Today, the underfloor heating system is extremely popular. This is due to a large number of positive qualities, as well as the possibility of installing any type of flooring. In addition, you can choose absolutely any option for the heating system, depending on the need and the room itself. But it is worth noting that when installing all components of a heated floor, special attention should be paid to the thermal insulation layer so that heat is not wasted just like that. An excellent option here would be underfloor heating. The main thing is to know which one to choose.

Mermen

The heating system is a hot water pipeline. This type of heating is most popular in private houses, because in apartments management companies do not want to give permission to connect to central house networks.

There are at least two reasons for this. The first is that it is almost impossible to control the consumption of thermal energy for a specific person. The second is an increase in the load on heating boilers, which is why they simply cannot cope with their task.

Installing an individual boiler in an apartment is possible, but it is very expensive, and sometimes it is very difficult to obtain permission for this.

Polypropylene boards

One of the optimal options for thermal insulation of water heating, it is not afraid of elevated temperatures and humidity, and is the cheapest material in terms of cost. It is not afraid of aggressive chemical compounds and does not emit harmful substances during heating. It has low flammability and does not support open combustion. The reproduction of various microorganisms, including mold, is inhibited on the surface. It is approved for use by sanitary control organizations without restrictions. The slabs may have ready-made grooves for laying pipelines.

Polypropylene boards

Sheet polypropylene

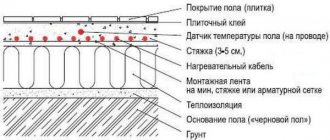

Electrical

Heating occurs due to the energy released by conductors under the influence of electric current.

By design, heated floors of this type are film, that is, infrared, and cable, which have a heating element in the form of simple flexible cables with conductive elements inside. During the installation of electric floors, complications may arise, so you should take into account all the parameters of the existing wiring in advance, as well as correctly calculate the protective fittings.

For heating to be effective, the design power per 1 m2 must be at least 0.25 kW. It is very important when installing a heated floor that the correct underlay for the heated floor is selected. There are a large variety of substrates, and each of them is designed to perform specific functions.

Is additional thermal insulation necessary or not?

Additional thermal insulation when installing an infrared floor is aimed at:

- Protection of the heated room from the penetration of cold air flows from outside;

- Saving heat indoors and preventing it from escaping outside.

The need for additional insulation depends on a number of factors:

- In what room is the floor installed? If it is located on the ground or above the basement, then the thermal insulation layer should be thicker.

- What kind of substrate is laid - that is, the type and its thickness. When using a thin foil product as a flooring, insulation made of expanded polystyrene foam, cork or polystyrene foam is required.

If you do not adhere to these rules, the floor will not work efficiently (heat will be wasted), and this will entail additional costs.

How to choose the right substrate

Before you begin installing the heating system, you should decide which underfloor heating substrate will best perform certain functions. Do not forget that each manufacturer tries to sell as many of its products as possible, and often the advertised product does not meet the qualities that were declared.

There are a number of factors that determine a high-quality substrate, and this is what you should proceed from when choosing it:

Thermal conductivity of the material

. The best substrate is considered to be the one with the lowest values, and they are determined by the thickness of the product and the material used. At the moment, there are substrates with improved energy conservation properties; they have a foil coating.

Energy saving occurs due to the reflection of infrared radiation - as a rule, this figure is 20-30%. All materials used in the manufacture of substrates meet the required construction standards for residential premises.

Strength characteristics – resistance to constant and dynamic loads

. There are materials that are compressed due to prolonged constant loads. Because of this, thermal conductivity increases. This effect should be avoided by selecting the correct load so that the mechanical impact over the entire surface is as uniform as possible.

Manufacturability

. Laying the material will be cheaper the easier it is to work with. This characteristic varies quite widely for many materials. It is best to give preference to polystyrene foam. It is very technologically advanced, the lining under a warm floor made from it is often thin, no more than 5 mm, and it is easy to cut with simple scissors.

The underfloor heating pad made of polystyrene foam is flexible, its edges are easy to connect to the walls. This material is easy to measure, cut off parts, make adjustments, and you can simply bend it near the walls. In this case, it is much easier than installing chipboard or OSB.

Additional qualities

. To simplify installation work even more, some manufacturers draw a grid on the front side or leave special bosses that protrude.

This modification greatly simplifies the installation of pipes, making it possible to secure them during the installation of the lining. The result is faster repair work, improved efficiency and longer service life of the heating system. The coolant can be installed at an equal distance, so that overheating in individual zones is excluded, that is, the entire floor is heated evenly.

Price

. This parameter is quite significant. If you have special technical knowledge, you can install heating in such a way as to obtain high heat saving rates, and also significantly save the finances necessary for the purchase of materials.

Environmental friendliness of the material

. Although any of the materials tends to emit toxic fumes, their quantity and intensity are not always the same. Due to the fact that the substrate for underfloor heating pipes will be used in conditions of elevated temperatures, it is worth paying special attention to indicators of environmental safety and harm to human health.

When looking at advertising brochures from various manufacturers about certain lining materials, not everything needs to be taken on faith, and some characteristics may not be paid attention to at all.

Noise-absorbing effect.

Any person who remembers at least something from physics lessons knows that sound is transmitted through air. Since absolutely any insulating material does not allow air to pass through, therefore, the same thing happens with sounds.

UV resistance

. Since the substrate under a heated electric floor, as well as under a water-heated one, is not directly exposed to ultraviolet radiation, this characteristic of the material does not in any way affect its performance. Perhaps it is necessary to isolate the source of X-rays, but this is unlikely to be found in a residential area.

Waterproofing properties

. Let us say right away that the presence of moisture under heated floors, both water and electric, must be eliminated during the heating installation process. If a leak suddenly occurs in heating water pipes, the faster it is repaired, the less expenses the owner will have, and the materials will not be exposed to prolonged exposure to moisture. But in the case of an electric heated floor, the presence of moisture is, in principle, excluded, otherwise short circuits are possible. Therefore, how well the substrate resists moisture does not matter.

Price factor

. In most cases, the cost of the material includes the costs of advertising and product promotion. That is, when buying a product from a well-known company, you significantly overpay for the brand. However, there are many types of quality products on the market at more affordable prices, just not as advertised. A competitive price allows new firms to promote their products on the market, attract the interest of buyers and earn a business reputation.

Thus, all of the listed indicators will help you not make a mistake when choosing a substrate for a heated floor, no matter what design, so that it lasts as long as possible, and you can save on assembly.

Which substrates to choose for electric heated floors

Sufficiently thin types of substrates are best suited for electric heated floors, for example, pressed cork, Folgoplastic, TMpro, Polyfom, Thermodom and other foamed polymer materials.

By the way, foamed polymers are able to withstand significant loads, which is why they are increasingly in demand in construction work. To produce a thicker substrate, foamed polystyrene foam is used.

Such a substrate can even withstand a concrete screed, since it is designed for heavy loads. Foamed polystyrene is actively used when laying heated floors with electric heating elements, be it flexible hoses or film floors.

In cases where preliminary leveling of the base for a heated floor is required, OSB and chipboards, as well as plywood, can be used as a substrate.

It is worth noting that for electric-type heated floors, it is not advisable to lay underlays equipped with a layer of reflective aluminum. If the aluminum insulation layer is damaged during operation, current leakage will occur, which may lead to negative consequences. The reflective layer must be on a polyethylene film, onto which vacuum deposition is applied.

Two initial factors should determine which brand of substrate will be chosen:

- Type of finished floor covering

. The heavier the coating, the stronger the substrate is chosen. Under the laminate you can put a simple backing made of foam materials (read: “Why do you need a underlay for laminate and which is better”), and under the tiles - a backing made of materials that are especially durable. - Room type

. It matters whether the premises are new or the renovation is carried out repeatedly in the old premises. Based on what type of electric floor will be chosen and what features of the load-bearing floor, the thickness of all layers of the heating system together with the floor covering can vary from 10-15 mm to 3-4 cm.

All these nuances must be taken into account when calculating the height of door and window openings. During the repair process, it is advisable to take into account all parameters in order to reduce the height of the heated floor as much as possible. This will allow you to avoid problems with the height of the doors not matching the opening, and so on.

If something goes wrong, the door leaf and vertical trims will need to be cut a few centimeters at the bottom. The most unfavorable outcome is that you will need to raise the lintel of the doorway or redo the entire heated floor system.

Only substrates on a rigid base should be laid under linoleum, and the screed layer should be low. The principle of installation of the substrate depends on the materials used, as well as on the recommendations offered by the manufacturer.

Stability of characteristics

Groups of porous materials, such as polyethylene foam and expanded polystyrene, have an unpleasant feature. Over time, under the influence of static stress (burden from lying pipes and the load when walking on the floor) they are compressed. The thickness of the substrate decreases, the process may proceed unevenly, differing in different areas of the room. This can cause unpleasant consequences.

You need to select a substrate material based on the service life and physical characteristics declared by the manufacturer. Temporary changes in geometry are taken into account, as well as production technology. For example, expanded polystyrene foam has an open structure and sticks together over time. At the same time, extruded has completely closed cells, is elastic, retains its geometry and properties for decades.

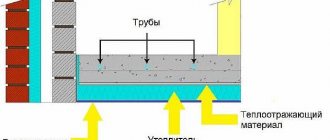

Types of underlay for floors with water heating

The specificity of underfloor heating with water heating is that a finishing cement-sand screed is always poured over the pipes.

In this regard, the lining under a warm water floor must meet more stringent requirements than, for example, for electric heating:

- Mechanical strength

. Craftsmen strongly recommend laying a durable substrate made of OSB or chipboard, plywood or extruded polystyrene foam for a water floor. These materials are not subject to permanent deformation and can withstand significant loads. - Resistance to high humidity

. This is important because in the event of an emergency, high-quality material can continue to be used after the leaks have been eliminated. Of course, during the installation of a water floor, all possible measures should be taken to prevent the system from leaking. - The substrate under the water-heated floor must also ensure reliable fixation of the heating pipes in the given direction

. In particular, for such purposes, pads with bosses are often used, which allow pipes to be evenly distributed over the floor surface and speed up the installation process.

The thickness of the substrate for water heating pipes is of great importance. To decide which underlay to choose for a warm floor, you should take into account the quality of the existing thermal insulation of the floor covering. For wooden structures, the floors of which are insulated with mineral wool, a thin underlay can be laid. But if it serves as the only heat-insulating layer in the room, then you should opt for materials with a low level of thermal conductivity. It is optimal if a reflective substrate is laid under the heated floor.

A variety of materials can be used as a finishing coating for underfloor heating with water heating - artificial and natural stone, ceramic tiles, linoleum, laminate and others. At the same time, it is necessary to take into account the fact that the resulting weight of the screed with the finished floor will directly affect the strength of the substrate. That is, the heavier the floor, the more reliable and thicker the bedding under it should be.

Proper selection of consumables for underfloor heating equipment in each specific case allows you to reduce the total cost of construction work, significantly increase its efficiency and increase its service life. Therefore, before choosing the type of substrate, you should carefully understand the characteristics and features of a particular type of material.

Laying technology

The technology for laying the substrate is simple and can be done independently. When installing a lining intended for heated floors, it is necessary to select its thickness depending on the type of system and the conditions under which it will be used.

The reflective side of the insulation should face the direction of the heat source. There should be an air gap of 15 - 20 mm between it and the finishing floor, for the circulation of air masses and the condensation process.

The main thing is to follow the established rules:

- Carrying out a calculation - determining the amount of material; it is better if the insulating layer has a minimum of seams.

- Preparing the base - it must be level, each difference will appear on the surface over time.

- Laying a waterproofing layer - it can be cork, chipboard, etc. Before this, you need to lay dense polyethylene, it will serve as a water barrier.

- Installation of the substrate (roll or sheet) - it is laid without tension, with the obligatory approach to the walls. The material must fit closely to vertical surfaces that are covered with damper tape.

- Connection - roll-type canvases (laid in an overlap) or mats (positioned in a joint) are combined using adhesive tape.

After this, you can begin installing the heating system. If a water- or electric-type heated floor is being laid, and a foam backing with bosses or a wooden backing with grooves is used, it is enough to place the pipe or cable in the grooves.

If the substrate is smooth, additional fixation will be required. Then you need to fill the screed, although there are ways to install heated floors without it. After which, you can begin the finishing coat.

Laying an infrared mat floor is an easier option. The rolled material is simply rolled out onto a flat surface and secured with tape. A concrete screed is not required here; it is enough to put a plastic film on top and install the flooring.

To summarize, we can say that the substrate is a structural layer that cannot be avoided when installing any heated floor. You should not save on this material, as repairing the system will cost much more.

Properly installed hydro- and thermal insulation will provide heating of the room and reduce energy consumption costs.