The use of automatic control makes the devices operate more efficiently. Solid fuel boilers thus better use the energy from fuel combustion, reduce the requirements for quality and intensity of maintenance, and become more autonomous. Having understood the basic principles of operation of control devices, the owner will be able to correctly select the necessary equipment and ensure its effective use.

Solid fuel boiler in the house Source tproekt.com

Video description

About the automation that regulates the air supply to solid fuel boilers

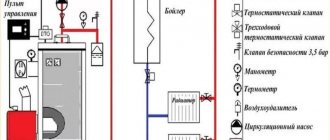

Automation for a solid fuel boiler allows you to provide optimal combustion parameters for the fuel. This is achieved by controlling devices such as a circulation pump, fan and some others. Combustion data is collected using special sensors and transmitted to an electronic controller. After processing the received information, he makes appropriate changes to the operating mode of the solid fuel boiler.

Blower fan for boiler Source tproekt.com

Combustion occurs over a long period of time. At the same time, the fuel gradually burns out and the operating mode changes. If no action is taken, the efficiency of the boiler will decrease. To do this manually, the master needs appropriate knowledge and experience. The automatic system makes the necessary adjustments with minimal human intervention. This improves not only the efficiency, but also the safety of its operation.

Adjustable ash door Source tproekt.com

DIY making

The thermostat, as an automatic device for regulating the operation of the heating system, can be purchased at the electrical goods retail chain.

At the back of this device there is a heat removal plate; it will need to be pressed against the exposed part of the unit. The thermostat has three contacts inside: common, normally open and normally closed. By rotating the adjusting knob, you can change the positions of the contacts.

So you need to set the handle to the minimum mark and connect to the open contacts:

- to the general one .

- We connect one wire from the turbine to the open one

- to the second wire from the turbine .

An automated control system is rightfully considered not only convenient, but also an effective device. With its help, you can significantly simplify the process of operating the heating system.

Advantages and disadvantages

Automation for solid fuel heating boilers has the following advantages:

- At different times, the required degree of heating may differ. Typically, in manual mode, the combustion intensity is adjusted by changing the position of the damper. This process is complex and often does not allow for precise control of the work. An automatic control system can not only provide the desired thermal regime at a certain moment, but also its implementation over a given period of time.

- Combustion efficiency increases by an average of 15%-25%.

- If the home owner plans to leave for several days, he must stop the boiler. After returning, it will need to be rekindled. Using automation, it is enough to set the minimum parameters for this period, and then use the boiler again in active mode.

- An important part in the art of using a boiler is the ability to properly light wood or other fuel. The automatic system can perform this operation independently.

- If wet fuel is used, the system selects the optimal combustion mode for it.

- When using automation for solid fuel boilers, fuel consumption is more economical.

- Adjusting the thermal mode eliminates the possibility of the boiler boiling.

- One of the most important tasks of the device is to maintain security at a sufficiently high level. For this purpose, a built-in diagnostic system is provided. It can automatically find various types of faults. If they exist, special measures are taken to disable certain nodes or to correct problems.

- For the operation of the system in question, a supply of electricity is required. If it stops, the system provides emergency power that operates for a certain period of time.

- If the user wishes, automatic control can be combined with manual control. The owner, having a good understanding of the operation of the device, can, for example,

- Some boiler models have an additional tank where there is fuel that can be added. The electronic controller will ensure that this operation is performed automatically.

- If necessary, the ash pit can be cleaned without human intervention.

- Various implementations of the control system may be provided. Sometimes this is as simple as using switches or pressing buttons directly on the device. In other cases, control can be carried out using a remote control.

When using the systems under consideration, the following disadvantages can be noted:

- Electricity is required to operate. In the event of an emergency shutdown, it can continue to operate for some time, but this is only enough to take urgent measures in such a situation.

- Such systems are more expensive than conventional ones. By spending more money, the owner will receive many useful features, but he cannot always afford this purchase.

- The fan operation may create additional noise, but in most cases it is quite quiet.

Using an automatic control system for a solid fuel boiler makes the owner’s life much more comfortable.

Diagram of the boiler operation with automatic fuel replenishment Source tproekt.com

Content

And yet, the majority of the population is put off by the maintenance of solid fuel boilers, which needs to be done every 3-4 hours. Due to the fact that fuel burns quickly, it is necessary to regularly add coal or firewood to the firebox. Cleaning the ash pan is also a labor-intensive and not the most pleasant process. And temperature regulation is a whole problem: to do this, the owner must adjust the position of the damper, which controls the flow of air masses into the firebox.

Now, thanks to automation, all these processes can be performed less frequently or remotely, while saving money on electricity and gas.

Installation procedure

The purchase of a solid fuel boiler equipped with everything necessary is available. But usually it needs to be installed. You can do this yourself. To complete this procedure, you must take the following steps:

- First install the fan. It can be placed where there is an ash pan door or one designed for air supply. Some models of solid fuel boilers already have space for installing a fan. If this is not the case, you will need to drill holes for the corresponding bolts yourself. In this case, the fan must be installed on a special heat-resistant gasket.

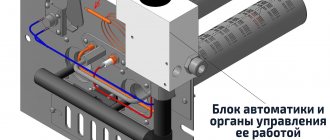

- Next, you need to directly connect the automation to the boiler. Typically, the installation location of the controller is provided in the upper part of the boiler body. It is important to make sure that the place where the electronic board is attached will not overheat. Otherwise, the increase in temperature may cause system malfunction.

- The necessary sensors are installed. Submersible ones can be used to control the coolant. Special sleeves are provided for them.

- All elements must be installed in accordance with the connection diagram. It is usually included in the documentation provided when purchasing the control system.

After the connection is completed, it is necessary to configure the equipment.

Operating principle of a solid fuel boiler Source househill.ru

Which is better - a smoke exhauster or a blower?

When the traction turbine is integrated into the heat generator by the manufacturer, such questions do not arise. Adding an exhaust fan to a conventional direct combustion boiler is another matter. You need to understand that in this case, the smoke exhauster solves only 1 problem - creating a vacuum in the firebox and increasing draft. There are a number of negative points here:

- Without an electronic control unit, performance will have to be adjusted manually. Automatic maintenance of coolant temperature is excluded.

- When air is supplied through the open ash chamber door, the fan will force the boiler to operate at maximum. Setting up a long burn mode will not be easy.

- In the event of an emergency stop of the impeller, fuel combustion will not stop, since gases pass freely through the volute or the body of the smoke exhauster. Air enters the firebox, increasing the likelihood of overheating.

- The impeller and internal surfaces of the unit become covered with soot, which must be removed. The rate of sticking depends on the moisture content and resin content of the wood.

Blowing machines always work in conjunction with a controller, so the problems listed above do not exist:

- the blower changes performance and turns off at the command of the control unit, the coolant heats up to the set temperature;

- during the combustion process, the ash pan door is hermetically closed, air is supplied through a separate channel;

- when there is a power outage, the air channel is automatically closed by a gravity damper;

- the impeller blades do not come into contact with hot smoke and soot.

Now let’s compare the cost of a traction fan and a blower fan, not taking into account the price of the controller. A smoke exhauster for a TT boiler up to 30 kW will cost 90 USD. e., supercharger - 60-65 cu. e. The difference is due to the design features of the exhaust unit - hot gases should not overheat the electric motor, plus the impeller is made of metal (when pressurized, it is made of plastic).

Behind the mounting flange of the unit there is a small impeller designed to cool the electric motor

The installation complexity of the units is approximately the same. Installation of the discharge volute involves cutting out an opening in the ash pan door, and the smoke exhauster involves disassembling or cutting out the pipe. It is easier to install a roof hood, but you will have to pull a long cable.

Equipping a boiler with electronic control

If the operation of the device is manually regulated, then the intensity of combustion depends on the draft in the chimney and other factors that can vary largely randomly.

Operating principle of a solid fuel boiler Source househill.ru

Automatic systems implement effective control almost regardless of external conditions.

Types of traction fans

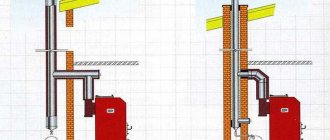

Several types of smoke exhausters are sold for solid fuel boilers and wood-burning fireplaces:

- boiler (the design is discussed above);

- centrifugal channel;

- overhead;

- fireplace/stove (aka roof).

Varieties of duct smoke exhausters, some models are equipped with temperature sensors. The duct fan is distinguished by its own housing with two connecting flanges or pipes.

The unit is installed vertically or horizontally into the gap in the chimney duct. The device and principle of operation are similar to the operation of a boiler smoke exhauster. The overhead smoke exhauster for a domestic boiler is equipped with a semicircular platform and clamps-ties. Installation is carried out on a vertical section of the chimney (uninsulated):

- An opening is cut out in the pipe using a paper template.

- The impeller of the traction machine is inserted into the hole, and the platform with the electric motor is pressed to the surface with clamps.

- The connection is sealed with an asbestos cord glued to the inside of the installation site of the smoke exhauster.

Electric fireplace hoods are mounted on the head of a brick chimney and secured with spacer bolts. The power cable is laid through a pipe and introduced into the room next to the home stove.

To choose a traction machine, you need to focus on 3 criteria:

- heat generator power, smoke exhauster models are designed for boiler performance up to 20, 30, 50 and 100 kW;

- installation point - on the boiler itself, pipe or head;

- for overhead models – the diameter of the uninsulated flue.

Overhead (left) and roof-mounted smoke exhauster (right)

Video description

How to make automation for a boiler using improvised means.

For this purpose, solid fuel boilers can be equipped with the following devices:

- The electronic control board must know the exact thrust level at every moment. For this purpose, a special sensor is installed.

- If the draft is not enough for proper combustion, a fan can be used to adjust the air supply to the chamber where the fuel is located.

- Sensors are used that transmit information about the water level in the jacket.

- The pressure level is recorded.

- A circulation pump that supplies the right amount of air to maintain the desired combustion intensity.

- If the coolant for the heating system is heated, then sensors for its temperature and fuel consumption can be installed.

- The control board can receive information about the loading of the container with firewood, pallets or coal. In accordance with them, the next portion can be served.

The electronic control board receives the necessary information about the operation of the device, processes it and gives the necessary commands. It ensures the execution of the operating mode specified by the owner.

Automation kit for boiler Source gradusplus.com

Main characteristics of the controller

Automation prevents freezing of pipes in the heating system

The characteristic indicators of electronic controllers built into the boiler include:

- the ability to control the intensity of fuel supply to the unit responsible for its combustion;

- implementation of all protective functions provided for such systems (against overheating or freezing of pipes, pump stops);

- number of control objects and the possibility of their priority selection;

- the presence of a GPS unit that allows you to control the boiler automation remotely;

- the ability to update software at certain intervals.

Boiler settings

Before you set the necessary parameters for the automation, you need to make sure that it is operational. To do this, do the following:

- The heating system is filled with coolant. You need to check for air pockets and, if necessary, get rid of them.

- You need to turn on the circulation pump and make sure that it is working properly.

- The system contains pressure temperature sensors. It is important to check how accurately they take measurements, as well as compliance with the standard values specified in the instructions.

- The furnace is ignited. After this, the required amount of fuel is added. During operation, you must make sure that the parameters measured by the sensors do not fall outside the normal range.

A boost fan installed on the boiler Source gradusplus.com

An electronic board can provide various options for the operation of a solid fuel boiler. To determine the option that the owner requires, he must set all the necessary parameters. This is usually done in the following order:

- It is necessary to determine when the circulation pump should start. To do this, indicate the appropriate temperature. Thus, the pump will not turn on immediately, but after the boiler has preheated. In most cases, a value of 50 degrees is used.

- Automation for the solid fuel boiler fan ensures air exit through the chimney. Its use is advisable in cases where the available traction force is insufficient. The owner has the option of the desired rotation speed. Preset fan operating modes may be available. If necessary, program pauses during which it remains disabled. Certain models provide for a smooth change in rotation speed.

- The owner has the opportunity to set the desired temperature in the room. The controller will receive information from the sensor and, depending on how much more or less it is than desired, the boiler operating mode is adjusted.

- You need to set the furnace ignition parameters.

Some models may provide programming for several days in advance. In such a situation, the user sets the desired algorithm, and the system ensures the execution of the commands specified by him.

Boiler automation operation diagram Source udobnovdome.ru

Features of choice

Since the boiler is not supplied with a regulator from the factory, when choosing a heating device you need to pay attention to the presence of a sleeve for the accessory on top of the body. The latter is mounted inside the water jacket and can be in three positions - side, front, top

The second requirement for the boiler is the ability to open the ash pan door upwards. Without this feature, the regulator cannot be configured.

In addition, it is recommended to consider the following parameters:

- the power of the device must be sufficient to easily lift the ash pan door;

- desired range of maintained temperatures (usually 60-90° C);

- the external thread of the regulator matches the internal thread of the sleeve;

- The angle of rotation of the lever allows you to fully open and close the door.

The design of boilers is usually such that the action of the regulator is limited in space, and this must be taken into account when choosing the location for installing the heating system. However, there are heating devices in which it works in any position

How to choose a control system

Automation is divided into two types: mechanical and electronic. Each option has its pros and cons.

Automation control panel Source otoplenie-expert.com

The mechanical system has its advantages:

- It can be used regardless of the presence or absence of an electrical outlet.

- The mechanical system is simple and easy to use.

- Compared to using an electronic control board, it is significantly cheaper.

- High reliability during operation.

- Installation can be done by those owners who do not have professional skills for such work.

The use of this option allows you to regulate the use of the air duct and perform other actions to optimize the operation of the boiler. The disadvantage is lower efficiency compared to automation implemented using electronic devices.

Various types of control units Source otoplenie-expert.com

The electronic version provides the following advantages:

- High quality work.

- Possibility of programming for several days.

- In some systems, remote control is available, including via the Internet.

The disadvantage is the high cost of equipment and energy dependence. Where there is no possibility to connect the power supply, the system will not function.

Various types of solid fuel boilers Source spasipiter.ru

Kinds

Automation for solid fuel units can be classified according to autonomy.

There are two types here:

- Automation that does not require electricity.

- Automation powered by electricity. This type performs all its functions only if it is connected to a power source. Of course, it is also equipped with a backup reserve if the power supply is suddenly interrupted. So, even if the electricity supply is interrupted, the boiler will continue to work for some time.

Of these two options, it is the second option that is recommended, since it has a large number of diverse functions and effectively fulfills its obligations.