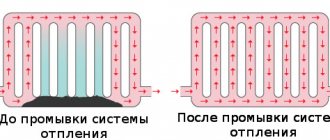

Equipment for flushing the heating system is used to effectively remove scale and other deposits that impede the efficient functioning of the equipment. The coolant that circulates through the pipes and radiators of houses contains a varied “cocktail” of all kinds of salts and even sludge that comes from water intakes and adheres to the walls of heat sources. All this interferes with the normal water flow within the system.

Photo 1: It’s not easy for water to get through rusty growths

Experts recommend flushing pipes at least once a year. It is more advisable to perform this procedure before the start of the heating season.

Ignoring flushing measures by utility services at any time can reduce the efficiency of the heating complex. Therefore, it makes sense to turn to the services of companies that professionally solve such problems. RemTeploService LLC is ready to quickly perform work on any site.

Flushing pump for descaling

During operation of boilers and heat exchangers, large amounts of rust and other contaminants can accumulate in them over time.

This can be prevented by using a descaling circulation pump. The benefits of its regular use include:

- preventing many breakdowns of expensive equipment;

- extending the service life of heat exchangers and boilers;

- reducing the load on the operating equipment after flushing operations and increasing the output received from it, which will be reflected in a decrease in its energy consumption.

Descaling using circulation equipment must be done at least once a year at public utility facilities and at least 2 times a year at production facilities, depending on technical regulations. The big advantage of using such equipment is that there is no need to disassemble heat exchangers and boilers to clean them.

How to make a booster with your own hands

In order to make a booster for washing heat exchangers with your own hands, you will need:

- reagent reservoir - a plastic canister with a minimum capacity of 10 liters, more is possible;

- flexible hoses ½ or ¾ inches;

- water pump.

Homemade booster.

You need to make a booster based on the type of pump. This can be a submersible or free-standing pump. If the pump is submersible, then no additional holes in the tank are needed. A hose is connected to the pump, which is screwed onto the heat exchanger. The second hose (return) will carry the acid directly back into the tank. In this case, even an ordinary bucket can be used as a reservoir for the reagent. It is important that the pump is suitable for working with acids.

It is more convenient to use remote pumps; by the way, even a regular electric circulation pump for heating is suitable. To connect it, you need to insert a metal pipe at the bottom of the tank and tighten it with nuts to the walls of the tank. Everything must be sealed. Next, a coarse filter is screwed onto the squeegee - you cannot allow debris to get into the pump, and it will be better for flushing. A pump is screwed behind the filter, from which a hose goes to the heat exchanger. The circulation hose goes straight into a plastic canister.

The average service life of heating pipes in an apartment is at least 25 years, but even half a century is not the limit.

Here we told you which pipes to use for heating in a private house with autonomous heating.

The disadvantage of a DIY booster for washing heat exchangers is the absence of a heating element. Descaling with a cold reagent will take longer, but you can save on electricity.

How to choose the right flush pump

When choosing washing equipment, you should consider what it is intended for:

- for boilers (there are models for domestic and industrial boilers);

- for heat exchange equipment (should be selected depending on the dimensions of the heat exchanger itself and the type of coolant used in it);

- for heating systems (devices with very high power are used for these purposes);

- universal installations (their only drawback is their high cost).

The minimum capacity of the circulation pump must be at least 50% of the volume of the equipment being washed. It can be made of special industrial plastic or composite materials. The first option is cheaper, and the second is more durable and resistant to heavy loads.

It is very convenient to have devices that make it possible to change the direction of fluid movement during flushing operations. This allows you to significantly reduce the time required to remove various types of contaminants and make washing work more efficient.

Types of flushing

There are at least three flushing options that successfully cope with system clogging with corrosion products, scale and sediment:

- hydroflushing (bubbling);

- hydrochemical treatment;

- pneumatic hydraulic shock.

Hydroflushing

A portion of compressed air and high-pressure water is supplied to the pipeline through equipment for flushing heating systems. Under a shock dose of liquid, the deposits formed inside are successfully exfoliated.

Photo 2: Hydrodynamic flushing

To achieve an acceptable result, not the entire pipeline is flushed, but in its individual sections. Hydrodynamic flushing is divided into:

- flow-through;

- filling method.

In the first case, the system is filled with water (the air collector valve opens completely). Once filling is complete, the valve is tightened and a stream of compressed air is supplied to the system. Such an operation can be curtailed as soon as completely clean water begins to flow out of the open pipe. At the end of the session, the system is freed from the spent water-air charge.

The filling method involves pouring water into a section of the system and simultaneously closing the air collector valve. Air is then supplied through another valve. Before starting cleaning, you need to carefully study the level of contamination - it and the length of the area being cleaned determine the duration of the air supply. At the end of the air attack, the shut-off valves are closed. At the end of the procedure, a solution of water and sediment is drained into the drainage. The system, cleared of plaque, is repeatedly washed with plain water.

Chemical cleaning

This method is based on the dissolution of in-pipe deposits with reagents. Experts consider it the most reliable, since the reagents destroy scale almost completely, and the rinsing with tap water that accompanies the procedure removes deposits from the system to the outside. Moreover, the so-called inhibitors or passivators included in the chemicals protect pipes from corrosion and help extend their service life.

The chemical solution is introduced into the pipes by connecting equipment for flushing heating systems. The pump pumps the liquid along the line. The duration of the process is determined by:

- type of heating system;

- the material from which it is made;

- degree of pollution;

- selection of reagents.

The only negative is the need for mandatory disposal of used cleaning solutions.

Photo 3: Everything is ready to flush the heating system

Pneumohydraulic hammer

The technique is used to clean a highway up to 60 meters long. A shock wave propagates over this distance, moving through the pipes at a speed of 1500 m/s. Thanks to the “massive assault”, deposits easily peel off from the inner surface of radiators and pipes. The good thing about this method is that it can be carried out without dismantling individual components.

Buy a flushing pump for heat exchangers and heating systems

offers flushing circulation equipment for heating systems, boilers and heat exchangers, as well as spare parts for them from domestic and foreign manufacturers with delivery in Moscow by couriers and to other cities of Russia by transport companies. To buy a reliable washing unit at affordable prices, explore our catalog and read detailed descriptions of the technical characteristics and capabilities that are provided for each model. If necessary, our employees will provide detailed advice on available products and help you choose the most suitable equipment to achieve your goals.

When is system flushing required?

Signs indicating the need to remove dirt and plaque:

- The temperature on the surface of the devices decreases significantly.

- The interval between turning on the heating system and completely warming up the radiators to the required levels increases.

- The batteries warm up unevenly, you can feel it to the touch: warm bottom, cold top.

- When radiator heating is completely absent, only the pipes remain hot.

- The monthly heating bill is increasing.

Facilities and equipment

Scale and rust reduce thermal conductivity. To maintain temperature conditions, it is necessary to increase fuel consumption and budgetary funds. Equipment such as a compressor is used for washing.

Cleaning the system with special equipment

Attention! Within 10 years of operation, the pipeline without cleaning can become clogged by 50%. One millimeter of layering on the inner walls increases fuel consumption by 25%. If you do at least one cleaning, the heating efficiency increases and budget costs are reduced.

Selecting equipment for flushing heating

Electronically controlled devices are considered the best equipment.

When using them, there is not a simple supply of chemical solutions or streams of compressed air, but a complete analysis of the intensity and nature of vibrations in the circuit. The operator is only concerned with timely regulation of the frequency and power of the pulses.

The devices are equipped with special sensors that monitor pressure and fluid flow and protection in case of unexpected activation.

Washing technology

First, it is necessary to check and assess the condition of the system. Afterwards, the cleaning method and equipment mode are determined. There are 2 ways:

- Filling method. The pipeline is filled with pure liquid or with chemical impurities. After 30 minutes the compressor turns on and compressed air is supplied. The supply valve is closed and the drain valve opens. Dirt is thrown out through it. The procedure is repeated until the water becomes clear.

- Flow washing method. This is a continuous supply of liquid with compressed air into the heating system. The growths on the walls peel off and are instantly removed.

Not every compressor unit is designed for two cleaning methods and can only supply water or compressed air. Ask the seller about technical specifications.

Design and features of washing devices

Boiler washing equipment consists of several main elements:

- A container into which the washing solution is poured. Because it contains harsh chemicals, the tank is made of highly durable, acid-resistant plastic.

- A pump responsible for moving a container through a pipeline system. It also maintains the required pressure level for intensive cleaning.

- A heating element (not present in all models) that ensures the required temperature of the rinsing solution.

Rules for working with equipment

Equipment for washing boilers and heat exchangers requires careful and careful handling with strict adherence to the instructions. The amount of reagent must not exceed the specified minimum and maximum markings on the tank. This is especially important for Italian sinks with a remote pump. Washers with liquid should not be carried, and during operation the lid must be opened to remove the gas formed.

The equipment requires compliance with the temperature level. The reagent should not be heated above a certain temperature (usually 40 or 60 degrees, the value is indicated in the instructions), this will lead to increased corrosiveness.

After completion of the work, the remaining acid solution must be neutralized and removed from the tank as quickly as possible. Following the manufacturer's instructions ensures that the unit can be used repeatedly without failure for washing heat exchangers, pipes and radiators.

Booster

Boosters are devices for chemical washing of heat exchangers in boilers and columns, any radiators and for cleaning the heating system. The operation is carried out without the need to disassemble the system. The installation consists of three parts:

There are systems without heating elements. However, they have low efficiency. Let's see how to make a booster for flushing heat exchangers. The first thing you need is a reservoir. A plastic canister with a volume of 10 liters or more can act as a container. You will also need ½ or ¾ inch hoses and a pump.

A booster is made based on the type of pump. This may be a submersible element or a separate pump. In the case of submersible, no holes are needed in the tank. A hose is connected to the pump, which is connected to the heat exchanger. The second one is taken out into the tank. The main thing is that the pump can withstand the effects of acid - there are a number of chemically resistant devices.

The disadvantage of such devices is the absence of TEN in the design. Washing the heat exchanger with your own hands using a cold reagent will take much longer. It also means higher electricity costs.

This need did not arise yesterday. Of course, there are specialists who do this (they charge a decent amount for it). To flush the boiler, dismantle the heat exchanger and, after flushing, install it in place (it is unknown whose). If this is not done, then the consumption of gas (electricity) increases and, ultimately, the passage of the exchange fluid stops.

But neither the gods sculpt pots. Having rummaged through my “bins” I collected the necessary set of used components (so as not to buy). The task is to create a flow of flushing liquid through the heat exchanger (without removing it from the installation), heat the flushing fluid, and control the heating temperature (in the machine). Everything is done very simply, I can give details separately.

Here is a view of the insides of a gas boiler (wall-mounted), (there are no step-by-step photos of production) I’m not interested in showing off.

Connecting the flushing hose to the installation. The end of the washing unit is visible in the mirror.

Good afternoon, gentlemen, members of the forum. I have been visiting this forum for a long time, but I was inspired to register only now. It’s stuck, as they say. Actually the question: We deal with plumbing, boilers and water heaters. Until recently, heat exchangers were given to our partners for cleaning, and it’s profitable for them, and we have less responsibility (although there is less money.). And now we’re ripe - we should get some kind of booster ourselves. Question in our market it is represented only by boosters AQuamax 10, 20, 40. I called the company and asked how it was, they say no one has returned it yet (of course). There are no reviews anywhere. Can you advise, don’t take it, it’s needed purely for washing heat exchangers of boilers up to 36 kW (10 liters would be enough). What kind of pump is there, well, obviously not peristaltic (as would be logical)? Can it be washed with diluted hodgepodge? Is it necessary to clean the insides after washing? Isn’t the reagent eating the insides? In general, who can share some information? Otherwise, in a stupor, 300 euros is not expensive, but if you call for 30 washes, then somehow it’s not comme il faut. If anyone can tell me what, rub your nose in in the corresponding thread, or share how to implement the idea without involving a bourgeois unit, I will be very grateful (within reason). Which pump would be better for such purposes (there are no peristaltic compact ones or I haven’t found them, and all the rest will be eaten up by chemistry) and how to implement reverse in this design.

Help, all hope is on you.

Thank you in advance for your answers. Sincerely, Alexander.