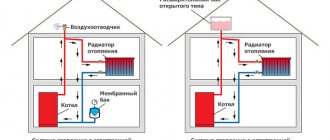

For heating networks in private houses and apartments, it is advisable to use boilers with closed coolant circulation, i.e. double-circuit. This design allows you to increase the pressure of the working fluid in the circuit.

High pressure in the heating system ensures safety and a higher boiling point of the coolant, therefore, the economic effect of the installation increases, and a decrease in pressure leads to problems in the system. Therefore, let’s look at why the pressure in the heating system of a double-circuit boiler drops and how to raise it.

The parameters of the boiler unit are monitored by measuring instruments - pressure gauges, main and additional. If a pressure gauge should be included in instrumentation and control measures, then choose models with electronic sensors.

Factors that affect the pressure inside the circuit:

- The impact of the coolant on the walls of the heating network elements;

- Height of laying pipes, hanging radiators and boiler unit;

- Design of main pipeline sections.

The pressure value for autonomous heating is not standardized. Acceptable values of network parameters are calculated based on the data of a specific object:

- Boiler type, pipe characteristics (diameter, presence of reinforcement, etc.), type and number of radiators;

- Equipment installation location, circuit length;

- Number of floors of the house;

- Parameters and condition of the external water pipeline.

Reasons for pressure drop in the circuit:

- Presence of leaks in the pipeline;

- Malfunction of the boiler, cracks on the surface of the heat exchanger;

- Malfunction of the membrane valve responsible for the safety of boiler equipment;

- Failure of the expansion tank membrane;

- Depressurization of the hot water supply circuit.

Why does pressure increase in a double-circuit gas boiler?

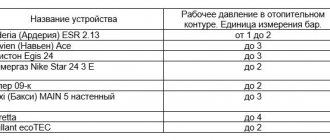

Let's consider the reasons why the pressure in a double-circuit boiler can constantly increase (or rather, increase until the pressure relief valve in the boiler operates). Considering that the operating principle of most boilers is similar, this malfunction can manifest itself in various models: Baxi, Ariston, Buderus, etc.

When the pressure in a double-circuit gas boiler drops, this is somehow understandable, but when the pressure itself increases! However, this is exactly what I once had to face - having bought a renovated apartment, signed a sales contract and received the keys, I did not spend the night in it and in the morning I discovered puddles of water on the floor and a damaged cabinet for a gas boiler.

The pressure in the heating system in a wall-mounted boiler increases

The presence of a stable operating pressure in the heating system (1 - 2 bar) is the key to the safe operation of a double-circuit gas boiler. The boiler will not start if the system pressure is less than 0.6 bar; if more than 3 bar, an emergency water discharge occurs.

- There are two reasons why the pressure in a double-circuit gas boiler can gradually but constantly increase:

- does not hold the make-up valve (most likely);

- The secondary heat exchanger is faulty.

This usually happens like this: the pressure slowly increases (sometimes you may not notice this and leave for a few days) until the safety valve is activated (usually at 3 bar). And so several times, in a cycle. As a result, the floor in the kitchen is flooded, the furniture and mood are ruined.

The heating system is autonomous (not connected to the water supply). This is essentially a closed circuit that can be heated by a gas burner. But to fill this heating circuit with water, there is a make-up tap, and if it leaks, then water from the water supply will leak into the heating system (increasing the pressure there).

Well, the second (unlikely) option is that in the secondary heat exchanger the water supply and heating pipes are located side by side, literally through a thin wall. And if a fistula has formed there, then there may be leakage from the water supply system into the heating system (until the pressure is equalized). And if the pressure in the cold water supply is more than 3 bar, the same pressure will eventually be in the heating system. Which will trigger the emergency valve (and release some of the water).

How to fill the heating system of a double-circuit boiler

The heating system of a double-circuit gas boiler is filled through a make-up tap, which is included in the basic configuration of any boiler:

How to pump up a boiler expansion tank

Diagram of boiler taps Ariston Class 24

A Fitting for draining water into the central heating circuit (CH)

B Connection for draining water into the hot water supply circuit (DHW)

C Connection for gas supply

D Connection for cold water supply

E Connection for supplying water from the central heating circuit

S Safety valve outlet

T Drain tap

F Filling tap

How to properly pump air into the expansion tank

We follow the specified order

- Turn off the boiler from the network.

- We turn off all the taps to the boiler, supply, return, and cold water input.

- Open the drain fitting in the boiler. (T - in the diagram) and completely drain the water. (Here is an article about how to drain water from the boiler) The pressure in the boiler should be zero!

- We connect the pump with a pressure gauge to the RB through the spool - the drain fitting is open.

- The pump needs to pump air into the tank until water stops flowing from the drain fitting. At this stage, the main goal is to empty the tank of water.

- We release the pumped air by monitoring the pressure with a pump pressure gauge, and if necessary, pump it up. The pressure in the expander should be within 1.1-1.3 bar. (See the passport for your boiler - often indicated)

- Close the drain plug.

- We open all the taps to the boiler - everything that was closed.

- We feed the boiler through the make-up tap (F) to a pressure of approximately 1.2-1.5 bar

- Let's start the boiler.

To pump air into the expansion tank, you can use any pump and pressure gauge. There is a car nipple there. I used an auto compressor. True, for this I had to drag the battery home. With an electric compressor, be careful to turn it off in time and not over-pump.

Before starting the boiler, it will not be superfluous to expel any air that has entered the system.

In Ariston class 24, to do this, press and hold for about 5 seconds. ESK button. The boiler will go into purge mode for 6 minutes, exit this mode on its own, or you can force it by pressing ESK again.

The pressure in the double-circuit boiler drops

This is a fairly common problem - it manifests itself in the fact that the pressure in the heating system slowly decreases and when it drops below normal, some boiler models turn off.

Most often, the cause is a simple water leak from pipes or leaky radiators. It is not easy to detect such a leak during the heating season - you will not see a puddle on the floor (well, of course, unless it is a serious leak). Most often, these will be just droplets and you will not see these droplets, since they quickly evaporate from heated pipes.

How and where to look for a leak - you need to pay attention to radiator plugs, joints or soldering of pipes and fittings. You can often see traces of water leaks in the form of rusty or salt stains. It will be easier to detect various types of leaks if you turn off the heating for a while, let the radiators cool and add pressure to about 2.5 Bar. After this, you will be able to see drops or puddles on the floor.

The boiler can also be the cause of the leak. For example, the primary heat exchanger itself or its connections are leaking. But as long as these are small droplets, you will not notice anything; they evaporate during operation of the boiler. As soon as it starts to leak more actively, you will notice “drops” from the boiler.

Pressure drops in a double-circuit boiler when hot water is turned on

When you open a hot water tap, the pressure in the heating system drops (by about 0.3 atmospheres). The tap is closed and the pressure is restored.

Types of pressure

Why does the pressure drop in a wall-mounted unit? First, let’s figure out what types there are and how they affect the operation of the equipment.

- Static. The higher the height, the higher the performance. With every meter there is an increase of 0.1 bar.

- Dynamic. Forced operation of the pump creates the rated pressure in a closed system.

- Working. Includes the two options above.

- Excessive. Determined by a pressure gauge as the difference between atmospheric and fixed.

- Nominal. The one indicated by the manufacturer in the documentation for a specific model.

- Maximum. The maximum that is allowed to avoid breakdowns and accidents.

- Crimping. Used in production when testing equipment.

In the heating circuit, indicators are measured in atmospheres. They may vary; It is important that the value does not exceed the permissible maximum and minimum thresholds. A low value is only possible when coolant is pumped into the circuit. In other cases, it should not deviate from the norm.

Why does the pressure in the boiler keep rising and falling?

An expansion tank is a sealed container divided in half by a membrane, one half of the tank is filled with inert gas (or just air), the other is filled with coolant (water). It is designed to compensate for the pressure created during the expansion of the heated coolant. Water expands when heated, and if it has nowhere to expand, it will burst heating radiators or pipes (since liquids are practically incompressible).

The expansion tank must be filled with air at a pressure of approximately 1.5 bar (see the instructions for the specific boiler for the exact figure). Air is pumped there through a spool (like in a car or bicycle), and if it leaks, the pressure will drop over time. To check, moisten the spool nipple head with a drop of water; if bubbles appear, the unit is faulty and requires replacement.

To check the tightness of the expansion tank membrane, open the feed tap. If the pressure rises at the moment, this is the first sign of lack of compensation. The membrane allows water to pass through, the air cavity behind the membrane is filled with water and does not compensate for the pressure. To check, you can press on the nipple of the spool valve, through which air is pumped into the expansion tank - water will flow out of it.

The pressure in a closed heating system can also change due to a large amount of air not removed from the system. And although modern boilers are equipped with automatic air vents, they may not work over time due to scale build-up.

Source

Actions in case of pressure loss

Low water pressure in a gas boiler or its drop to a minimum means that there are serious complications in the boiler and in the network. If the pressure gauge shows a reading below 1 atm, you need to add water manually. To do this, the make-up valve opens. If after this the gas boiler does not hold pressure, then you should call a specialist.

Another way to increase the water pressure in a gas boiler is to inspect all networks for water leaks. It happens that during initial startups and increased pressure, the butt sections of pipes crack. This is where leaks occur. As a result, the pressure gradually drops. Leaks must be repaired promptly.

You also need to pay attention to the expansion tank: diagnose and check it. This work is carried out by a specialist.

Boiler recharge: automatic and manual

During operation of the heating boiler, the volume of internal coolant that circulates from the source to the heating devices and back decreases, reducing the pressure in the network and the quality of heat transfer.

If such a circuit is not replenished with network water, then the pressure level will gradually drop to 0 atm, which will cause an emergency stop of the boiler unit. Therefore, according to the requirements of the rules for the safe operation of gas and solid fuel units, boilers must be recharged.

For this purpose, a special unit is used, the responsibility for the presence of which rests with the manufacturers of the units. Therefore, for all certified devices, for example, an Ariston boiler feed tap is included in the basic delivery kit.

Briefly about the main thing

Normal pressure in the heating system contributes to comfortable living. Ensuring that the pressure gauge needle shows the normal pressure value in the gas boiler is the responsibility of every owner of a house with a heating boiler.

Of course, how much pressure should be in a gas boiler is different for specific systems, since the type of system, equipment features, number of floors of the room - all this affects the value of the normal operating pressure in the heating design.

Signs that there is not enough water in the heating system

Operating personnel or the owner of the boiler unit must accurately determine the deficiency of coolant in its circuit. First of all, using a pressure gauge, since the pressure of the medium in the network will drop if there is a leak.

In modern autonomous systems equipped with multifunctional automation, water leakage from the heating network is included in the mandatory indicator for boiler protection, therefore, if it falls, the personnel will be warned by alarms: audio and visual.

For older modifications of the boiler, a drop in coolant pressure due to unproductive leaks is determined by the following criteria:

- overheating of the supply coolant, despite the fact that the radiators quickly cool down due to disruption of water circulation in them;

- the water in the network begins to gurgle, especially in heating risers;

- the boiler clocking process begins, when the burner of the gas unit is often turned on/off;

- activation of the safety valve of a solid fuel boiler due to overheating of the coolant.

The situation with leaks is especially dangerous in solid fuel boilers, since due to the high inertia of the combustion process, the boiler cannot stop until all the stored fuel has burned out, which means there is a high possibility of overheating of pipes or heat exchangers located in the firebox, with their subsequent rupture and leakage open fire source in the furnace room.

Reasons for deviation from the norm

The need for heating occurs throughout the entire cold period of the year, which means 6 months of continuous heat supply (for mid-latitudes). During such a period of time, the system must uninterruptedly produce the required thermal power, and the pressure in the line must have a constant value. In practice it doesn't always happen this way. The influence of external and other factors causes interruptions in the operation of heating equipment. Let's consider the reasons that affect the parameters of autonomous systems.

Why do pressure readings drop?

The first and main reason for a decrease in the operating parameter is a coolant leak at the junctions of pipelines with heating equipment. To temporarily eliminate this deficiency, use a boost valve. If not, refill the line with coolant as the pressure drops, from the water supply network or well. Such measures will temporarily normalize the pressure force.

To completely eliminate the deficiency, you must:

- detect a leak;

- turn off the heat source;

- drain the coolant in the main section, having previously shut off the flow of water;

- repair the required unit;

- pump water, turn on the boiler.

IMPORTANT! If it is not possible to drain the coolant in a separate area, in autonomous systems the line is emptied, and after the malfunction is eliminated, it is refilled!

Leak detection is possible if there is a wet spot or droplets on the pipe connections. In cases where it is not possible to see a leak, first increase the pressure to 3 atmospheres and turn on the circulation pump. If this does not help, then drain the water and pump in air. The location of the air leak is determined by sound, and verified using soapy water, which will indicate the exact location of the defect.

The reason for the decrease in pressure may be wear and tear of heating equipment, the appearance of scale in the heat exchanger and system pipes. Another little-known reason for a decrease in operating parameters is a decrease in temperature. When an unheated house cools down in the cold season, and the coolant cools accordingly, the parameter value drops by 0.5 atm or more. In such a situation, maintain the lower limit of the value at 0.9-1.0 atm and prevent the coolant from freezing during periodic heating operation.

Why does blood pressure increase sharply?

A malfunction of the automation system that ensures automatic filling of the main line is often the reason for a rapid change in parameters. In addition, slowing down the circulation of coolant through the pipes leads to overheating, and accordingly to an increase in pressure. The reason may be air locks, as well as the presence of dirt in the filter or other system components.

To identify the reasons for the growth of the controlled parameter, all emerging factors are compared, and then conclusions are drawn. A simple method of eliminating a sudden increase in pressure is to bleed off excess coolant, forcefully turn on the pump, then pump up water, if necessary, to the set value. Repeating the procedure with a smaller amplitude of jumps and gradual leveling of the controlled parameter indicates the elimination of the air lock.

The inability to eliminate the cause using this method indicates the presence of “impenetrable” dirt that interferes with the normal operation of the boiler. To eliminate this reason, first clean the filter, and if that doesn’t help, clean the heat exchanger. Cleaning methods are used both mechanical and hydraulic. It is important not to damage the internal cavity and connecting pipes.

REFERENCE! When operating solid fuel boilers, especially during ignition, the pressure surge can change the value by 1-1.2 atm! It is important to compare the change in the controlled parameter with the increase in temperature. The direct dependence of the compared values indicates the need to slow down the ignition of the unit.

How does the make-up valve work?

The valve is installed in order to maintain operating pressure in the internal circuit of the heating network by adding water from the city water supply. The standard pressure for the heating network depends on the number of floors of the building and internal pressure losses in the network; usually, a pressure of 2 to 2.5 atm is sufficient.

A pressure reducing valve is used as an automatic filing device. At the same time, if the water pressure drops, the pressure on the valve stops, the spring acts on the rod, moving it lower, and thus opens the hole in the seat. Through it, water from the city water supply or tank enters the network. As the system fills, the pressure will increase and close the membrane and hole.

The pressure reduction valve is especially often triggered in systems with an automatic air vent, which removes air from the network. In order to protect the system from the reverse movement of the medium through the reducer, a check valve is installed into the municipal water supply.

Which faucet to choose

The gas boiler feed tap is installed on almost all modifications of both domestic and foreign boilers: boiler feed tap Ariston, Baxi, Immergas, Ferroli and Vaillant. Usually the user is forced to replace such a faucet if the factory model malfunctions. In this case, it is best to install one similar to the one that was supplied with the boiler. When choosing another model, you need to pay attention to the dimensions, operating pressure and water flow.

Popular gas boiler feed taps:

- Ariston electromagnetic boiler feed tap, price: 1,780 rubles;

- Baxi Main boiler feed tap, price: RUB 1,590;

- boiler feed tap Bosch ZW23-1KE/AE, price: 1090 rub.;

- boiler feed tap Daewoo Gasboiler 100-300 ICH, price: 1820 rub.;

- make-up tap for boiler Vaillant Max, Pro, Plus, price: 590 rub.;

- make-up tap Immergas Mini 1.015093, price: 320 rub.;

- feed tap for Ferroli Divatech, Divatop double-circuit gas boiler, price: 800 rub.;

- make-up tap Protherm Panther v18, price: 560 rub.

Elements of the make-up device

The recharge scheme for heating networks will depend on the hourly productivity of the standard recharge. For large main heating networks, in which the standard recharge is hundreds and sometimes thousands of cubic meters of water per hour, the complex includes: a water tank, chemical water treatment, automation, electric pump and shut-off and control valves. When performance decreases, the number of circuit elements can be significantly changed.

Boiler gearbox

The reducer is installed on the return pipeline in front of the boiler to supply make-up water to the network circuit. Water from the city water supply flows through the valve when the pressure in the network pipeline drops due to leaks or release of an air lock. If the diagram provides for the installation of a circulation pump, then it is installed second. Otherwise, the operation of the entire heating system may be disrupted.

Manual recharge scheme

The easiest way to replenish the heating circuit with water is to refill it manually. In order to fulfill it, it is necessary to stretch a pipeline from the city water supply and connect it to the return line of the heating network. A shut-off valve and a water purification filter are installed in this area.

The scheme functions perfectly in simple heat supply systems for one-story small-area households. The line is connected to the return line before the circulation electric pump, since this section has the lowest pressure and temperature of the network water.

For open heating networks, the make-up system organizes the supply of water not to the return, but directly to the expansion tank. To do this, you do not need to go into the attic to check the recharge level. According to the diagram, the expansion tank is connected with 3 independent terminals: make-up, supply and return pipelines.

The level in the tank is controlled by opening the valve on the control pipe directed to the sewer. When water flows after opening the valve, this means that the system is full; if not, the make-up valve opens, which is kept open until there is overflow from the control pipe.