensure uniform distribution over the surface.

Manufacturers

In order not to make a mistake in choosing a high-quality thermal insulation coating, it is better to purchase products from well-known and trusted manufacturers. Among Russian manufacturers of thermal insulation paints, four leading ones can be identified:

One of the most popular manufacturers of thermal insulation mixtures is.

Liquid heat insulators from this company can be used to treat the following surfaces:

- metal containers;

- rooms with high humidity levels;

- boiler rooms;

- facade of buildings;

- surfaces inside residential and administrative buildings;

- chimneys;

- motor transport, passenger aircraft, railway cars;

- pipelines.

produces several types of paints and varnishes, depending on their scope of application. The following modifications of Korund products are produced:

- "Classic". A universal coloring composition that is suitable for external and internal work. Widely used in building construction.

- "Facade". This heat insulator is designed for treating concrete walls. Painting can be done both outside and inside the room. The material has a high level of waterproofness and heat permeability. The coating protects the walls from overheating in the warm season and from freezing in the cold season.

- "Lotus". It has the same qualities as the “Facade” modification. This material is intended for application to the surface in the form of a final layer.

- "Winter". A distinctive feature of this modification is that the dyeing procedure can be performed at sub-zero temperatures. You can work with such material at temperatures not lower than -10 degrees.

- "Anticor". Used for painting metal surfaces. This paint and varnish material protects the metal from atmospheric influences and prevents corrosion.

"Termalcom"

produces a line of heat-insulating paints "Astratek". The paint and varnish coating is made on the basis of polymers. offers products with high performance characteristics at reasonable prices.

Liquid thermal insulation "Astratek" is widely used in the construction, industry and housing and communal services sectors. There are six modifications of this company’s thermal paint:

- "Astratek Universal". Suitable for painting all types of surfaces. It has a high level of vapor permeability, which helps prevent the appearance and spread of mold on the surface.

- "Astratek Metal". Used for painting metal structures and devices that are operated in unfavorable conditions of high humidity. Such a coating will increase the service life of products made of ferrous and non-ferrous metals, prevent corrosion and eliminate the formation of condensation.

- "Astratek façade". It is used for thermal insulation of building facades.

- "Astratek NG". It is a special fire-resistant modification of the material.

- "Astratek Universal BC". An all-season coating that is temperature and weather resistant.

- "Astratek decor-acoustic" It is used as additional thermal insulation of walls, and also significantly improves the acoustics in the room.

GC VIRTs "Bronya"

The products are widely used in various fields of construction and industry. The manufacturer offers the best conditions on the thermal paint market in terms of price/quality ratio.

Thermal insulating ceramic paint "Bronya" was previously used mainly for painting gas networks and water supply systems. However, the company regularly expands its line of thermal insulators with new modifications.

Thermal paints are divided into three groups:

- basic modifications;

- budget modifications;

- special modifications.

"Akterm"

is one of the leading manufacturers of liquid thermal insulation. The company independently develops a unique manufacturing technology for its products. In the production of heat-retaining materials, only high-quality raw materials are used.

Liquid thermal insulation currently has fifteen different modifications, differing in composition and properties.

The main functions performed by Akterm thermal insulation coatings are as follows:

- preventing the formation of condensation;

- anti-corrosion protection;

- water protection;

- thermal insulation;

- fire protection

Recommendations for application:

- Before using ultra-thin insulation, it is necessary to prepare the surface to be treated: remove rust, clean from dust and grease, and prime if necessary. It is advisable to apply the paint and varnish composition at a humidity of no more than eighty percent and a temperature of at least seven degrees Celsius.

- When carrying out external painting work, it is better to choose calm weather. Due to wind, paint consumption can increase by up to five percent. The following tools can be used to apply the coloring composition:

- roller;

- spray gun;

- paint brush.

- It will be most convenient to apply the mixture using a spray gun. If the ultra-thin insulating mixture is too thick in consistency, it can be diluted with water. Also, do not forget about using a respirator to protect your respiratory organs.

Thermal insulation paints for interior work

The main properties here are stability and the absence of substances that can harm human health. The work usually involves mixtures with a water base. In the case of heating systems, acrylates are more relevant due to their ability to resist elevated temperatures.

The main properties here are stability and the absence of substances that can harm human health.

Insulating paints for exterior work

Here the emphasis is on the ability to withstand negative environmental factors such as high humidity and prolonged exposure to ultraviolet rays and temperature changes. It is easier to avoid the appearance of condensation with high vapor permeability. Manufacturers produce separate materials to perform outdoor work. Example - “Corundum Facade”.

Here the emphasis is on the ability to withstand negative environmental factors.

Thermal paint application methods

Foam compositions are least often used for finishing residential premises. After all, when applying them you cannot do without special equipment.

Conventional heat insulating paints are more often used for interior work. Working with them is not much different from using conventional compounds. Manual processing in this way leads to the formation of a 5-6 mm layer; brushes and rollers become indispensable tools. This layer is enough to fully protect the object, but the costs of the composition itself increase. It is better to use a spray bottle when you have it on hand.

The coloring rules are described as follows:

- Prepare the surface, ridding it of all contaminants.

- Wait for everything to dry after the initial treatment.

- The mixture is prepared to evenly distribute the granules over the surface.

- Applying the first layer with the base material.

Work continues until it is completely dry. After applying the 2nd layer, drying is also necessary. Typically, 5-6 layers are used, rarely raising the number to 10.

When using sprayers, it is important to maintain atmospheric pressure of a maximum of 6 atmospheres. The amount of material varies among different types of surfaces.

Typically, 5-6 layers are used, rarely raising the number to 10.

Additional recommendations

Thermal insulation paints are easily applied to surfaces with any geometric features. The work is easy to carry out and can be completed by any craftsman at home. In this way, you can also apply insulation to the walls.

Important Tips:

A paint brush is a suitable tool, but a spray bottle will be a more convenient and effective solution.

The main thing is that the layer is uniform when applied; preservation of warm weather is equally important. We separately monitor omissions, there should not be any

Otherwise, the use of expensive compounds loses all meaning.

The use of a respirator is advisable when performing interior work (indoors). Then small particles of ceramics will not get into the lungs. But such a protective measure will be relevant when carrying out any paintwork.

Paint for thermal insulation of walls: does it replace insulation?

Complete replacement of the entire volume with paint for insulating walls outside is unacceptable, but it helps reduce material costs. For example, the compositions are relevant where sudden temperature changes occur. This property is relevant in corner rooms with the formation of condensation. Thermal paint saves heat by 20%.

Complete replacement of the entire volume with paint for insulating walls outside is unacceptable, but it helps reduce material costs.

Efficiency assessment from experts

We can cite as an example some calculations by masters who have already become familiar with this material to some extent.

- When using warm paint, the cost of 1 m2 with a thickness of 1 mm is 100 times more;

- 300 rubles will be the cost of extruded polystyrene foam 50 millimeters;

- Let's take a millimeter thickness with a 6-ruble cost;

- The total cost compared to the same amount of paint is 400 rubles per square meter. The paint loses here, this is a common story. The deception here is definitely not visible, but the facts are obvious.

But other experts say that in terms of heat-saving characteristics, polystyrene foam is at least 50 times worse than paints. Due to the rough surface after paint treatment, an increase in the surface reflectance is ensured.

But the opinions of many are similar in that there are no alternatives to heat-saving paints when it comes to hard-to-reach places. Heating only benefits in this case.

Due to the rough surface after paint treatment, an increase in the surface reflectance is ensured.

Basic tips for choosing paint

The ratio between price and quality is the main factor when purchasing such materials. For example, foreign compounds are easily replaced by domestic ones. This does not reduce the level of energy savings and quality, but the costs are much lower.

There are other factors worth considering:

- What type of surface are the compounds applied to?

- Thermal paint is applied inside or outside;

- Loading of materials by function.

The ratio between price and quality is the main factor when purchasing such materials.

Calculation of the amount of thermal insulation paint

When planning material costs, the following parameters are taken into account:

- Method of application;

- What type of surface is it?

- How thick are the layers;

- Roughness index;

- The application area that needs to be thermally insulated.

The embossed surface will increase consumption. The numbers also depend on the base itself - whether it is brick or metal.

The embossed surface will increase consumption.

The use of thermal insulation materials under any conditions gives good results. But such modern solutions do not always completely replace traditional analogues. Compliance with the instructions for use is mandatory for paints. Otherwise, the coating will not give the desired result.

Fighting condensation with heat paint

Liquid thermal insulation allows you to avoid the manufacture of complex structures necessary for attaching a thermal insulation layer near the roofs of hangars and residential buildings. Painting pipelines of engineering systems is much cheaper than protecting pipelines with polystyrene foam shells, winding with basalt wool, and then waterproofing the insulation.

Condensation control is available to a home craftsman with minimal painting skills. Liquid thermal insulation is sold in convenient buckets and jars, is completely ready for use, and has instructions for use. The weight of the roof practically does not increase when applying a millimeter layer, while the comfort of using the premises increases many times over.