When arranging their own home, many homeowners are faced with the problem of choosing radiators for heating structures. A fairly good option are steel radiators whose technical characteristics are impressive.

Information regarding the technical characteristics of heating devices, and more specifically:

- working and testing pressure;

- coolant temperature;

- other parameters that influence the efficiency of a particular model.

This information is completely understandable for every consumer. This article talks about the technical characteristics of steel heating radiators.

Heating batteries made of steel come in two types:

Panel type steel radiators

The peculiarity of such devices as steel panel heating radiators is that they combine the properties of a convector and a battery. They are usually produced in the form of rectangular panels of different thicknesses and dimensions. In the photo you can see what they look like.

The design of steel heating panel radiators is simple:

- the base of the device is a panel consisting of two profiled steel plates, which are connected along the perimeter with a weld. Inside, vertically located oblong channels are formed from steel using the stamping method. Hot coolant circulates through them during the heating process;

- U-shaped ribs are welded to the panels on the back side, resulting in more efficient heat transfer. This element for convective heating of a room is made from cold-rolled steel, only thinner;

- the design of one device can consist of the three panels described above. In the case of connecting several panels into a single system, manufacturers cover them using side covers;

- A steel panel heating radiator can have a variety of dimensions. Most models presented on the domestic market have heights from 300 to 900 millimeters and widths from 400 to 3000 millimeters. The depth of the panel device depends on the number of steel panels and can reach 170 millimeters.

According to connection options, panel radiators are:

- with side connection;

- with bottom connection;

- with universal connection.

In terms of cost, the most expensive models are those with a lower connection option, since they often have a thermostat built into them. If the device does not have a built-in thermostat, it is connected using a special thermostatic valve.

Panel steel radiators have technical characteristics depending on the model:

- operating pressure in the range of 6 - 8.5 atmospheres;

- crimping pressure does not exceed 13 atmospheres;

- The maximum temperature of the coolant is no more than 110 – 120 °C.

The fact that the testing pressure is low is the reason why experts in the field of heating engineering do not recommend installing steel panel radiators in multi-storey buildings.

Of steel

This category includes heat devices with high efficiency and a working pressure of 9 atm, withstanding 13 atm. crimping. Such batteries are in demand in individual construction, or if multi-storey buildings have their own heating unit.

Radiators are made of steel sheets with stamped recesses for coolant. Protruding fins are welded on the back side to increase thermal output: they enhance the conventional air flow. Heating devices are made of low-carbon steel with high anti-corrosion properties. Coating – powder enamel.

They are divided into two categories: panel and tubular. Panel ones represent a continuous heat-conducting surface, tubular ones consist of sections in the form of vertical pipes and can be different in design, as a result of which their cost is slightly higher.

Tubular steel heating radiators

The design of tubular radiators can be very attractive; they are often made in the form of interior items, as in the photo. They have the following parameters: height 190 – 3000 millimeters, depth – no more than 225 millimeters, length has no limit.

Experts recommend: if tubular steel heating radiators are installed under a window, make sure that their length is at least 75% of the width of the window opening.

These devices have the following parameters:

- working pressure not higher than 12 atmospheres;

- crimping pressure up to 25 atmospheres;

- maximum coolant temperature 120 °C.

Since tubular devices can withstand strong water hammer, they are considered an ideal solution for installation in apartments of multi-story buildings.

Cast iron sectional radiators

The first development of cast iron batteries was carried out almost 150 years ago by our compatriot.

A few years later, the Americans received the patent and finalized the design. Radiators gained popularity after the advent of the central heating system, and their mass production began during the Industrial Revolution. The batteries that were used in the USSR and now remain in many homes are branded MC 140. The value “140” is the power supplied by one section. The operating and test pressure of the battery is 9 and 18 atmospheres, respectively. Number of sections – from 4 to 10.

Today, cast iron radiators are again gaining popularity, thanks to improvements in their design and design.

The advantages and disadvantages of batteries of this type are approximately the same.

- Long service life (more than 50 years);

- Affordable price;

- Resistance to mechanical damage;

- Corrosion resistance;

- High abrasive wear. Pebbles and sand in water do not cause much damage to the battery from the inside;

- Heating efficiency with the maximum number of sections.

- Heavy weight and bulkiness;

- Possibility of depressurization of joints;

- Accumulation of rust inside during long-term use;

- Unpresentable appearance;

- Difficulty in integrating radiators into autonomous heating systems, the impossibility of saving on coolant;

- Difficulty in cleaning.

Flat steel radiators: technical specifications

The flat steel heating radiator is the most popular device in Europe today. Its widespread use is due to its compactness. In addition, they are adapted for automated heating systems, and the technical characteristics of steel heating radiators are simply amazing.

Steel plate heating radiators are available in single-row, double-row and three-row designs. Additionally, they are equipped with convective fins.

To produce steel flat heating radiators, manufacturers use cold-rolled steel, which is durable and resistant to corrosion.

Design

Flat heating radiators consist of two plates, made by stamping and welded together. Between such plates there is a space (channel) - this is where the coolant will circulate. To connect the batteries to the heating system, there are special pipes. Using certain types of connections, you can form flat, thin heating radiators from two or three plates.

That is why the power of a device that has fins will be almost 60% greater. But there will also be more dust on such products, so they are placed in rooms that have high sanitary requirements.

Sectional view of a panel heating radiator

In order to correctly classify plate heating radiators, special designations with numbers are used, which are the same for most manufacturers of such products. The first number is the number of plates, the second is the number of plates that have convection fins:

- 10 – one plate without convection fins.

- 11 – one plate with convection ribs.

- 21 – two plates, one of them has convection ribs.

- 33 – three plates and each has convection ribs.

The thin heating radiators, which are presented above, are also additionally equipped with side casings with grilles on top. They are usually white in color.

White flat radiator

If we talk about the standard delivery set, it includes a set of fastening elements for brick walls. If your walls are different, you will have to buy separately all the fasteners that are required to install narrow radiators.

Typically, narrow heating radiators are connected either directly to the heating system riser, or using special fittings.

In addition, there are also batteries that immediately have a kit for connecting to a thermostatic valve. With the help of such an insert with a thermostatic head, the speed of water in the product is controlled. Such a kit is usually connected on the right side, however, upon special order, the manufacturer can create a battery with a kit for installation on the left side.

Flat vertical radiator with connection in the middle

Some manufacturers have in their assortment such narrow horizontal heating radiators that can be connected to the heating system in the middle - with or without a valve insert. If the heating radiators have an integrated kit, then they will be ready to be connected to the heating system from below, when the pipes are hidden under the floor. Special connecting elements with pipes that are hidden in the wall are also used. Such pipelines will not spoil the appearance of the room that is heated.

For a standard type heating system, when the pipes go on or in the wall, plate heating radiators with a side connection are used. For a system with a pipeline in the floor - connection from below.

Advantages and disadvantages of stainless steel radiators

When comparing the performance characteristics of steel batteries with devices made of other materials, heating radiators made of stainless steel have advantages in a number of indicators:

- Due to the simplicity of the design, they have a long service life. High-quality heating devices are made of thick steel (1.2 - 1.5 millimeters), which has a positive effect on their strength;

- The presence of different options makes it much easier to install steel radiators yourself. On the website of well-known manufacturers there are always instructions that clearly and in detail explain how the device should be connected for different heating design schemes;

- The design of steel radiators makes them one of the worthy components of an apartment’s interior.

Conclusions and useful video on the topic

Useful tips from experts will help you understand the choice of heating device:

The best choice of heating radiator can be considered the one that achieves the greatest comfort and coziness. The radiator can be invisible or, on the contrary, be part of the overall design. But the most important thing is reliability and no hassle.

You can tell us about how you chose a radiator to replace old batteries in an apartment or to furnish a new home in the block below. Please write comments, ask questions, share useful tips and photos on the topic of the article. We are interested in your opinion.

Types of steel heating radiators

Steel heating radiators can be divided into three types according to design features:

Panel flat

Such a battery consists of two steel plates in which recesses with a flat bottom . When two plates are connected, channels for coolant circulation.

The plates are fastened using spot welding. The device has holes in the corners for incoming and outgoing water. an air bleed valve on one of the fittings

A tap is installed on the pipe through which the coolant enters the heater to regulate the water supply.

These models have a convection function . Convection fins are located on the side that is attached to the wall. When the heater heats up, these fins also heat up. Hot air rises, forming natural convection, which speeds up the heating of the room.

Important! Some models of steel panel heating devices do not have convection fins .

One radiator can accommodate from one to three panels . Depending on their number, as well as the presence of a convection function, there are 7 types of panel heaters:

- 10 - has one panel. It does not have a convector or cladding.

- 11 - has one panel and a convector.

- 20 - has two panels and an air outlet grille on top. There is no convector.

- 21 - two-panel heater with a protective casing and a convector attached to one of the panels.

- 22 - two-panel device with protective covers and convectors.

- 30 - three-panel radiator, covered with an air outlet grille on top.

- 31 is a three-panel device with protective covers and a convector.

Photo 1. Internal structure of some types of steel panel radiators, small and large.

Tubular or sectional

Some tubular heaters are similar to conventional cast iron sectional batteries. They are also called sectional, since the coolant circulates in them through sections connected into a single structure.

One section of such a device can have from 2 to 6 tubes . Tubular heating devices can have any size. The lowest height is 0.19 m , and the maximum is 3 meters.

Lamellar

Plate heaters consist of a large number of plates, a heat exchanger and a casing.

The heat exchanger is an arc-shaped pipe. The number of pipe bends (bends) depends on the specific model. As a rule, one or two elbows are used.

The pipe is heated by the coolant and then transfers heat to the plates. The plates act as a convector , but the convection created by the ribs of panel heating devices is much stronger.

The protective cover has two functions . Due to the fact that the plates and pipe are very hot from the coolant, they can burn the residents of the house. The casing temperature does not exceed 40 °C . In addition, this casing plays an aesthetic role. Externally, such batteries are similar to panel batteries.

The technical characteristics of steel plate heaters are such that they can be part of the heating systems of panel houses, as they can withstand pressure up to 40 atmospheres.

Attention! Over time, the heat transfer of steel plate heating devices decreases due to dust settling on parts of the structure. To avoid this, the device must be cleaned periodically.

What types of low heat exchangers are there?

Devices are distinguished based on the following criteria: the type of material from which they are made, the design features of the main components - sections, plates and height. They are produced in heights from 200 to 450 mm, lengths from 500 to 6,000 and depths from 10 to 230. The following types are distinguished:

1. Cast iron sectional, ribbed. The advantages are good thermal inertia and corrosion resistance. Disadvantages: low operating pressure up to 10 atmospheres, fragility, susceptibility to the accumulation of dirt and plaque inside the channels, which reduces heat transfer over time. Compact batteries made of cast iron are models MC 140M-300 (height 388 mm).

2. Steel panel radiators consist of one or more heating plates enclosed in a ribbed shell. They have excellent thermal conductivity and low inertia, and consume a minimal amount of coolant. For example, a steel radiator measuring 100 mm deep, 300 mm high and 1,000 long can create an effective thermal curtain near a window with a glazing area of up to 4 m2.

Disadvantages: not resistant to water hammer; when water is drained, corrosion can form on the walls of the panels; the convection method of heat transfer contributes to the formation of small dust particles in the room. Of all compact heating devices they have the highest cost. For example, the price of a Kermi radiator with a height of 300 mm, depending on the length and depth, is 1,260 - 5,100 rubles.

3. Aluminum casting and extrusion sections are characterized by light weight, good heat dissipation and elegant design. The technical characteristics of a low aluminum radiator allow it to withstand operating pressures of up to 16 atmospheres. Disadvantages: low convection, service life (10-15 years), instability to water hammer and, as a result, possible leaks between sections. You can buy a 200 mm battery made of aluminum for 340 - 1,250 rubles.

4. Bimetallic ones consist of 2 parts: a core made of steel or copper pipes and an aluminum shell. The advantages are: the ability to withstand high (up to 100 atmospheres) pressure, small volume of water consumed and good corrosion resistance. The sectional low bimetallic radiator Rifar Base 200 has a closed rear surface, which allows it to be mounted in close proximity to glass surfaces. Some models are equipped with legs for installation on the floor. However, in terms of heat transfer, bimetallic batteries are inferior to aluminum products, and their cost is 10-15% higher.

5. The lowest are plate batteries of the convector type. Such linear or plinth radiators have a height of 200 to 400 mm and can be attached to the wall and floor, and, if necessary, covered with decorative grilles. They are characterized by good heat transfer and the ability to withstand operating pressures of up to 20 atmospheres. Produced in the form of solid products of a certain length. If there is a leak, they require a complete replacement, which causes some inconvenience.

What to consider when purchasing

The modern market for heating appliances is saturated with products from Russian and global brands that differ in technical characteristics, quality, and price. In order to avoid unnecessary costs and not make mistakes with quality, experts recommend taking into account the following factors:

1. For centralized heating systems that are installed in residential multi-storey buildings, cast iron radiators are suitable. For buildings with panoramic windows, it is better to use bimetallic or aluminum ones.

A clever meter that saves electricity. Pays for itself in 2 months! Everyone needs to know this in order to save!

For closed heating systems that are installed in private homes, batteries made of steel or aluminum are recommended.

2. The length of the radiator must correspond to the size of the window opening or be 10-20 cm longer. Otherwise, it will not be possible to create an effective thermal curtain, which will lead to uneven heating of the air in the room.

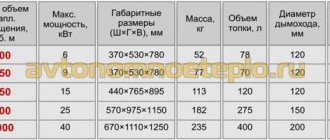

Technical characteristics and cost of the most popular models

Technical characteristics of steel batteries

Battery specifications include:

- heat transfer;

- inertia;

- operating pressure.

Each type of heating structure has its own technical features. Heat transfer depends on several factors:

- sizes ;

- presence of a protective casing;

- functions ;

- masses.

The protective casing reduces heat transfer, and the presence of a convector increases it.

Inertia - the property of steel to quickly heat up and cool down, depending on the temperature of the carrier.

The weight of each radiator is determined by the model and dimensions. But, in comparison with their cast iron counterparts, steel batteries are much lighter.

The operating pressure that steel heating devices can withstand depends on the specific model and the wall thickness of the pipes and sections. Thus, panel batteries can withstand pressure up to 40 atmospheres , while tubular models will not withstand pressure above 13 atmospheres.

pros

A steel panel radiator of any type has the following advantages:

- high heat transfer at low cost;

- the ability to create an interesting design due to a wide selection of colors, shapes and sizes;

- the ability to independently regulate the air temperature and calculate the heating area;

- small volume and weight;

- radiators are resistant to chemical solutions, including alkaline ones;

- optimal combination of radiator and convector properties.

Selecting a radiator type

The choice of model depends on the needs and technical characteristics of the heating system. Any type of radiator is suitable for private houses with an autonomous heating system.

If you are purchasing a device for an apartment located in a multi-story building , you should think about purchasing a panel model, since the operating pressure in such buildings is quite high.

In addition, in multi-apartment high-rise buildings, the heating system “suffers” from pressure surges . Tubular and plate batteries may not withstand water hammer, become deformed or lose their tightness.

When choosing a heater, you should also take into account the interior of the room . There are decorative models whose height is only 20 cm . They are installed near the floor and serve not only as heating devices, but also as interior elements.

Heating elements for cast iron batteries

It is not surprising that today many consumers are looking for alternative types of heating their homes. The cost of utilities is constantly rising, which cannot but cause concern. One of the ways to create autonomous heating in an apartment is a cast-iron battery with a heating element for heating.

A heating element is an ordinary metal tube with a spiral located inside it, which is separated from it using a filler. You can make it yourself from available materials. Batteries with heating elements are distinguished by high performance, economy and reliability, and the fact that they are built into the heating system itself allows you to save space and ensure their unnoticeable presence.

Such a device can be equipped with a thermostat to regulate the degree of heating of the coolant and serve as both an additional and the main source of heat.

There are heating elements of different power on the market, so you should make calculations in advance of how many watts will be required per radiator section to heat each individual room.

Design and purpose of plate radiators

You can select, buy and install any radiator, but it will be useless if the room or building is not insulated - only in combination with thermal insulation work will a plate radiator prove to be most effective. In addition, the efficiency of a radiator is not the high temperature of the coolant, which is released into the air through tubes and plates, but the maintenance of a constant and comfortable temperature in the room throughout the entire time. Therefore, if you correctly decide on the surface of such heating batteries, you cannot get burned - firstly, the temperature will not be critical, and secondly, the plates are covered with a metal casing.

If we approach the issue fundamentally, then plate heating radiators are a design variant of convectors with a difference in the number of tubes and plates (fewer tubes, more plates).

Internal structure of a plate radiator

Similar to panel-type radiators, in plate-type devices there is a classification according to the number of heat exchange tubes and panels (plates), which are manufactured by hot stamping and spot welding. Due to the tight connection, heat is transferred not only from the surface of the plates, but also from other areas of the device - from tubes and even connecting seams and joints. The marking of devices occurs in this way: if the radiator has one panel (plate on the body) and one heat exchanger, then it is marked as class “11”. Three plates and two tubes - “32” class, etc.

If you want to buy and install a new radiator in a store or replace an old one, then complete with the new model you will receive an installation kit and instructions for assembly and fastening. Depending on the design of the device, its connection can be threaded or welded, which depends on the coolant input/output device. In addition, you will need to connect the Mayevsky tap and thermostat or two separate devices - the Mayevsky tap itself and a separate thermostat. It is not at all necessary to install a thermostatic valve, but it will allow you to automatically regulate the temperature in a separate room by limiting the flow of coolant into the radiator coil. The latest models of plate batteries are often equipped with built-in thermostats and taps.

Plate heating radiators with thermostat

Aluminum

Aluminum heating radiators are made not from pure aluminum, but from an alloy based on it. This metal was not chosen by chance, as it has one of the highest heat transfer coefficients - 4-4.5 times better than cast iron and 5 times better than steel.

Table with thermal conductivity coefficients of different metals

That is why aluminum radiators are distinguished by their high power (180-190 W per section), no less high heating rate and low inertia. They work very effectively in tandem with thermostats, allowing you to maintain a stable temperature with an accuracy of one degree. The advantages of aluminum radiators include their low weight (one section weighs 1.5-2 kilograms), which makes delivery and installation easier. Another positive point is that the shape is designed so that it has a large cross-section of channels for the coolant (slightly smaller than that of cast iron “accordions”). This is good, since there is a low probability that these channels will become clogged and the radiator will stop heating.

Now about the disadvantages of aluminum radiators. They are related to the properties of aluminum. As you know, it is a chemically active metal. It actively interacts with most of the chemical table, and reacts especially violently with copper. And in modern heating systems, copper parts are often found. Such a proximity threatens the rapid release of copper parts of the system and system, as well as increased gas formation. They have learned to deal with gases - they install automatic gas vents (valves) in systems, and they save copper by not placing it close to aluminum appliances. The process, of course, is still going on, but not with such intensity.

Aluminum radiators look modern

The chemical activity of aluminum also manifests itself in demands on the quality of the coolant. Not in the sense of its contamination, but in the sense of its acidity. Aluminum radiators work normally in systems with coolant acidity no higher than 7 (Ph 7).

The softness of aluminum is also not very good for the operation of the heating system. The alloy from which heating radiators are made contains additives that increase its hardness, but still, they do not work in high-pressure networks. Typical operating pressure is 8-16 atm depending on the type and manufacturer.

Based on all of the above, there appears to be an area in which aluminum radiators will be the best. These are individual heating systems with boilers controlled by automation. They also do well in apartments, but only in small buildings (up to 10 floors), in which coolant with Ph 7-8 circulates.

Determination of thermal power of plate heating devices

The formula for determining the thermal power that a steel plate heating radiator can produce, and a real example of calculating this parameter, are given below. To calculate the power of the device, it is enough to know the heat loss coefficient of the heated room, the area of the room and its total volume. The passport of any radiator indicates its calculated power at a hot water temperature in the system of 60 0 C. Also, the attached documentation indicates recommendations for the heated area for a specific radiator model.

The thermal output (power) of heating devices depends on the length of the body and the number of plates. The standard height of radiators is 200 mm, the number of plates varies. For example, heat transfer for a radiator with one tube and a body length of 600 mm will be equal to ≈ 347 W. When the length is increased to 3000 mm, the heat transfer will increase to 1730 W. But with the same body length (3000 mm) and an increase in pipes to 4, heat transfer there will already be 4179 W, and with a body length of 1000 mm, four tubes with coolant will give 1393 W of power. Therefore, which radiator is best to buy for a specific room is determined based on the following requirements:

- To heat 1 m2 of a room with a ceiling height of 3 m, you need to spend 100 W;

- For a room with an area of 16 m2, the radiator must have a thermal power of 1600 W, provided that the room has no more than one window, the room is not corner and the ceiling has a height of no more than 3 m. For other initial conditions, correction factors Kp are introduced:

- For two windows Kp = 1.8 / 1600 x 1.8 = 2880 W;

- For a corner room Kp = 1.8 / 2880 x 1.8 = 5184 W;

- For a ceiling 2.65 meters high Kp = 2.65 / 3.0 = 0.88 / 5148 W x 0.88 = 4547 W;

- For PVC windows Kp = 0.8 / 4547 W x 3637 W.

A standard metal-plastic window is 1400 mm wide, so to fully block cold air flows, a radiator of four sections 1400 mm long, with a power of 1950 W, is installed underneath it.

Power table

The heating radiator works like this:

- Under pressure or gravity, the coolant moves through the battery tubes, heating them;

- The tubes heat the plates welded to them, and together the structure heats the air between the radiator elements, which rises up to the ceiling of the room;

- Cold air masses, under the pressure of warm air, fall down to the radiator, where they heat up;

- Then the cycle repeats.

Installation process

Options for connecting radiators - side, bottom.

Flat modifications are installed only in closed heating systems, where the movement of the coolant is regulated by special pumps, and the system itself contains an expansion tank.

Coolant movement technology:

- By means of a pump, thermal energy moves along the pipeline.

- It goes through the valve.

- Reaches to the end consumer.

- Moves along the air vent.

- Then towards the return pipeline until it reaches the expansion tank with a membrane.

- Then the movement process is repeated.

When such samples are connected to an open heating system, their service life is significantly reduced. This is explained by corrosive processes affecting radiators when oxygen enters the battery, which is formed due to frequent drainage of liquid in the system.

In rooms with high humidity levels, the installation of flat radiators is not recommended.