Ecoover insulation has become a popular thermal insulation material. This is a reliable product created based on basalt raw materials. It is manufactured using modern technologies in the form of special plates, which allows it to be used in many construction industries.

Insulation production lines are characterized by a high degree of localization, and basalt raw material processing plants are located in close proximity to mining sites. In combination with the use of the most modern equipment in the manufacture of insulation, the reduction in costs of transporting raw materials makes thermal insulation economically accessible to a wide range of consumers.

Insulation manufacturers, due to an increased level of automation, are able to process raw materials - solid basalt - into the final product, a lightweight fibrous insulating material. At the exit, the goods are packaged for subsequent transportation.

The insulation manufacturing process is a procedure of melting mineral raw materials with the parallel addition of synthetic additives. At the same time, stretching the raw material mass using advanced technologies and specialized equipment gives the composition a fibrous structure. Production lines are equipped with filtration units that process production waste, protecting the environment from harmful emissions.

The technology has been awarded international quality assessment. Finished products have all the necessary certificates of quality and compliance.

Features and nuances of production of Ecover insulation

Ecover mineral wool insulation is made from basalt rocks and industrial waste

Ecover brand products are made by melting raw materials with a mineral base, to which synthetic components are added. The technology of drawing out the liquid mass using specialized equipment ensures the production of a fibrous structure. The preparation of raw materials is carried out in filtration plants that process industrial waste.

Three methods for producing basalt threads have been developed:

- blowing;

- centrifugal roller;

- centrifugal-blown.

The choice of a specific technique is influenced by the availability of the required equipment. Technologists control every stage of the production process. All insulation modifications go through the following manufacturing stages:

- remelting;

- centrifugation;

- adding special synthetic sealants to the mass;

- pressing the resulting composition.

At the last stage, the canvas is cut into slabs and packaged.

How to choose roof insulation

Future requirements for thermal insulation depend on the type of roof your home has, since it can be flat or pitched, and can also have residential and non-residential attic space.

Selection principles:

- roofing insulation must be environmentally friendly;

- have excellent sound insulation;

- low thermal conductivity;

- frost resistance;

- must be fireproof;

- must retain its geometric parameters;

- have dimensional stability;

- small mass;

- be durable.

Recommendations to follow:

- for a pitched roof it is better to use materials with increased density;

- for non-load-bearing structures it is recommended to use the least rigid insulation materials.

Advantages and disadvantages

The insulation is not afraid of ultraviolet radiation, so there is no need to rush when finishing.

Thermal insulation Ecover has a number of advantages when we compare this insulation with analogues:

- reduction of thermal losses by 50%;

- the material is not susceptible to bacteria, fungi, mold;

- rodents do not spoil the product;

- UV resistance;

- good sound absorption rates;

- environmentally friendly material;

- has the ability to withstand high temperature influences;

- does not deform under mechanical and static load;

- long service life - more than 50 years;

- good hydrophobicity and vapor permeability;

- easy installation.

The main disadvantage of insulation is its high cost.

What are the advantages of URSA and Izover heat insulators

I had to work with Russian mineral wool. Despite the special protective suit and respirator, particles of material got onto the body and into the lungs, causing very unpleasant sensations. People who constantly worked with her often received dangerous occupational diseases. Another drawback is that this heat insulator breaks down quite quickly in the wall and sags, as a result of which the upper part of the wall loses its thermal insulation, while in the lower part it deteriorates significantly. The thermal insulation materials that we offer are completely environmentally friendly and even pleasant to the touch, durable, have better insulating properties and, finally, are cheaper than those made in Kstovo or Vyksa.

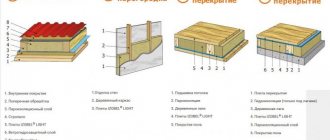

Application of insulation

This material is used for all types of structures to provide a durable and reliable layer of sound and heat insulation. Basically, Ecover is intended for installation on:

- frame walls;

- attics;

- attics;

- internal partitions;

- floors;

- facades.

Thermal insulation has high thermal protection and physical and mechanical properties, which guarantees the creation of an optimal microclimate in the room and durability.

Roof insulation using Ecover light

Glass wool NEMAN

The products of the Belarusian glass factory meet the highest requirements. NEMAN glass wool has excellent thermal insulation and sound insulation properties, is not fire hazardous and is durable. The raw materials for production are domestic products.

Sevenfold compression of the material reduces transport costs.

Glass wool is produced in roll form. This facilitates the work on thermal insulation of pipelines and insulation of industrial installations.

Neman glass wool is mainly used for insulating pitched roofs, installing suspended ventilated facades and suspended ceilings. It is possible to use glass wool when carrying out thermal insulation work both outside and inside the building.

The topic of modern thermal insulation materials, both imported and domestically produced, continues to interest readers, because thanks to these materials it is possible not only to reduce home heating costs, but also to significantly reduce the cost of building construction. A leading specialist advises.

Manufacturer information

Ecover thermal insulation is produced at a modern Russian plant in the Sverdlovsk region. The choice of location was based on proximity to deposits of the gabbro-basalt group of rocks. Thanks to advanced technical equipment, the production of high-quality products is achieved that can solve issues of improving the energy efficiency and environmental friendliness of buildings.

The insulation composition includes: mineral wool created on the basis of rock and a binding component of synthetic origin. At the same time, it complies with all current standards of GOST 9573-2012.

What is better rockwell, isover or ursa

- Which is better: rockwell, isover or ursa?

- How to choose good insulation for walls

- How does mineral wool affect health?

All these materials are high-quality insulation materials that are successfully used at construction sites. The structure of isover, rockwell and ursa is the same: tiny fibers of cotton wool, between which cavities filled with air are formed. It is the most effective heat insulator. This ensures the high thermal insulation properties of each of these materials.

What are the differences

Rockwell is made on the basis of basalt fiber, and Ursa with isover is made on the basis of fiberglass. The differences between these materials are as follows:

— basalt ones have higher thermal insulation properties — the hygroscopicity of materials based on basalt fiber is less than 1%. (in isover and ursa, since their structure contains fiberglass, the hygroscopicity is 10-20% higher than that of rockwell) - basalt fibers are more resistant to alkalis and steam - during installation of isover and ursa, the release of the smallest particles of fiberglass is observed - the thorniness of rockwell much lower than that of materials made from glass fibers—isover and ursa, in the event of a fire, begin to burn out at lower temperatures than rockwell

What properties are similar

Each of these materials provides high-quality sound insulation, which increases the comfort of living in the house. All of them are durable and have high thermal insulation characteristics. Each of the insulation materials is vapor permeable. That is, in the cold season it is able to remove excess steam outside, and in the summer it can prevent overheating of the internal space of the house.

Izover, Ursa and Rockwell are easy to install, but the latter provides greater ease of operation. All insulation materials are capable of maintaining the stability of their size, that is, they have a fairly high coefficient of resistance to mechanical stress. It is recommended to use slabs for vertical insulation, and rolled materials for horizontal insulation.

If you need to protect your home from rodents, it is better to use glass wool, as it is more dangerous for them than basalt fiber. There is a point of view that the advertised benefits of stone wool are just an excellent marketing ploy. By and large, the differences between fiberglass and basalt are minimal.

Therefore, any of these insulation materials will serve flawlessly for a long time.

But to ensure maximum thermal insulation effect, when choosing materials you need to pay attention to the degree of their density. For example, for Ursa it can be as follows: P-15 (13-16 kg/m3), P-30 (26-32 kg/m3), M-11 (1 kg/m3), etc.

Benefits of Ecover

Ecover mineral wool slabs have unique heat-insulating and sound-proofing properties.

They are non-flammable, due to their strength parameters they are resistant to deformation and subsidence, are not saturated with moisture (hydrophobic), and are environmentally friendly. All this is confirmed by relevant certificates and test reports at all stages of production. The material has passed the necessary operational tests. This type of stone wool based on basalt-type minerals produced by the modern company Ecover was developed specifically for use in non-load-bearing structures of premises. A large number of standard sizes of sheets of material: from 50 to 200 mm by 600, 1000 mm allows you to organize a waste-free system for insulating buildings. Different thicknesses allow you to optimize and reduce the cost of work.

The low specific gravity and the unique ability to maintain its original shape throughout the entire period of operation leads to an increase in the maintenance-free maintenance period of multi-pitched roofs, attics and ventilated types of facades with a significant glazing area.

— There is no difference between URSA and Izover

If it exists, it is very conditional. Both materials are fiberglass, both have the same technical characteristics, even their appearance is so similar that not every specialist will be able to distinguish them when unpacked. By the way, their packaging is the same - shrink film, which reduces the transport volume by up to 35 percent of the working volume, which allows you to place three cubic meter packages of this heat insulator in a regular Zhiguli.

But we bring Izover from Finland, and URSA is manufactured in the city of Chudovo, Novgorod region. Many consumers prefer imported material (it is a little more expensive), although the Germans, the owners of the Chudovsky plant, strictly ensure that the material produced here is no different from that produced in their homeland or at the concern’s factories in other countries of the world. Another question is that the capacity of the Chudovsky plant is not enough for the whole of Russia and very often people are simply forced to use imports... - Where are these heat-insulating materials used and what are their varieties? — They differ among themselves in rigidity - from M-15 to P-75 (the stiffer the material, the higher the wall it can be installed in, but the more expensive it is), in thickness - from 50 to 140 mm. Polyethylene film, foil or kraft paper may be applied to one or both sides of the material. Since they are classified as non-flammable and have excellent thermal insulation properties (their thermal conductivity coefficient is only 0.04-0.05 kcal/mhS, which means that 18 cm of heat insulation protects the house from the cold in the same way as two-meter brickwork), they are environmentally safe, then they can be used for thermal insulation of roofs, and interfloor ceilings, and external walls, and floors, and basements, and internal partitions, and heat pipelines. In short, they are universal. Moreover, such materials are very convenient to work with. When installing an interior partition, place an insulating board of medium hardness, only 50 millimeters thick, between the wooden beam or metal profile on which the plasterboard or gypsum board is attached. Such a partition will provide better heat and noise insulation than one laid out with one and a half bricks. But it doesn’t need to be plastered. The labor costs for its construction are incomparably less. Due to its light weight, it can be placed almost anywhere, and the cost of the materials themselves is lower...

This is probably the main advantage of modern thermal insulation materials:

You talked about the advantages of the URSA and Izover materials, but did not mention anything about their disadvantages.

Flaws? Perhaps only one. They don't like moisture. When ingested, they partially lose their properties. Therefore, they cannot be wetted, and condensation should not accumulate on them inside building structures. For this purpose, special ventilated structures have been developed or polyethylene film, aluminum foil or kraft paper are used as vapor barriers.

General building insulation

The main purpose of these products is heat and sound insulation inside buildings and structures. Depending on the density of basalt slabs and the additives used, it is divided into several groups.

Light Universal

Designed to create an effective internal thermal insulation layer in unloaded structures of any type. These include building walls, attic spaces (suitable as insulation for attic roofs), and soundproofing partitions. For ventilated facades it can be used as an inner layer.

Light

For this group, you can select slabs depending on the density of the material. Their purpose completely coincides with the “Light Universal” described above. However, the expanded range makes it possible to choose the optimal model of basalt slab for internal insulation.

Light Universal

Light

Standard

This is a truly universal insulation material that can be used to create a reliable thermal barrier inside buildings. The increased density (60 kg/m³) is the main factor in the improved thermal insulation properties of this type of basalt wool.

Acoustic

To create good sound insulation, the manufacturer recommends installing a special type of basalt wool Acoustic. It is mounted in interfloor partitions, ceilings and floors, in which logs are provided. It is noteworthy that depending on the required level of noise reduction, you can select slabs of appropriate thickness - from 40 to 250 mm. A special series of basalt slabs was developed for external thermal insulation.

Insulation from manufacturers Knauf, Ursa, Izover

You need to be especially careful when choosing thermal insulation for your home. And for this it is necessary to have complete information about the properties of materials. And we are ready to help you with this.

Ursa insulation

One of the most popular materials for thermal insulation of pitched roofs is Ursa insulation. The product is made from fiberglass using binding components. The technical characteristics of the material are: strength, frost resistance, increased elasticity and the ability to resist high mechanical loads.

Due to their properties, Ursa insulation completely adheres to the mounted surface and fills all existing gaps. This material has a high level of resistance to chemical attack, so it can be used for thermal insulation of rooms with high humidity.

Knauf insulation

Insulation products from the manufacturer Knauf are made from glass or basalt fiber and have excellent characteristics not only as thermal insulation, but also as a sound-absorbing material.

Installing Knauf insulation will allow you to feel warm during the cold winter and cool on hot summer days, as well as save money on heating.

You will not be disturbed by extraneous street noises. If a fire hazard occurs in the house, Knauf insulation will not contribute to the spread of fire, which will allow family members to safely evacuate without causing harm to health.

Izover insulation

Izover insulation is used not only in private housing construction, but is also widely used in the construction of industrial enterprises, thermal insulation of baths, saunas and heating mains. And everywhere the material is reliable protection from cold and drafts.

Plates for external roof insulation have increased rigidity and strength and are able to withstand strong wind and snow loads. Izover insulation as an internal thermal insulation has a soft layer that allows you to fill all the gaps and irregularities to avoid heat loss. The price of Izover insulation depends on the type and strength coefficient of the material.

For thermal insulation of wooden houses, use inter-crown insulation made from linen-based cord. It will completely fill all the cracks between the logs, and even when the house shrinks, it will retain its excellent characteristics.

Our company offers low prices for building materials, so purchase all the necessary products from us.

Facade insulation

The development of technology and the experience of builders when working on insulating walls of building facades raised the question before developers about the need to create a material suitable for thermal insulation of walls. This is how the basalt insulation of the ecover façade became. Traditionally possessing high resistance to external factors, the new product began to be used for insulating external walls and in ventilated facade systems.

Ecover vent facade 80 is also applicable for single-layer insulation of wall surfaces as the main thermal insulation material. It is also used as a surface layer with an air gap in ventilated systems on top of other heat insulators.

For thermal and sound insulation of wall surfaces in façade systems, eco-facade eco-cover is suitable for plastering with a thin layer. It has greater strength compared to other products. Due to its technical characteristics, eco-facade eco-facade is suitable for use in finishing works on buildings of any number of floors. Ecover vent facade has less water absorption than insulation for interior work.

There are several types of insulation for facade use, among which are the following brands:

- Facade decor;

- Façade decor optima;

- Sandwich;

- Sandwich K.

Brand Facade decor

Ecover façade decor is a rigid thermal insulation composition based on basalt minerals with the addition of hydrophobic and synthetic additives. It is applicable in external facade systems for further plastering of walls using reinforcing mesh.

Product Parameters:

- Density is 150 kg per cubic meter.

- Resistance to compression over 50 kPa.

- Water absorption less than 1.5%.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.039 to 0.037 W/m*K.

- Included in the class of non-combustible materials.

Brand Facade Decor Optima

Ecover façade decor optima is optimally suited for plastering façade walls in a small layer. According to its data, it fully satisfies all the requirements of the regulations for plastering systems. Mineral boards have high adhesion properties to adhesive compositions suitable for their installation.

The surface of the plaster after application to the insulation does not become stained when it dries.

Options:

- Density 135 kilograms per m3.

- Compression resistance greater than 45 kPa.

- Water absorption 0.75 kg per square meter. meter.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.037 to 0.035 W/m*K.

- Non-flammable

Brand Sandwich

Ecover sandwich C is a three-layer “pie” consisting of a central thermal insulation layer and two profile sheets on the outer and inner sides.

The Ecover brand produces this product to order in thicknesses of 100 and 200 mm. Builders use it to construct the walls of buildings from metal structures. Options:

- Density from 80 to 110 kg per m3.

- Compressive strength varies from 50 to 75 kPa.

- Water absorption 0.75 kg per square meter. meter.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.042 to 0.039 W/m*K.

- Non-flammable

It also has all the properties necessary for façade thermal insulation.

Brand Sandwich K

As a product for thermal insulation work, Sandwich K differs from the previous one in its greater density and the possibility of use for the installation of warm roofing floors.

It has found its wide application in the construction of industrial, shopping and entertainment centers. The use of this insulation significantly reduces the installation time. Product Parameters:

- Density from 120 to 140 kilograms per m3.

- Compressive strength varies from 85 to 110 kPa.

- Water absorption 0.75 kg per m2.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.044 to 0.041 W/m*K.

- Non-flammable

Specifications

Mineral insulation is made from basalt raw materials, mined by a manufacturer of thermal insulation materials at the Bazhenov deposit in gabbro rocks. Ecoover is endowed with its characteristics and features by adding water repellents and modified additives to the main raw materials. Its thermal conductivity is not inferior to other popular products on the market among insulating products for construction purposes. 50 mm of insulation has properties equal to almost 200 mm of wood or 300 mm of masonry made of gas or foam concrete.

The characteristics of Ecover basalt fibers give the material a special feature: it is highly resistant to heavy loads.

One square meter of surface can withstand pressure of 8 tons.

Ecoover mineral wool melts at temperatures above 1000 degrees Celsius, which makes it a practically fire-resistant product. The density of insulation in the product line of this brand reaches 150 kilograms per cubic meter. The ecoover light station wagon has a reduced density, in which it is less than 30 kg per square meter. meter. The compressibility of insulation varies from 5 to 25 percent depending on the type of material. When partially immersed in liquid, thermal insulation is characterized by an absorption rate of no more than one kilogram per square meter. At the same time, it allows water to pass through itself without absorbing it. Depending on the operating conditions, the thermal conductivity coefficient of the insulation changes. On average it is 0.035-0.040 W/m*K. The characteristics allow the insulation to be used as a soundproofing product; among the entire line of products, Ecoover Acoustics is the most suitable for these purposes. It is suitable for use in non-load-bearing structures such as frame house partitions, timber floor frames, etc. Has high vapor permeability. The composition contains no more than 3% organic additives.

Dimensions

When choosing mineral wool, you should definitely take its parameters into account. The standard dimensions of Ecover insulation are as follows:

- length 1000 mm;

- width 600 mm;

- thickness ranges from 40-250 mm.

The level of moisture absorption of products is 1 kg per 1 m2. Good heat resistance is ensured by a structure made of stone-basalt fibers and a special binder, which can withstand maximum heat.

It is worth noting that each series has individual characteristics and dimensional data, making the selection process for a particular purpose easy and correct.

Acoustic

Acoustic eco-cover has become a material that can not only retain heat, but also exhibit a good sound-absorbing effect. It is suitable for creating a sound threshold. Ecover acoustic creates the necessary acoustic effect in cultural premises.

Ecover acoustic has the following characteristics:

- The sound absorption coefficient is 0.95.

- Compression resistance does not exceed 12%.

- Water absorption 1 kg per m2.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.035 to 0.037 W/m*K.

- Non-flammable composition.

In addition, ecoover acoustics are highly effective in apartments when there is a need to protect yourself from neighbors.

Tips and tricks

Numerous reviews indicate that it is quite difficult to determine its quality by the appearance of Ecover insulation, so the choice of these products should be approached with great responsibility.

- The presence of appropriate quality certificates from the seller is an important guarantee that the material is original and manufactured in accordance with GOST.

- Packaging in the form of a special shrink polyethylene film reliably protects mineral wool from external factors. It should be stored on pallets in order to maintain integrity, as well as convenient loading and unloading. During transportation, this insulation should not be exposed to moisture.

- recommends paying attention to the presence of brand markings printed in the form of a dark stripe. During installation, this surface must be attached to the wall, thus forming a good basis for plastering work.

- It is worth noting that the insulation of this brand can retain its original qualities for 50 years of operation. In addition, to carry out the installation process, it is enough to have the most basic means at hand.

- Strict adherence to the instructions on the packaging will help prevent various types of errors and alterations during the installation process. The edges of Ecover products must be neat so that the joints are as smooth as possible and suitable for further processing.

- It is recommended to tightly fix mineral insulation to a particular surface to create a truly high-quality effect. To reliably insulate a flat roof, thermal insulation boards should be laid in 2 layers. If the installation is carried out in an attic that is in use, then in this case it is necessary to use a special two-layer mineral wool.

- When starting to cut Ecover slabs, it is recommended to strictly adhere to the required dimensions in order to prevent the appearance of cracks that can become sources of cold penetration. This stage of work should be carried out in special protective clothing, as well as gloves, goggles and a mask. The room where installation is carried out must be fully ventilated. It is strictly forbidden to move on the surface of the slabs, so as not to violate their protective properties.

- Immediately before purchasing Ecover products, it is recommended to study in detail the general characteristics and purpose of a particular item. You should definitely take into account the density of the material.

- It is believed that the higher the degree of density of products, the lower their thermal insulation properties. It must be remembered that only a professional approach to the process of choosing mineral insulation can provide the desired result in the form of high-quality installation and a long service life of the products themselves.

Best answers

Elena:

You named different brands. We need to look at the insulation. If the humidity is high (or at risk). then foam plastic (plain or extruded) is better. If there is no moisture, then cotton wool is more environmentally friendly. At normal humidity, all modern insulation materials have approximately the same heat transfer resistance coefficient.

Special opinion:

insulation is better in mats than in rolls. their other parameters are almost the same.

Andrey Denisov:

there is also penoizol

Alexei:

read - what they are made of, the smelliest ones are those with phenol-containing fiber.

Marina Alskaya:

The difference is in cost and durability of materials. But no matter what you choose, installing insulation from any of these companies is equally difficult. If the walls are insulated, then waterproofing is also necessary.

Ecowool-Voronezh:

Manufacturer. Each manufacturer has materials of different prices and different densities, some have “eco-friendly”, some have “soundproofing”, which is basically the same thing. They differ in features and density. There are different densities for different applications. The higher the density, the colder it is. Everyone is afraid of moisture - a vapor barrier is required. The thermal resistance coefficient for all is indicated for absolutely dry material.

HUMAN:

I used Rockwool to insulate the house... a house according to Norwegian technology with autonomous heating... permanent residence... cool in summer, warm in winter within 22 degrees... 100mm of insulation in terms of thermal conductivity is equal to 300mm of timber...

Don't know where to buy Ecover? Moscow and the region are already insulating their homes!

Our website presents the largest selection of domestic brand insulation at competitive prices from an official dealer, it’s like buying Ecover in Asbest without leaving your hometown! Hurry up to purchase insulation, as well as order its installation on our website! Then you can spend the money you save on nice things, and not on paying for utilities! Dial the number +7(495) 212-06-41

and all your questions regarding the purchase of thermal insulation will be resolved! A large assortment of insulation of the domestic brand Ecover at dealer prices in unlimited volumes and with deliveries on a regular basis can only be provided by our online store! Give your loved ones warmth with Ecover - it's that simple!

Have questions? Call the number

8

Head of Sales Department