An indirect heating boiler is a storage tank (capacity) in which water is heated for domestic hot water needs by transferring thermal energy from a hot medium (coolant) to a cold medium (sanitary water). By design, they are divided into tanks with a built-in heat exchanger (one or two) or “tank in tank”. Most boilers presented on our market have the first design. The main advantage of indirect water heaters over conventional electric ones is faster and cheaper heating. Also, most manufacturers have so-called combined boilers in their model range. In such water heaters, indirect heating is combined with heating from electric heating elements. This is especially true when installing a boiler with solid fuel boilers. This allows you not to heat a solid fuel boiler in the summer and heat water like in a regular electric boiler.

Installation of an indirect heating boiler with a gas boiler

If the water supply system of a private house has a low consumption of hot water (1-2 water points), then a double-circuit gas boiler will be sufficient for you. If your domestic hot water consumption is significantly higher, and you want to comfortably use hot water, you need to consider a single-circuit boiler and an indirect heating water heater. Installation of such a system is quite simple. Most wall-mounted gas boilers already have a built-in three-way valve and only a boiler sensor is needed to connect the boiler and water heater.

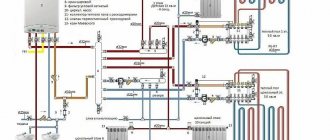

Piping diagram for the gas Vailant and the S-Tank boiler in the village of Lesnoye, Minsk region - drawing by Vladimir Trukhan, our installer (see his other drawings):

Installation of an indirect heating boiler with a solid fuel (pellet) boiler

This system is installed in almost the same way as with a gas boiler, but there are a number of small differences. The boiler requires the installation of a separate pump to load the boiler, and the control of the water temperature in the water heater can be implemented in different ways. If the boiler is equipped with automatic control, then, as a rule, the controller allows you to control the operation of the boiler pump and the DHW recirculation pump (depending on the boiler model). If the boiler is simple, the temperature and pump can be adjusted either using a simple relay (applied thermostat) or using more complex automation (like tech st-21CWU, etc.). Everything is individual and depends on the specific tasks and strapping scheme. Also, since solid fuel boilers operate at higher temperatures than gas boilers, this allows them to heat the boiler to the required temperatures faster.

Electrical connection

Any electric boiler is equipped with a plug and wire. You can connect it directly to the outlet, or you can take the wire out to the electrical panel and run it there through a separate machine, although this will require a little tinkering with replacing the wire, but it will be more correct. If you usually use an outlet, then two rules must be followed:

- The outlet must be grounded

- The socket should be away from water

Here is an article about an indirect heating boiler, this is the same storage water heater, but with a tricky connection. This connection saves a lot of energy.

And for places of temporary residence, for example, a summer house, or for a short period of water outage, instantaneous water heaters for a summer house will save you.

Installation of an indirect heating boiler with an electric boiler

In this case the situation is slightly different. Compared to a gas boiler, there will be no difference in heating costs between an indirect heating boiler and an electric one, because In any case, heating comes from electricity. But the difference will be in the heating time (speed). If the power of the electric boiler is small, it is better to consider a conventional electric boiler (since you will not notice much of a difference in the heating rate, and the costs of a system with an indirect water heater will be much higher). If the power of the electric boiler is large enough (more than 7 kW), it is better to mount the system with an indirect heating boiler. Since the power of the heating elements of an electric boiler is only 1.5-2.2 kW, the time difference will not even be 2 times, but much greater. As for the choice of an electric boiler, taking into account the installation of an indirect heating water heater, it is better to pay attention to boilers with automation, which (using special components) allows you to connect the boiler directly to the boiler, so as not to be tricky with the wiring diagram in the future.

Connection diagram for an electric boiler with an indirect heating boiler: 1) indirect heating boiler, 2) heat exchanger for an indirect heating boiler, 3) shut-off valve, 4) hot water outlet, 5) distribution element, 6) shut-off valve, 7) electric boiler, three-way valve, 9) three-way valve drive, 10) cold water supply, 11) safety valve with check valve, 12) check valve in the direction of hot water circulation.

three-way valve, 9) three-way valve drive, 10) cold water supply, 11) safety valve with check valve, 12) check valve in the direction of hot water circulation.

Please note that since January 2022, a universal 3-in-1 electric boiler has gone on sale at a budget price from the Belarusian S-Tank plant - an electric boiler and an indirect heating boiler are integrated in one tank, as well as a hydraulic arrow and other useful things. Details can be found here.

Thus, regardless of the heat source (be it a gas, solid fuel or electric boiler), installing an indirect heating boiler is the optimal solution for the full and comfortable use of hot water.

Mistakes made during installation

When carrying out installation work, it is important to avoid any mistakes. This can lead to unpleasant consequences. For example, it is important not only to ensure that the water heater is located close to the boiler, but also to set the correct direction of the pipes to the pipeline for easier installation. Another common mistake is incorrect connection of the pressure pipe and coolant inlet. Cold water is always supplied to the lower pipe, and hot water to the upper part of the water heater. There is also a risk of the pump being connected incorrectly. It is important to comply with the parameters set out by the manufacturer.

So, we have discussed with you possible methods of connecting a water heater to the heating system. We hope this information will be useful to you and will help you complete this task yourself. We also provide diagrams and video material to help.

Questions and Answers

How to determine the required boiler volume? 150 liters for a private home.

The volume of the boiler is equal to the peak discharge of hot water in your family during the complete renewal of the contents of the boiler - in fact, this is the moment and duration of use of the shower. The number of residents and the size of the house do not matter; the heat extracted by the heated towel rail in the boiler circuit is not critical. How does boiler power compare with boiler power? An indirect heating boiler has priority in receiving boiler power before heating. The boiler receives all the heat from the boiler during the preparation of hot water. The boiler must have equal or greater power than the boiler heat exchanger - otherwise we will experience a slowdown in the preparation of hot water. The less power the boiler has compared to the boiler rating, the longer the heating system of the house does not receive heat from it, which is fraught - everything goes to the hot water supply.

How many heating elements should an indirect boiler have? Heating elements are used to maintain the temperature of the boiler when the boiler is out in the winter, and are also used in the summer when the boiler is not used at all. In the summer, it is important to note that the heating elements in total have much less power than the boiler received from the boiler, which sharply slows down the preparation of hot water with the resulting loss of comfort. If the networks allow, you can change the heating elements for more powerful ones, or consider the summer mode of the boiler for the boiler.

Author: Yuri Bedulin

domkotlov.by

Indirect heating boilers are companions of any boiler. They serve to accumulate hot water, which is supplied to the mixer. Often customers do not understand why a gas boiler needs a boiler if they can purchase a double-circuit boiler that will both heat and heat water. And here we need it!!! You have accumulated from 100 liters of hot water in your boiler, and the boiler gives, at best, up to 12 liters per minute. If you open several taps, there will not be enough hot water for several consumers.

See: Installation and piping of an indirect heating boiler (water heater) Boilers Gas boiler Buderus Logamax U072-24

One of the most popular electric boilers, Proterm Skat, paired with an indirect heating boiler, Aquastik, is installed at a private house. The client signed up for a preferential electricity tariff for heating his home. At this tariff, the monthly payment during the heating season will not exceed 50-60 rubles. The indirect heating boiler was not chosen by chance. The fact is that, unlike an electric boiler, indirect ones heat up much faster from the boiler. And electric boilers with tags of 1.5-2 kW heat up many times longer. The piping is made with a copper pipe with a press connection. This material is used for the durability of the system. It is also ideal for piping a boiler.

See: Indirect heating boiler Aquastic AQ 150 FC Electric boiler Protherm SKAT 9 KE

An indirect heating boiler is an integral attribute of any heating system. Our customers, when submitting technical specifications for organizing hot water supply, most often assume what kind of boiler they need. S-tank water heaters are loved for their affordable price, reliable quality, and availability of service. Although, from time to time we still encounter skeptical opinions about Belarusian production. To these objections, we can say with confidence that the production capacity of the S-tank plant can be the envy of European manufacturers.

See: INDIRECT HEATING BOILER S-TANK SOLAR 300 Boiler S-Tank P 300

The photo shows a 500 liter electric boiler. As you know, water heater manufacturers do not have such boilers with built-in heating elements. There are tanks of any size, but heating elements must be inserted into them. Such tanks are also produced by the Belarusian manufacturer S-Tank. This is an enameled tank with additional outlets for 4 heating elements (3 of 6 kW each and one of 3 kW - a total of 21 kW). The boiler is installed both electrically and waterwise. The boiler is piped using a Geberit stainless pipe using a press system. A prerequisite for our installation was the installation of a mixing valve at the hot water outlet from the water heater. This is done for the safety of users.

See: Boiler S-TANK P 500 Heating element S-TANK 6 Installation of heating equipment

The facility was installed in April 2022. The next heating season will delight the owners of the house with warmth. The Proterm Skat electric boiler was purchased in a store in Minsk. Aquastik indirect heating boiler is a good budget option. The installation and piping of the boiler and boiler was carried out with a copper pipe using press connections. This is the most reliable and modern way to install a boiler room. The facility has a collector distribution system for radiators paired with heated floors.

See: Electric boiler Protherm SKAT 9 KE Indirect heating boiler Aquastic AQ 150 SC COLLECTOR FOR WARM FLOOR WARMING Maincor FOR 7 OUTPUTS. (COMB)

Bestseller!

Strapping functions

Piping is a set of instruments, devices, and pipelines used to transfer coolant to heating radiators. Its structure includes the entire heating system, excluding radiators.

Any gas equipment is potentially dangerous. Installation errors lead not only to problems with heating the home, but also to an explosive situation. When drawing up the project and installation, it is necessary to strictly comply with the safety requirements and standards of SNiP 41-01-2003 “Heating, ventilation and air conditioning”.

The selection of the scheme depends on the type of boiler being installed, the structural and functional features of the building, and the type of heat supply system. The scheme needs to be planned in advance, the optimal points for installing equipment must be selected, and the nuances of pipeline arrangement must be determined.

The boiler is the main element of the heating system

The harness performs the following important functions:

- Pressure control. With a properly arranged piping, thermal expansion is leveled out, therefore, the pressure will not reach dangerous values.

- Prevent airing. Plugs in the pipeline are formed due to air bubbles. Heating efficiency decreases since the batteries do not heat up completely with constant fuel consumption.

- Preventing blockages. If the boiler is not properly installed in pipes and batteries, there is a high risk of rust and scale formation. The presence of even small particles of debris in a liquid leads to contamination of the entire system. This leads to an increase in fuel consumption and, accordingly, costs for heat supply with a loss of its quality.

- Connecting additional circuits. It is allowed to install a “warm floor” and a storage boiler.

The quality of heating a house depends on the method of connecting the gas heater to pipes and other elements, therefore the piping plan must be selected and developed in advance.

BiLight horizontal with heat exchanger B12 TSRC 80

GCHS 804420 B12 TSRC Combined horizontal electric water heater with built-in high-efficiency heat exchanger (coil) and copper heating element. Volume - 81 liters. Installation type: horizontal. Reviews (2)

RUR 749 Buy

Bestseller!