Heating equipment on the modern market is represented by a huge number of models. Of these, the most common are units powered by gas. This fact can be explained quite simply: the described fuel is one of the available energy products, with the help of which systems operate in autonomous mode. The operating principle and advantages of double-circuit floor-standing boilers are known not only to specialists, but also to many private property owners.

If you also decide to install a heating system in your home, you should know how a wall-mounted double-circuit unit with an open combustion chamber differs from a floor-mounted version with a closed chamber. It will also be useful to know where dual-circuit systems are used, as well as what their structure and operating principle are. Models of gas boilers can be classified into single-circuit and double-circuit.

The former have a coil that only provides heating in the house. Double-circuit boilers have two coils or circuits, one of them is intended for heating, while the other is for water, which is usually used for sanitary needs.

Operating principle

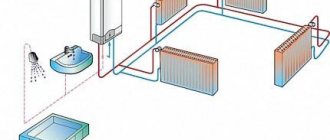

Double-circuit floor-standing boilers from different manufacturers have a certain design, but they have one common solution - there are two circuits inside. The one responsible for heating operates in a closed circuit. The water moves in a circle there, bypassing the radiators in the premises of the house. The heated liquid, which moves in a closed circuit, does not enter the second circuit. A separate valve is used for this. When the water consumption tap is opened in the faucets in the bathroom or kitchen, the valve shuts off the coolant in the heating system, which ensures the supply of hot water to the water supply circuit. When the taps are closed, everything happens in reverse.

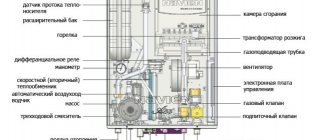

Almost all double-circuit floor-standing boilers have similar technical components, and models from different suppliers differ in some details. Looking at the assembly diagrams, you can see that the devices have three blocks, among them the following should be highlighted:

- automation;

- burner;

- heat exchanger

As for automation, it is responsible for controlling the installation.

Price policy

The pricing policy for such heating systems varies quite a bit in cost. It all depends on the manufacturer, because both domestic models and foreign-made units are offered for sale. Prices vary from 10,000 rubles to 200,000 rubles.

Everything is taken into account: the manufacturer, the power of heat generated, and how much space can be heated. European manufacturers are currently in the lead, since their main priority remains the safety of the heating installation, but since the device is equipped with all sorts of additional sensors, the cost increases in proportion to this.

It is also necessary to take into account the issue of payment for delivery, as well as the cost of consumables and necessary materials when installing the unit. You need to remember all the subtleties of preparing the thermal circuit so that natural rotation of the coolant fluid inside it can occur, and also, with a large boiler, you will need a large boiler room.

Features of the design of condensing and convection boilers

A double-circuit floor heating boiler can be classified according to its operating principle. This equipment may be convection or condensation. First, when fuel burns, steam is released, which is discharged out through the chimney. Condensing boilers have a second combustion chamber. It accumulates waste steam, which is heated and passes through a heat exchanger. The latter takes away the generated heat. These options have their advantages and disadvantages.

Convection boilers have a simpler design, which means they are easier to control. And their price is lower than that of condensing models. The steam is completely removed outside, so condensation does not form inside, which is very good, because excess moisture can be dangerous for the durability and safety of metal elements. But they are not afraid of corrosion here.

Combustion products are removed outside by natural draft, so there is no need to use ventilation equipment. Condensing double-circuit floor-standing boilers have one important advantage, which is that they are able to use gas most efficiently. This is due to the fact that the devices provide a second combustion chamber, which increases the efficiency by one and a half times or more. This is their main advantage over convection devices.

But there is only one drawback, but experts advise to take it into account. The installation is designed in such a way that it requires constant condensation of steam inside. This is only possible when cooled coolant is supplied to the circuit. Therefore, to heat your home, it is worth using powerful batteries with an impressive heat transfer capacity. When choosing a battery, it is better to give preference to aluminum or bimetallic varieties, but their installation is quite expensive. It should be borne in mind that a condensing double-circuit floor-standing boiler will not work efficiently if old cast iron batteries are installed in the system.

Material from which the heat exchanger is made

Floor-standing boilers can be equipped with three types of heat exchangers. It’s difficult to say clearly which one is better, but let’s look at the features of each. The cast iron heat exchanger is not subject to corrosion. It is insensitive to heat shock and acid attacks.

With proper use, such a part can last 20-30 years. The main disadvantage of cast iron is its fragility, which is important to consider when transporting it and during operation.

Before installation, it is recommended to carefully check the heat exchanger for cracks. When using the boiler, it is very important to maintain the required temperature conditions and not allow a temperature difference between return and supply of 45° or more.

Otherwise, the heat exchanger may crack. Another disadvantage of cast iron is its heavy weight, which makes it difficult to install the part and its subsequent dismantling if necessary.

Heat exchangers made of steel are lighter and more durable. They are not prone to cracks and are not subject to deformation. Their main disadvantage is their susceptibility to corrosion and burnout.

Depending on the quality of the alloy steel, the average service life of a steel assembly will be 10-15 years. If operating conditions are violated, the part will fail much earlier.

Extending the life of a steel heat exchanger is quite simple. It is necessary to ensure that the temperature inside the boiler does not fall below the “dew point” value for the exhaust gases. If this happens, condensation will form on the walls of the part.

It is carbonic acid dissolved in water. The aggressive substance will damage the heat exchanger. Thus, it is necessary to constantly maintain a sufficiently high temperature inside the boiler, which leads to higher fuel consumption.

Heat exchangers made of copper are characterized by excellent thermal conductivity, corrosion resistance and low weight. However, they are installed extremely rarely in floor-standing boilers. This is due to the high cost and “capriciousness” of the metal. During operation of a powerful floor-standing appliance, copper wears out very quickly. For low-power wall-mounted devices this option is more suitable

About the design and principle of operation from the point of view of the combustion chamber

The equipment described may have a combustion chamber of one of two types, which are open or closed. Quite often, consumers wonder how they differ. The operation of an open chamber involves the intake of air for fuel combustion from the same room where the device is installed. Oxidation products are removed through the chimney. Therefore, the unit should be installed only in a separate room that has an intensive ventilation system. If this feature is not taken into account, the device will not work well due to lack of fresh air. In this case, carbon monoxide will begin to penetrate into the home, which can create a danger not only to health. Moreover, it can even threaten human life.

It is important to remember that gas boilers with an open chamber can only be installed in a separate room. For the normal functioning of such units, a vertical chimney is required, which will provide natural draft. A double-circuit floor-standing boiler with a closed chamber operates on a different principle. For such devices, a coaxial chimney is constructed, into which combustion products penetrate using forced draft. This entire process is ensured by an electric fan. One pipe is placed into another, larger in diameter, which allows you to get the same coaxial chimney. Air enters through the outer pipe, which helps support the combustion process. But through the inner pipe, combustion products are discharged outside. Such a chimney can have any direction - both vertical and horizontal.

Operating rules

During operation of an open-type gas boiler, it is necessary to ensure a sufficient air supply in order to ensure complete combustion of gas.

Otherwise, the efficiency of the unit will be low, and the volume of unburned gas will be large, with possible release into the room. In closed fireboxes, it is also important to monitor the sufficiency of air and the functionality of the blower fan. Basic rules for the safe operation of a heating boiler operating on gas fuel if there is a gas smell:

- immediately turn off the gas valve to the burner device;

- open windows for ventilation;

- in closed-type boilers, forced ventilation is turned on in the chimney system of the gas boiler;

- do not use electrical switches and matches;

- immediately turn off the open flame;

- report an emergency to the gas service.

Autonomous heating is gaining popularity; for many homeowners it has become as necessary in the cold season as an air conditioning system in the summer - an affordable level of comfort in residential premises that ensures normal life activities.

The main function in this is performed by modern boiler installations - technologically advanced, innovative units capable of solving multi-level thermal problems.

Is it worth choosing a boiler with a closed combustion chamber?

A floor-standing double-circuit gas heating boiler with a closed combustion chamber has several advantages. Among them, it should be noted that there is no need to allocate separate rooms for its installation, so installation of the equipment can be carried out inside the house. In addition, such installations are more efficient. But such boilers also have their drawback - without electricity, the fan’s operation stops. This indicates that during power failures the heating system will stop operating. This should be taken into account before purchasing such a unit.

Design and principle of operation from the point of view of burners

Burners in boilers are responsible for power. In boilers they are mounted in chambers. Here fuel combustion occurs, which is accompanied by the release of heat. Oxidation products are removed to the outside using draft through the chimney. Above the burner there is a heat exchanger, which is a container with coolant. When combustion products reach the top, they rush into the chimney and heat the walls of the container, which helps to increase the temperature of the coolant. In this case, water enters the external circuit through special pipes.

A floor-standing double-circuit gas heating boiler can have one of two types of heat exchanger. The most common today are plate and bithermic structures. The former consist of copper tubes and plates, which are treated with an anti-corrosion compound during the production process. One pipe provides heating, while the other is responsible for hot water supply. Heat is transferred to the environment using plates.

Looking at the bithermic heat exchanger in more detail, you can understand that it has a different design. It provides for the presence of two tubes, which have different diameters and are placed one inside the other. The smaller one is used for hot water supply, while inside the larger diameter pipe there is water for heating. Such a device is not so reliable, and the water quality is not very high. This is due to the fact that over time, sediment forms on the walls of the tubes, clogging the interaxial space. This causes the device to stop working effectively.

Number of circuits in the device

The boiler can have one or two operating circuits built into it. In the first case, the device will only heat the coolant, that is, function as a heating device.

Such equipment is equipped with one heat exchanger, which significantly simplifies its design and reduces its size. True, the latter also depends on the power of the device. If single-circuit equipment is installed, you will need to purchase an additional unit to heat the water.

In this case, you can additionally install an indirect heating boiler, for example, or any other device. Single-circuit boilers are chosen for heating objects that do not require hot water supply or for large houses, where all the power of the device will be used to heat the building.

Double-circuit models are capable of simultaneously heating the coolant and heating water for domestic needs. Double-circuit boilers have two heat exchangers built in, which significantly complicates the design.

There are models with a so-called bithermic heat exchanger, which is divided into segments. The coolant moves through one of them, and the heating water moves through the other. Such devices are as compact as possible, but less reliable and easy to use.

The best option can be considered units with two completely separate heat exchangers. They form less scale. In addition, the circuits are separated, so there is no need to shut off the heating segment when distributing hot water. Whereas in boilers with a bithermic heat exchanger this is exactly what happens.

Double-circuit boilers are optimally used for small residential buildings. In large areas, mandatory separation of circuits is required, which is due to safety requirements, lack of total power, etc.

Most popular manufacturers

If you are looking for a gas floor-mounted double-circuit boiler for a private home, then you should consider the most popular models from manufacturers that have proven themselves in the heating equipment market. Among other proposals, the Pechkin KSGV-16 model should be highlighted, the cost of which is 19,500 rubles. This device is intended for household use.

The device can be operated in a closed heating system. The boiler has a high efficiency and low fuel consumption. The power of this double-circuit floor-standing gas boiler for a private house is 16 kW. The maximum thermal power consumption reaches 19 kW. The output is equivalent to 4 liters per minute, which is true when the coolant temperature reaches 25 °C.

You may also be interested in the overall dimensions of the device, which are 720 x 340 x 490 mm. The unit weighs 53 kg. The heating temperature varies from 40 to 90 °C. The maximum natural gas flow rate is 1.8 m3/h.

One of the well-known manufacturers is Protherm. Description of the boiler “Bear 50 KLZ”

If you want to choose heating and water supply equipment for your home, then you should pay attention to another model presented on the modern market - “Bear 50 KLZ”. Its cost is approximately 145,000 rubles. This boiler can operate on main and liquefied gas.

The unit is equipped with an open combustion chamber. To remove combustion products, a fan should be connected to the boiler. The heat exchanger is made of cast iron, which increases the service life of the equipment and reliability of operation. To protect against overheating of the coolant, the system is equipped with a cooling circuit. Convenient starting of the unit is guaranteed by electric ignition. Such double-circuit floor-standing gas boilers for heating a private house provide an efficiency factor of up to 92%. Their power consumption is 130 W. Maximum natural gas consumption is 5.2 m3/h. The hot water temperature can vary from 40 to 70 °C.

Dependence on automation

In gas heating equipment, automation plays the role of additional security. Thanks to special functions, the operation of the devices becomes more reliable and a constant optimal temperature is maintained.

Automation performs the following tasks:

- turns off the system when gas supply stops;

- regulates the burner power level;

- displays the indicators.

Additional features prevent device damage.

One of the leaders in popularity is . Description of the boiler “Premium 16N B”

When choosing equipment for heating and hot water supply, you should pay attention to models from. Among the company’s other offerings, “Premium 16N B” should be highlighted. This device has an acceptable cost - about 25,000 rubles. The boiler is equipped with a durable casing made of 2 mm steel. The equipment can be used for autonomous heating.

The heat exchanger is reliably protected from corrosion by an enamel coating. Inhibiting compounds provide protection against aggressive factors. Such double-circuit floor-standing gas boilers for home heating provide the consumer with the ability to connect equipment to liquefied gas. You can use the soft start option. The control panel consists of a thermometer and temperature controller. Using the first one, you can monitor the heating temperature of the coolant.

This device has a power of 16 kW. The maximum natural gas flow rate is 0.95 m3/h. Heating temperature – 90 °C. These double-circuit Lemax floor-standing boilers weigh 60 kg. They have many advantages, for example:

- ease of maintenance;

- advanced security protection system;

- increase in primary and secondary air flow;

- boiler compliance with all environmental and safety requirements;

- the ability to connect a room thermometer, with which the consumer will be able to adjust the temperature of the unit taking into account the temperature inside the room.

Non-volatile equipment: “Premium-12.5 V”

One of the popular models is “Premium-12.5” from. It costs from 21,000 rubles. The unit is a device for heating houses and cottages whose area does not exceed 120 m2. This equipment can also be used for hot water supply. This energy-independent floor-mounted double-circuit boiler is designed for autonomous heating. This indicates that the consumer will not experience terrible power surges that can damage equipment. This also applies to prolonged power outages.

This equipment is also called atmospheric, because it has an open combustion chamber, which provides for the formation of a combustible mixture when air is taken from the room, while combustion products are removed due to the draft created by a vertical chimney. This gas floor-mounted double-circuit non-volatile boiler does not have weather-sensitive automation and a built-in Wi-Fi module.

Among the main technical characteristics, the minimum useful power should be highlighted, which is 12.5 kW. The efficiency is 90%. This device does not have an expansion tank. If you plan to install it yourself, then you may need the diameter of the chimney. It is 130 mm. The design provides for a primary heat exchanger made of cast steel; this equipment does not have a secondary heat exchanger. This also applies to the circulation pump. The heated volume reaches 336 m3.

Description of another non-volatile boiler: “Lemax Premium-40 B”

This model is also energy-independent and is a device for heating houses with an area of up to 400 m2. If you choose the equipment described, then you should be interested in the prices for double-circuit floor-standing heating boilers for your home. In the case of the described model, the cost is 42,130 rubles. The unit runs on natural gas, but if necessary, it can be converted to operate on liquefied fuel, for which you will need to additionally purchase a set of nozzles. This model belongs to the category of autonomous heating, which indicates energy independence. The device is assembled in Russia, which reduces the cost. The manufacturer's warranty lasts for 36 months.

The unit runs on natural gas and has an open combustion chamber. The minimum useful power reaches 40 kW. The efficiency of this double-circuit floor-standing boiler for heating a private house is 90%. There is no expansion tank in the design. The chimney diameter may be needed by home craftsmen who plan to do the installation work themselves. This parameter is 140 mm.