Replacing a heating system, in particular radiators, is a very complex and responsible task. The modern market offers a fairly diverse number of models from different materials. Just a few years ago, cast iron was inferior to aluminum and steel structures.

Scheme of cast iron heating radiators.

But installing modern batteries everywhere, people are faced with the fact that the reliability and durability of new radiators is not as good as that of cast-iron models.

Therefore, recently there has been a trend towards increasing sales of cast iron heating products.

What is heat transfer and power of radiators

The power of cast iron heating radiators and their heat output are among the main characteristics of any device that provides room heating. Typically, manufacturers of equipment for heating structures indicate this parameter for one section of the battery, and the required number is calculated based on the size of the room and the required heat transfer of cast iron radiators.

In addition, other factors are taken into account, such as the volume of the room, the presence of windows and doors, the degree of insulation, climatic conditions, etc. The heat output of heating radiators depends on the material they are made of. It should be noted that cast iron is inferior to aluminum and steel in this matter. The thermal conductivity of this material is 2 times lower than that of aluminum. But this drawback is compensated by the low inertia of cast iron, which gains heat and releases it for a long time.

In closed heating systems with forced circulation, the efficiency of aluminum batteries will be much greater, but subject to the presence of an intense coolant flow. As for open structures, cast iron has more advantages with natural circulation.

The approximate power of one section of a cast iron radiator is 160 watts, while for aluminum and bimetallic devices the same parameter is within 200 watts. Therefore, under equal operating conditions, a cast iron battery should have a large number of sections.

Nuances of choice

Coolant temperature and temperature conditions in the heated room.

When choosing a battery, you should consider the maintained room temperature. The optimal air temperature is considered to be from 22 to 24 °C. In an autonomous heating system, you can regulate the heating temperature of the coolant. In apartments with central heating, this is not possible, so you should choose from those models that can withstand high temperature and hydraulic loads.

Radiator connection diagrams.

The percentage of heating efficiency also depends on the method of connecting the device. The most effective is considered to be a diagonal connection, which ensures uniform heating of the sections. If you have a different scheme for connecting batteries to the pipeline, you should choose models with a power slightly higher than calculated.

Single pipe heating system.

It is worth remembering that a single-pipe system is characterized by uneven heat distribution between the heating radiators, so the heating device farthest from the supply pipe should be larger than the others.

The ratio of glazing area to room area.

For large rooms with two window openings, it is worth purchasing two batteries, taking into account the glazing area. Heating devices of equal power are installed in a room with two identical window openings.

The procedure for calculating the number of sections

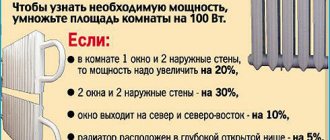

There are different methods for performing technical calculations of radiators. Accurate algorithms allow calculations to be made taking into account many factors, including the size and location of the room in the building. You can also use a simplified formula that will allow you to find out the desired value with sufficient accuracy. So, you can calculate the number of sections by multiplying the area of the room by 100 and dividing the resulting result by the power of the cast iron radiator section in watts.

In this case, experts recommend:

- in the case where the result is a fractional number, round it up. A supply of heat is better than a lack of it;

- when the room has not one, but several windows, install two batteries, dividing the required number of sections between them. As a result, not only the service life of radiators increases, but also their maintainability. The batteries will be a good barrier to cold air coming from the windows;

- If the ceiling height in the room is more than 3 meters and there are two external walls, in order to compensate for heat loss, it is advisable to add a couple of sections and thereby increase the power of the cast iron heating radiator.

Finally, a few clarifications

Heating devices can operate in different conditions and be connected according to different schemes. These factors influence the heat transfer of heaters during operation. When determining the power of room radiators, consider several recommendations:

- If the battery is connected to the pipelines using a different bottom circuit, the heating efficiency deteriorates. Add 10% to the calculated power rating of the devices.

- In combined systems (radiator network + warm water floors), convection devices play a supporting role. The main heating load is carried by floor circuits. But the calculated heat transfer of radiators should not be underestimated; if necessary, the batteries should completely replace heated floors.

- Homeowners often cover heaters with decorative screens, even covering them with drywall, leaving convection gaps. In this case, the infrared heat generated by the heated surface of the device is completely lost. Accordingly, the battery power will have to be increased by at least 40%.

- Do not install 1-3 radiator sections, even if the calculation shows this amount. To get a normal heating device, you need to install at least 4 fins.

- Non-freezing liquids are inferior to ordinary water in terms of heat capacity, the difference is approximately 15%. When using antifreeze, increase the heat transfer area of the batteries by 10% (increase the number of radiator sections or panel sizes).

When calculating heating radiators, consider a simple rule: the lower the water temperature in the supply line, the larger the heat exchange surface area needed to heat the rooms. Select boiler equipment correctly and install systems so that you do not have to solve problems by expanding battery sections.

Dimensions and weight of cast iron heating radiators

The parameters of cast iron radiators using the example of the domestic product MS-140 are as follows:

- height – 59 centimeters;

- section width – 9.3 centimeters;

- section depth – 14 centimeters;

- section capacity – 1.4 liters;

- weight – 7 kilograms;

- section power 160 watts.

You can hear complaints from property owners that it is quite difficult to move and install radiators consisting of 10 sections, the weight of which reaches 70 kilograms, but the good news is that such work in an apartment or house is done only once, so the dimensions of cast iron heating radiators must be correctly calculated.

Since the amount of coolant in such a battery is only 14 liters, when thermal energy comes from the boiler of an autonomous heating system, then you will have to pay for the extra kilowatts of electricity or cubic meters of gas.

Heating devices of single-pipe systems

An important feature of the horizontal “Leningrad” is the gradual decrease in temperature in the main line due to the admixture of coolant cooled by the batteries. If 1 ring line serves more than 5 devices, the difference at the beginning and end of the distribution pipe can reach 15 °C. The result is that the latest radiators emit less heat.

Single-pipe closed circuit - all heaters are connected to 1 pipe

To ensure that long-distance batteries transfer the required amount of energy to the room, make the following adjustments when calculating heating power:

- Select the first 4 radiators according to the instructions above.

- Increase the power of the 5th device by 10%.

- Add another 10 percent to the calculated heat transfer of each subsequent battery.

Explanation. The power of the 6th radiator increases by 20%, the seventh by 30, and so on. An expert will tell you in detail in the video why to expand the last batteries of a single-pipe Leningradka:

Working and testing pressure

Among the technical characteristics, in addition to the fact that the power of cast iron heating radiators is important, mention should be made of pressure indicators. Typically, the operating pressure of the coolant liquid is 6-9 atmospheres. Any type of battery can cope with this pressure parameter without problems. The standard pressure for cast iron products is considered to be exactly 9 atmospheres. In addition to the working one, the concept of “pressure testing” is used, reflecting its maximum permissible value that occurs during the initial start-up of the heating system. For the cast iron model MS-140 it is equal to 15 atmospheres.

According to the regulations, during the process of starting the heating system, it is necessary to check the ability to smoothly start centrifugal pumps, which should operate in automatic mode, but in reality everything is far from as it should be.

Unfortunately, in most homes, automation is either absent or faulty. But the instructions for carrying out this type of work stipulate that the initial start-up should be performed with the valve closed. It is allowed to open smoothly only after equalizing the pressure in the coolant supply line.

But utility workers do not always follow instructions. As a result, in case of violation of the regulations, water hammer occurs. With it, a significant pressure surge leads to exceeding the permissible pressure value and one of the batteries located along the path of the coolant is unable to withstand such a load. As a result, the service life of the device is significantly reduced.

Types of heat exchangers

A heating radiator is a device that consists of sections combined into a single device through which a heated coolant moves—usually water. Compartment - a battery element, usually a cast two-tubular structure, capable of radiating heat, which is transferred to the surrounding air, which allows you to create a comfortable atmosphere in the apartment.

According to their design, heating devices are divided into panel and sectional. There are also registers - a tubular product with a large diameter, or a shaped coil (a heated towel rail in the bathroom), they cut into the system.

Heating devices are: steel, cast iron, aluminum, copper. Cast iron products, which we are used to seeing in our homes, need painting to give a good appearance.

Cast iron

Products made of cast iron are the most common; they have a simple shape and design. They are mounted and on legs.

Manufactured by casting. These are massive structures that store heat for a long time; in terms of operation, they are the most profitable.

Pros:

- transfer heat well;

- resistant to corrosion;

- durable, last at least 30 years;

- not picky about water quality.

Minuses:

- heavy, difficult to install;

- bad design.

Steel

Steel heat exchangers come in panel and tubular types.

Panel models are made of metal 1.5 mm thick, so they have a small thermal capacity. This quality allows you to quickly adjust the temperature. They are efficient in operation, their efficiency reaches 75%. The advantages also include low cost and simple operation. Disadvantage: poor corrosion resistance.

Tubular varieties have all the advantages of the panel type, but unlike them, they have a high pressure level of 9 - 16 bar, the first 7 - 9. And the heating power (120 - 1600 W) and water heating (120) are equal for both models.

Aluminum

Aluminum heat exchangers are recommended for private buildings with autonomous heat supply. This model is not intended for use in centralized heating, as it is exposed to low-quality coolant. Presented on the Russian market.

Aluminum batteries are cast and extruded:

- cast - have several compartments, they are durable, with thicker walls and wide channels for water;

- extrusion - according to production technology, the device is extruded from an aluminum alloy mechanically, resulting in a solid product, but the number of compartments cannot be increased.

All aluminum batteries have high thermal output, they are lightweight and easy to install. Externally they look presentable. In terms of pressure and temperature levels, they can be equated to steel products.

Bimetallic

Bimetallic heat exchanger - tubular steel core and aluminum body. It is durable and reliable, able to withstand high pressure. Despite its low inertness, it has increased heat transfer with low water consumption. Outwardly it looks presentable and is not difficult to care for.

The main disadvantage is the high price.

Copper

Copper has been used for the manufacture of heat exchangers for a long time, but such models have become widely used recently. Since heating systems require a refined type of copper, and new technologies have made its production inexpensive.

With the same technical indicators as other models, they weigh less and heat transfer is higher. This property significantly reduces electricity costs.

Copper has increased mechanical strength, so pipes can be used in combination with water heated to 150 degrees, at a pressure of 16 atmospheres.

Coolant quality for cast iron radiators

As previously noted, for cast iron radiators the quality of the coolant fluid does not matter. These devices do not care about the pH value or its other characteristics. At the same time, foreign impurities, such as stones and other debris present in municipal heating networks, pass without interference through the fairly wide channels of the batteries and are transported further. They often end up in the narrow holes of steel inserts in bimetallic radiators of neighbors. Naturally, over time, the power of the cast iron radiator section decreases.

If an autonomous heating system is used in a private house, it does not matter what coolant will be used - water, antifreeze or antifreeze. Before using water as a heat carrier, the property owner needs to prepare it, otherwise the heating boiler, hydraulic group or heat exchanger will quickly fail (read: “Chemical cleaning of boiler heat exchangers”). The power of the heating unit may also drop.

Painting

It can be carried out using any type of composition, but under one condition: the solution must be resistant to high temperatures.

The surface of the heating radiator is painted using a regular or curved brush. First, gloves are put on your hands and gauze, foam rubber or rags are placed nearby. They can be used to wipe off paint that has flowed down the brush handle.

The dyeing process is as follows:

- Use a flexible brush to update the appearance of hard-to-reach places (they are located between the pipes of the sections). In some parts the brush will not touch the cast iron. You can use gauze folded into a tourniquet. It is placed between the sections, paint is applied to the middle and then the ends are pulled in turn. This way the paint will adhere to the alloy.

- Paint the top and easily accessible places.

- Always moving from top to bottom. It is better to apply the paint in several layers.