Weak boiler power will ruin everything, including the standard of living. Due to excess power, the system will operate in impulses: fuel consumption will increase, and the service life of the equipment will be shortened. The boiler may boil. Or brains. How to calculate correctly, what parameters to take into account, what heat loss is and other customer questions about boiler power can be read here.

How to easily calculate the power of a heating boiler?

You can calculate the approximate power of a boiler for a home by area and volume .

1) A simplified version of calculations by area : 10 kW per 100 m² of a house (or heated area). And this figure will only show the minimum power, below which you cannot fall.

| Graph of boiler versus area |

To take into account climatic zones, coefficients have been developed that correct this formula:

- Central Russia is 1-1.5;

- Northern regions are 1.5-2;

- Southern territories – 0.7-0.9;

- Moscow and Moscow region – 1.2-1.5.

To get closer to a realistic figure, you also need to take into account possible heat loss. To do this, add 10-15% to the minimum value. If the ceilings are higher than 2.7 meters, then we divide the actual ceiling height by the standard height. We get another correction factor.

| Vacation home |

Example:

Let's calculate the power of a boiler for a house in the Moscow region. Ceilings – 3 meters, area – 150 m². A double-circuit boiler is needed - for heat and hot water supply.

The formula gives 15 kW - the minimum power value for the future boiler. Next, to the number 15 we add 10% of heat loss, multiply by the climate coefficient 1.2. The ceilings are higher than 2.7m, so we multiply the resulting figure by a factor of 1.1.

Boiler power = 15 kW (minimum) + 10% (heat loss) * 1.2 * 1.1 = 21.7, rounded to 22 kW.

2) Second formula based on volume : 1 m3 – 40 W. Plus the markups that were included in the first formula, except for the ceiling coefficient. Let's calculate the same house in the Moscow region using this formula.

Boiler power =((150 m²*3m)* 40 W + 10%) * 1.2 * 1.1 =23522 W ≈ 24 kW. The difference between the first and second calculations is 2 kW. The option of calculating boiler power by air volume is the most correct.

You could stop reading this article here. But the difference between an approximate and an exact calculation is in several nuances. What are the nuances, you ask. The answer to this question is contained in the following paragraphs.

What values are used when calculating gas heating equipment

There is an old method for determining the required amount of thermal energy to heat a house. They are still used today, but the calculation method is approximate. It is based on the ratio of one square meter of house area and unit of gas boiler power.

The ratio is this: 1 kW of thermal energy should be consumed per 10 m². This takes into account that the ceiling height does not exceed 2.8 m. For example, if the total heated area of the building is 100 m², then to heat it it is necessary to install a gas boiler with a capacity of at least 10 kW.

The formula is simple, but it does not take into account other factors affecting the heat loss of a building. For a small building this calculation is acceptable.

Only a heating engineer who takes into account all factors can accurately calculate the power.

To do this, he will need the following quantities:

- house design with floor plan;

- construction specifications, which specify the materials to be used;

- thermal conductivity coefficient of these building materials;

- type of windows installed, their total area;

- type of ventilation system, its maximum and planned performance;

- average monthly air temperatures in the region;

- Rose of Wind;

- location of the building relative to the cardinal directions.

Additionally, right on site, a heating engineer can conduct studies of the building’s structure using tools and instruments: infravisor, pyrometer and others. With their help, a heat leakage map is drawn up, which allows you to make adjustments, that is, carry out additional thermal insulation measures.

The calculation is carried out by premises. The heat loss of each room is determined, and then everything is summed up. This is a serious calculation that is impossible to carry out on your own without having an understanding of heating engineering.

Calculation of gas boiler power for a typical house

Here you can use the first option, that is, for 10 m² 1 kW of thermal energy. But without adjustment factors such a calculation will not be complete. They are shown in the table.

| Amendments | Values |

| Power reserve | 1,2 |

| Climate zone | 0,8-2,5 |

| Additional coolant consumption in the form of hot water supply | 1,3 |

Returning to the previous example with a house of 100 m². Without correction factors, the power of the gas boiler should be 10 kW. With odds:

10x1.2x1.0x1.3=15.6 kW.

There is no such standard indicator, so the closest one is chosen. This is 17.5 kW.

What parameters, besides volume and area, influence the choice of boiler? And why is this important?

A simplified calculation formula often leads to the purchase of an unsuitable boiler. Each house is individual, and heat loss percentage cannot be equal for all houses. Before calculating power, consider the data of a specific house:

1) Measure the area of walls, windows, doors;

2) Specify the thickness of the walls, indicate the type of finishing and material, the height of the ceilings;

3) Observe the minimum temperature of the house in cold weather;

4) Determine the desired temperature as a result of installing the boiler;

5) Write down the thermal conductivity values for the materials from which the house was built.

| Wall material | Wall thickness and material thermal resistance | Required thickness for home |

| Brick (1600 kg/m³ - density) | 510 mm (if laying two bricks), R=0.73 °C m²/W | 1380 mm 2190 mm |

| Wooden beam | 150 mm, R=0.83 °С m²/W | 355 mm 565 mm |

| Expanded clay concrete (1200 kg/m³ - density.) | 300 mm, R=0.58 °С m²/W | 1025 mm 1630 mm |

| Wooden panel (inside filled with mineral wool + 25 mm layer of inner and outer cladding) | 150 mm, R=1.84 °С m²/W | 160 mm 235 mm |

| Arbolit | 0.80-0.17W/m² | — |

| Foam concrete | 0.14-0.38 W/m² | — |

| Aerated concrete | 0.18-0.28 W/m² | — |

Thermal resistance of materials

Why is this necessary? The key parameter influencing the choice of boiler is the heat loss of the house. Houses with the same area and volume, but different degrees of insulation, will require equipment of different power.

Where does the heat go:

| Surface | Heat loss in% |

| Roof and ventilation | 20-25% |

| Foundation, if it is adjacent to the ground | up to 15% |

| Walls, windows and doors | 10-15% |

| Ground floor and unheated rooms, basement, for example | up to 15% |

It also matters: how different the outside temperature is from the inside, the climatic region, the strength and direction of the wind, how the house stands relative to parts of the world.

| Heat loss |

Installation Requirements

When sufficiently reliable consumption data is obtained, the total energy capacity of the boiler house and its constituent units is calculated. When performing this, the following points should be taken into account. Today, boiler installations operating in stand-by mode (maintaining the boiler in a “hot” state without power take-off) are practically not designed, since the costs in this case are high. At the same time, shutdowns and starts of burners should occur as rarely as possible. In any case, it is recommended to distribute the power to at least two heat generators. In this case, the optimal solution is often to choose boilers of different capacities. A smaller boiler will be used during periods of low heat consumption, for example, at night or on weekends in the summer, as well as to cover peak load (as already mentioned, this usually occurs in the morning in winter). If increased heat consumption occurs in boiler rooms during the summer period, for example, in industrial enterprises, then the minimum boiler power must be calculated so as to ensure consumption. It is also necessary to ensure that if large pieces of equipment fail, the boiler room operates - at least in a mode of limited functionality - until the faults are completely eliminated. In some cases, especially when using solid fuel installations, the use of buffer heat storage devices has a positive effect. For relatively small (less than 4 MW) boiler houses, it is recommended to implement automatic regulation according to specified temperature and pressure ranges, and for larger boiler houses - according to heat and steam consumption, which allows optimal load regulation. In the latter case, the compromise that customers and designers often make in order to reduce the cost of the control system leads to negative results during the operation of the boiler room.

How to calculate power taking into account heat loss?

What is heat loss? Let’s say it’s -20 degrees outside, but the average temperature at home is +20 degrees. These quantities are balanced through the exchange of energy. Heat losses occur. The amount of heat loss under severe weather conditions helps to calculate the boiler power with high accuracy.

Step 1

Heat loss is determined by the formula: Q = Q roof + Q walls + Q floor + Q doors + Q windows .

Where the extreme value of Q is the heat loss of each surface of the house.

Each Q value is calculated using the formula: Q = S * T / R

Where Q is heat loss in W, S is the area of a specific surface in m², T is the difference between street and room temperatures in degrees, R is reference data on thermal resistance by type of material.

Step 2

This formula additionally includes involuntary heat loss through cracks, ventilation, exhaust hoods, opening doors and ventilation through windows. For independent calculations without a program, an additional 5% of the total leakage figure is added.

Step 3

Next we move on to determining the boiler power. There are only two formulas to choose from:

Rkot. = ( S room * P beat ) / 10 , where Rkot. — boiler power, Sroom. - the total area of rooms in the house where heating is planned, Pud. — specific power according to climate conditions.

Rkot. = ( Q losses * S from area ) / 100, where Rkot. - boiler power, Qloss - heat loss, Sot. area – total area of heated rooms.

Step 4

For an electric and gas boiler, you can use the table to check:

| Option | House area, m² | Heating, kW | Recommended number of devices | How many people live | DHW boiler, l/kW | Warm floor, m² | Warm floor, kW | Total power | Boiler power | Standard range of boilers, Cat, Ns/A/Nd |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 2 | 150 | 19 | 10 | 4 | 100/28 | 16 | 0,75 | 48 | 28 | 28/27/28 |

| 3 | 200 | 22 | 11 | 4 | 100/28 | 20 | 1 | 51 | 28 | 28/27/28 |

| 4 | 250 | 25,5 | 17 | 4 | 160/33 | 20 | 1 | 60 | 33 | 32/35/36 |

| 5 | 300 | 27 | 20 | 6 | 160/33 | 30 | 1,5 | 62 | 34 | -/35/36 |

| 6 | 350 | 31 | 26 | 6 | 200/33 | 40 | 2 | 66 | 39 | -/44/44 |

| 7 | 400 | 4 | 30 | 6 | 200/36 | 50 | 2,5 | 70 | 43 | -/44/44 |

| 8 | 450 | 36 | 44 | 8 | 300/36 | 60 | 3 | 75 | 45 | -/53/52 |

Calculation options

In addition to calculating 1 kW per 10 m², as well as using thermal engineering calculations, it is possible to calculate the required power of a gas boiler using an online calculator. Not the most accurate option, but can be used for small buildings.

Another factor that affects the calculation of the power of a gas boiler is the type of equipment. That is, is it single-circuit or double-circuit.

The first is a standard design with one heat exchanger that works for the heating system. The second circuit has added one more circuit - for the hot water supply system. When a hot water tap opens, it flows into it from the heating network. In this case, the burner begins to operate at full power, and the heating is turned off using a three-way valve.

For each type of gas boiler, its own calculation is made.

For a gas boiler with one circuit

The same option is used here as in the case of a standard house. But if, according to the project, non-standard solutions given in the list were used inside the building, then the power of the gas boiler will need to be calculated only using a thermotechnical method.

Namely:

- pool;

- winter Garden;

- high ceilings;

- large glazing area, etc.;

Accuracy is important here. In addition to the above factors, it is necessary to take into account other coefficients, for example, heat dissipation. The difference in temperatures inside buildings and outside is also taken into account. This calculation is complicated.

For a gas boiler with two circuits

Here one coefficient is added, which is responsible for the consumption of hot water - 1.2-1.4. The more consumers in the house, the greater the value of the coefficient. For example, the bath or shower has the most consumption. Less - at the sink.

For models with boiler

A single-circuit unit is used here. But a container is added to it in which hot water used for domestic needs is accumulated. It is called a boiler. This DHW scheme is much more efficient than the double-circuit version, because a large volume of hot water is stored in the tank. And its consumption does not affect the heating network.

The volume of the storage tank is determined from the average daily consumption of hot water. The latter indicator is influenced by the consumption rate of certain plumbing fixtures.

| Type of plumbing | Water flow rate, l/min |

| Bath | 8-10 |

| Shower cabin | 9-10 |

| Sink | 4 |

| Kitchen sink | 4 |

The total power of the equipment is the sum of the capacities of the boiler and the boiler. The first is taken from the passport, the second is calculated taking into account correction factors.

Why count if you can buy a boiler with a power reserve?

Sometimes boilers have a capacity reserve. This is good when the reserve is no more than 25%. Especially when the family plans to develop the area: complete a swimming pool, sauna, or other heated area. When the required power is exceeded significantly, the owner spends extra money, and the equipment operates in abnormal mode:

| Boiler repair |

- Breaks or malfunctions;

- The efficiency of the system decreases;

- A higher power boiler costs more;

- More fuel is consumed than is required to heat the house;

- A more powerful and expensive pump will be needed;

- The house will be very hot;

- Automatic regulation becomes difficult, the boiler may boil;

- The boiler begins to cycle - it turns on and off in a short period of time, equipment components wear out;

- Condensation appears in the chimney. When burned, the condensate reacts with the emissions and produces acid. It destroys the chimney and sometimes the boiler.

Conclusion: frequent switching on and off wastes more fuel than continuous operation. Buying a boiler with excess power not only makes no sense, but is also harmful to the budget and equipment.

Burner selection

When choosing a burner, determining the minimum boiler load is of great importance. The minimum power of two-stage burners is 40-60% of the nominal, three-stage burners - about 35%. For modulating burners it can be even less. Boilers with a power of up to 2 MW are mainly equipped with two- and three-stage burners. The use of modulating burners in this case does not make it possible to reduce the main load, but increases the costs of the burner, its maintenance and adjustment. For more powerful boilers, the best option would be a modulating burner.

With a fixed, no downward shift in the nominal power of the boiler, in some cases it is better to use a burner with a slightly higher power. And with a slight decrease in the rated power, the use of a smaller burner by one standard size will allow you to expand the power control range and optimize its lower limit. Therefore, more attention should be paid to the boiler to burner power ratio, especially in cases of multi-boiler installations. The final burner selection should be made so that when the boiler is operating at full load, the burner will operate at the upper end of the power range. This will reduce the burner power at low load, eliminating its frequent starts and stops. In addition, before each new burner start, the combustion chamber is purged with fresh air to avoid flashes. The air, forcedly heated in the boiler, then leaves through the chimney. So, for a UL-S 5000 boiler, the air temperature at intake is 24, and after heating -184 (coolant temperature) °C. Purge of the combustion chamber lasts 65-135 s. Heat loss during one on-off cycle is 4.77-9.91 kWh. Boiler suppliers should not strictly prescribe the use of certain burner types. On the other hand, the power of the individual boilers that make up the boiler room must be varied in such a way as to optimize the burner operating parameters, as well as the cost of its purchase. The boiler manufacturer must have a tolerance of ± 10% of the total plant output. Only with this freedom of action can optimal operation of the boiler be ensured. As an example, consider the following situation: when upgrading a steam boiler with a nominal capacity of 5000 kg/h, which consisted of installing an economizer, the back pressure in the furnace increased so much that theoretically it became necessary to use a burner of the next standard size (Fig.). The solution in this case may be to reduce the maximum power of the boiler by 3-4%, which will allow maintaining the originally used burner while achieving a power control range of 1:4 (if a higher-power burner was used, it would be 1:2.8). If you do not take into account the range of tolerances, then in some cases you will have to accept overestimation of equipment power - at the expense of optimizing performance and costs. The need to optimize burner parameters today is also due to the use of new solutions aimed at reducing the emission of harmful substances into the atmosphere. Typically these solutions limit the flexibility of the burner. Thus, the permissible frequency of switching on and off cycles of a burner with flue gas recirculation is, as a rule, no more than four per hour. Of course, this seriously affects the design process and further operation of the boiler plant.

How to solve the problem of high power and weak demand?

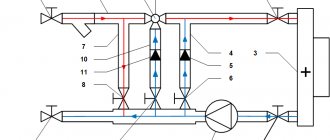

In an ideal situation, the boiler operates at a constant, rated output. At the same time, the outside temperature is constantly changing, and there are even abnormal jumps. What to do? Four-way mixing valves in the hydraulic system will help. Or an option with thermo-hydraulic distribution. These devices solve the problem not by adjusting the boiler power, but by adjusting the control valve. Or the speed of the circulation pump changes. The temperature of the coolant in the batteries becomes comfortable without disturbing the optimal conditions of the boiler. This solution has a minus - a high price.

| Four way mixing valve |

For gas and liquid fuel boilers, multi-stage burners solve this situation. A lower stage reduces the boiler power if necessary. Advanced models have a smooth adjustment of burner power - modulation. It is cheaper and not as troublesome as the first option.

| Multi-stage gas burner |

Solid fuel boilers also have built-in power settings and automatic fuel supply. This helps solve the issue of excess power when the external temperature changes.

| Automatic fuel supply device for liquid-heat boiler |

Classification of boiler installations according to consumption criteria

The designer’s algorithm of actions is largely determined by the purpose of the boiler room (whether it is focused on covering the technological or heating load), as well as by the presence or absence of information about energy consumers at his disposal. Let's consider the case when the heat generated by a boiler house is spent primarily on technological needs. If we are talking about an existing boiler house, the re-equipment of which is carried out only for the purpose of modernization or bringing its operating characteristics into compliance with new environmental protection rules, then the power consumption diagram is usually known (the consumption parameters remain unchanged). In the absence of the necessary data, it is recommended to determine the actual energy consumption by measuring it over certain periods of time. In this case, the periods of time with the lowest (for example, on weekends, at night in summer) and peak (the coldest days, periods of maximum intensive production, etc.) energy consumption are important. It is necessary to register and calculate the dynamics of changes in consumption (for example, to identify its peaks). When the data is collected, it is necessary to check the justification of the required maximum parameters of the heating medium at the outlet of the heat generator. Any unnecessary increase in coolant temperature (for a hot water boiler) or steam pressure (for a steam boiler) means additional costs that can be avoided. Often the calculated temperature and pressure of existing heating networks are too high, and they need to be reduced to the actually required values. If there are peak consumers with a certain time program, it is necessary to check how necessary and possible the linkage of energy consumption and boiler control systems is. In many cases, the power of a boiler plant can be reduced if its control system receives information about the power demand in advance and puts the plant into standby mode. In case of short-term consumption peaks over long periods of time, it is necessary to check how much thermal energy storage in the storage tank is necessary. For new facilities, boiler systems are often designed with a margin - designers, manufacturers, suppliers of equipment components and operators make an addition to the actual required energy consumption. Such additional reserves must be identified when discussing the project. If possible, you should find out from your suppliers the composition of the existing equipment and its actual energy consumption in order to use this data in the design. Prerequisites for the correct selection of parameters are the involvement of serious suppliers of individual components and taking into account the possible further increase in energy consumption. Despite the already planned increase in power, it is necessary to provide for possible additional reserves in the design of networks and the dimensions of the boiler room. If the priority consumer is heating systems, actual heat consumption is determined by weather conditions. The range of required power of a heating boiler room is much wider and more uncertain than that of an industrial one. During the summer season, boiler plants are partially kept in operation to produce hot water, but on cold winter days, their entire heating capacity is required. When determining peak power, it must be taken into account that it is only needed for a few days a year. At the same time, in an emergency (in particular, if the boiler fails), when the ability to produce heat is limited, under no circumstances should the coolant be allowed to freeze in equipment components or networks. That is, when calculating the minimum power of each boiler, high accuracy is required. It is also very important when determining temperature parameters (both the maximum heating temperature of the coolant and the temperature range). The largest extraction of heat from the boiler room occurs in winter at moments when groups of consumers switch from night-time energy consumption (power is reduced) to daytime. And, as a rule, in the early morning hours there is a peak consumption that exceeds the design capacity of heating installations. This must be prevented by equipping the heating system with modern control devices and staggering the connection time of individual consumer groups. It should be taken into account that when switching settings in the network in this way, a decrease in temperature may occur until the boiler system “catch the rhythm”.

What happens if you buy a boiler of lower power?

When the owner made a mistake with the power on the smaller side, this is just as bad as an oversupply. The system is working at its limit. Service life is reduced. The house is not heated sufficiently; the system may freeze during abnormal frosts.

| Freezing of the heating system |

The influence of heat loss on the quality of heating

To ensure high-quality heating of the house, it is necessary that the heating system can completely replenish heat loss. It leaves buildings through the roof, floor, windows and walls. For this reason, before calculating the power of a boiler for heating a house, you should take into account the degree of thermal insulation of these housing elements.

Some property owners prefer to seriously deal with the issue of assessing heat loss and order the corresponding calculations from specialists. Then, based on the calculation results, they can select a boiler based on the area of the house, taking into account other parameters of the heating design.

When performing the appropriate calculations, you should take into account the materials from which the walls, floors, ceilings are built, their thickness and degree of thermal insulation. It also matters what kind of windows and doors are installed, whether the supply ventilation system is equipped and its performance. In a word, this process is not easy.

There is another way to find out heat loss. You can clearly see the amount of heat lost by a building or room by using a device such as a thermal imager. It is small in size and the actual loss of thermal energy is visible on its screen. At the same time, it is possible to find out in which areas the outflow is the largest and take measures to eliminate it.

People often wonder whether for an apartment or a private house, when calculating a solid fuel boiler or other type of heating unit, it is necessary to do this with a reserve. According to experts, the daily operation of such equipment at the limit of its capabilities has the most negative impact on its service life.

Therefore, you should purchase a device with a performance reserve, which should be 15–20% of the design power; it will be sufficient to ensure conditions for operation.

At the same time, selecting a boiler in terms of power with a significant margin is not economically profitable, since the greater this characteristic of the device, the more expensive it is. The difference is significant. For this reason, if you do not plan to increase the heated area, you should not purchase a unit with a large power reserve.

Why contact a specialist?

We found out that buying a boiler from the square is wrong. It is important to consider the heat loss of the building. For example, a house of 300 m² can be heated by a 15 kW boiler if all surfaces are thoroughly insulated. And a house of 150 m² may require 30 kW equipment with thin walls and uninsulated roof and ventilation.

There are hundreds of standards and regulations on this topic, there are dozens of formulas. Sometimes one thing contradicts the other, or standards change and it is difficult for a non-professional to understand whether these requirements are relevant. You can calculate all this armed with a stack of reference books. Or contact specialists who will make accurate calculations in the program and explain all the details. They will help you save money, time, and model an efficient home heating system.

How is the heat load distributed?

Let's consider water heating: the sum of the thermal power of all heating devices in the house should be equal to the maximum thermal power of the boiler. To find out how the heat load is distributed, you need to consider some factors:

- Location in the house. Those rooms located in the middle of the house lose less heat than rooms located at the end or corner of the building.

- Ceiling height and room area.

- Required room temperature. If the room is located in the middle of the house, then the temperature should be 20°, and rooms located at the end or corner of the house should have a temperature of 22°. In the kitchen, 18° is enough, as there are electric or gas stoves. The highest temperature in the bathroom should be 25°.

- Distance from heat source.

- If the heating system uses a convector, electric heaters, etc. as a heat source, then the desired temperature regime is set on the thermostat. And if air heating is used, then using the throughput of the air hose, heat flow enters the room. To regulate it, you can adjust the position of the ventilation grilles with temperature control.