The Stropuva solid fuel boiler is a long-burning heating unit. This fuel combustion process is characterized by the release of a large amount of thermal energy and high efficiency. The main feature of the Stropuva boiler is that firewood, pellets, fuel briquettes or coal burn in the firebox from top to bottom. In this case, combustion occurs exclusively in the upper thin layer of fuel.

It is very easy to understand the essence of such combustion using the following laboratory example. If you light an ordinary match and measure the combustion temperature, which occurs from bottom to top, the result will be as follows: in 15 seconds the temperature of the thermometer will rise to 60 degrees. Now let's light a match and measure the temperature as it burns from top to bottom. The results are impressive: in 30 seconds, and it will burn exactly twice as long, the thermometer will heat up to 120 degrees!

This is exactly what was adopted by the Lithuanian engineer Edmundas Strupaitis. He patented a long-burning scheme, and subsequently the Stropuva boiler was developed. A result that has literally become a legend in the heating world. Conventional solid fuel boilers have low efficiency, since heat losses during the combustion of solid fuel are high. Firewood and other solid fuels burn very quickly in them, so frequent refills are required. All these disadvantages are absent in Stropuv boilers.

Features of Stropuva boilers

The main feature of Lithuanian equipment is the increased combustion duration. One load of fuel is enough for 2-5 days, depending on the type. "Stropuva" are distinguished by top combustion. The movement of fire from top to bottom significantly increases the duration of the active phase. The thermal energy released by the fire is reduced; the design of the equipment is simple.

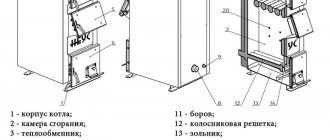

In fact, the boiler is a double barrel, which plays the role of a firebox and a water jacket. The inner part is usually steel or cast iron, up to 6 mm thick, and the outer part has a thickness of 2-4 mm.

The internal structure is welded in such a way that air distribution in the combustion zone is improved. For example, Stropuva long-burning solid fuel boilers have a special air duct, thanks to which the fire temperature is maintained for a long time.

Bubafonya stove with water jacket

Pyrolysis furnace Bubafonya from a gas cylinder with a water jacket.

Finally, we got to the domestic analogue of the Stropuva boiler, which is much simpler to implement, since it has a non-folding pipe for supplying air to the firebox. There are already so many instructions on how to make a Bubafonya stove with your own hands that only a blind person would not have seen them, unless, of course, they were interested in this topic. And why all? Yes, because the process is so simple and if you take the matter seriously, you can get a finished product from scratch in a day. What is the Bubafonya stove made from with your own hands:

- from a gas cylinder;

- from a barrel;

- from pipes

It can be either round or square. Let’s not repeat the same thing, just read the article: “Bubafonya stove from a gas cylinder” - and everything will become clear to you. Today we will consider a version of the product with a water circuit, as if we will try to repeat the principle of operation of the Stropuva boiler. All that is required is to make a simple Bubafonya and insert it into a pipe of a larger diameter. Thus, we obtain a gap in which the coolant will be heated.

Naturally, this space above and below is sealed so that various debris does not get there

What is important when making a Bubafonya stove with a water jacket with your own hands:

- use of heat-resistant steel;

- wall thickness of at least 4 mm;

- the presence of a tap for draining and replenishing water.

Immediately provide a hole in the upper part through the outer and inner walls for installing a chimney into it. There should also be enough space for water. The distance from the outer to the inner wall is about 10 cm. When connecting, do not confuse the supply and return pipes (supply from above).

Types and technical characteristics

At the moment, Stropuva is available in three varieties: wood-burning, pellet and universal. Each of these three varieties is designed for a specific type of fuel, but can work on any other, albeit with less efficiency. In total, the line includes 4 standard sizes: 10, 15, 20, 40 kW and a Mini version with a power of 8 kW.

The Stropuva wood-burning boiler is equipped with a special air distributor, which allows efficient burning of wood, and has the following characteristics:

ModelMini SS10S15S20S40

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,3 | ||||

| Firewood capacity, dm³ | 120 | 150 | 200 | 230 | 360 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Burning duration, h | 31,5 | ||||

| Price, rub | 65 000 | 87 150 | 92 348 | 97 545 | 107 730 |

The pellet version is equipped with a distributor for fuel pellets and an air supply manifold. Boilers operating on pellets have the following data:

ModelMini SPS10PS15PS20PS40P

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,3 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | |||

| Burning duration, h | 72 | ||||

| Price, rub | 65 000 | 91 350 | 97 072 | 102 795 | 112 980 |

The last representative of solid fuel boilers is universal. These devices can operate on coal, wood, fuel briquettes and pellets. The delivery set includes distributors for all types of fuel, as well as an air supply manifold. They have the following technical characteristics:

ModelMini SPS10PS15PS20PS40P

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,8 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Duration of coal combustion, h | 130 | ||||

| Price, rub | 65 000 | 102 700 | 114 608 | 121 380 | 127 995 |

As you can see, from the presented model range you can choose a solid fuel boiler for any room, type of fuel and available budget.

Where it all began

An engineer from Vilnius, Mr. Strupaitis, in 2000 patented a unique method of burning solid fuel that he invented, as well as a heating device that works using it. It was immediately dubbed a new generation device, completing the development of this class of equipment.

He managed to incorporate all the best ideas of a solid propellant device, these are:

- Energy independence

- High efficiency

- Long working time

In 2005, this product of the Lithuanian company received a quality certificate confirming its remarkable features.

And in 2008, the Stropuva solid fuel boiler became the laureate of the competition as the highest quality and most progressive. This became the impetus for Lithuanian products to enter the markets of other countries. Today their number exceeds two dozen. In Lithuania, it occupies a leading position in the sales ranking. In 2009, the Stropuva solid fuel boiler appeared on the Ukrainian and Russian markets.

Advantages and disadvantages

The equipment is recommended mainly for heating summer cottages and country houses for temporary use. The equipment is designed for 50-500 sq.m. area. The models are distinguished by automated control, which is configured remotely. From a remote distance, the owner can not only monitor, but also set the temperature.

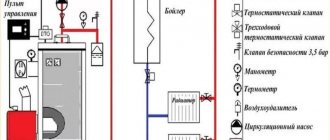

Important! The Stropuva boiler is compatible with pressure and non-pressure heating systems. The equipment is also suitable for gravity pipe routing.

The manufacturer provides warranty service for five years. Moreover, both components and parts, as well as the design of the boiler as a whole, are subject to warranty repair.

The main disadvantage is the high cost. On average, models are sold for 80-130 thousand rubles.* In this case, it is necessary to additionally install a special chimney.

The models are characterized by increased sensitivity to the quality of the coolant. Its temperature matters; for example, when it drops to 55 degrees, the efficiency of the equipment drops to zero. In addition, the internal surface of the equipment is covered with condensate, which forms a crust that reduces the transfer of thermal energy by 5-15%.

Note! For “Stropuva” long-term burning, only dry firewood with a humidity of about 15% is suitable. Raw fuel produces thick smoke, which causes soot to settle on the walls. Firewood produces a lot of ash, and untimely cleaning of it reduces the combustion temperature of the fuel.

At the same time, ordinary coal is categorically not recommended for Stropuv. When burned, the top layer of fuel turns into a sintered crust. It will not let the fire go lower, as a result, no afterburner chamber will be formed, and the efficiency of the device will drop significantly.

What influences the choice of heating equipment?

Purchasing complex devices is always associated with some difficulties.

They have a number of requirements that must be met, and not always one product sample meets all of them. Most classic solid fuel boilers have a number of disadvantages, which hinders consumer demand for them. However, the Lithuanian manufacturer managed to take into account all the shortcomings of standard heating equipment and do the seemingly impossible - to combine the advantages of all boiler equipment in one product.

The result is a Stropuva solid fuel boiler, the price of which, although quite high, is quite comparable with the quality.

Not the last place when choosing a heating device is given to its aesthetic characteristics. And here Stropuva rose to the occasion. Its original and ergonomic design was able to win over the consumer. It has a cylindrical shape with a minimum number of protruding parts, a pleasant color and, despite its rather large size, looks very impressive.

And if you have not yet chosen a boiler model for your home, then pay attention to Stropuva products, they will be able to conquer you with their data

Design and principle of operation of Stropuva boilers

Loading fuel into the Stropuva furnace is possible only from above. For better ignition, the main fuel is mixed with sawdust; you can add flammable liquid. Ignition also occurs through the top door, which must be closed tightly after all actions.

The chimney will form a draft, the fire will flare up from the top of the fuel. Quickly igniting the firewood will ensure good air flow. Fire and smoke rush through the inner housing structure to the smoke hole. Some of the hot gases also rush upward, simultaneously heating the metal and water.

The internal chamber of the air duct increases as the fuel burns. An afterburning chamber is formed in the increased space, which has a positive effect on efficiency. In this case, the fire will not flare up too much, the protection will work in the device. Thanks to the device, the air damper either opens or closes, increasing or decreasing the draft or combustion temperature.

Sources

- https://www.tproekt.com/kotel-stropuva/

- https://kotlydlyadoma.ru/kotel-dlitelnogo-goreniya-stropuva.html

[collapse]

Bubafonya stove with water jacket

Pyrolysis furnace Bubafonya from a gas cylinder with a water jacket.

Finally, we got to the domestic analogue of the Stropuva boiler, which is much simpler to implement, since it has a non-folding pipe for supplying air to the firebox. There are already so many instructions on how to make a Bubafonya stove with your own hands that only a blind person would not have seen them, unless, of course, they were interested in this topic. And why all? Yes, because the process is so simple and if you take the matter seriously, you can get a finished product from scratch in a day. What is the Bubafonya stove made from with your own hands:

- from a gas cylinder;

- from a barrel;

- from pipes

It can be either round or square. Let’s not repeat the same thing, just read the article: “Bubafonya stove from a gas cylinder” - and everything will become clear to you. Today we will consider a version of the product with a water circuit, as if we will try to repeat the principle of operation of the Stropuva boiler. All that is required is to make a simple Bubafonya and insert it into a pipe of a larger diameter. Thus, we obtain a gap in which the coolant will be heated.

Naturally, this space above and below is sealed so that various debris does not get there

What is important when making a Bubafonya stove with a water jacket with your own hands:

- use of heat-resistant steel;

- wall thickness of at least 4 mm;

- the presence of a tap for draining and replenishing water.

Immediately provide a hole in the upper part through the outer and inner walls for installing a chimney into it. There should also be enough space for water. The distance from the outer to the inner wall is about 10 cm. When connecting, do not confuse the supply and return pipes (supply from above).