At one time he specialized in heating boilers - their installation, connection, automation, production. Lately I rarely take on such orders, but recently I took on one of these. It was necessary to connect a very sophisticated boiler. After I saw it, I became interested in making a similar automation for a solid fuel boiler with my own hands. Therefore, I’ll tell you further about it, its functions and how to make the simplest automation for a boiler.

Source gradusplus.com

About new models of solid fuel boilers

Solid fuel boilers of the new type differ from their previous counterparts by a special modernized control system. It increases the functionality and number of options, and also simplifies the operation of the unit.

Adjusting the parameters of these boilers required for operation is quite advantageous from an ergonomic point of view, since it is carried out only once, and there is no need for periodic adjustment.

In addition to the quality of components, the cost of solid fuel boilers is also affected by their main difference - an improved version of the control unit, naturally, the more expensive the unit, the more modern the automation that is used in it.

The main direction of operation of the automatic control system is control over the combustion process in the heat generator. The main tasks of the control unit and fan are to maintain the specified temperature of the coolant in the system, ensure a high efficiency rate and help increase the overall level of efficiency. They work regardless of the quality of the fuel. Thanks to equipping the boiler with an automatic control system, it was possible to increase the burning time of one load by 25-35%, and it also became possible to adjust the temperature regime.

Source prom.st

What can be controlled using automation

Automatic systems perform a number of important tasks:

- optimally dose the air supply required for traction;

- control the performance of the heat generator;

- regulate the power of the device depending on weather and temperature factors;

- guarantee the safe operation of the water heating installation of the device;

- feed firewood, pellets, briquettes or coal automatically;

- ignite and extinguish the firebox.

Operating principle of a solid fuel boiler

While in older models of solid fuel boilers it was necessary to monitor the temperature independently, using a thermometer, and to regulate the air supply it was necessary to manually open or close the ash pan door, in new models of units an automatic draft regulator is installed. Its list of functions includes both closing and opening the ash pan damper, depending on the water temperature, and the device itself is volatile.

Instead of an ineffective thermostat, new models began to install similar automatic fans to supply the required volume of air to the combustion chamber. All this is due to the fact that manufacturers began to take into account the dependence of the unit on natural draft in the chimney and the inaccuracy of settings. In this case, the operation of the fan is ensured by a controller that receives information about the state of the water and its temperature directly from the sensor.

In turn, the controller consists of a screen and a control panel, thanks to which the required heating temperature of the coolant is set.

Models that do not have such an element can be equipped with a similar kit. Before installation, you must first disconnect the ash pan door, and install the fan itself on the mounting plate.

Source ytimg.com

The coolant temperature can be adjusted regardless of external conditions. You can also install an additional automatic system on the boiler with an increased range of capabilities, which includes an outside air sensor and remote temperature controllers.

This should be done to maintain the temperature in the room while taking into account outdoor conditions.

To connect this system, both wired and wireless methods are used. Thanks to the sensors that are located in the heated room, information about the temperature is transmitted to the system and thus the selected temperature mode in the room is maintained.

This is considered the most rational technique.

Recommendations for choosing a device

Oddly enough, you can still find budget models of wood-burning heaters on sale that are not equipped with any automation. Most of them have in the basic configuration only a sleeve mounted inside the water jacket. To automate such a boiler, you will have to buy and install a draft regulator yourself.

Hence the first recommendation: when choosing a heat generator, pay attention to the presence of such a sleeve and an ash pan door that rises upward.

A boiler with the ability to install a regulator (left) and with manual control (right)

To choose the right mechanical regulator, you must adhere to the following recommendations:

- the force developed by the drive (indicated in the product data sheet) must be enough to lift the door;

- select the temperature control range from 60 to 90 °C;

- make sure that the operating stroke of the drive is sufficient to fully open and close the sash;

- The threaded connection on the body must match the mating part in the boiler, usually ¾”.

You should also pay attention to the location of the liner in the boiler body. It can be on top, front or on the side panel. For the first option, you need to select a device that can work in a vertical position, for the other two - in a horizontal position. There are traction regulators, for example, Regulus rt3, which work in any position and have 2 adjustment scales.

Safety valve

Modern automatic models of solid fuel boilers include ignition control, an ignition system, and even a continuous fuel supply.

Source oteple.com

For self-ignition, a special electric incandescent element is provided, which is turned on after the pallets are fed into the auger container or burner. The signal to turn off the electric ignition is a stable flame, which is detected by the photosensor and transmitted to the controller in the form of a pulse.

During operation, granules from the hopper are fed into the auger. The volume of the latter allows you to provide heat to the entire room for several days without additional human intervention.

New models of solid fuel boilers are equipped with devices for controlling the heating system, as well as newer safety devices, one of which is a safety valve.

This device is needed to discharge water from the boiler tank if the coolant overheats. This is done to protect the casing from destruction and stabilize pressure.

Additionally, the unit may include an overheating sensor, which will signal if the temperature is exceeded at the initial stage.

Source graviterm.com.ua

Let's summarize. Modern solid fuel boilers are equipped with the best automation: a draft control sensor, pressure recorders, a fan, a smoke exhauster, water level sensors in the jacket, level sensors for pellets or coal in a container, and a circular pump. All these devices are connected to a controller, thanks to which control and notification of emergency situations are carried out. The most sophisticated models can have a remote control function - the automation of a solid fuel boiler is controlled via mobile applications and the Internet.

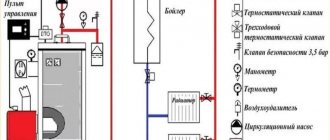

Strapping scheme

A solid fuel unit is usually connected to a boiler that runs on a different type of fuel. This is usually an electrical unit.

An electric one is installed parallel to the solid fuel stove. This is the so-called auxiliary element. Its role is as follows: if, for example, the owners are not in the house for a long time, and the solid fuel boiler has run out of fuel, then the auxiliary element, in this case, the electric unit, automatically comes into working condition. It maintains positive temperatures. More on how it all works.

First, the coolant under pressure from the circulation pump is supplied to the boiler, passing through which it heats up. Next, the coolant enters the radiator, where movement follows the principle of natural circulation. Then it enters a special boiler, inside of which there is a coil that is immersed in water. The coolant, passing through the coil, heats it, as a result of which the water heats up. Thus, the residents of the house are provided with hot water.

After the boiler, the coolant again enters the radiators and underfloor heating coils. But before that, he must pass a special crane. If the temperature of the coolant corresponds to the established norm, then the tap opens and the coolant circulates through the floor coils, and if the temperature is higher than normal, the tap closes.

Automation for a solid fuel boiler using improvised means

A thermostat, which is used as an automatic device for regulating the operation of the heating system, can be purchased at any electrical goods retail chain. The device will have a heat removal plate on the back, which will need to be pressed against the bare part of the boiler.

Inside the device there will be three contacts - normally closed, normally open and common. While rotating the handle, you can change the position of these contacts. Therefore, next you need to set the handle to the minimum mark, and then make the connection to the open contacts as follows:

- A phase must be connected to the common contact.

- One wire from the turbine is connected to the open one.

- A direct zero is connected to the second wire from the turbine.

Source hyperauto.ru

I recommend the following video, in which the author makes automation for a solid fuel boiler:

Brands

Today, the most well-known manufacturers of such remote monitoring systems are the following companies:

- Vaillant;

- Buderus;

- Protherm;

- Viessmann;

- Evan;

- Xital.

Installation and connection of the system are not too complicated, so you can handle it yourself.

At the same time, VIESSMANN offers heat generators already equipped with special units and compatible controllers. Devices from . They are quite functional and the gsm heating control “Xital” provides, for example, the possibility of using 2 SIM cards and the presence of a reliable algorithm that guarantees their smooth operation.

The video instructions cover how to install the Xital system yourself.

What in the end...

Automation for a solid fuel boiler is a set of devices for adjusting and controlling the entire heating system. These include traction control sensors, pellet or coal level sensors in the tank, pressure recorders, water level sensors in the jacket, a circular pump, a remote control system, photo sensors, temperature sensors and others. It is not difficult to make the simplest automation for a solid fuel boiler; for this you will need to buy and connect a thermostat to the boiler.

Question

Write in the comments whether you think the price for the most modern models of solid fuel boilers is justified?

Features of use

Weather-compensating automation (PA) is used in two types of boilers.

Wall

Automation is built into most of these devices by the manufacturer. They are hung on a vertical surface during installation, which is why they got the corresponding name. A medium-sized device takes up little space. Recommended for use in small private houses where it is impossible to allocate a separate room for the boiler room. Compared to the floor version, the wall version is cheaper. PA involves installing a sensor that measures outdoor temperature.

Photo 1. Wall-mounted boiler installed in the kitchen. Typically, such devices are equipped with weather-sensitive automation.

Floor

The use of a floor-standing boiler is justified in a large country house. The cost of the device is higher than that of its wall-mounted counterpart, but operation is cheaper.

Rare models have a built-in controller - you will have to buy it separately. You will also need to purchase and install a lot of additional equipment: mixing units, terminals, hydraulic system. For strapping you need a place, preferably a separate room. In addition, you will need to hire a specialist for connection and debugging. The total amount will be 100 – 150 thousand rubles.