close ×

In country buildings or cottages, metal wood-burning stoves are often installed for heating rooms and cooking. This is economical, practical and functional, since by heating such a structure, you can simultaneously cook food, heat water and supply warm air to the rooms. Traditional brick stoves do not have such high productivity, so owners of country houses choose steel/metal stoves for heating.

Before installing such a structure in your own home, there are several factors to consider. First, the expected frequency of use of the oven. Secondly, will people live indoors permanently, or only periodically, and over what period of time this will happen. Thirdly, the area of the house and the location of the rooms are taken into account. If you are not in a hurry, you can choose the best option for a country stove that runs on wood.

Types of iron stoves for summer cottages

Modern stoves, which run on wood and are made of metal, bear little resemblance to a “potbelly stove”. Metal stoves for the home are usually divided into two groups:

- Classic ones that operate using a direct combustion system.

- Heating units designed for long-term combustion.

This or that system may be present in steel ovens that are intended for cooking or heating. There are a large number of such stoves on the market, among them the following are worth noting:

- A bell-type stove is a heating stove; it uses the principle of convective movement of gases that move through channels and then exit into the chimney. Instead of a hob, an open oven is installed, which is located directly under the hood. This helps keep food hot for a long time. Firewood is loaded horizontally; the firebox door is made of fire-resistant glass.

- Direct combustion furnace. Most often these are small-sized models, for example, Termofor or Cinderella. The design performs two functions at once - it heats the room and helps in cooking. The thermal power of such a “baby” is 4 kW or a little more, which allows you to heat a room up to 50 m2. There are models that are equipped with electricity generators, which increases the voltage production and power of the furnace. For example, the Indigirka cooking stove, which runs on wood, not only heats the house, but is also suitable for charging gadgets.

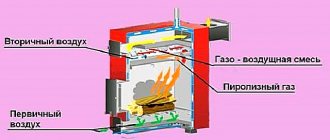

- Gas generator furnaces. They are perfect for summer cottages, since the designs are economical and compact in size, and have a high level of efficiency, which reaches 80%. For long-term operation of a stove of this type, it is necessary to equip a chimney and burn it with high-quality firewood. Gas fired stoves work by loading wood (or another type of fuel) into the combustion chamber, igniting it, and then closing the door. Fresh air flows through the telescopic pipe, which drops lower when the amount of firewood decreases. The air supply process is regulated by a damper. The operating life of the furnace is, on average, three days. If gas generator stoves have a water heating mode, you can save on the use of firewood.

How the stove works

For a steam room, a heater will suffice, under which there will be a firebox that heats the stones to 250 degrees. Thanks to this, you can obtain the necessary steam for the sauna.

The bathhouse has a different microclimate, which is created by small droplets that heat the air to 150 degrees Celsius. Due to this, the steam is called dry. We get dry steam only at temperatures above 500 degrees.

Home stove models

Buleryan

This is a Canadian designed and built oven. It is quite easy to use and has a simple design. The main part of the stove (firebox) is made in the shape of a steel cylinder, the thickness of which is 5-6 mm. The hole for supplying coal (door) is made at the end of the furnace. Adjacent to the main part are round (or rectangular) pipes that are hollow inside. After heating, these pipes create the necessary transfer of warm air in the desired direction.

A grate for maintaining coal (grid) is made at the bottom of the firebox. At the top of the firebox there is a fence that divides the main part of the stove into two halves. This is done so that it can be heated with both coal and gas. The smoke exit hole is located on the back side of the door and is combined with the firebox, allowing smoke to escape safely to the street.

Butakov stove

It was tested in extreme conditions of a cold climate, not meeting the expectations of the owners of the patent for this invention. This brand has several varieties. The models, which are planned to be used around the clock, are improved with glass barriers. The stove consumes 12 times less fuel than a potbelly stove, and two times less than conventional brickwork.

Model "Student"

This happens due to the fact that in such a furnace the fuel does not burn, but smolders (pyrolysis process). The only negative is that the chimney pipe is not sealed enough and water may drip from there during the transition of steam into liquid. There are 6 types of such stoves. “Gymnasium student” is the most convenient in size.

Breneran

Russian model of the Buleryan stove. The oven is not heavy and compact. It is suitable for both living space and garage. Testing of such a stove was carried out in the mountainous areas of Tajikistan, where border office premises are equipped with stoves of this type. Breneran stoves come in 5 sizes, with a power of up to 35 kilowatts.

Teplodar-Matrix

This is a successful combination of design and functionality. In stoves of this type, it is possible to burn continuously for 8 hours (with one fuel supply). The convection compartment housing creates uniform heating and protects against negative radiation. The depth of the smoke exhaust compartment and the compact design of the stove saves space and creates additional advantages during installation - the chimney can be made in the direction in which it is necessary or convenient. This manufacturer has a fairly large selection of models, so you can choose the best option based on your needs and preferences.

Teplodar-Matrix 100

Teplodar-Matrix 200

Suitable if you need to heat a room up to 200 square meters. For garage premises, the best option is the Teplodar T series. For kitchen areas, a Vertical fireplace stove is ideal. If uniform heating of the living space is of paramount importance, it is better to choose the Vesuvius model.

Termofor

High-quality domestic stoves for heating areas with an air volume of 50 to 250 cubic meters. The power of such furnaces reaches 13 kilowatts. Suitable for heating both residential and non-residential premises. Some models have added fans for better dispersal of warm air. A large number of different models are presented - Ermak, Normal, Indigirka, Cinderella, etc. These stoves are compact and have an efficiency of up to 90%. Some models have glass shutters.

Description of a metal sauna stove and its main characteristics

You can, of course, buy a metal stove for the bathhouse. However, the best option would be to make it yourself. A simple option is a potbelly stove, which is a metal structure equipped with a door and a pipe. Low heat transfer and significant financial costs for purchasing fuel do not allow the heating installation to be used effectively, so it can be seen in rare cases.

Another thing is modern iron stoves. Their attractiveness, high efficiency and highest fire safety rating are impressive. They are made from sheet iron, more than 0.4 centimeters thick. The structural components are:

- It is customary to use a thermal chamber for filling and storing stones;

- There is a tank designed to store water with a volume of 30-70 liters.

An iron sauna stove requires lining with refractory bricks. This makes it possible to evenly heat the air in the room and makes the structure completely safe for use.

Advantages of wood stoves

The main advantages are:

- The presence of a casing that has holes for air or a combustion chamber with a system of pipes that exhaust air.

- The casing absorbs all the radiation, and when it heats up, it releases heat into the room.

- You can regulate the flow of fresh air into the firebox.

- The presence of several partitions located above the combustion chamber. As a result, the gases do not exit directly into the pipe, but first give off heat and only then go into the pipe.

- A long period of operation, which is associated with the use of refractory bricks in furnaces, the use of hobs made of cast iron, steel or other metal.

- The presence of heat exchangers that heat water, but such systems are only available in a few models.

- The so-called afterburning process of pyrolysis gases that are released during combustion occurs.

- The wood in the stove produces electricity.

- Wood-burning metal stoves release smoke to the right place, which allows you to regulate the heat balance in the living room. As a result, the rooms can maintain a stable temperature for 24 hours.

Other advantages of metal stoves, the operating principle of which is based on wood, include environmental friendliness, safety, and affordability. In particular, this applies to firewood, which is considered an environmentally friendly type of fuel. And its price is lower than for coal or peat. It is worth considering that firewood supplies must be replenished and placed in a specially designated place.

Classification of furnace units

Most often, homemade stoves are made with cooking surfaces.

According to the characteristics of the device they are made:

- chamber;

- duct;

- bell-shaped

In chamber stoves, flue gases enter a special chamber and are completely burned there due to natural circulation. Their design creates a similarity to the burning of an ordinary fire in a confined space. In domestic models, the combustion compartment is connected to the afterburning compartment into a single module called the crucible. Its vaulted shape ensures complete combustion of fuel. An example of such a design is the classic Russian stove.

In a ducted unit, the flue gases first burn out, then gradually cool down and move through the channels located between the partitions. When moving, they give off heat to the furnace body. There is no afterburning inside until the temperature in the combustion chamber reaches 400 degrees. The efficiency of these devices does not exceed 60%.

In a bell-type furnace, combustion products move to the roof of a special bell and linger there, burning out completely. Then the gases sink to the bottom and give off heat to the body. To kindle such a unit, it is enough to warm up only a small area of the hood. Its efficiency can be 75%.

Disadvantages of metal stoves

No matter what high-quality stove model that is suitable in size and functionality is chosen, it must be remembered that any stove, no matter how ideally it fits, always has disadvantages.

Metal stoves are inferior to brick stoves in terms of heat retention. When heating a room with such models, warm air is retained in it for only a couple of hours, and in the morning there will be no heat. But we can solve this drawback if we buy a metal stove that operates continuously. After purchasing and installing it, you can forget about adding fuel for 8 hours.

The operation of metal furnaces can last up to 20 years. According to statistics, much earlier than this, the metal in the firebox burns out and requires replacement.

When buying a metal stove, you need to think about who will service it and how. If you plan to install it for residential premises, then it is worth considering the presence of people with chronic diseases of the respiratory tract or cardiovascular system. In addition to the fact that such stoves create powerful radiation, they create the effect of “dry air.” This problem can be solved if you cover the metal base of the stove with bricks (calculate whether the floor can withstand the additional weight). This will greatly reduce the operating time of the stove and void the product warranty. The heating rate will become slower, but the heat capacity will increase.

Choice: nuances

To choose a metal boiler, you need to understand the difference between the materials used.

Made from ordinary steel

One popular option is regular steel. Thus, the tensile strength of this substance during prolonged exposure is about 400°C (at 2 hours it increases to 600°C). The thickness of the steel starts from 4 mm, but the stove quickly burns out due to intense heating, so it is not suitable for climates with severe frosts.

However, there are long-burning furnaces that do not maintain long-term heating of the body above 600°C, and those parts that become as hot as possible are made massive and replaceable. They are suitable for large houses and frosts.

Made from heat-resistant steel

The second material is heat-resistant steel, which is often used in industrial production. Such special steels are taken with a thickness of 3 mm and provide a service life of more than 20 years, efficiency is above 80%, and are also lightweight. Such branded units are mounted on the floor and only need to be connected to the chimney. They are certified and completely safe under intense heating, which means they are well suited for harsh winters.

Equipped with a hob and a “water heater” allows you to use them both at the dacha, in a country house, and in a permanent home. It is very difficult to produce them yourself; you need to master intricate welding technology (TIG/MIG) and the corresponding expensive equipment. It is easier to purchase a ready-made device.

Made of cast iron

Cast iron is known and highly respected as a base - it is a kind of metal, but not quite a metal. It is as strong as steel, but also as brittle and heat-intensive as ceramics. Cast iron stoves heat up after heating for up to 3 hours, and warm up for about 40 minutes.

The thickness of cast iron is taken in the range of 6-25 mm: not thicker, so that the expansion coefficient from heating does not work to the detriment, but not thinner - the unit will be fragile.

The high efficiency of cast iron stoves is only possible when heating houses with an area of no more than 60 m3 - i.e. For large rooms such a heating device is not suitable. However, he is not afraid of interruptions in the firebox or dampness.

Therefore, a cast iron stove is an ideal option for small outbuildings (sheds for keeping livestock, greenhouses, cottages, etc.). It is impossible to make such a unit with your own hands - after casting at the factory, the material cannot be machined by home craftsmen. The maximum is painting.

Features of metal furnaces

Wood-burning metal stoves for summer cottages are considered super economical because they consume a small amount of oxygen during combustion. While they smolder, heat is released and the room is heated.

You can try to find models that have an additional combustion chamber designed to burn carbon monoxide. To reduce the amount of firewood and oxygen consumed, it is necessary to properly stack the firewood in the firebox. The fewer gaps remain between them, the longer the tree will smolder. Considering that oxygen in heating furnaces is supplied to places of smoldering and not combustion, the process is prolonged several times.

Particular attention should be paid to the design of the chimney, which is needed to create draft and remove combustion products. In metal home stoves that burn wood, it is necessary to install round chimneys so that they do not create air turbulence, characteristic of rectangular models, and it is difficult to clean such a structure. Round chimneys are excellent for cleaning from soot and soot. There should be no bends in the pipe, or their number should be kept to a minimum. The chimney is installed before the stove itself is installed.

How to install the stove correctly

- The first priority is choosing the installation location and measuring the area. Everything must comply with safety regulations. The stove should be installed at a distance of at least 60 cm from the plaster and 80 cm from the wallpaper.

- The stove must stand on a concrete slab (at least 0.7 cm), asbestos or basalt cardboard.

- The furnace elements are assembled according to the instructions, after which it is necessary to check the tightness of the assembled structure.

- A protective element must be attached above the stove, on the ceiling.

- Installation of a chimney (it is better to choose a round option - rectangular ones have worse draft).

- If you want to paint the stove, then any paint will not work for this. You need to choose special enamels (silicate or organic).

- Call a fire inspector who will check the correct installation.

- Test check of the entire system.

Calculation of basic parameters

Bricks

To calculate the required amount of material for a country stove, you can use the diagram below, which shows the bricks in each row of masonry. The image shows that the width and length of the future building are the same, so the design of the stove will have a square shape.

The small size of the structure is convenient for construction in the countryside

According to established standards, a single red brick has dimensions of 250x120x65 mm.

Standard Material Size

Knowing these parameters, it is not difficult to calculate the length and width of the building. Let's substitute the values: 250+250+120=620 mm - the size of one of the sides of the furnace.

To build a furnace, you will need 300 bricks, excluding damaged material.

Foundation

Construction of a brick kiln for a summer cottage requires the installation of a foundation. For this, a slab base is used. The length and width of the foundation must be made 150–200 mm wider than the furnace parameters, and its thickness must be at least 150 mm. Let's substitute the values: 620+200=820 mm - this is the length of one of the four sides of the base.

Having these parameters, it is easy to calculate the area of the furnace base. To do this, you need to apply the formula for finding the area of a figure, which looks like this: S=a², where “a” is the size of the sides of the figure being studied. Let's substitute the values: 820·820=672400 mm² or 0.6724 m².

To find out how much concrete mixture is required to fill the base, you need to use the geometric formula for determining the volume of a cube, which looks like this: V=h, where “h” is the length, width and height of the foundation. Let's substitute the values: 0.82·0.82·0.15=0.10086 m³.

Armature

The concrete base of the furnace must be reinforced with metal rods 10–12 mm thick. To do this, the reinforcement is fastened in the form of a lattice, with cells measuring 10x10 cm. To calculate how many linear meters of reinforcement are required to make the reinforcing mesh, it is necessary to determine how many rods are needed for the width and length of the structure. Since each rod is located at a distance of 10 cm from each other, you need to divide the length of the base by the width of the cell: 0.82:0.1 = 8.2 pieces.

It is also necessary to take into account that you will need a mixture for laying bricks.

The thickness of the adhesive layer between bricks should be at least 15–18 mm.

The foundation has a square shape, so the perpendicular side of the lattice will have a similar number of rods. Let's add these values: 8.2 + 8.2 = 16.4 pieces of reinforcing rods. Now let’s set the total length of the metal rods: 16.4·0.82=13.448 linear meters of reinforcement, rounded to 13.5 m.

Tips for use

- The more densely the wood is stacked in the stove (this increases the smoldering time), the greater the fuel savings.

- Regular chimney cleaning is an essential safety measure.

- To ensure that no one touches the stove or gets burned on the structure, you can install screens or cover the metal body with bricks.

- If the oven door is glass, then it will constantly turn black from soot. It is better to clean before the glass has cooled, otherwise you will have to deal with resin. Cleaning can be done with regular glass cleaner and a sponge or newspaper. You should not use metal scrapers as they will cause scratches.

- Make sure that the metal parts (especially the grate) do not burn through. They need to be changed in a timely manner.

- The ash pan needs to be inspected and cleaned regularly.

A metal stove for a wood-burning home is an effective solution to the heating problem, which is popular due to its intuitive operating principle and easy maintenance. When choosing from the presented options, you should take into account not only the cost, but also the technical characteristics and reviews of owners who already own one or another model.