Connecting the boiler (installation-piping-installation) is NOT the next stage after purchasing a solid fuel boiler, it is important to decide who will install it and how, determine it in advance, and NOT buy a solid fuel boiler without installation, especially in Minsk. After all, having bought it, you can still install it crookedly, and then what is the point of a solid fuel boiler, you should approach it with all seriousness and responsibility. Tying a solid fuel boiler requires specific knowledge, skills and abilities. It is unlikely that you will be able to tie a solid fuel boiler yourself. Yes, and this is a dangerous idea. So, if you still decide to entrust the connection of a solid fuel boiler to a specialist, then our advice: try to understand this process and at least try to understand the nuances of installing the boiler yourself (you will continue to use it for many years and operate the heating system, by the way, the boiler is firewood is most often used and has more nuances for piping).

- Preparation

- Safety

- Scheme

- Photo

- Video

- Let's summarize

Piping is a set of works to connect equipment to the engineering system (boiler piping). There are harnesses: safety harnesses for sports and for industrial mountaineering, strapping of the foundation with boards.

We will try to list some of the nuances when connecting a solid fuel boiler. Installation of heating boilers begins with preparing the floor and removing smoke:

- preparing the base for installing a solid fuel boiler - it must be strictly horizontal. Because Since a solid fuel boiler weighs a lot, the floor screed poured under it should be 7-10 cm. The dimensions of the base should correspond to the dimensions of the boiler, increased by 10%.

- Also, any heating boiler (except electric) requires a chimney to be connected. It can be either indoors (not insulated) and exit vertically through the roof, or initially exit horizontally through the wall and rise along the wall of the house above the ridge (insulated). Any chimney must be cleaned annually and its condition monitored.

How to properly tie a solid fuel boiler

Piping a solid fuel boiler requires ensuring certain safety measures for the heating system:

- installation of an emergency valve (or boiler safety group). If the pressure in the heating system rises, an emergency discharge of the coolant into the sewer will occur. And this will prevent the boiler from exploding.

- Installing a cooling circuit on a solid fuel boiler will protect you from the boiler exploding, as well as from the need to recharge the heating system in the case described above.

- connecting a UPS uninterruptible power supply to the boiler and pumps will allow the heating system to operate properly even during a power outage, which we often hear about in the news in many settlements in Belarus.

- According to fire regulations, connecting a solid fuel boiler must only be done with a metal pipe (ferrous metal, galvanized, stainless or carbon steel), any option will do. As for diameters, most often we connect boilers with a power of up to 30 kW with a 1 1/4″ pipe, boilers with a power of up to 50 kW - 1 1/2″, and boilers with a power of up to 100 kW - 2″ or 2 1/2″.

- In the connection diagram of a solid fuel boiler and, accordingly, when piping a solid fuel boiler, it is necessary to provide an open or closed expansion tank (depending on the heating system). The volume of the expansion tank is calculated using a simple formula:

V tank = V system: 10The connection diagram for a solid fuel boiler requires installing an expansion tank on the return line. This will extend the life of the tank membrane.

- It is advisable to connect a solid fuel boiler (with a power of up to 70-80 kW) not by welding, but by threaded connections. In the future, this will simplify the maintenance of the entire system, and will also allow you to easily replace any failed component.

- The connection diagram for a solid fuel boiler implies the presence of a thermostatic mixing valve (for steel boilers this is protection against excess condensate, and for cast iron boilers it is protection against cold return flow, under the influence of which a section of the boiler may burst).

These are just some of the nuances that you need to pay close attention to when connecting a solid fuel boiler. The safety of the home heating system is the first place heating design begins.

Checking heating system elements

Without the correct functioning of all components of the heating system, it will not be possible to start it correctly. First of all, you need to check the operation of measuring devices - thermometers and pressure gauges.

It is also necessary to check the functioning of the protective elements. The system may not start if the bleed valve or air vent seats do not move due to limescale or rust. For this reason, each of them is opened manually.

The pressure of the air chamber controls the expansion tank; it must exceed the nominal value in the system by 5-7%. If the design of the tank allows you to change the membrane, it should be disassembled and checked in what condition it is.

The cost of the service for launching a heat supply system in a private household depends on many factors and is determined individually.

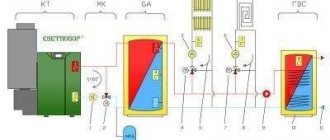

Boiler connection diagrams for a general overview

Let's look at the wiring diagrams. Simple boiler piping includes:

- circulation pump (1) to ensure the movement of coolant (water) in the pipes and equipment of the heating system,

- the expansion tank (2) takes excess water (coolant) from the system when it is heated and releases it back into the system,

- The boiler safety group (3) with a safety valve throws excess water into the sewer when the boiler boils.

Next come the safety systems for people and the boiler itself. We protect the boiler heat exchanger from exposure to excessively cold water, which causes it to fail ahead of time. We install a 3-way thermostatic mixing valve (8) - if cold water comes from the return from the heating radiators, which is more than useful for the boiler heat exchanger, the valve will turn on the addition of hot water.

Now we protect people from explosions and burns. A feature of the piping of a solid fuel boiler is: the combustion of solid fuel in the boiler is completely uncontrollable, like in gas and electric boilers. Therefore, when connecting a heating system with a solid fuel boiler, it is imperative to prevent excessive overheating of the water to 95 degrees. in pipes and heating radiators to temperatures dangerous for human touch. And for this there are 3 separate methods of cooling water to heating radiators, which can be used simultaneously.

Option 1: The mixing valve (7) adds cooler water from the return water from the heating radiators into the pipe to the heating radiators as needed. Looks simple enough.

Option 2: 4-way emergency cooling valve of the heat exchanger (4) with a remote sensor when overheating up to 95 degrees. It will run cold water from the water supply into the boiler through the return line, and throw the superheated water from the boiler into the sewer. Since this is possible when there is a power outage in the house. The boiler pump stops, but also the pump in the well. Therefore, cold water for cooling the boiler is taken from the water supply accumulator and it may not be enough: we install an additional hydraulic accumulator (5) with a check valve (6) to disconnect it from the water supply.

Option 3: Emergency gravity circuit with check valve (9) - the diagram shows this option, however, the circuit requires specificity, a certain low pressure and temperature, and may contain a heating radiator for these purposes.

Option 4: Use several methods at the same time.

Boiler room project for a private house selection criteria

Installation of a boiler room in a private house begins with planning and drawing up a project. It is problematic to implement such a task without the help of a specialist. In addition, a professional designer has a list of all standards and official documentation.

In the process of designing a boiler room in your home, you must indicate exact calculations on the drawings, determine the amount of necessary equipment and related accessories, and also describe all financial costs. You need to create a step-by-step guide according to which all work will be performed.

The complexity of the plan determines the duration of all official issues and documentation preparation. Only when the paperwork is completed can the main work begin.

When drawing up a boiler room project, you should consider the following points:

- Operating mode of the heating system.

- Type of heat carrier.

- Installation location.

- Placement of the ventilation system.

- Availability of lighting fixtures.

Determining the optimal location for the boiler room

If you are going to carry out large-scale and general renovations in your house, the arrangement of the boiler room should concern you first. But since according to the old design it is sometimes impossible to install a boiler inside the home, you have to build an additional extension or choose a specially designated place in the home.

The first option is not popular, because... it requires additional investment of time and money. Such a structure does not always fit into the overall concept of the style of the room.

If the option of designing a boiler room in a house is being considered and there are no problems with the layout, then it is necessary to take into account all the requirements and standards that are specified in SNiP. Taking into account all the rules for the location of boiler equipment in the basement of a private house or any other part of it, you will be able to deprive yourself of additional hassle and will be able to implement the project in a short time.

Premises requirements

When planning to equip a room for a gas boiler, you should consider the following requirements:

- The distance between the ceiling is 2-2.5 m.

- The room must be located separately from the living areas.

- The area of the extension is calculated using the following formula: one boiler must have at least 4 m².

- The doorway must have a width of 0.8 m.

- The walls and ceiling are made of materials that are protected from fire.

Finishing the boiler room from the inside

If the walls of the boiler room are made of brick or concrete, they must be covered with plaster and treated with a water-based paint composition. As an additional finishing layer, you can use ceramic tiles or metal panels for cladding. If internal work is not carried out, there will be a lot of dust in the building, which will negatively affect the performance of the equipment.

If there are wooden walls, they must be carefully treated with a fire-prevention agent. Sheets of drywall should be secured and the surface covered with plaster. Aluminum sheets are fixed behind the boiler unit.

The floor covering is leveled using a cement-sand screed, since ceramic tiles do not have the required strength, and under the influence of heavy equipment they can become deformed or crack. Another reliable material is porcelain stoneware, which is characterized by high strength and is not afraid of heating.

To protect the boiler room from leaks, it is necessary to install a drain gutter. If it is not possible to do this, waterproofing pipes are placed at a height of 5-10 cm from the level of the floor covering, and the boiler unit is raised to a height to isolate it from interaction with the liquid. Bricks or porcelain stoneware can be used to cover the boiler.

When choosing the latter option, you should opt for light shades with a matte texture, since they do not accumulate shoe marks and dust.

A pipeline and other communications are laid in the ceiling space above the boiler. To hide them, you need to prepare a plasterboard box.

Requirements for the door

When installing a door, it is important to choose non-combustible materials, because... wood ignites quickly

The best solution is steel treated with a non-flammable paint composition.

You can treat the surface with nitro enamel. Combining powder with nitro enamel is the most optimal option, which protects the structure from fire, the negative effects of ultraviolet rays and other factors.

The minimum door width stated by SNiP standards is 80 cm.

What you need to know about ventilation

In order for the boiler to operate without failures, it is necessary to create a good ventilation system and prepare oxygen by releasing it from the air. This is necessary to prevent carbon monoxide from accumulating in the room and entering the house.

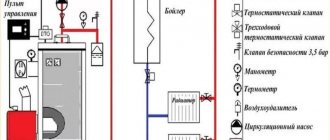

Solid fuel boiler piping

Solid fuel boiler connection diagram

The piping of a solid fuel boiler with a connection to a closed circuit of the heating system necessarily contains a boiler safety group, an expansion tank and a circulation pump. Solid fuel boilers do not have a number of safety functions; therefore, the piping of a solid fuel boiler must additionally include the specified safety systems. Safe connection of the boiler is the safety of life and health of household members and must ensure the minimum operating temperature of the coolant at the entrance to the boiler at a level of at least 60°C. The heat exchanger should not be subject to large thermal changes - this will prevent unwanted metal deformations and the formation of tar and soot in your boiler. This condition is ensured by the installation of a mixing unit. It will maintain the required coolant temperature at the inlet to the solid fuel boiler.

Installation of solid fuel boilers and piping of a solid fuel boiler should be carried out exclusively by specialists. Installing a solid fuel boiler yourself is extremely dangerous, especially since such a boiler installation will most likely not be accepted by firefighters. This material on how to connect a solid fuel boiler is intended to introduce you to the topic so that your choice and control of installation specialists is more competent.

Photo installation of heating – Minsk region, Dzerzhinsk

Heating installation: Minsk – diagram drawing, Dzerzhinsk – boiler piping on site, chimney installation. Yes, we start by drawing in pencil a diagram of the future heating system of the house with real heating equipment: solid fuel boiler SAS 58 kW, buffer tank / heat accumulator S-Tank 2000 l, expansion tank 300 l, circulation pump Grundfos 32-60. By the way, like everyone else, the client chose chimneys for the Boiler House.

The installation of a solid fuel heating boiler in the photo was carried out by Boiler House Bai, Minsk.

Step-by-step installation of a heat generator and chimney

Do-it-yourself installation of heating system elements is not difficult, especially with proper preparation of the room and the immediate area where the structure will be installed.

Step-by-step installation instructions consist of several stages:

- Installing the device and leveling it vertically using metal pads or special legs. It is necessary to take into account the ratio of the pipe and the hole prepared for the installation of the chimney.

- Prepare several insulated pipes or take regular ones, wrapping them in basalt fiber.

- Make a hole in the wall that is 35-38 cm wider than the chimney pipe.

- Install a metal passage box, pass a pipe through it, and fill all remaining space with basalt wool.

- From the outside, the chimney pipe is installed vertically, parallel to the wall. A kind of umbrella is attached to the top to prevent the ingress of large amounts of water, and to the bottom there is a collector for condensate.

- The part of the chimney coming from the heat generator is mounted at a slight angle towards it.

After completing the work, you should make sure that the chimney is not located under the ridge of the roof and water will not flow into it during rain or melting snow.

Also photo: VIEW PHOTO OF INSTALLING SOLID FUEL HEATING BOILERS

Connecting a solid fuel boiler with a heat accumulator (buffer tank) on video

In the video, Sergei Nikolaevich, chief engineer of the House of Boilers, Minsk, begins connecting a solid fuel pellet boiler with a heat accumulator with simple truths.

Installation of a solid fuel boiler, installation of a solid fuel boiler, piping a solid fuel pellet boiler with a heat accumulator, answers to the question of which boiler is better and what heating equipment to buy - our entire website of the online store House of Boilers by, Minsk is devoted to all these topics.

Author: Yuri Bedulin

24.01.2019

domkotlov.by

Have you already noticed that we like Altep boilers? This is true! We like their size, the thickness of the steel, the size of the firebox, the design of the heat exchanger with long smoke ducts... The price of Altep boilers is adequate, which is no less important in our time. The boiler, in the photo, has been heating warehouses near Minsk since 2018. This was a trial version for the client. Previously, they heated their warehouses with Atmos boilers. In 2019, the client ordered another boiler to heat a new warehouse. According to customer reviews, the customer liked the operation of this boiler more.

See: Solid fuel boiler ALTEP Duo UNI Plus 75 Connection, installation, installation and piping of a solid fuel boiler

Pellet boilers are at the peak of popularity. One of the most popular manufacturers is the Belarusian Tis. You can rightfully be proud that Belarusian minds and hands have made such a worthy boiler. And these are not just the words of sellers, but also feedback from installers and many users. Before the heating season, these pellet boilers sell like pie. Every year before the heating season there is a queue of people who want to receive a boiler even with 100% prepayment. But you have to wait from 4 to 6 weeks.

See: Boiler TIS DUO new Pellet 95 (tis duo pellet) TIS boilers (TIS) - reviews Installation, installation of a pellet boiler

The Altep boiler was installed in the Vitebsk region instead of its predecessor Burnit. The customer approached us with a technical task - to be able to heat the house with both wood and pellets. We have been doing this type of work for a long time and with pleasure. We feel like a fish in water, by the way, without false modesty.

See: SOLID FUEL BOILER ALTEP DUO PLUS 50 Pellet burner KIPI ROT POWER 50 kW Installation of pellet burners Pellet hopper for 1200 l.

This is a selection of photos from an object near Bobruisk. Customers asked at the beginning of 2022 for help in selecting a solid fuel boiler for their country house. After discussing the wishes, we prepared a commercial proposal for consideration. The control center was made up of parts: water supply, sewerage, radiator stage, heated floor stage and furnace room. The client also ordered the execution of the work in stages. The following equipment is installed in the furnace room: boiler SAS UWT 17 with automation, heat accumulator S-Tank, indirect heating boiler Elektromet in wall-mounted design. Barberi pumping groups are responsible for the operation of the heating system. To maintain a positive temperature when the owners of the house are away, an Evan electric boiler was installed. In our opinion, the furnace turned out very well. In addition to functionality, there is also aesthetics.

See: Solid fuel steel boiler SAS UWT (with automatic) 17 kW Heat accumulator S-Tank AT Prestige 500 l

Solid fuel boilers are our shared love. We like to sell and install solid structures. We work with many manufacturers of solid fuel boilers. But there are favorites, including the Ukrainian Altep. Our installers affectionately call him Altepchik (cute, not for brutalists). This manufacturer also has a unique boiler for the Belarusian market with an upper chimney outlet. For houses in which reconstruction and replacement of old boilers with new ones is underway, this is an ideal option. It does not take up much space, has a top connection, is made of 5mm steel and is equipped with automation.

See: Solid fuel boiler ALTEP Classic Plus 16 Installation of solid fuel boilers Installation of insulated chimneys

The object was installed in February 2022. The client received a question: will all the equipment fit into a small furnace room and so that all piping units are accessible for maintenance. We thought for a long time, turned it around and this way and that... And they said that we would squeeze it in. But only virtuoso installer Vladimir Trukhan can handle the installation of this complex boiler room. That’s when we decided that we would make an estimate for approval. When the estimate was ready, the client said the usual objection “EXPENSIVE.” I had to recalculate the estimate for “welding.” It turned out cheaper and we shook hands with the client. Vladimir installed this boiler room in 4 days. We think the result is very good!

See: FLAT HEAT ACCUMULATOR ALTEP 800 l Steel solid fuel boiler TIS UNI 15 Buffer tank piping (heat accumulator installation)

Bestseller!

Pellet boilers

Pellets are wood pellets. In other words, pressed wood waste, which is consumed by the heat generator as it is burned. As a rule, the volume of the pellet boiler bunker is sufficient for autonomous operation of the heating system from 1 to 6 days with an efficiency of up to 85%. Based on practicality and efficiency, a pellet boiler is the best choice for heating a private home. From a budget point of view, this is one of the most expensive types of boiler equipment.

In addition, when purchasing a pellet boiler, you should solve the problem of storing pellets. They cannot be stored outside, as they will have high humidity. For storage in the house you need to allocate a sufficiently large space with a good ventilation system.

Solid fuel boiler Defro KDR 35 kW

Long-burning floor-standing boiler with a longer firebox and manual fuel supply. Efficiency 81%. Automation S3P with PID function (OPTIONAL). Heat-resistant boiler steel P265GH 6 mm thick. Includes mechanical regulator RT-4. Power 35 kW. Reviews (2)

RUB 6,166 Buy

Bestseller!

Foundation

It is necessary to say a few words about the base on which TT equipment is installed.

- For boiler units with a power of up to 50 kW, a screed can be used as a base.

- For equipment with a power of more than 50 kW, a separate concrete foundation is required, not connected to the foundation of the house.

- The foundation must protrude at least 250 mm beyond the boiler installation.

Installing a solid fuel boiler in a wooden house does not have any special requirements, with the exception of the use of floor materials.

The TT boiler unit cannot be installed on a wooden base. Advice: If a wooden house does not have a separate foundation for a boiler installation, then it can be made from fire-resistant bricks, on which a sheet of asbestos and metal is laid. The base must be larger than the boiler TT (minimum) by 150 mm. from each side. In front of the loading door, the metal must extend at least 200 mm beyond the heating installation.

The problem of arranging a separate foundation is associated with the large weight of powerful heating units and the vibration loads that boilers equipped with a screw conveyor for supplying fuel exert on the TT support.

Important! To ensure the required fire resistance (45 min.), combustion chambers must be made of non-combustible materials.

Premises requirements

Solid fuel boilers are installed in rooms with low humidity levels. The parameters of the boiler room are determined by the number and parameters of the equipment. As a rule, an area of 7-8 square meters is sufficient. You should also decide on where to store the fuel. It must be protected from atmospheric influences.

The walls of the room where the boiler will be installed are covered with a thick layer of plaster, asbestos and sheet iron. You need to pay attention to the ceiling. If it is not protected from high temperatures, the upper part of the room must be at a distance of at least 120 cm. There are several more requirements:

- the boiler should be located on a fireproof platform 7-10 cm thick;

- It is necessary to have brickwork and steel sheet at the base;

- it is allowed to use a cement screed with a thickness of 5-8 cm;

- A safety zone is established from the combustion chamber - 40-50 cm.

Increased attention should be paid to wooden structures. They must be protected by brickwork.

Ventilation in the boiler room is mandatory. It is designed to perform several important functions:

- ensure the supply of air masses necessary for the combustion process;

- remove harmful gases from the room that are formed during fuel combustion;

- create equal amounts of exhaust and supply air.

The room must be equipped with two openings: supply and exhaust.