The steel hot water heating boiler Zhytomyr-3 Atem KS-G is designed for heating residential buildings and public utility buildings equipped with continuous heating systems with natural or forced circulation of coolant.

The coolant is water. The device is designed to operate on low pressure natural gas and discharge combustion products into the chimney.

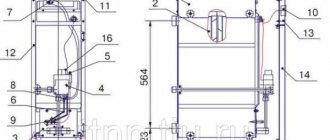

Construction of a gas boiler Zhytomyr-3 Atem

The Zhytomyr-3 gas boiler is made in the form of a rectangular floor cabinet, the front side of which is closed by a door that provides access to start and control its operation.

The apparatus consists of the following main parts: boiler body 1 (Fig. 1), which consists of a firebox and a heat exchanger. Turbulators 18 are installed in the heat exchanger for the most complete selection of heat when burning natural gas and transferring it to the coolant; flue 2; burners: main 5 and pilot 4; safety automatics with gas valve 6; inlet pipes 13 and coolant outlet 14.

The Zhitomir-3 Atem KS-G boilers with a built-in water heater are equipped with 12 connecting pipes. On the front part of the housing there is an inspection window 3 to monitor the ignition and operation of the unit. A thermal indicator cylinder 17 and a thermal cylinder 9 of the gas valve are installed in the cup 7, which serves to control its operation. Thermostat (draft sensor) 10 serves to ensure its safe operation.

For the most complete heat extraction from the outside, the unit body is covered with thermal insulation and a decorative steel casing coated with powder enamel. A temperature indicator is installed in the upper part of the casing to control the water temperature.

When the boiler is ignited, the pilot burner is first lit, which heats the thermocouple and gives a signal to open the gas valve for supplying gas to the main burner.

All boilers are equipped with piezo ignition 16, which greatly simplifies its ignition.

The gas valve installed on the device is a multifunctional gas control device that has:

— thermoelectric protective device for automatic shutdown;

— safety device to protect against incorrect operations;

— a combined thermostat that provides a quick increase (decrease) in gas supply with modulated control from maximum to minimum gas supply;

— adjusting screw for gas supply to the ignition burner;

— gas pressure regulator;

— control points of inlet and outlet gas pressure;

Rice. 1. Design diagram of the gas boiler Zhitomir-3

1 - boiler body; 2 - gas duct; 3 - viewing window; 4 — pilot burner; 5 — main burner; 6 — automatic safety system with gas valve “630 EUROSIT”; 7 — cup of the boiler body for installing thermal cylinders; 8 — machine oil; 9 — thermal cylinder; 10 — traction sensor; 11 — traction sensor wire; 12 — outlet pipe of the water heater; 13 — coolant (water) supply pipe; 14 - coolant (water) outlet pipe; 15 — gas valve control knob; 16 — piezo ignition button; 17 — temperature indicator cylinder; 18 — turbulator; 19 — overheating sensor; 20 - thermal insulation; 21 - flue pipe (manufactured in two versions - vertical and horizontal)

An ignition burner is installed on the body of the Zhitomir-3 KS-G boiler, which serves to ignite it and ensure safe operation.

— Water heater 12 operates on the “water-to-water” principle, i.e. The temperature of the water used for household needs depends on the temperature of the water in the unit.

— Therefore, to obtain the maximum amount of hot water, it is necessary to maintain a temperature of 90°C; for this, when installing the boiler, it is necessary to install an overflow pipe with a valve that connects the inlet and outlet of water from the heating device.

— Using valves, the temperature of the water in the boiler and the temperature of the water supplied for household needs are regulated.

— When operating the device for heating water in the summer, it is necessary to close the valve installed at the inlet completely, and the valve installed on the overflow pipe to open completely.

— A correctly installed unit makes it possible to obtain hot water with a temperature difference of 35°C.

Boiler safety devices Zhytomyr-3

Protection in case of sudden gas shutdown

If the gas suddenly turns off or the pilot burner flame blows out, the heating of the thermosensitive element of the thermocouple stops: the decreasing emf of the thermocouple will turn off the magnetic block of the gas valve, which will shut off the gas supply.

Protection in the absence of draft in the chimney

To protect the KS-G boiler in the absence of draft, a draft sensor is connected to the gas valve.

The traction sensor is a thermal relay that opens the contacts when the temperature exceeds a preset one.

In the absence of traction, the thermal relay placed on the gas duct heats up and opens the circuit connecting the thermocouple to the gas valve. In this case, the magnetic block of the gas valve will shut off the gas supply.

overheat protection

A shutdown sensor is installed on the body of the unit, which, if the temperature of the coolant in the boiler rises above 95°C, opens the circuit connecting the thermocouple to the gas valve.

In this case, the magnetic block of the gas valve closes the valve and the gas supply stops.

FAULTS AND REPAIRS

REPAIR OF GAS HEATTER

BOILER SPARE PARTS

Why does the gas boiler Zhitomir 3 go out?

boiler shutdown

is the lack of traction, but if we talk about the technical part, the following is most likely: 1. the thermocouple-valve cable connection has oxidized;

2. The thermocouple is incorrectly set relative to the pilot burner; 3

. the pilot burner or tube is clogged (dirt, spider?); N 4.

Interesting materials:

How to insert a check mark in Word? How to insert a picture into a picture in Word? How to align text in a table in Word? How to get to the root in Word? How to replace a line break with a space in Word? How to replace all characters with others in Word? How to see everyone at the same time on Zoom? How to Vectorize a raster? How to return sheets in Excel? How to return a post from an Instagram archive?

Specifications

The Atem-Frank private enterprise, located in Zhitomir, produces two types of gas heating systems:

- in floor version;

- in a suspended version (so-called parapet boilers).

Floor-standing units are produced as single- and double-circuit, the latter can supply hot water to 2-3 consumers at low costs. General technical characteristics of the Zhytomyr gas boiler for the entire range of floor heaters are presented in Table 1.

The DHW capacity of double-circuit floor-mounted installations is from 175 to 1400 l/h with a heated water temperature difference of 35 ºС. The product can be equipped with a circulation pump, installed as an option. The characteristics of the model range of parapet units can be seen in Table 2.

Double-circuit parapet boilers provide hot water consumption from 160 to 345 l/h with a water temperature difference of 35 ºС.

As can be seen from the tables, the suspended and floor-mounted single-circuit boilers Zhitomir are adapted to the conditions of low gas pressure in main pipelines, which is their advantage. A significant drawback is that the maximum permissible coolant pressure in the heat exchanger of the unit is quite low, for floor-standing versions - up to 2 kgf/m2, and for suspended ones - up to 0.7 kgf/m2. At the same time, foreign analogues can operate with system pressure up to 3 kgf/m2. This suggests that ATEM gas installations are more adapted to gravity systems and small houses with 1-2 floors. It is not recommended to purchase suspended models for two-story cottages, since there is simply not enough pressure for normal operation of the system.

Passport for Atem boilers (Zhitomir) ⋆ SIVtermo

Do you need to quickly find a passport for the Zhytomyr Atem boiler? Then come to Us! The website contains passports for gas and combined equipment of the Zhitomir-3, Zhitomir-M, Zhitomir-10, Zhitomir-9, Zhitomir-5 models

Operating manual Gas and combined boilers Atem produced in Zhitomir differ in their design from similar gas boilers of other brands, this can be seen both at first glance and upon careful examination of the product passport. Developers of boilers and AOGV Zhitomir try to bring a zest to each of their devices, as well as bring to the market models that are radically different from their analogues. For example, in 2016–2017, combined boilers appeared in the Atem boiler model range, which combine a gas and solid fuel boiler or a gas boiler and a gas water heater.

In 2022, a completely new type of parapet boiler appeared, equipped with two pipes instead of one coaxial one.

To make it easier to understand the features of these boilers and accurately understand whether they are suitable for you, below are the passports, or rather the operating manuals for this equipment.

You can also download a passport for the gas convector Zhitomir -5. It indicates not only the dimensions of the convector, but also all its technical data, as well as the operating instructions.

You can always buy Zhytomyr brand products, whether gas or solid fuel boilers, gas convectors, etc. in the online store sivtermo.com.ua

If you have any questions please call:

073–17–04–754

067–17–04–754

099–17–04–754

to your website.

www.sivtermo.kh.ua

Boiler repair and adjustments Zhitomir

A floor-standing boiler Zhitomir-3 KSGV-10 sn was installed, the first year everything was fine, but this year, when the main burner ignites, a crackling sound (and a strong one) and the sound of boiling water can be heard from the device, what is the reason and how to eliminate it? The radiators all heat up well, and how dangerous is this? Will the unit burst? Condensation drips onto the burner. Warm up the boiler and heating system well - the sound should disappear. I checked with an electronic thermometer on 1st 84-85 degrees, on 3rd at 90 degrees it did not work, turned it off manually, the oil was filled. The thermostat may need to be replaced. There is no way to take the device back to the store. Most likely, the gas valve has failed, and the 95-degree overheating sensor is also responsible for the safe operation of the boiler. The gas boiler Zhitomir-3 KS-GV-10 SN with Eurosit 630 automation is in operation. A heating area of 80 sq.m. was installed a couple of months ago. 1 - the first room, which is closer to the device, heats perfectly, the second is very bad, and this is if it is with a pump. If you turn off the pump, it barely heats up at all. 2 - water is constantly dripping onto the burner, and this despite the fact that it heats at 60 degrees. 3 - it’s impossible to get rid of the air pocket in the last battery in a distant room. Two sections of the last battery are cold, the pump was installed on top. He works constantly on one. What are we doing wrong, what is the problem? Before this, there was an apparatus, it heated all the rooms perfectly, heated all the radiators, they were hot and heated up very quickly, but this was a real problem. We have already spent a lot of water because we are constantly adding water, please help! This is clearly not a matter of the boiler. You need to look at the heating system. If the device heats water, it should circulate even without a pump. Be sure to check all hydraulics. I tried to turn on the device, but it didn't work. Explain what a throttle valve is and how it should be in order to open the Zhytomyr 3 boiler. The throttle valve allows you to temporarily increase the temperature of the exhaust gases, due to which the chimney warms up faster and, accordingly, good draft occurs, which makes the initial start-up of the device much easier. The principle of operation is this: before igniting the boiler, you must fully pull the damper handle towards you. After the chimney has warmed up, the handle must be pushed back. A more detailed description of the operation is in the insert to the instruction manual. A floor-standing boiler Zhitomir-3 was installed for 120 sq. m., it is difficult to light the wick. What could be the reason? Does not light well due to a clogged pilot burner (wick). I have 250 sq.m., please tell me whether it is worth installing an Atem boiler, could there be problems with it and which one should be installed on such an area? If you install the boiler correctly there will be no problems. According to the calculation, 1 kW of the device per 10 sq.m. with a ceiling height of 2.5 m, and also pay attention to the amount of water. Malfunction of the Zhytomyr parapet boiler with Eurosit 630 automation, shuts down above 60 degrees, help. The traction sensor is the one that triggers the most. Check the chimney. The Zhitomir gas boiler has been in operation for 5 years, a week ago it froze at 45 degrees and is not adjustable, it is constantly on. What could be the reason? It is possible that the gas supply pipe from the automatic control system to the burners and the burner nozzle are clogged. Tell me, is it possible that due to low gas pressure the Atem Zhytomyr boiler goes out, a click occurs and goes out. What is the problem? Is it possible to temporarily disable automation and how? It is forbidden to turn off the automation. It's not safe for life. Regarding low gas pressure, contact a service center. It is quite possible that the problem is not the pressure, but a clogged gas supply pipe or poor draft. A Zhitomir-3 floor-standing boiler has been installed, tell me how to switch it so that there is no heating in the summer, but there is hot water? Close the supply tap (if there is one naturally). The Atem Zhitomir-M 12 CH gas boiler with Eurosit 630 automation is in operation. Installed this year. The first heating season is coming soon. Tell me: what temperature to set the numbers to take a shower. And one more thing: what temperature corresponds to each indicator from 1 to 7. For example: what temperature will it be when set to 2. The numbers on the control knob are not strictly tied to the temperature. They serve for ease of use of the device. And the temperature depends on the individual operating conditions (thermal insulation of the room, amount of water in the system, heated area, etc.). For orientation - “1” - 40 C, and “7” - 90 C. Gas boiler Zhitomir-M AOGV-12 SN. The technician installed it and did not say that the expansion tank was set to 0.9 atm. How many atmospheres can I pump cold water into the system when starting the boiler? I pumped 1.2 atm according to the pressure gauge. The pressure dropped all the time, there were no leaks anywhere. And on the second day the device leaked. And all the water is under him, on the floor. How can I fix it? What could have caused the breakdown? Tell me how to take it apart? The maximum pressure, according to the instruction manual, is 0.7 atm. You put 1.2 atm into the system. cold water and “crushed” the expansion tank, practically eliminating it from the heating system. After heating the boiler, the pressure, accordingly, increased further, and most likely because of this, the tightness of the heat exchanger was broken. For repairs, it is best to contact the service department and there you will see whether it is possible to fix it on site, or to completely replace the unit housing. Here’s a question: a house of 210 sq.m., 2 floors, so that there are no problems with gas workers, the boiler power should not exceed 23 kW. In operation Atem 20 by 220 sq.m. Will it be enough? It depends on the height of the ceilings. 220 sq. m is the estimated area for a ceiling height of 2.5 m. If it is higher, the volume of air is correspondingly larger and the device is needed more powerful. But, on the other hand, if the house is well insulated and heat loss is kept to a minimum, then it is quite possible to install. Malfunction of the boiler Zhitomir 10. When heating, there is a strong knocking sound in it, as if it is boiling. What is the reason? Won't it be torn apart? The unit is not leveled correctly or the heating system is clogged. The device has nothing to do with it. A floor-standing boiler Zhitomir 3 Atem KS-GV-12 SN (12.5 kW, 630 Eurosit) was installed; after 8 years of operation, it stopped turning off when heated and began to work continuously, raising the temperature to over 80 degrees. What could be the reason? This is your problem with automation, i.e. The thermostat does not work, you will have to change the automation completely. I turn on the Zhytomyr parapet boiler (new). Everything is working. I turned it on in the evening, everything worked until night. We woke up in the morning and the boiler had gone out. And already three times. Before this, they turned it on once, everything was fine, and then it got warmer, and they turned it off, and the second time there were such problems. There is a craving. He worked for at least exactly three hours. This is most likely due to oxidation of the traction sensor, it does not see the contact and because of this it quickly goes out. It is necessary to clean the connections until they are shiny and the boiler is working. The Atem Zhitomir-3 KSGV-10 SN gas boiler with Eurosit 630 automatic switches off. It began to go out on low and medium gas. From 1 to 5 it will work and the gas supply will be turned off. It works fine on 6 and 7. The second season has worked, the circulation pump is installed. It even happened that the igniter did not light up, cleaned the terminals, worked normally for about a day and began to turn off again. In principle, it’s already spring and I don’t want to call an unfamiliar gas worker. Yes, maybe I can figure it out on my own. Can anyone tell me what the problem might be and its solution? The igniter flame - the root third is bluish, the middle and top are yellow, fluctuates quite strongly. The main thing for me is to know whether there is a problem with the automation or whether everything just needs to be cleaned? In general, in the fall there was a strange symptom: if you turn on the igniter and immediately turn on the burner, the gas supply turns off after a minute or two. And if the igniter burns for five minutes, the gas supply does not turn off. We had a similar situation. During assembly, the thermal breaker was not fully screwed into the magnetic valve. Apparently the contact between them was not initially the strongest, and over the two seasons of work the contact worsened. And apparently, at 1-5 there was not enough contact, but at 6-7 there was enough. We tightened it a little more and everything became normal. I had the following problem: my gas boiler Zhitomir-M (parapet), installed in 2006, began to go out. The most interesting thing is that it goes out in position 2 and 1 in position 3 lights up without problems. This happened just yesterday, before that everything was normal. The house is heated by a gas boiler Zhitomir-3. Atmospheric gas burner with igniter. Is it possible to install an electric ignition so that the device ignites without an igniter? My igniter goes out and, interestingly, at a certain wind direction. I do not know what to do. If the pilot burner goes out while the main burner is running, try reducing the gas pressure to the main burner. When starting the boiler, while gas is supplied to the igniter, the following happens: I press the gas supply “key”, gas flows to the igniter, I release the gas “key” - it still “goes”. The metal plate does not heat up as before; gas has to be supplied to the main burner immediately. This phenomenon began gradually, from year to year it was necessary to hold down the “key” less and less, now it is not necessary at all. And to top it all off, the boiler began to go out, up to 5 times a day. It used to happen that it would go out once a season. I checked the traction - the traction is excellent. Can you see something wrong with the equipment? I advise you to switch to automatic Sit. Atem boiler malfunction. Installed automatic 710 minisit. 2 days already problems. 2 times, after much torment, I managed to turn it on, but it turned off spontaneously. Now when you press the ignition button, gas flows and ignites from the button. According to the instructions, you need to hold it for 10 seconds, but it turns off. The traction is normal, I replaced it with a new one. 3 meters higher than the roof, not blown by the wind. The thermocouple is ok, I checked it with a tester, when heating the current reaches 22-23 mVolt. I also cleaned the contacts. What could be the reason? How does the operation of the safety magnetic valve installed in the automation depend on the presence of air in the expansion tank? Last year I bleed the expansion tank by mistake and it worked until the end of the season. This year I worked for a month. On the advice of specialists, I decided to pump it with air and drained all the water from the system the day before yesterday and at the same time change the exhaust pipe. It was not possible to pump in air, there was a problem with the pump, and the pipe was changed. And from then on the problems began. To light the igniter, neither draft nor water is needed in the system. If the thermocouple is ok, then look for a bad connection somewhere or an open in the draft sensor. Can be short-circuited temporarily. And then - more, in the automation itself, for example, EHR. The parapet boiler goes out, I light it with a piezo ignition, the wick burns as long as I hold the button, as soon as I release the button it goes out. What could be the reason? Boiler Zhitomir, automatic 630 Eurosit Italy. We unscrew the nut that goes into the valve, and pull out the copper tube (thermocouple tail, not gas!). Then, using the tester, in the ohm-kilo-ohm resistance measurement mode, we measure between the center and the tube. If the readings of the device do not change, then the thermocouple has burned out, if they change, you can torture it further - we light the wick, set the tester to millivolt mode, and measure the voltage after 10 seconds. About 20 mV is normal, more is better. If it is less, then perhaps the flame is barely reaching the sensor - then we unscrew the igniter and clean it (in the picture in the center). That's it with a thermocouple. Now the valve. Resistance tester, one contact on the metal of the valve, the second in the center of the hole, from where the tail of the thermocouple was pulled out, without touching the edges of the thread with the probe. If it's about 0 ohm, then it's normal. If you want, then look further - the battery with one pole (no difference) on the metal, the second in the center of the valve (insulated wiring). We press the button, light it and immediately release it (no need to wait). If it continues to light, the valve is normal. If the contacts have been oxidized, they will be cleaned after unscrewing and tightening. If there is a draft sensor (in the chimney area, with two wires), we close its contacts (you can use a paper clip in place, or you can insert one into the other). A gas boiler Atem-10 was installed (Zhitomir 3). This year I made myself a closed heating system using polypropylene pipes with aluminum radiators, it worked fine for two months, and then suddenly the pressure in the system began to drop. I checked everything, there are no leaks anywhere, I tried pumping water into the system and pumping pressure into the expansion tank, it helps, but for a while, after about a day, the pressure gradually begins to drop. Tell me what to do? The pipes are all open (i.e. visible and easy to access), my highest point is the protection group, which is located immediately behind the boiler, the pressure was previously maintained at 2 atm. I checked the expansion diaphragm - normal. Your boiler is sectional (made up of separate sections), I would start by checking it. Fill with air (no need for water - it expands much more when the temperature rises) to the maximum pressure (look in the passport) and leave for a day. After this, you can check the entire system in the same way (if necessary). But these are things for the month of May. Now you can lower the pressure in the system to 1 Atm. and (if the leak stops) sleep peacefully. In your case, the pressure in the system is only needed to reliably close the automatic air vent. Pay attention to the membrane tank. Personally, I had a case with a pumping station: I bought (for installation) a 50 liter hydraulic accumulator, immediately after purchase I checked the air pressure of 1.2 atm, installed it because... it was supposed to work with a water pressure of 6 atm. pumped up the air to 2 atm. After 2 weeks they called - “the pump twitches” (i.e. it constantly turns on and off), pumped up the air - after 2 weeks the same thing, after a very long search they found 2 microscopic pores in the weld seam of the air cavity of the tank. We brewed it with argon - everything was fine for 2 years. We installed the Atem boiler with Eurosit 630 automation. We connected it, pressurized it, everything was fine. We lit the igniter according to the instructions, it burns normally. Then we turn on the main burner, 15 seconds pass, and the entire burner turns off (both the igniter and the main burner). Because It’s impossible to find a specialist, I’m asking for help - what can I try to check first? I began to understand the automation device of Eurosit 630. As far as I understand, there are two sensors that cause an emergency shutdown of the gas valve - a reverse draft sensor (thermistor?). And a thermocouple next to the igniter is a flame absence sensor. I checked the draft - it sucks in smoke from burning paper well. I removed both connectors from the traction sensor contacts and shorted them together. As a result, the valve began to turn off after about a minute (initially it turned off after 15 seconds). So it's not the traction sensor? I assume that the malfunction may be caused by a weak igniter flame; turning on the main burner may deflect the pilot flame away from the thermocouple. Please advise on replacing the draft sensor on the Zhitomir-3 boiler. It began to go out, I found out the fault - apparently the draft sensor is faulty, it is marked 75 C. Question - I will buy a sensor on the market, I couldn’t find one for 75 C, they suggested I buy 95 C. Will this be normal for the boiler? Or should I still look for a 75 C sensor? 95 is a lot. When the outside temperature is above zero degrees, the automation turns off after a minute. You can run it a hundred times and it shuts down a hundred times. Parapet boiler Zhytomyr. Where and what needs to be adjusted so that the boiler works at any outside temperature? There is no need to twist anything anywhere! Due to the fact that when the outside temperature rises, the draft from the igniter “blows out” the flame. Tell me, the difference in characteristics, filling of thermal cylinders for Eurosit 630 automatic boilers. For boilers, 42-82 degrees. Malfunction of the Atem parapet boiler, automatic 630 Eurosit. The size of the wick torch has decreased; the device does not turn on again after the temperature drops, as the wick goes out. The filter in front of the boiler is clean, the tube on the wick is also not clogged. I enlarged the hole in the wick nozzle - the wick torch increased, and the work returned to normal. A week later, the size of the wick plume decreased again and the problem returned. I checked everything that I checked before - everything is clean. They advised to increase the size of the wick torch in the boiler automation with an adjusting screw; I twisted and increased the torch slightly and this did not help. I also checked the chimney, it is clean. Does the amount of gas at the wick nozzle (pilot burner) produce a sufficiently large amount of gas? Is the injector clogged with debris? The tube to the pilot burner from the valve is intact - are there any gas leaks? Are the air suction holes for the pilot burner not closed? Is the pilot burner itself clogged with debris? The wick does not burn with a yellow flame? Does the wick go around the edge of the thermocouple? Is the thermocouple intact - does it produce the required voltage? Are the draft and overheat sensors (if equipped) normal? Is there any current leakage or voltage loss on the wires leading to the sensors? Is the pilot burner wick not being blown out by through air? How to check the draft of a boiler and not a chimney? Zhitomir-3 KS-GV-12 SN was installed (chimney outlet up). The instructions don't say anything specifically, just a drawing from which you can't understand anything. Like, put a sheet of paper on top of the device. I can’t figure out where exactly to place the sheet of paper. The installer didn't understand it either. The instructions say that you definitely need to check. I don't know, no one has pointed out how to check the traction. They always only brought a match to the window. And it’s not clear why they should be brought up. The boiler is working anyway. The only question is the length of the pipe. And the fact is that its internal diameter is not much larger than the total diameter of all outlet holes.

The lineup

The price range largely characterizes the model range of gas boilers in Zhytomyr. The boiler names contain alphanumeric designations. The letters indicate the main features of the boilers. The numbers give a characteristic of thermal power.

Floor standing boilers

Floor-standing boilers have a wider range of models. Their price depends on the power of the boiler. Thus, the most powerful boiler ZHITOMIR-3 KS-G-080SN has a thermal power of 80 kW. A floor-standing gas boiler is capable of heating a building with a heated area of up to 800 sq.m.

Floor-standing gas unit Zhytomyr

The presence of an additional letter “B” in the name, for example, ZHITOMIR-3 KS-GV-080SN, indicates a double-circuit gas boiler “Atem Zhitomir-3”, which can not only heat the room, but also heat water.

The amount of hot water produced is proportional to the thermal output of the boiler. This dependence is due to the presence of a copper coil inside the heat exchanger. Boilers with a higher heat transfer value also have a larger surface area of the coils. This explains the high hot water output.

Wall boilers

Wall-mounted boilers have a smaller range of sizes. They are less often installed inside private houses. The main purpose of ATEM ZHITOMIR wall-mounted boilers is heating apartments in multi-storey buildings. Wall-mounted boilers are much lighter in weight. They have a lower heat exchanger area. The maximum area of such devices allows heating up to 150 sq.m of housing area.

Gas wall boiler Zhytomyr

Wall-mounted boilers have a peculiarity - they are connected to coaxial chimneys that exit through the wall.

How to turn on an automatic gas boiler?

Turning on the boiler

to work with

Kare automation press and hold the solenoid valve trigger button; press and release the piezo lighter button (you may have to press several times until the igniter starts to burn);

Interesting materials:

What to do if the phone does not find the speaker? What to do if the phone does not disconnect from the headphones? What to do if your phone does not connect to the TV via USB? What to do if your phone does not connect to the TV? What to do if your phone does not connect to Wi-Fi? What should I do if my phone and headphones don't work? What to do if the phone does not respond to charging? What to do if your phone doesn’t recognize Xiaomi bluetooth headphones? What to do if the phone does not see the Bluetooth device? What to do if your phone doesn't see Bluetooth?

Design features

The general structure of the Zhytomyr floor-mounted gas boiler is shown below:

The design of the water heating installation is simple and ensures energy independence for all models of the manufacturer. The gas burner is an atmospheric, single-stage type from the Italian brand POLIDORO, of simple design, whose reliability has been tested by time. The automation systems for gas boilers Zhitomir, made in Italy, are equally reliable in operation. The automatic non-volatile gas valve of the EURO SIT brand is the most popular among all manufacturers of boiler equipment; leading foreign and domestic brands install it in their products.

To transfer thermal energy to the heating system, the installation uses a fire-tube-type steel heat exchanger. This means that high-temperature flue gases pass through several pipes immersed in the water jacket of the boiler. They transfer their heat to the water and come out at a temperature of 110-150 ºС. The pipes have a rectangular cross-section, which increases the exchange surface area and makes the unit more efficient. In double-circuit versions of boilers, coils of a copper coil are located around the heat exchanger pipes to heat water for household needs.

To slow down the movement of gas combustion products in smoke pipes and make it multi-pass, turbulators are used in the heat exchangers of floor- and wall-mounted gas boilers. Their additional function is to absorb soot deposits. The latter settle on the planes of these parts located perpendicular to the gas flows, and soot practically does not linger on the walls of the pipes.

Subsequently, soot deposits can be easily removed from the turbulators, since when disassembling the unit they are removed from the smoke pipes. This technical solution allows the internal surfaces of smoke pipes to remain clean for a long time and effectively transfer heat to the water jacket. Otherwise, a layer of soot deposited on the walls can significantly impair their thermal conductivity, then the temperature of the gases at the outlet will increase and the heat will be released outside.

Household gas boilers Zhytomyr are adapted to chimneys with insufficient draft. For this purpose, the unit is equipped with a direct damper, which opens the way for flue gases to the outside, bypassing the heat exchanger. It works like this:

- The damper must be opened before ignition. By default, the chimney has insufficient draft force.

- The valve adjustment wheel and the piezo ignition button are pressed sequentially, and the igniter lights up.

- The wheel turns a couple of notches, gas is supplied to the burner and it ignites.

- High-temperature gases (up to 200 ºС) begin to flow directly into the chimney. Due to the temperature difference in the chimney pipe, the draft increases and the boiler enters operating mode.

- After 5-7 minutes, the damper closes and heating of the coolant begins, the improved traction force is maintained.

The Zhitomir parapet chimneyless boiler largely repeats the design of its floor-standing “brother”. The difference is in the design of the chimney pipe; in suspended models it is coaxial. This is a double-walled pipe, inside which combustion products move, and air from the street moves towards them between the walls of the outer and inner pipes. Accordingly, the gas burner device does not use air from the room for its operation, but takes it from outside, while the combustion chamber is closed. In foreign analogues, a fan is used to suck in air; in Zhytomyr units, the entire process is energy-independent and operates with natural draft.