Gas boilers have reliably taken their place among efficient, economical and energy-independent heating devices. The history of their use as a means for heating domestic premises, from the development of the design to the modification of the latest generation, goes back about 100 years. The difference between modern devices and old-style devices is visually and technically noticeable and manifests itself in terms of power, durability, and external aesthetics.

They differ:

- the boilers are old, characterized by a primitive design;

- ultra-modern gas appliances equipped with energy-saving automation of the latest developments;

- modified, combining the developments of old years with new technologies.

Old boiler

Popular manufacturers of energy-independent single-circuit boilers

Some of the most popular models of non-volatile single-circuit boilers are Baxi slim, Protherm Volk, Siberia AOGV, Zhukovsky AOGV.

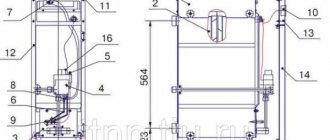

Baxi slim

This model of floor-standing gas boilers has 5 modifications, which differ in power from 22 to 110 kW. Baxi slim is equipped with an atmospheric burner, a cast iron heat exchanger and a safety system. Reviews say that it is better to connect a Baxi chimney to the boiler to eliminate leaks and other problems with the removal of combustion products.

These units are easy to operate and maintain; you can clean them yourself without involving specialists. They are equipped with a self-diagnosis system that finds problems and fixes them independently.

Note! It is important to monitor the draft in the chimney so that the water pressure sensors do not fail. Baxi slim gas boilers are easy to set up using an LCD display that provides complete information about the settings

Baxi slim gas boilers are easy to configure using an LCD display that provides complete information about the settings.

Protherm Wolf

The gas single-circuit floor-standing energy-independent boiler Protherm Wolf has a small power range - from 12.5 to 16 kW. This is enough to heat a cottage or retail space up to 140 m². The efficiency of the unit is about 90%.

The burner is ignited using a piezo ignition built into the combustion chamber. The piezo ignition runs on a standard battery, so it is advisable to always have a spare battery.

This boiler is equipped with a single-stage burner. The intensity of combustion can be adjusted by reducing or increasing the gas supply using a special valve.

The security system has a sensor that monitors the extinguishing of the flame and automatically stops the gas supply if the fire goes out. There is also a sensor in the combustion chamber that prevents the system from overheating.

Siberia AOGV

A prominent representative of the domestic atmospheric floor-standing boiler is Siberia AOGV. Depending on the model, they have a power from 11 to 50 kW, efficiency = 90%. The advantages of these units include independence from electricity.

Non-volatile automation includes the following functions:

- piezoelectric ignition;

- magnetic valve;

- flame control;

- modulating thermostat.

Siberia heating units are distinguished by their unpretentiousness to changes in the electrical network and gas pressure, as well as to water quality. Fuel combustion occurs in an open firebox equipped with an Italian-made Worgas burner. It is considered environmentally friendly, since carbon and nitrogen oxide do not remain in the exhaust gases.

AOGV Zhukovsky plant

Non-volatile gas boilers from the Zhukovsky plant are presented in three modifications: “Economy”, “Universal” and “Comfort”. They are equipped with a steel heat exchanger, temperature sensors, atmospheric burner, draft sensor and piezoelectric ignition. Automation controls heating of the coolant from 45º to 90ºC. Gas units can be effectively operated with both open and closed combustion chambers.

The AOGV “Universal” model, unlike the “Economy” model, is supplemented with a modulating burner, which gradually changes the combustion power, which helps to save fuel. The boilers are equipped with more advanced European-made SIT automation. The security system blocks the operation of the unit when it overheats or to prevent an emergency.

Units of the “Comfort” series are the most popular among consumers from the range of gas boilers of the Zhukovsky plant. They are represented by 15 models of varying power from 11 to 43 kW. The most productive unit is capable of heating an area of up to 350 m².

Floor-standing, non-volatile single-circuit gas boilers represent a certain segment of products that simply cannot be avoided in regions where there are frequent power outages and in places remote from civilization.

Choosing a floor-standing gas boiler with an integrated boiler

When choosing a 2-circuit boiler with an integrated storage tank-water heater, take into account the thermal characteristics and the operating principle used. According to their internal structure, the following models are distinguished:

- Atmospheric boilers have an open combustion chamber. During operation, the air from the room is burned. The installation requirements are high.

- Condensing boilers - accumulate heat from exhaust gases through targeted condensation formation. They have an efficiency of up to 108%.

- Turbocharged models have a closed combustion chamber, supplemented by a turbine that pumps air pressure. The device uses forced intake of air masses and removal of combustion products.

After selecting a boiler by type of operation, the required power and throughput are calculated.

Calculation of the required boiler power

When calculating a double-circuit unit with a built-in storage tank, two operating parameters are taken into account:

- Required power to heat the room.

- Performance reserve for DHW.

- Boiler volume.

The first parameter is calculated using a simple formula, 1 kW = 10 m². So, for a house of 100 m², you will need a 10 kW heating device. An additional 30% is added for DHW heating. The volume of the built-in tank varies from 40-60 liters for domestic boiler equipment, to 500 liters in industrial units. A properly selected boiler provides peak demand for hot water supply (simultaneous consumption from all taps installed in the house). It is possible to install an additional free-standing container of the required volume.

Which brand of boiler with an internal boiler is better?

A floor-standing double-circuit gas heating boiler with an indirect heating boiler is offered by foreign manufacturers. You can make it easier to select a suitable boiler by distributing the most popular models by region:

In order for the model you like to enjoy a long period of flawless operation, before purchasing you should pay attention to the following:

- Adaptation to domestic operating conditions - in the EU countries and the Russian Federation, different parameters of main gas pressure, water quality for hot water supply, etc.

- Type of connected heating system - condensing boilers are installed for low-temperature heating and are optimally suited for connection to heated floors.

- Having a service center near your home is another significant plus. The official representative of the company that sold the boiler guarantees that if the heat generator breaks down, you will not have to wait several months until the necessary spare parts are delivered from abroad.

A consultant from a company selling heating equipment will provide assistance in choosing a suitable boiler.

Economical

As already mentioned, the main parameter that determines the efficiency of a boiler is its coefficient of performance (efficiency). All major developments of the world's leading boiler manufacturers are aimed at increasing it. The efficiency of modern boilers is in the range of 91-93%. It is the desire to ensure maximum efficiency that can explain the emergence of so-called condensing boilers, which not only use the heat of combustion of gas, but are also capable of partially utilizing the heat of condensation of water vapor contained in the combustion products. According to information provided by manufacturers, the efficiency of such boilers reaches 107-108%. Paying tribute to such equipment, it is necessary to note some features that are often hushed up in front of a potential buyer. Firstly, the indicated efficiency is achieved only in low-temperature (40-50 °C) systems, while in traditional systems (with a coolant temperature of 80-85 °C) it does not exceed 94-96%. Secondly, condensing boilers cannot be used with a conventional classic brick chimney. Thirdly, when heating water for domestic hot water, the efficiency of a condensing boiler is almost the same as that of a conventional one.

We should also not forget: the boiler is only part of the heating system, and its high efficiency is only one way to achieve its overall efficiency

What is important for the consumer is not so much how economically the combustion process in the boiler proceeds, but what is the gas consumption in general. Of great importance, for example, is the error with which the boiler automation determines the temperature (for different boilers it ranges from 1 to 5 °C), the ability of the boiler to operate effectively in equithermal control mode (change the temperature of heating water depending on the outside air temperature), etc. .d

Practice shows: using only weather-dependent regulation allows you to save up to 10-12% of gas!

Smoke removal

There are two types of smoke removal methods: natural and forced. Which one is better to use depends on several factors: the condition of the chimney, room ventilation, etc.

Natural

Often, a wall-mounted gas boiler is installed with a natural chimney. In this case, the smoke is exhausted through a vertical pipe passing through the roof. The only condition for this method is the presence of good ventilation in the room where the water heater is installed.

Forced

If a private house does not have a chimney pipe or its condition leaves much to be desired, it is recommended to purchase a device with a built-in fan. Then the smoke can be removed through a hole in the wall, although such equipment will cost a little more.

Coaxial

Modern wall-mounted gas boilers are equipped with a coaxial smoke exhaust system. This is a special chimney in which one pipe is located inside another. The smoke is removed through the inner pipe, and air is supplied to the burner through the outer pipe. The advantage of such a system is that the pipe can be located both in a vertical and horizontal plane.

What to follow

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we will highlight several types of boilers.

Gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive and is available to a wide range of consumers. What types of gas heating boilers are there? They differ from each other depending on what type of burner is atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products escape through a special pipe using a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall-mounted gas boiler

As for the method of placing boilers, the choice of heating boiler involves the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to supply hot water, then you can install modern wall-mounted heating boilers. This way you won’t need to install a boiler to heat the water, and this will save money. Also, in the case of wall-mounted models, combustion products can be discharged directly onto the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall-mounted models is their dependence on electrical energy.

Electric boilers

Next, we will consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. These types of heating boilers are small in size, so they can be used in small houses, as well as in cottages with an area of 100 sq.m. All combustion products will be harmless from an environmental point of view. And installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and its prices are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as backup heating devices.

Solid fuel boilers

Now it’s time to consider what solid fuel heating boilers are available. Such boilers are considered the most ancient; such a system has been used for heating premises for a long time. And the reason for this is simple - fuel for such devices is available, its quality can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not able to operate in autonomous mode.

Gas generating solid fuel boiler

A modification of such boilers is gas generator devices. This boiler differs in that it is possible to control the combustion process, and the productivity is regulated within the range of 30-100 percent. When you are thinking about how to choose a heating boiler, you should know that the fuel that such boilers use is wood, and their humidity should not be less than 30%. Gas fired boilers depend on the supply of electrical energy. But they also have advantages over solid fuel ones. They have high efficiency, which is two times higher than solid fuel devices. And from the point of view of environmental pollution, they are environmentally friendly, since combustion products will not enter the chimney, but will serve to generate gas.

The rating of heating boilers shows that single-circuit gas generator boilers cannot be used for heating water. And if we consider automation, it is great. You can often find programmers on such devices - they regulate the temperature of the coolant and give signals if there is an emergency.

Gas generator boilers in a private home are an expensive pleasure. After all, the cost of a heating boiler is high.

Liquid fuel boilers

Now let's look at liquid fuel boilers. Such devices use diesel fuel as a working resource. To operate such boilers, you will need additional components - fuel containers and a room specifically for the boiler. If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this purpose, replaceable burners or special burners are used that can operate on two types of fuel.

Liquid fuel boiler

Technical specifications

When choosing a wall-mounted gas boiler for a private home, first of all, you should take into account its technical characteristics. Main parameters:

- performance;

- volume of water consumed;

- ignition type;

- number of circuits.

Power

On average, heating 10 m² of private house or cottage area with a ceiling height of 3 m requires 1 kW of heat. However, when making calculations, a combination of several factors should be taken into account: the number of storeys of the building, the thermal insulation of the walls, the height of the ceilings, the number of windows and doors.

Contour

Double-circuit wall-mounted gas boilers will easily provide hot water supply to a kitchen sink, washbasin and bathroom. If you plan to organize the supply of hot water elsewhere, it is better to install a device with one heating circuit. In this case, to supply hot water, you need to purchase a boiler.

Ignition

There may be two types; which one is better to choose is determined by the owner of the house. Electric ignition is carried out automatically using a spark. This method is more economical and safe, but it has a significant drawback - energy dependence.

If there are power outages in your area of residence, it is better to install a wall-mounted gas boiler with piezo ignition. In this case, the device is turned on using a button that ignites the igniter. When the boiler is turned off, the wick itself does not go out, so this method is not very economical.

Materials

Modern heat exchangers are made from various materials. Many qualities of these parts, as well as their pros and cons, depend on this parameter. Let's take a closer look at what heat exchangers for gas boilers are usually made from.

Steel

Most often, heat exchangers made of steel are found in gas heating equipment. Their prevalence is explained by the affordable cost of steel and the ease of its processing. Steel parts have their own distinctive characteristics, for example, such a heat exchanger turns out to be quite plastic. In addition, such options have a long service life, which attracts many consumers.

It should be noted that the ductility of steel specimens plays one of the most important roles when it comes to contact of the exchanger with high temperatures. Thanks to this characteristic, cracks do not form on the constituent elements of the boiler when serious thermal stress forms in the inner part of the metal near the burner.

However, steel options have one serious drawback - they are susceptible to corrosion. Of course, the appearance of rust shortens the service life of the exchanger. In addition, it must be taken into account that defects of this kind can appear on both the inner and outer half of the device.

Another disadvantage of steel exchangers is their large size and weight. In addition, with such parts, gas consumption will increase. This happens because most modern manufacturers strive to achieve a high level of inertness and expand the volume of the internal cavities of the heat exchanger.

Cast iron

The second most popular heat exchanger is rightfully made of cast iron. This model differs from a steel model in that when it comes into contact with liquid, it does not become susceptible to corrosion. Thanks to this distinctive feature, we can safely talk about the durability of cast iron options.

However, we must not forget that cast iron exchangers require regular maintenance and careful attention. In addition, these options are distinguished by their fragility. If scale accumulates on a cast iron heat exchanger, heating in the system may become uneven, which will lead to cracking of the exchanger. In order to extend the service life of this element, it is necessary to carry out periodic washing. In most cases, if running water is used, then washing is done once a year. If antifreeze is used as a heat carrier, then such work will need to be carried out once every 2 years.

Copper

Copper specimens are practical and durable. They have more pros than cons. The following characteristic features inherent in such exchangers should be highlighted:

- copper parts are lightweight;

- differ in small dimensions;

- do not become covered with destructive rust;

- they need very little fuel to warm up well.

Thanks to such advantages, the copper heat exchanger is recognized as one of the most popular. However, it is expensive, so they do not buy it so often. In addition, such elements become less strong and reliable under heating conditions. Copper heat exchangers burn out very quickly and then fail.

Aluminum

Many branded models of gas boilers contain aluminum heat exchangers. This material is distinguished by high plasticity, so it can be used to make exchangers of any shape and complexity. In addition, you need to take into account the fact that the level of thermal conductivity of aluminum is 9 times higher than that of another popular raw material - stainless steel. Aluminum heat exchangers have a very modest weight. Thanks to such positive characteristics, we can safely talk about the practicality of such components, as well as their reliability and functionality.

Such devices are also good because they usually do not have any vulnerabilities. For example, in stainless steel structures there are welding seams, kinks and other similar areas. They are very vulnerable, so they endure significant loads during equipment operation. In aluminum versions there are simply no such problems. Aluminum parts have strong chemical resistance, which is excellent for condensation.

Operating principle

Cast iron gas heating boilers are similar in operating principle to conventional units. They contain the same elements: circulation pump, gas burner, heat exchanger, combustion chamber. The operating process of the device is based on burning fuel in a combustion chamber; it transfers thermal energy to a coil with water. The coil, made of cast iron, is the main key element of the boiler; its purpose is to gradually and evenly heat the coolant.

There are many positive aspects in the operation of such units:

- Firstly, they are not susceptible to corrosion.

- Secondly, heat is distributed evenly.

- They withstand thermal loads well.

- With proper care they can last for decades.

As a disadvantage of a gas boiler with a cast iron heat exchanger, it can be noted that such devices are prone to mechanical damage and also weigh a lot. Another drawback is that cast iron is very sensitive to the temperature difference between the supply and return coolant. In the event of a strong drop, cracks appear on the heat exchanger, as a result you will have to resort to repairs, which will be expensive.

Which boiler is better for a house or apartment?

It is difficult to give a universal assessment, since each situation is individual, but basically in practice it happens like this:

- floor structures are purchased for heating the private sector (houses, cottages);

- hanging - for apartments due to their small size and visual appeal.

Although it is important to make a reservation here. In every sense, floor-mounted mini-boiler rooms are definitely more reliable, since they have a more durable heat exchanger, and they are also easy to use even at critically low temperatures outside

Plus, add energy independence to everything, and then you will understand why many people prefer to install them even in apartments.

Wall-mounted boilers are good because they can be built into kitchen units and take up a minimum of usable space in small urban kitchens

But if you have limited living space and live in a region where severe frosts are very rare, it is more rational to install a wall modification. It will also cost less.

How to choose power for a room and calculation formula

The power of gas boilers is selected based on the area of the premises. The simplest formula is that 1 kW of boiler power is taken into account per 10 m2 of area.

This technique is most effective for rooms with a height of no more than 3 m . If the ceilings are higher, it is necessary to slightly reduce the ratio of the size and power of the unit.

For double-circuit boilers, the power should be increased by 20% to compensate for losses in water heating.

Heat exchanger

Pay attention to the heat exchanger material. The heat exchanger is located in the combustion chamber

Sellers can display it either open or closed. In any case, you will not be able to carefully examine the heat exchanger. You will only be able to see its edges, the burner and the space where the gas burns. Water circulates along the circuit of the gas boiler and passes through the heat exchanger, where key heating occurs.

In wall-mounted gas boilers, there are three types of heat exchangers:

- copper;

- aluminum;

- heat exchangers made of stainless steel.

Copper heat exchangers are still the most popular in the best wall-mounted gas boilers. In high-quality models, copper is coated with a special protective silumin composition, which, according to manufacturers, extends the life of the heat exchanger, increases corrosion resistance and heat resistance. In practice, such heat exchangers should last longer.

Copper heat exchanger with a protective layer for the Italtherm City Class gas boiler

Thus, the first thing you need to pay attention to is the material of the heat exchanger; if it is copper, pay attention to whether a silumin composition is applied to it or not. If there is no composition, then the manufacturer decided to save a little

If there is, then the manufacturer has tried and spared no expense in covering the heat exchanger.

It is copper heat exchangers that have the highest efficiency, the best efficiency indicator is achieved with copper heat exchangers in wall-mounted gas boilers. Plus, these heat exchangers are the most durable. In practice, they “live” much longer than aluminum and stainless steel ones. But copper ones have one main disadvantage. It lies in the fact that copper is an expensive spare part; if you say goodbye to your heat exchanger after a long time, then as a spare part it will cost as much as possible.

Aluminum heat exchangers

They are used quite rarely. They are mainly used by the Ariston and Fondital brands. According to the manufacturers of Ariston equipment, heat exchangers made of aluminum are in no way inferior to heat exchangers made of copper. And in terms of efficiency they are inferior by only 0.8. Therefore, aluminum ones are practically no worse than copper ones. But in fact, using aluminum means reducing the cost of production, yes, with aluminum you can achieve great heights in terms of the production of heat exchangers, but in practice such heat exchangers last less. But the plus is that aluminum heat exchangers are cheaper as spare parts. Therefore, in principle, they have the right to exist.

Stainless steel heat exchangers

Navien boiler stainless steel primary heat exchanger

They are easy to notice, they have a characteristic shine and are noticeably different from the rest. And in general, manufacturers do not hide what their heat exchangers are made of. They do not “live” for long, as spare parts are quite cheap. Thus, if there are several gas boilers on your list, the winner should be the one that uses a copper heat exchanger, ideally coated with a silumin protective compound. If you want to save money, take a boiler made of aluminum or stainless steel, but if it is the same price category, the difference in cost is small, copper is your choice. In our opinion, it is better not to buy wall-mounted gas boilers with aluminum and steel and copper for the same price.

Specifications

Cast iron gas boilers are the most popular heating units, which, according to their technical characteristics, are most suitable for use in buildings intended for permanent residence.

The operating principle of all cast iron boilers operating on gas is built as follows: heat is released, which owes its appearance to the fact that the fuel is burned and the air is heated. In short, the next stage of work occurs, that is, when fuel such as gas enters the combustion chamber, it burns and transfers all the heat to the coolant.

Then the coolant, which circulates through the system in a closed loop, is supplied to the batteries and the room heats up - the batteries begin to give off heat.

The technical characteristics of gas boilers with a cast iron heat exchanger differ in that:

- such a device does not require constant operation, since the heat exchanger retains heat well, and the temperature sensor, detecting temperature fluctuations, does not perform manipulations that will start the boiler;

- One of the main parameters that dominates the technical characteristics is the durability of this type of material, even though the conditions may be extreme.

Protection against calcium salt deposits

This problem is most acute for boilers with a bithermic exchanger, but it is there that it is most problematic to protect against this. In boilers that use a secondary heat exchanger to heat hot water, it is this that is protected. This is done in the following ways:

- increased flow turbulence in the secondary heat exchanger;

- special coating or treatment of the internal walls of the heat exchanger;

- limiting the maximum temperature of the primary circuit heating the secondary heat exchanger (this method is the most common due to its simplicity, but significantly reduces the efficiency of heating hot water).

Which is better - convection or condensation?

First of all, it is necessary to understand the difference between the operation of one and another unit.:

- Convection - works on the usual principle of heat transfer. The coolant is heated due to the thermal energy released during fuel combustion.

- Condensing is a boiler that produces two-stage heating of the coolant. First, the OM receives a certain amount of thermal energy from the condensation of water vapor, which is contained in the exhaust combustion products. The partially heated coolant then enters the primary heat exchanger and is finally heated in the usual way.

The advantage of condensing boilers is the ability to reduce fuel consumption and, accordingly, reduce the heating intensity of the heat exchanger. Since the liquid has already received some heat, the burner operating mode can be reduced.

All this together allows you to increase the service life of the boiler components and parts and increase its efficiency. The efficiency of condensing boilers, declared by all manufacturers, is 107-109%, although in this case the usual marketing ploy takes place.

Such efficiency cannot exist by definition, but this is not the main problem . Condensing boilers are able to demonstrate proper efficiency only in low-temperature systems, where the degree of return heating is lower than the condensate temperature.

This is only possible if the difference between external and internal temperatures does not exceed 20°, which is simply impossible in Russian realities.

Therefore, you can choose a condensing boiler only in southern regions with warm winters.

PLEASE NOTE! The price of a condensing boiler is almost twice the cost of convection models of the same power. If operating conditions do not allow you to obtain the expected effect, you should refuse to purchase a condensing model.

Manufacturers

Currently, on the Russian market you can find a large number of different models of cast iron gas boilers, which are produced by different manufacturing companies. Let's look at the most popular of them.

Ariston (Italy)

Gas boiler with cast iron heat exchanger Ariston Unobloc

The Ariston company produces atmospheric gas cast iron boilers of the Unobloc series. They are well suited for domestic operating conditions, are reliable and have a long service life. The efficiency of the devices is high, reaching up to 90%. The model range is represented by devices with power from 24 to 64 kW.

The cast iron heat exchanger is not subject to corrosion processes and various thermal stresses. The atmospheric burner includes electric ignition and ionization flame control. Ariston boilers, whose power varies from 24 to 31 kW, include a circulation pump, an expansion tank, a safety valve and a minimum pressure switch.

Thanks to the large variety of units made in a variety of design solutions, everyone can choose a heating device that will not only become a source of heat, but will also fit perfectly into the interior.

Biasi - Italian gas boilers with a cast iron heat exchanger.

Baxi (Italy)

Models of floor-standing gas boilers with a cast iron heat exchanger Slim from Baxi got their name due to their small dimensions (width is only 35 cm). In this regard, they can be placed in any room, even the smallest. The manufacturer offers units with atmospheric and inflatable burners. Power ratings range from 15 to 62 kW.

During the operation of boiler equipment, continuous electronic modulation of the flame occurs both in heating mode and in hot water supply mode. These Baxi cast iron boilers are highly safe; they are equipped with an electronic self-diagnosis system, ionization flame control, a protective thermostat against overheating of the liquid in the primary heat exchanger, as well as a draft sensor to control the removal of combustion products.

If your boiler room is quite large and you need a more powerful boiler, then Baxi offer a range of units with an atmospheric burner, the power of which ranges from 83 to 116 kW. The boilers are very well adapted for operation in Russian conditions.

Gas floor-standing boiler Baxi SLIM

Electrolux (Sweden)

Floor-standing gas boiler Electrolux FSB 50 Mi

Electrolux cast iron heating boilers are represented by the FSB series, which includes both single-circuit and double-circuit devices with natural removal of combustion products.

Due to the fact that production is carried out using the most modern technologies, the devices have a long service life and are very economical in fuel consumption.

It is worth noting that Russian cast iron gas boilers are not much inferior to their European counterparts in their technical and operational characteristics and are also very popular among users.

Thanks to a sectional cast iron heat exchanger made using Drop Stop technology, an Electrolux gas boiler can operate successfully for 25-30 years.

Distinctive features

Floor-standing cast iron gas boilers, unlike steel units, have a prefabricated sectional design. It is worth noting that the units are assembled only by hand.

Features of cast iron heat exchangers:

- Cast iron, once heated, retains and releases thermal energy for a very long time. This material also resists aggressive environments and acids well.

- Since the design of the cast iron heat exchanger is prefabricated and it consists of separate sections, in case of any damage, all parts can be replaced individually.

- The heat exchanger is not afraid of high temperatures and can withstand heating up to 300°C.

- The service life is quite long - 25 years or more.

Cast iron heat exchangers can be found in both domestic and industrial boilers.

You can read about the types of heat exchangers for gas boilers here.