During the combustion of any type of fuel, soot and tar deposits accumulate on the internal heating surfaces of the boiler unit. They are good heat insulators and, with their significant thickness, reduces heat transfer from the internal heat exchanger to the heated water. In addition, such deposits clog the flow sections of the smoke ventilation system, as a result of which the speed of movement of flue gases in them decreases.

This process contributes to overheating of the structural elements of the boiler with subsequent failure. Soot, in addition, has the ability to ignite in smoke ventilation ducts, creating a fire in the house. For prevention and in order to prevent the occurrence of such dangerous processes, each heating boiler must undergo periodic cleaning of heating surfaces and smoke exhaust channels. And the owners of such equipment should know how to clean the boiler from tar.

Causes of resin accumulation

Particularly dangerous fuels in terms of the formation of tar on heating surfaces are firewood, low-quality coal, peat fuel and pellets. In solid fuel heating units, tar accumulates much earlier for the following reasons:

- Use of low-quality or raw fuel;

- an excessively large amount of firewood is loaded into the combustion chamber;

- use of a heating unit for the disposal of industrial and household waste;

- low-temperature regime of furnace combustion processes, due to which the fuel smolders and does not flame;

- the use of firewood containing a huge amount of volatile resinous substances that settle on the walls of the boiler in the zone of low combustion temperatures;

- lack of oxygen supplied from the air to organize complete combustion of the fuel, resulting in underburning of the fuel.

Procedure

In order to properly and effectively clean a gas boiler from soot and carbon deposits, it is necessary to perform the following steps:

- close the gas supply valve;

- sequentially remove the boiler door, thermocouple, nozzle and burner tube;

- the top cover of the boiler is removed;

- the thermal insulation sheet is removed;

- the chimney is carefully dismantled;

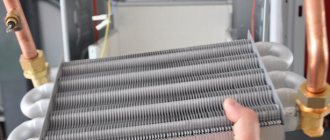

- by choosing a suitable metal brush, the heat exchanger is thoroughly cleaned of soot;

- to clean the heat exchanger channels, you need to use a vacuum cleaner;

- The walls of the boiler are first cleaned with a brush and scraper, and then can be wiped with a rag;

- cleaning the chimney is carried out with a brush, and if it is of sufficient length, then it is possible to use a steel cable;

- All boiler components are reassembled in reverse order.

Watch the video in which an experienced user clearly shows how to clean a gas boiler (AOGV) from soot:

How to prevent large boiler contamination

In order to prevent the formation of tar, it is necessary to heat the boiler with a maximum volume of air, which in turn guarantees the complete combustion process of the fuel. This mode ensures the operation of the solid fuel boiler unit with maximum efficiency. You need to buy wood fuel a year before the heating season and store it in a dry place so that it has time to dry out during this period. It is allowed to use firewood with a moisture content of 20% and below.

A conventional solid fuel boiler (not condensate type) must operate at a water temperature in the return pipeline of the heating circuit of at least 55 C. This mode is supported by a three-way valve with a thermal head. Such a temperature schedule for the return of coolant from the consumer will prevent the formation of tar and “dew point”, at which destructive acid caused by the formation of condensation accumulates in the smoke ventilation ducts.

The result of the work done

This boiler is cleaned regularly every year before the heating season. No critical contamination was found during cleaning, but it is clear that dirt accumulates throughout the year. The need for such a procedure is obvious. After cleaning, the boiler ignites easily and gains temperature well.

P.S. Photographs of the boiler show traces of burnt paint in the area of the inspection window. This is a clear sign of insufficient draft or contamination of the boiler channels. In this case, the problem was fixed long ago, but traces, unfortunately, remain.

Why is the resin in the boiler dangerous, the frequency of cleaning

A heating boiler operating on solid fuel, the heating surfaces of which are covered with soot, resin and tar, cannot function for a long time. First of all, its main module, which is responsible for heating - the heating heat exchanger - will fail. In addition, oily accumulations that accumulate in huge volumes are corrosive, which in turn reduces the operating period of such a device. Likewise, the risk of gas contamination in the combustion chamber increases due to a fall or zero draft in the combustion chamber.

How often does the boiler need to be cleaned?

The frequency of preventative cleaning of the unit is determined by the type of fuel. If you use high-quality dry raw materials for combustion processes, then cleaning is carried out no more than once every 40 days. When using low-quality wet fuel - 2 times per heating month. In addition, during operation, it is necessary to monitor the vacuum in the furnace and the completeness of fuel combustion; if these parameters do not correspond to the technological conditions, additional cleaning of the boiler heating surfaces is carried out.

To slow down the processes of soot formation in smoke exhaust ducts, folk remedies are often used:

- Table salt, which is poured directly into the firebox. It has been proven that it successfully breaks down deposits on heating surfaces and carries them through the flue into the atmosphere.

- Potato peelings or starch poured into the firebox over hot fuel. Has a softening effect. After the fuel has burned and the firebox has cooled, clean off the top contaminated layer with an iron spatula or scraper.

Long-burning pyrolysis boiler "Prometheus Eco"

Our review ends with a story about the Prometheus Eco pyrolysis combustion boiler. The plant produces only one standard size of this model with a power of 30 kW. Unlike previous devices that use the traditional method of burning fuel, the Prometheus Eco wood-burning boiler is based on the wood pyrolysis method.

As is known, in the process of pyrolysis, combustion of solid fuel occurs in two stages. At the first stage, the firewood smolders in the loading chamber due to a lack of oxygen, releasing wood gas. By means of a fan, pyrolysis gas is pumped into the combustion chamber, where it is burned at a high temperature. In this way, significantly higher fuel efficiency is achieved than with conventional combustion.

Photo 6: Prometheus Eco long-burning gas generator boiler

The main requirement for fuel for pyrolysis combustion is its dryness. It is permissible to use firewood with a humidity of at least 20%. When adding more humid wood, the boiler will smoke and its efficiency will decrease. This is true for all gas generators. For example, a household double-circuit pyrolysis combustion boiler Burzhuy K has the same fuel requirements.

Pyrolysis boilers "Prometheus Eco" are available in two modifications: Comfort and Optima. "Eco Comfort" is controlled automatically, while "Eco Optima" has manual control.

Let's briefly look at their advantages:

- The duration of combustion during pyrolysis is significantly longer than during classical combustion. The boiler will have to be loaded less frequently than usual.

- Almost complete combustion of fuel, with minimal formation of ash and gaseous waste, allows them to meet the highest environmental standards.

- Maximum heat removal allows achieving high efficiency values of up to 93%.

Main technical characteristics of the Prometheus Eco series:

| power, kWt | 30 |

| Room area (max), m² | 300 |

| Fuel | firewood (brown coal) |

| Loading chamber volume, l | 170 |

| Efficiency, % | 93 |

| Chimney diameter, mm | 150 |

| Price, rub | 198 000 |

Well, in conclusion, the owner’s review:

I spent a long time choosing a pyrolysis machine for my dacha, and eventually settled on Prometheus Eco. The prices are certainly steep, but the characteristics impressed me. They installed it for me quickly, no problems arose. I’ve been using it for almost a month now, and it burns wood almost completely. There is almost no ash as such, and there is not smoke but a little steam coming out of the chimney. I can’t tell you about the wood consumption, but next month I’ll try to measure how much it consumes.

For more information about installation, piping and connecting the Prometheus boiler, watch the following video:

produces solid fuel boilers for a wide variety of heating systems, which is not difficult to get confused. We hope our review helped you navigate among the variety of Prometheus boilers and you were able to choose the most suitable heating device for your home.

Boiler flushing, cleaning and repair is one of the services we provide to regular and new clients. Our specialists competently perform chemical, hydrodynamic and mechanical cleaning of this equipment. Under the influence of high temperatures in a boiler device of any brand, sooner or later during operation, deposits, soot, and sulfur compounds begin to form. Salts and scale negatively affect thermal conductivity and increase energy consumption.

Removal of scale formed in boilers and heat exchangers can be done by two methods: mechanical and chemical cleaning. To remove hard-to-remove scale, combined cleaning is sometimes used - chemical with mechanical purification.

Mechanical cleaning involves removing scale and loose deposits (sludge) using scale cleaning heads of various designs, which are driven by pneumatic or electric drives.

Chemical neutralization of deposits requires a minimum of tools, a pump and a special solution. Chemicals clean and protect heating systems. The insulating and dispersing effects of these products dissolve limescale, rust, dirt and deposits of iron hydroxide and magnetite, allowing the heating system to be cleaned. Lubricates valves and pumps, improves heat exchangers and returns the piping system to normal operating efficiency.

The essence of the chemical cleaning method is that acids, interacting with scale during the process of washing the boiler unit, dissolve it, converting water-insoluble salts. The chemical cleaning method is that acids, interacting with scale during the process of washing the boiler unit, dissolve it, converting salts insoluble in water into soluble ones.

Combustion chamber cleaner “METANO THERM SPRAY” (400 ml)

Powder combustion chamber cleaner EC-MIX

Liquid for removing deposits MR-501/R (1 l)

Thread sealant SISEAL strong fixation 100 g

Liquid for washing heat exchangers, made of steel, copper, cast iron

Liquid for washing stainless steel heat exchangers. steels (light alloys and Al)

Installation method and operating instructions for the solid fuel heating boiler "PROMETHEUS"

1 Installation method

:

1.1 The room in which the boiler is installed must have a window or door to the street, and be equipped with supply and exhaust ventilation. The premises must meet fire safety requirements and be kept clean.

1.2 Installation of the chimney and cutting of the ceiling and roof is carried out taking into account fire safety requirements.

1.3 The heating boiler is installed on a flat, durable, fireproof base without slopes.

1.4 The height of the chimney is selected from the level of the grate to the pipe cut of at least 6 m or more if the pipe cut falls into the wind pressure zone.

1.5 The chimney is made of a steel pipe with a diameter no smaller than the outlet pipe of the boiler chimney, preferably made of stainless steel. Installation is carried out in such a way that there are as few turns as possible. When turning at an angle of more than 45°, cleaning is installed. The horizontal section of the chimney should not exceed 1.5 m. If condensation appears inside the chimney, the chimney must be insulated.

1.6 The expansion tank is installed at the highest point of the heating system (preferably indoors) and must be reliably insulated. An overflow pipeline of at least Ø25 and a supply pipeline of at least Ø20 are mounted along the shortest path from a straight steel pipe with a slope from the expansion tank and are also reliably insulated.

1.7 A thermometer and a safety group (or necessarily a safety valve) are installed on the boiler supply pipe.

1.8 The distance from the front wall of the boiler to the wall is at least 1.5 m.

1.9 It is not recommended to build the boiler into walls, openings and niches.

2.1. Before igniting the boiler, make sure that there is a sufficient amount of water in the heating system and that the boiler communicates with the atmosphere through the expansion tank, and that the boiler valve is open.

2.2. When the boiler is operating, it is necessary to maintain the coolant temperature from 65 o to 90 o C.

2.3. Before the start of the heating season, thoroughly clean the boiler and chimney, and during operation at least once a month, and possibly more often if the combustion mode is not maintained correctly.

2.4 Coal is laid in small portions of 3-5 kg in dry form, no more than 5x6 cm in size, stirring periodically, creating a combustion mirror, but it is not recommended to tightly fill burning coals. The fuel is placed on the grate in a layer no more than 7 cm thick.

2.5 Fuel must be stored in a separate, dry room.

3.1. Raise the pressure in the boiler and boiler above 2kg/cm2.

3.2. Raise the temperature in the boiler above 90 o C.

3.3. Ignite the boiler without making sure that:

ü There is sufficient water in the heating system.

ü The boiler communicates with the atmosphere through an expansion tank (if an atmospheric expansion tank is installed).

ü The boiler valve is open.

ü The safety valve is in good condition

3.4 Filling an overheated boiler with water.

3.5. Make changes to the boiler design.

3.6. Use water from the heating system for any needs.

3.7. Install a chimney with a smaller diameter than the boiler chimney outlet.

3.8. Use fuel not intended for combustion in heating boilers (rubber, plastic, etc.).

3.9. If a membrane expansion tank is installed, fire up the boiler without making sure that the safety group is in working order.

3.10. Use fuel with high moisture content.

3.11. Install a membrane expansion tank without a pressure reducing valve for filling the heating system and a safety group.

How to clean tar from a solid fuel boiler

There are many methods for cleaning boiler heating surfaces; it is better to use the one specified as the main one by the boiler manufacturer. If the user does not have such information, it can be found on the Internet. In this matter, the frequency of cleaning is of greater importance. There are 3 key methods for cleaning tar and soot from the internal heating surface of the boiler: mechanical, chemical and steam.

Mechanical

This method is performed using specialized tools in the form of steel brushes and scrapers of various sizes. It is necessary to prepare in advance for the cleaning procedure. Before cleaning the boiler from the resin, warm it up. This will require half a bucket of anthracite or 15 kg of non-resinous dry firewood. They are burned in a furnace to create conditions for burning most of the resin, thereby simplifying further cleaning.

During the work process, care must be taken not to damage the internal surfaces of the device with the tool. Basic cleaning points:

- Melt the unit to soften the hardened resin.

- Turn off the boiler and wait until it cools down to a temperature of 40-50 C.

- The smoke ventilation damper must remain open.

- Carefully remove all contaminants on the internal heating surfaces of the boiler.

- After cleaning is complete, I fire up the boiler so that the remaining deposits burn out completely.

Chemical

It is based on the use of specialized means for cleaning heating surfaces. Today it is very popular because it does not require a significant investment of time and money.

There are 2 types of dry cleaning:

- Before cleaning the boiler from tar, the slagged partitions of the boiler are treated with a cleaning acid solution, which quickly destroys unwanted deposits, and after which it will not be difficult to get rid of them mechanically.

- The chemical cleaner is poured directly onto the burning fuel. It reacts with tar deposits and destroys them, removing them from the boiler unit through the chimney.

More commonly used as a reagent are:

- Adipic acid solution, calculated concentration. Interacting with furnace deposits, the acid dissolves them, converting them into salts, which are washed off with ordinary clean water.

- A solution of sulfamic acid easily destroys soot and resin and is also easily washed off with tap water.

Steam

This cleaning method requires a steam generator to generate steam for cleaning. This could be an ordinary household steam device, used, for example, for cleaning the house and capable of producing high pressure steam. It softens deposits and makes removal easier. Electric steam cleaning provides an option to simply get rid of not only soot deposits and resin deposits, but also fungus and mold. In some cases, the source of steam can be obtained from a nearby operating steam heating boiler.

Do you need to flush your gas boiler? What is the cost of the service on the market?

The average cost for cleaning heating systems, heat exchangers, various boilers and heating appliances on the market varies. It all depends on the various requirements of the customer himself and the volume of work performed. The cost of washing reagents also affects the final price of the service. The threshold price level ranges from 4,000 rubles to 10,000.

Service centers offer not only boiler flushing, but also troubleshooting equipment problems in a short time. The specialist’s visit is carried out according to the schedule; the master arrives with an important and necessary set of materials and tools. As a rule, chemical cleaning of equipment is an order of magnitude higher than mechanical cleaning.

Only you can choose whether to flush the gas boiler yourself or hire a professional. If you have recently purchased equipment and the technical characteristics of the model frighten you due to the presence of terms and incomprehensible designations, it is better to trust the specialist. In the case when the operation of the boiler is clear to you, and you can easily understand the instructions for the unit, you can do it on your own. Moreover, we provided recommendations and advice regarding the repair and operation of heating equipment.

Video about cleaning the boiler from tar

Thus, we can say with confidence that resin deposits on the heating surfaces of the boiler cause enormous harm to its internal structural elements. In solid fuel boilers operating on dry high-quality fuel, the boiler is cleaned at least once every 40 days, and also based on the results of the unit’s operation. If the vacuum in the furnace drops, it must be carried out immediately. There are many methods for cleaning the internal heating surfaces of a boiler, the main thing is that they all require strict adherence to safety precautions. The user who will perform such operations must have protective clothing, a respirator, goggles and gloves.

Negative effects of deposits and cleaning frequency

If you do not regularly clean the boiler, negative consequences cannot be avoided. First of all, heat transfer rates decrease. The room will warm up slowly and the heat will spread unevenly. The next disadvantage is that you will need to use more fuel, and costs will increase accordingly.

A solid fuel boiler that is not promptly cleaned of ash, soot and tar will not last very long, since its main elements responsible for high-quality heating will quickly fail.

By regularly cleaning the pyrolysis boiler, you will ensure not only its efficient operation, but also increase its service life.

The frequency of cleaning procedures for a solid fuel boiler depends on the quality of the fuel used.

If you use high-quality firewood, coal, etc., then it will be enough to clean the unit once every 30-40 days. If you use low quality fuel with high humidity, then the boiler must be cleaned at least once every two weeks.

In any case, you need to constantly monitor the operation of the solid fuel boiler. If you notice any problems or malfunctions, then carry out extraordinary cleaning, regardless of when it was last done.

You can read about the features of pellet boilers here.