Owners of private houses, apartments or any other objects have to deal with thermal engineering calculations. This is the basis of the fundamentals of building design.

Understanding the essence of these calculations in official papers is not as difficult as it seems.

You can also learn to perform calculations for yourself in order to decide what kind of insulation to use, how thick it should be, what power the boiler should be purchased and whether the available radiators are enough for a given area.

The answers to these and many other questions can be found if you understand what thermal power is. Formula, definition and scope of application - read the article.

What is thermal design?

Simply put, thermal calculations help to find out exactly how much heat a building stores and loses, and how much energy heating must produce to maintain comfortable conditions in the home.

When assessing heat loss and the degree of heat supply, the following factors are taken into account:

- What kind of object is it: how many floors does it have, the presence of corner rooms, is it residential or industrial, etc.

- How many people will “live” in the building?

- An important detail is the glazing area. And the dimensions of the roof, walls, floors, doors, ceiling heights, etc.

- What is the duration of the heating season, the climatic characteristics of the region.

- According to SNiPs, the temperature standards that should be in the premises are determined.

- Thickness of walls, ceilings, selected thermal insulators and their properties.

Other conditions and features can be taken into account, for example, for production facilities, working days and weekends, the power and type of ventilation, the orientation of housing to the cardinal points, etc. are considered.

Nuances of creating a system

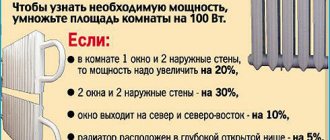

The heating system must be such that heating is sufficiently fast and uniform . Batteries are installed in each room of an apartment or house, the number and power of which must be calculated.

The heat gained by the room must be equal to the heat loss. One simplified method of calculation can be distinguished, according to which per 10 sq. m area you need to install a radiator, the power of which should be equal to 1 kW . However, in reality, it is best to install structures with a small margin, and it is advisable to increase the resulting value by 15% . This approximate calculation of the efficiency of devices is considered optimal for private use. Typically, the resulting power will be slightly greater than the required value, but you can be confident in the reliability and quality of heating.

When calculating heating, professionals use more complex and specific methods that can even determine the power of the device per 1 square meter.

Why do you need a thermal calculation?

How did builders of the past manage to do without thermal calculations?

The surviving merchant houses show that everything was done simply with reserves: smaller windows, thicker walls. It turned out to be warm, but not economically profitable.

Thermal engineering calculations allow us to build in the most optimal way. No more or less materials are taken, but exactly as much as needed. The dimensions of the building and the costs of its construction are reduced.

Calculating the dew point allows you to build in such a way that materials do not deteriorate for as long as possible.

To determine the required boiler power, you also cannot do without calculations. Its total power consists of energy costs for heating rooms, heating hot water for household needs, and the ability to cover heat loss from ventilation and air conditioning. A power reserve is added for periods of peak cold weather.

When gasifying a facility, coordination with services is required. The annual gas consumption for heating and the total power of heat sources in gigacalories are calculated.

Calculations are needed when selecting heating system elements. The system of pipes and radiators is calculated - you can find out what their length and surface area should be. The loss of power when turning the pipeline, at joints and passing through fittings is taken into account.

When calculating thermal energy costs, knowledge of how to convert Gcal to KW and vice versa can be useful. The following article discusses this topic in detail with calculation examples.

A complete calculation of a warm water floor is given in this example.

Did you know that the number of sections of heating radiators is not taken out of thin air? Too little of them will lead to the fact that the house will be cold, and too much will create heat and lead to excessive dryness of the air. The link provides examples of correct calculation of radiators.

Comparison of different types of radiators

Thermal power is one of the main characteristics, but there are others that are no less important. Selecting a battery only on the basis of the required heat flow is wrong. You need to understand under what conditions a particular radiator produces the specified flow and how long it will last in your home heating system. Therefore, it is more correct to consider all the main technical characteristics of sectional types of heaters, namely:

- aluminum;

- bimetallic;

- cast iron

Let's compare heating radiators according to the following main parameters, which play an important role in their selection:

- thermal power;

- permissible working pressure;

- crimping pressure (test);

- capacity;

- weight.

Note. We do not take into account the maximum degree of heating of the coolant, since for batteries of all types it is quite high, which makes them suitable for use in residential buildings according to this parameter.

Operating and test pressure indicators are important for selecting batteries for different heating systems. If in cottages or country houses the coolant pressure rarely exceeds 3 Bar, then with centralized heat supply it can reach from 6 to 15 Bar, depending on the number of floors of the building. We should not forget about water hammer, which is not uncommon in central networks when they are put into operation. For these reasons, it is not recommended to include every radiator in such networks, and it is better to compare heat transfer taking into account characteristics that indicate the strength of the product.

The capacity and weight of heating elements play an important role in private housing construction. Knowing the radiator capacity will help calculate the total amount of water in the system and estimate the thermal energy consumption for heating it. The weight of the device is important for determining the method of attachment to an external wall, built, for example, from a porous material (aerated concrete) or using frame technology.

To familiarize yourself with the main technical characteristics, we present in the table the data of the well-known manufacturer of aluminum and bimetal radiators - the company RIFAR, as well as the parameters of cast iron batteries MS-140.

Calculation of thermal power: formula

Let's look at the formula and give examples of how to make calculations for buildings with different dissipation coefficients.

Vx(delta)TxK= kcal/h (thermal power), where:

- The first indicator “V” is the volume of the calculated premises;

- Delta "T" - temperature difference - is the value that shows how many degrees warmer inside the room than outside;

- “K” is the dissipation coefficient (it is also called the “heat transmittance coefficient”). The value is taken from the table. Typically the figure ranges from 4 to 0.6.

Approximate dissipation coefficient values for simplified calculations

- If it is an uninsulated metal profile or board, then “K” will be = 3 – 4 units.

- Single brickwork and minimal insulation - “K” = from 2 to 3.

- Two brick wall, standard ceiling, windows and

- doors – “K” = from 1 to 2.

- The warmest option. Double-glazed windows, brick walls with double insulation, etc. - “K” = 0.6 – 0.9.

A more accurate calculation can be made by calculating the exact dimensions of the surfaces of the house in m2 that differ in properties (windows, doors, etc.), making calculations for them separately and adding up the resulting indicators.

Comparison of heating radiators by heat transfer

The real heat transfer of heating radiators of various types continues to be the subject of controversy, which continues on various Internet sites and forums. The debate is in the context of which of them are the best in terms of this indicator, which ultimately influences the choice of certain heating devices by users. Therefore, it makes sense to compare the thermal power of different types of radiators, assessing their actual heat output. This is what is discussed in the material presented to your attention.

Example of thermal power calculation

Let’s take a certain room of 80 m2 with a ceiling height of 2.5 m and calculate the power of the boiler we will need to heat it.

First, we calculate the cubic capacity: 80 x 2.5 = 200 m3. Our house is insulated, but not enough - the dissipation coefficient is 1.2.

Frosts can be down to -40 °C, but indoors you want to have a comfortable +22 degrees, the temperature difference (delta “T”) is 62 °C.

We substitute the numbers into the heat loss power formula and multiply:

200 x 62 x 1.2 = 14880 kcal/hour.

We convert the resulting kilocalories into kilowatts using a converter:

- 1 kW = 860 kcal;

- 14880 kcal = 17302.3 W.

We round up with a margin, and we understand that in the most severe frost of -40 degrees we will need 18 kW of energy per hour.

We can calculate heat loss in W for each m2 of walls and ceiling. The height of the ceilings is known to be 2.5 m. The house is 80 m2 - this could be 8 x 10 m.

Multiply the perimeter of the house by the height of the walls:

(8 + 10) x 2 x 2.5 = 90 m2 of wall surface + 80 m2 of ceiling = 170 m2 of surface in contact with the cold. The heat loss we calculated above amounted to 18 kW/h, dividing the surface of the house by the estimated energy consumed, we find that 1 m2 loses approximately 0.1 kW or 100 W every hour at an outdoor temperature of -40 °C, and indoor temperature +22 °C .

These data can become the basis for calculating the required thickness of insulation on the walls.

Let's give another example of a calculation; it is more complicated in some aspects, but more accurate.

Formula:

Q = S x ( delta ) T / R:

- Q – the desired value of heat loss at home in W;

- S – area of cooling surfaces in m2;

- T – temperature difference in degrees Celsius;

- R – thermal resistance of the material (m2 x K/W) (Square meters multiplied by Kelvin and divided by Watt).

So, to find “Q” of the same house as in the example above, let’s calculate the area of its surfaces “S” (we will not count the floor and windows).

- “S” in our case = 170 m2, of which 80 m2 is the ceiling and 90 m2 is the walls;

- T = 62 °C;

- R – thermal resistance.

We look for “R” using the thermal resistance table or formula. The formula for calculating the thermal conductivity coefficient is as follows:

R = H / K.T. (N – material thickness in meters, K.T. – thermal conductivity coefficient).

In this case, our house has walls made of two bricks covered with foam plastic 10 cm thick. The ceiling is covered with sawdust 30 cm thick.

The heating system of a private home must be designed taking into account energy savings. Calculation of the heating system of a private house, as well as recommendations for choosing boilers and radiators - read carefully.

How and how to insulate a wooden house from the inside, you will learn by reading this information. Choice of insulation and insulation technology.

From the table of thermal conductivity coefficients (measured by W / (m2 x K) Watt divided by the product of a square meter by Kelvin). We find the values for each material, they will be:

- brick - 0.67;

- polystyrene foam – 0.037;

- sawdust – 0.065.

Substitute the data into the formula (R= H/ K.T.):

- R (ceiling 30 cm thick) = 0.3 / 0.065 = 4.6 (m2 x K) / W;

- R (brick wall 50 cm) = 0.5 / 0.67 = 0.7 (m2 x K) / W;

- R (foam 10 cm) = 0.1 / 0.037 = 2.7 (m2 x K) / W;

- R (wall) = R (brick) + R (foam) = 0.7 + 2.7 = 3.4 (m2 x K) / W.

Now we can start calculating heat loss “Q”:

- Q for ceiling = 80 x 62 / 4.6 = 1078.2 W.

- Q walls = 90 x 62 / 3.4 = 1641.1 W.

- All that remains is to add 1078.2 + 1641.1 and convert to kW, it turns out (if you round right away) 2.7 kW of energy in 1 hour.

You can notice how big the difference was in the first and second cases, although the volume of the houses and the temperature outside the window in the first and second cases were exactly the same. It's all about the degree of fatigue of the houses (although, of course, the data could have been different if we had calculated the floors and windows).

Comparative findings

As the table below compares the heat transfer of heating radiators shows, the most efficient in terms of power are bimetallic heaters.

Let us remind you that they are an aluminum finned body with a strong welded frame inside made of metal tubes for the flow of coolant. In all respects, this type of heater is suitable for installation both in heating networks of high-rise buildings and in private cottages. Their only drawback is their high cost. The heat transfer of aluminum radiators is slightly lower, although they are lighter and cheaper than bimetallic ones. In terms of test and operating pressure, aluminum devices can also be installed in buildings of any number of floors, but subject to: the presence of an individual boiler room with a water treatment unit. The fact is that aluminum alloy is susceptible to electrochemical corrosion from low-quality coolant inherent in central networks. It is better to install aluminum radiators in separate systems.

Cast iron radiators differ sharply from others. the heat transfer of which is significantly lower with a large mass and capacity of the sections. It would seem that with such a comparison they would not find application in modern heating systems. Nevertheless, the traditional MS-140 “accordion” continues to be in demand, their main trump card is durability and resistance to corrosion. Indeed, gray cast iron, from which MS-140 is made by casting, can easily serve for up to 50 years or more, and the coolant can be anything.

In addition, a conventional cast iron battery has high thermal inertia due to its massiveness and capacity. This means that when the boiler is turned off, the radiator remains warm for a long time. As for the operating pressure, cast iron heaters cannot boast of high strength. Purchasing them for networks with high water pressure is risky.

Other features of choosing a device

The heating system is considered one of the most important, so when calculating it is important to take into account every square meter of the room . It must be remembered that if the device is intended for low-temperature pressure, then the indicator obtained as a result of the calculation must be doubled.

The heat transfer of products is also affected by the place where they will be located in the room. It is also necessary to take into account the method that will be used to connect them.

Thus, it is possible to determine the efficiency and other parameters of radiators in different ways. In this case, you can decide how many items should be purchased. For this, a special table of values, a simplified version of the calculation, or a complex method involving the use of a specialized formula can be used. The last option is considered the most correct, since it allows you to get the exact value.