General information

Due to the high cost of diesel fuel and electricity, as well as additional costs for connecting gas equipment, in many cases the choice is made towards a solid fuel boiler. As a result, you get a heating system whose operation is not affected by the presence or absence of external energy sources. As a rule, most devices of this type do not require electrical energy, or consume it in very small quantities.

Most often, solid fuel boilers are equipped with individual heating systems in remote areas experiencing serious difficulties with the supply of main gas. There are entire areas of our country where wood boilers are used as the main heating unit.

From theory to practice

More often, those who want to make equipment with their own hands opt for a vertical solid fuel boiler. The manufacturing process will be considered using the example of a solid fuel boiler for heating a house with an area of 100 m2. This system consists of seven radiators and a plumbing system.

So, let's make a heat exchanger:

- We manufacture vertical bases for the heat exchanger. To do this, we take four profile pipes, each 30 cm long, which will be located on the side of the combustion chamber;

- We make four holes in them with a diameter of 5 cm using a gas cutter. We remove irregularities with an angle grinder (grinder). There should be eight holes;

- in the pipes that will be located at the back of the equipment, we make four holes with a diameter of 40 mm and four with a diameter of 50 mm. All of them should be located on the side connected to the front pillars. The result should be eight holes;

- in a profile pipe 500 mm long, we cut out a hole for attaching a pipe through which waste water will be discharged;

- We make a hole in the upper part of the rear pillar to supply water to the system.

Then we proceed to assembling the heat exchanger. The vertical bases are connected by a profile pipe. To do this, we place it on bases installed perpendicular to the surface. We weld the joints. We connect this entire structure on the reverse side with a profile pipe with holes for water drainage. As a result, we get the front wall of the heat exchanger.

Next, we install the vertical bases perpendicularly and weld them with four round pipes. This turns out to be the rear wall of the heat exchanger. We connect the front and back walls together. To do this, you need to bring the longitudinal pipes to the holes and weld them, and then weld the pipes for supplying and discharging water to the structure. We weld the joints using pieces of metal and check the strength of the heat generator.

After checking the strength of the weld, close the water drainage pipe with a plug, and pour water into the inlet hole. We check the tightness of welding joints for visible leaks.

Making the case will also require effort. To do this, we cut out eight walls from sheets of heat-resistant steel - 2 front, 2 rear and 4 side. The area of each of them should be 850 x 300 mm. We take all measurements using a meter ruler and cut the material with a grinder. Then we cut out two plates measuring 450 x 450 mm: one for the bottom, the other for the top plate of the boiler.

We make two holes for the doors in the front wall: the first - at the level of the grate for igniting the fuel and cleaning the combustion chamber, and the second - a little higher level for loading fuel. In our work we use a drill and a grinder. From the sheet we cut stiffening ribs 80 cm long.

Water jacket

The principle of operation of a solid fuel boiler implies the presence of double walls in its firebox: in the interval between them they are filled with coolant. This design is called a water jacket. As the fuel burns, the liquid in the water jacket heats up. This leads to the appearance of heat flows that lift the hot coolant to the upper part of the container. From here, hot water flows into the heat pipe. After the liquid passes through the entire heating circuit and gives off heat to the home, it returns back in a cooled state. For these purposes it has a lower pipe.

To speed up the circulation of water inside the heating system, special pumps are installed on some solid fuel boilers. However, most models are produced for open heating systems. This refers to schemes where the coolant moves not due to a running pump, but due to a slight slope of the pipeline. This is explained by the simplicity, reliability and efficiency of inertial systems. In addition, they are completely independent of the availability of electrical energy. Thanks to this, they can be used in remote areas deprived of the benefits of civilization.

Open circuit with gravity circulation

This option is easy to perform even for a beginner.

Here water circulates in the system due to the difference in density of cold and hot liquid. According to the laws of physics, hot water begins to flow upward (since its density is less), and then it cools down and returns to its starting point. Despite the fact that this type of strapping is quite simple, it requires compliance with a number of requirements. Firstly, in order for water to circulate freely in the system, you need to install the heating equipment half a meter lower than the radiators are located in the house. Secondly, in order to minimize the manifestation of hydraulic resistance, pipes with a cross-section of up to 5 cm are needed, while distribution pipes on batteries can have a value of 2.5 cm. Thirdly, locking devices and fittings directly affect the free circulation of water in the system, therefore, there should be a minimum of such elements.

But for the sake of fairness, it is worth saying that an open system with natural circulation also has a number of its advantages. In addition to the fact that it is the easiest to set up, the financial costs for it are not so great. True, the owner will not be able to constantly control the temperature of the coolant at the outlet, which is why the heating of the circuit is somewhat reduced. Also, the expansion tank occasionally remains open, which means that oxygen has contact with the coolant, which gradually increases the risk of corrosion.

To summarize, it is worth saying that experts recommend this type of heating scheme only for those private houses where people live from time to time, and not on an ongoing basis, for example, for a summer house.

Temperature control and regulation

As you know, a prerequisite for the combustion process is air supply. Moreover, the burning rate directly depends on the intensity of this supply. This principle is used in the design of solid fuel boilers, where there are mechanical dampers and dampers to regulate the air flow.

This design of a solid fuel heating boiler is characterized by simplicity and reliability: the damper is firmly attached to a special regulator. If the temperature rises excessively, this provokes expansion of the walls of the regulator and subsequent lowering of the damper. As a result, the intensity of oxygen supply into the combustion chamber decreases. The process of cooling the regulator activates the reverse process of raising the damper: air is able to flow in a larger volume, thereby increasing the intensity of combustion.

At first glance, it may seem that, given the operating principle of a long-burning solid fuel boiler, such a scheme for controlling the combustion process is too primitive and archaic. However, it is simplicity that is the key to its effectiveness and reliability. This explains the widespread use of slide control in most models of solid fuel heating boilers. Strictly speaking, this approach still does not experience much competition, because in this case, expensive electricity is not required.

Installing a heating system yourself

Boiler installation. In general, installing a TT boiler in a house is not considered some kind of super complicated work. You just need to set the heating boiler level, this is done by adjusting the legs of the boiler.

Ventilation and chimney

Any CO needs air, which, in fact, supports normal combustion of the fuel in the chamber. Therefore, it is necessary to equip the boiler room with good ventilation, and also install a chimney to remove gases and smoke from the firebox that remain after burning wood.

- Before making good ventilation, you need to carefully read the SNIP. If the room is large, then you can get by with passive ventilation, but if it is small, then you will need to install ventilation with coolers that will draw in air masses.

- Before directly purchasing and installing a chimney, you need to go to a website with an online calculator for chimney sizes. After all, the diameter and height of the pipe should be chosen depending on the location of the boiler, its power, as well as the possibility of outlet through the ceiling or wall.

The greatest attention should be paid to the issue of fire safety; passage through a wall or ceiling is made using fire-resistant materials

Here it is also important to be guided by SNIP

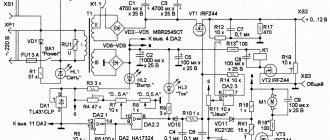

TT boiler connection

For proper operation of a solid fuel boiler, it is important to ensure the correct supply of coolant to the boiler. After all, it shouldn’t start working when it’s cold, since in this case condensation accumulates on the walls of the chimney, on which soot easily settles.

To prevent this from happening, it is necessary to provide a piping with a bypass and a 3-way valve.

- It is set to a temperature of approximately 55 degrees Celsius, in this case the water will circulate through the smallest circuit until its temperature reaches the desired level, then the valve will open slightly and gradually add coolant from the main circuit.

- The boiler is connected to a ready-made circuit made of polypropylene pipes with radiators; an expansion tank is placed at the top point, and a circulation pump at the bottom (if you do not have natural circulation).

Types of solid fuel boilers

The operating principle of solid fuel boilers allows them to be part of various modern schemes. We are talking about both the simplest single-circuit devices and the most powerful multifunctional units with high performance. There are several ways to classify solid fuel equipment.

According to the material of manufacture:

- Of steel . The cost of steel appliances is lower than that of cast iron. In addition, they are easier to maintain: cleaning takes place without any problems. One of the disadvantages is the sensitivity of the models to the temperature in the return pipe: it must be at least +60 degrees. This involves the use of special valves to maintain the required temperature by mixing hot water from the supply pipe into the return.

- Made of cast iron . They are characterized by higher durability, but require complex maintenance. The use of cast iron solid fuel boilers is recommended in case of continuous use. Purchasing an ultra-reliable cast iron unit only for emergencies is not a practical solution. Cheaper steel models can cope with such tasks.

Types of devices that you can create yourself

You should start building a boiler with an idea. The first step should be choosing the type of product to be created. In some cases, you can select the type based on the available parts, the specific configuration of the equipment, as well as the personal needs of the creator. Only after considering your own capabilities should you select drawings. As a final result, you should select a long-burning boiler based on the fuel combustion direction parameter:

- Lower. The fuel is ignited from below (most boilers work this way).

- Upper. The fuel ignites at the top and burns gradually towards the bottom level.

Boilers with a lower combustion direction can be divided into two types:

- Traditional. The supplied solid fuel elements are ignited and burned in one compartment. The smoke is released using a standard smoke exhaust pipe.

- Mine. There are two cameras here. One serves to supply fuel, and the other is a heat exchanger.

Several options for combustion methods are also being considered. The boiler may have a standard fuel absorption circuit. Here the process is carried out in the same way as under standard circumstances. A striking example is a stove in a private house. A boiler with pyrolysis combustion has a special design that involves the release of wood gas and its subsequent ignition.

An important difference is the heat exchanger. This element is manufactured using a special technology. There are several ways to solve the issue of its creation. In addition to the features of the heat exchanger, the boiler can use coal and wood for the combustion process, or only one of the presented fuel options. In this case, the rationale for using a certain fuel should be calculated in advance. The design of the product itself will depend on this choice.

Principle of operation

The boiler runs on solid fuel, usually wood, peat, lumber waste, special wood briquettes, coal and pellets (pellets made from crushed wood, resin, pine needles, etc.). Particularly popular are universal-type devices that can consume almost all types of solid fuel.

According to the method of heat transfer, boilers are:

- Air.

- Steam.

- Water (found most often).

According to the principle of fuel combustion:

- Traditional . They work on wood and coal. The operating principle is the same as that of a conventional wood stove.

- Long burning . Innovative development in the field of heating equipment. Long-burning solid fuel boilers have the form of an elongated combustion chamber surrounded on all sides by a water jacket. When burning, the flame spreads not from bottom to top, but from top to bottom, reminiscent in this respect of the process of burning a candle. The operating principle of a long-burning boiler allows complete combustion of fuel to be achieved. At the same time, the combustion interval of one load of fuel increases (up to 7 days). A long-burning boiler operates, as a rule, at a consistently high coolant temperature, which increases its efficiency by an order of magnitude. The uninterrupted and safe operation of such models is achieved by incorporating fans for emergency extinguishing, a safety valve and a circulation pump into the design.

- Pellet . Special pellets are used as fuel here. Such boilers are additionally equipped with an automatic pellet supply system and a fuel storage bunker. Thanks to electronic sensors, the presence of fuel inside the firebox is monitored. To operate such a system, a stable electrical supply is required.

- Pyrolysis . Unique equipment where, along with the energy from the combustion of solid fuel, the heat release of gases is also used. This makes it possible to convert a small amount of fuel into a significant portion of thermal energy. As a result, an increase in boiler efficiency and a reduction in harmful emissions is achieved.

The operating principle of long-burning solid fuel boilers makes it possible to use automation. Operating units of this type is so simple that a child can handle it.

Detailed instructions for making a structure with your own hands

A simple non-volatile top combustion boiler is made like this:

- A hole is cut out in the old cylinder and a curved smoke outlet pipe is welded in this place. It is better for a beginner to use MP-3 electrodes.

- The upper part is scalded around the perimeter with sheet material 2-5 mm thick.

- A lid is made from the cut off top of the cylinder by cutting a hole in it and attaching the neck.

- An air distributor is made by welding a disk with channels from a corner to the end of the pipe. The part is equipped with an adjustable damper.

- Making a water jacket. To do this, insert the cylinder into a pipe of larger diameter and weld the structure at the ends.

A non-volatile boiler can be made from a cylinder.

Startup order:

- Fuel is loaded into the inner chamber and ignited at the top.

- Place the air distributor disk on the firewood so that its pipe faces the sky.

- Put on the lid.

By adjusting the draft with a damper, an optimal combustion mode is achieved.

Calculation of thermal power

The burning time of a properly manufactured boiler is 12 hours. Based on this, its power is determined by the formula:

N=n*(m*15*10^6/ (12*3600)), where:

N - installation efficiency, taken equal to 60-75%;

m—mass of fuel load, kg;

15*10^6 - specific heat of combustion for dry firewood (birch, pine), J/kg;

3600 is the number of seconds in an hour.

Calculations show that fuel weighing 27 kg produces a power of about 7 kW.

Results

At the beginning of the review, we looked at the simplest models, which are not only cheap, but also quite reliable. As they become more complex, improve their functionality, and equip them with automation, not only the efficiency of the devices increases, but also the cost.

As a rule, the more complex the design of the unit, the higher the price of the direct model and its installation. By the way, it is better to entrust the installation and connection of heating equipment to professionals.

It is worth contacting specialists to carry out preliminary calculations to make sure that your choice is correct. Because a boiler is a little more complicated than a heating stove for a home.

Expensive models are characterized by comfortable operation and operation with minimal human intervention. They do not require frequent fuel supply; the combustion processes are controlled by an automatic system.

Go to choosing a solid fuel boiler

Specifications

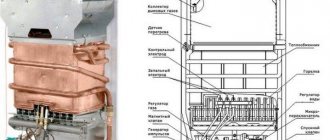

Heat exchanger of an industrial water heating boiler

The main technical characteristics of water heating equipment are as follows:

- device - fire tube, water tube;

- operating temperature - low temperature (up to + 115 ºС), high temperature (+ 115-200 ºС);

- coolant - water;

- functionality - single-circuit (heating only), double-circuit (heating, hot water supply);

- nominal pressure in the system - 0.6-0.8 MPa;

- produced power - 3-28 kW;

- types of fuel - firewood, briquettes, gas, diesel, mining, fuel oil, electricity;

- control - manual, automatic.

The choice of product is made based on its purpose, size and configuration of the facility in which it will be installed.

Application area

Powerful models are installed at facilities where large volumes of water need to be heated

The scope of application of hot water boilers extends to all areas of human life. The products are used for heating residential and commercial buildings, covering almost all areas of industry:

Subject to compliance with safety requirements, heating equipment can be installed in the following places:

- apartments, dachas, cottages, private houses;

- warehouses;

- agricultural buildings;

- buildings for keeping animals and poultry;

- storage for vegetables and grain;

- hangars and closed pavilions;

- mines, drilling rigs, artels and settlements located outside populated areas;

- tourist centers and holiday homes.

When choosing a boiler, it is recommended to pay attention to the origin of the product. Priority should be given to trusted, world-famous manufacturers.

Classification

Currently, all industrial heating equipment is divided into several categories. The main division occurs into two groups. If the main sign of separation is the movement of gases or water, then industrial boilers are divided into fire-tube and water-tube. In the first case, heating is carried out with saturated steam with a high moisture content, in the second - with water brought to a temperature of almost +100 °C.

If the division is made according to the fuel used to heat water, then the classification here is broader:

- solid fuel;

- liquid fuel;

- electrical;

- gas;

- units running on alternative fuels.