Today, among heating systems used in everyday life, warm water floors are gaining popularity. The increased attention from consumers to this heating method is explained by the high efficiency of heated floors, especially when emphasis is placed on the quality of interior decoration of residential premises. Heating radiators do not always look aesthetically pleasing, while a water circuit hidden in the floor is completely invisible.

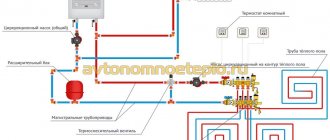

In this case, the installation of heating equipment is also captivating. With proper planning and compliance with all the necessary technological details, making heated floors in your own home is quite realistic and within the power of everyone. In order to achieve success, it is enough to have an idea of how heated floors work, which is included in the equipment package. In the process of work, you will have to deal not only with the choice of heating method for the coolant, the selection and installation of water circuit pipes and screed equipment. The key element of the “warm water floor” heating system is the heated floor mixing unit.

What kind of equipment is this? What is its design and purpose? Let's look at these issues in more detail.

What is a three-way valve?

A three-way valve for heating with a thermostat looks like a brass tee (sometimes steel or cast iron). But it works differently. There is a special thermoregulatory mechanism inside it. Based on the structure of the mechanism, there are two types of such mechanisms: rotary and saddle.

In the first, due to the rise of the rod, the pipes open, the cold and hot flows are mixed, and the overall temperature of the exiting liquid decreases.

The other (rotary) is based on the rotation of a spherical shape. The space between the nozzles is opened fully or partially by turning the ball with the opening (reminiscent of a ball valve).

Equipment

To make a high-quality connection of the mixing unit to the heating, you need two main devices.

- Circulation pump. It is necessary for the movement of coolant along the low-temperature circuit.

- Thermostatic three-way valve. The element is responsible for supplying hotter coolant at the moment when the small circuit cools down.

Thermostatic three-way valve comes in two types.

- Bellows. Which involves the expansion effect of a solid, liquid or gaseous medium during heating.

- Electric. It is equipped with elements such as a thermocouple and a servo drive.

Diagram of operation of a valve with a seat mechanism:

With fifth wheel actuator

The cone (3) fixed to the rod (4) overlaps the seat (5).

Valves differing in their actuators can be of two types: separating and mixing.

The mixing valve (SV) has two inputs for one output. The main application is for heated floors. Different temperature streams arrive at the inputs, which, when mixed, equalize the temperature to the specified level.

A separating valve (VV) has the opposite situation: there are two outputs per inlet. The flow is divided by the valve into two different directions.

The differences are related to the number of balls: one in the SK, two in the RK. They are built into the outlet pipes. There are as many outputs as there are ball valves. The movement of water is indicated by arrows.

SCs are used more in heating lines. Separating – for DHW. One divided stream will have a constant thermal regime (the quality of the liquid is important here), in the second stream the regime can change (only the quantity is important).

Adjusting the rod allows you to achieve the required temperature in a constant circuit. A variable circuit can completely overlap.

The principle of operation of the valve in the heating system

The flow enters the device from the left. It gradually heats up, and at some point the expansion of the special liquid in the thermal head begins. Which ultimately leads to the lowering of the rod with the opening of the pipe below for less hot water from the heating return line. It is mixed with hot inlet water. A less hot flow is already flowing onto warm floors. The thermoelement contracts and the rod moves down.

While the coolant is heating up, the rod continues to descend. It can drop to the very bottom, stopping the flow of hot water, opening the warm water pipe as much as possible. This will continue until the coolant cools to the required level. Then the top valve will open and hot water will flow from the inlet again.

Purpose of the device

Even with accurate thermal calculations when designing houses in a microdistrict, excess heat may appear in the apartment due to external factors: hot sun, strong wind, household appliances purchased by the owners that produce heat. It is not possible for individual apartments to reduce the temperature of the coolant, since the weak point of simple boilers is the heat exchanger, which cannot withstand low temperatures. A different type of boiler is needed - a condensing boiler, but it is significantly more expensive. If you have a simple boiler, you can reduce the amount of hot water to the radiator.

This is why a three-way heating valve is included in the connection.

Specific use cases of three-way valve:

- Heating of floors (warm floors). The two inputs of the valve are supplied with return and supply respectively. A mixed (cooled) flow flows through the outlet. This does not affect the rest of the circuit in any way.

- Maintaining return temperature. The boiler operates normally as long as the water entering it is no more than 60 0 colder than the water leaving it. To do this, the water from the supply is divided, and part of it is sent to the return to heat it.

- So that condensation does not collect. The water in the heat exchanger must not pass the dew point. Therefore it cools down.

- To prevent the boiler from overheating. Achieved by similar cooling.

- Combined operation of the boiler with the boiler - the valve thermostat is activated when the water in the boiler cools below a predetermined level, the mechanism opens.

- If you need a bypass - a parallel path, then the easiest way is to use the valve.

How to choose a three-way thermostat valve

There are several selection criteria:

- by the method of temperature regulation;

- by capacity;

- according to the material.

By temperature control method

There are manual three-way valves:

The rod is connected to a handle or valve, which is set to marks that set the temperature. The cheapest and most reliable option, but it cannot react to a changing external environment on its own; human intervention is necessary.

In thermostatic valves, the built-in thermostat is responsible for adjusting t.

It is configured, then it itself connects the position of the rod with the temperature of the passing flow. The principle of operation is based on a special liquid or gas that changes volume at the slightest change in temperature. When the latter increases, they increase the size and push the rod.

Thermostatic valves are divided into mechanical and electronic. Their two main advantages over manual valves: automatic monitoring of the installed temperature and the same heating of water throughout the entire system. But much more expensive.

The most accurate regulators are electronic, with electric drive. From the thermostat, the signal reaches the controller, which moves the rod vertically.

For residential buildings and other cases that do not require special precision in temperature control, a simpler thermostatic valve - a mechanical one - is considered optimal.

Material of manufacture

It is better to exclude silumin devices from consideration; the material (low-strength alloy of aluminum with silicon) is too bad.

Black steel - products made from it are durable and not expensive, but they rust. And chrome or nickel plated ones are much more expensive. It's the same with stainless steel.

Cast iron is durable, essentially eternal, not afraid of corrosion, but fragile and can crack due to sudden temperature changes. Scope of application: with solid fuel boilers.

Brass and bronze are also good for everyone, but they are not suitable for industrial conditions (t up to 200 0 C). But for household needs they are better suited than others. Mostly brass is used since bronze is more expensive.

Bandwidth

At the valve, it should slightly exceed the design capacity of the general heating system. When passing through a circuit of 2 m 3 / hour, a valve of 2.5 m 3 / hour is needed. But the condition of the valve also affects how open or closed it is. A hundredfold difference in flows is considered ideal. But ratios of 50:1 and even 30:1 are sufficient.

Functional Features

An analogue is a two-way valve. Also considered a shut-off valve. But the three-way works fundamentally differently. The constant flow is not completely blocked.

But with variable flow this is quite possible. Thanks to these features, it is possible to regulate the flow/pressure.

From two two-way valves, you can get one three-way valve if you connect them in reverse, that is, when one closes, the other should open.

Popular valve manufacturers

Place and role of mixing valves in the heating system "warm floors"

The main task that consumers have to face when deciding to install heated floors in their home is to achieve the required coolant temperature. For radiators, water at a temperature of 750C is quite acceptable, which cannot be said about pipes that are laid in the thickness of a concrete screed.

Important! Excessive heating of the concrete screed leads to a deterioration in the temperature balance inside the heated room. At high temperatures, flooring (in most cases wood-based) quickly loses its aesthetic and technological qualities, becoming unusable.

In accordance with sanitary standards, the normal heating temperature of heated floors should not exceed 260C. Then the middle layers of the air mass inside the room warm up to comfortable values of 20-220C. In order to obtain such temperature parameters, the water entering the loops of the water circuit must be heated to 500C. Slightly less than 50% of the thermal energy of the heated water is spent on heating the layered cake of the heated floor. Taking into account the thickness of the concrete layer, material and type of floor covering, the temperature on the floor surface decreases.

A mixing unit, which is a set of interconnected instruments and devices, helps to achieve a significant reduction in the temperature of the boiler water at the entrance to the heating water circuits. One of the main roles in the operation of the mixer is played by the thermomixing valve, which mixes water for the heated floor. Thanks to this small device, two streams of water are mixed, cold and hot, so that the output is water at the required temperature. Valves installed in mixing units are of two types, three-way and two-way. Each type of crane performs its own tasks and functions determined by the technological process. Which device is best to use for your heated floors? What is behind the choice of the type of mixing and control device?

Thermostatic valve and control valve - differences

The use of thermal valves on a single-pipe heating system is especially important, but only if it is not flow-through. That is, if there are jumpers at the junction of the radiators - bypasses. It happens that there are no bypasses. As a result, the coolant sequentially passes through all radiators, one after another. Installing a thermostatic valve on such a system can only cause harm. Because the thermostatic valve will turn off all radiators located after it. Therefore, if for some reason it is very necessary for a flow-through system, it is better to install a control radiator valve. And don't cover it completely.

The difference between a control valve and a thermostatic valve is the ability to adjust the gap for the passage of coolant - more or less. The thermostatic valve, on the contrary, can only be in two positions. Firstly, it is open to a certain, previously adjusted level. Secondly, it is completely closed. Therefore, there is no need to install a thermal valve on a flow-through heating system without bypasses. Since, when the valve is closed, the circulation of coolant throughout the system will stop. This will create cooling and unbalance the heating system. It will also have a negative impact on the heating boiler. The situation can be aggravated by the absence or poor functioning of the safety valve. That is, a breakthrough may occur in one of the weak points of the system.

What materials are they made from?

Corrosion-resistant metals are used to make the thermostatic valve body:

Additionally, the surfaces of brass products are nickel-plated, and the bronze body is either also nickel-plated or coated with a layer of chrome.

Advantages and disadvantages

The advantages of installing thermostatic valves in the heating system include the following factors:

- Energy independence of the device.

- Compactness.

- High precision temperature control.

- Easy to operate and highly reliable.

- Aesthetic appearance.

- The optimal combination of price and functionality.

The disadvantages of using thermostatic valves are:

- Difficulty setting up.

- There is a danger of the thermal head malfunctioning under the influence of a draft or a nearby stove.

Types of taps

Classification of the product according to various criteria:

- Depending on the valve, there are:

- Regulating. It is equipped with an electromechanical device that opens the required valves. It also includes a rod with manual or automatic adjustment. Important! The rod cannot be knocked out even with the strongest water pressure, since it is located inside the device.

- Constipated. It includes a ball device that switches the flow of water. The peculiarity of this device is that it is installed on low pressure systems. It is very simple in design, requires constant maintenance and wears out quickly.

- According to product material:

- Brass is the most popular material due to its long service life, small size and low weight.

- Carbon steel is an excellent alternative to brass.

- Cast iron - used for large diameter pipes (40 mm and more). It is not practical for private houses.

- Bronze is a material with a long service life.

- Depending on the installation method:

- coupling;

- flanged;

- pin;

- for welding;

- fitting-end.

- For the heating system, the following types are used:

- With constant hydraulic mode - adjustable in accordance with quality indicators. It is suitable for consumers with high-quality coolants of a certain volume.

- With variable hydraulic mode – adjustable according to the required amount of water. It is more suitable for those for whom quantity matters.

- From the device flow path option:

- trial run;

- full bore.

- From the type of built-in shutter:

- conical;

- cylindrical;

- ball.

- Based on the shape of the plug valve, the following types are distinguished:

- T-shaped;

- L-shaped;

- S-shaped.

- From the mechanics of the bolt element:

- Stuffing box – controls the adjustment of the water jet from above the fittings due to the stuffing box;

- Tensioners - controls the adjustment of the water jet from below the fittings due to the nut.

- Depending on the heating of the case:

- with heating;

- without heating.

- Depending on the technical parameters, the following valves are distinguished:

- T-shaped – the adjustment knob can be in 4 positions;

- L-shaped - the adjustment knob has two modes, including a rotation angle of 180 degrees.

- From the device control mechanism:

- Manual - connects water flows in approximate proportions, cheap, looks like a standard ball valve;

- Electric drive - for operation, additional equipment is used - a motor or a magnetic method, there is a possibility of getting a shock from the current;

- Pneumatic drive is the most optimal option for use. Important! With an electric drive, you can easily balance the heat so that the temperature level in the rooms farthest from the boiler is the same as in those close to it.

Types and their structure

In a thermostatic distribution valve installed on a heated floor, the heated water is mixed with cooled water from the return pipe. This process is continuous as long as the heating is on.

There are two-way and three-way mixing valves for underfloor heating. They also differ in the method of mixing and the direction of flow.

Two-way

The two-way thermostatic valve is an improved manual type model. It can be hydraulic, pneumatic or electrically driven.

The design is simple, but capable of effectively regulating the temperature level of the coolant in automatic mode. The device is mounted in the heating system, instead of a manual valve.

- Automatic reduction of liquid temperature level;

- Simplicity of design and low price;

- Easy installation.

Disadvantages - the possibility of installing it on pipelines with a small size. If you use this faucet when installing heating in a room with a large area, the thermostat will function intermittently. A two-way valve is more often used if heated floors act as additional heating.

The valve device is a brass or bronze body, with one or two seats. A double-seated valve can completely shut off the flow of water.

The device is equipped with a thermostatic head with a scale. The head position can be changed manually or automatically. Manual models are simple and inexpensive. More modern devices work automatically.

Installation recommendations

To achieve maximum performance from a three-way valve, it must not only be selected correctly, but also connected properly.

Installing this product is no different from installing other fittings. It is advisable to take into account the following recommendations during the work:

- You don’t have to think about the spatial location of the crane. The operation of the device is not affected by its vertical or horizontal position;

- To position the faucet in the desired direction, take a look at its body. An arrow will be visible on it indicating the direction of coolant flow;

- The control device of the tap must be located so that it can be easily accessed;

- If the installation is carried out using a welded method, it is important to prevent scale or other debris from getting into the pipeline;

- During welding work, it is necessary to protect the valve from heating. To do this, you can provide it with some kind of heat sink;

- Before the start of each heating season, it is necessary to check the operation of all control and shut-off valves.

By installing a high-quality three-way valve into the circuit of your heating system, you will be able to regulate the temperature of various heating devices at will, control and change the temperature in individual rooms.

How does automation work?

A thermostatic three-way valve for underfloor heating is connected in front of the manifold. A certain temperature heating mode is set on the sensor. The device starts working when the parameters are changed.

- The device consists of a semiconductor, which has the temperature of the coolant entering the line. Energy is transferred to the thermostat fluid.

- As the heat increases, the liquid expands and puts pressure on the rod, which lowers.

- In this case, the outlet from the hot pipe is closed and the outlet from the return circuit is opened.

- The cooled coolant enters the three-way mixer chamber, where it is combined with hot water from the boiler. The mixing process can take place according to a T-shaped pattern: hot and cold coolant flow enters the thermostatic mixing valve symmetrically from both sides. The liquid exits into the main line at an angle of 900. With an L-shaped design, hot water enters the mixing chamber from the side.

- The coolant temperature decreases. It enters the floor line cooled. The heating mode strives to reach the set norm.

- As the temperature drops, the liquid in the thermostat contracts. The spring-loaded rod straightens, closing the outlet of cold water that flows through the return pipe. Hot coolant again enters the main line.

When using servo drives, a device that operates from the network is connected to the mixing valve for heated floors. The sensor heats up and closes the electrical circuit. The plate is heated, which in turn transfers heat to the thermal fluid. It expands, pressing on the rod, which makes the poppet valves work.

When using a servo drive, the heating system changes operating mode within 3 minutes. If you use a thermal head as an automatic device, it will take up to 15 minutes to heat the liquid in the thermostat.

The operating principle of a two-way valve for underfloor heating is somewhat different. When the temperature in the main increases, the thermostat causes poppet valves or a ball device to operate, which completely blocks the outlet for hot water. The cooled coolant from the return pipe returns to the floor circuit.

Installation

Installing the offset node:

- The unit is installed to the underfloor heating circuit.

- Installation can be right-handed or left-handed.

- The unit can be mounted in a room, closet, or boiler room.

If the unit does not fit into the interior, you can hide it.

- A pump and temperature sensor are installed.

- The mixing valve is mounted on the first main circuit, the return valve on the return circuit.

- The return outlet is connected to the cold pipe.

- You need to check that the node is connected correctly. At high or low coolant temperatures, the valve capacity is increased or decreased. The thermostat is set to the desired temperature.

The mixing circuit ensures smooth operation of several heating circuits. Makes a person’s life comfortable and calm. The main thing is to choose and install the model correctly.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

How to choose a thermal head?

The floor covering heating system has a mixing unit, the most important element responsible for changing the parameters of the heating circuit. This is due to the fact that the moisture from the heating equipment enters the pipeline too hot, sometimes up to 90 degrees Celsius, and inside the screed there can only be a maximum of 40 degrees Celsius.

In order not to overheat the system, a thermal head is installed on the damper, maintaining acceptable parameters of the coolant. The mixer is responsible for bringing together the temperatures of different flows, as a result, antifreeze or water of the required and permissible temperature enters the water circuit.

Types of thermal heads

Depending on the substance in the bellows, thermal heads can be gas, liquid or paraffin based. Liquid - inertial, working slower, taking a long time to heat up and cool down, but the most accurate.

Gas ones have a large error and are vulnerable to drafts. Inside the head there is a mnemonic diagram on which zones with temperatures are marked.

The thermal head can be controlled mechanically or electronically. Manual, mechanically controlled, have a radial scale with marks of 2...5 degrees. Turning the knob will increase the distance between the elements and increase the pressure on the rod.

Electronic devices are controlled by a display, and an electric drive presses on the rod. Such equipment is more expensive, but is highly accurate.

The thermostat contacts the surface in several ways, so the thermal head can be a surface-mounted one, with an air sensor, or an immersion type.

The thermostat heats up at the place of fixation, and the overhead and air thermostats are connected to the sensor by a sealed capillary-type tube. The bellows expands from the heating of a canister located remotely - such units are used in heated floors.

How much does a finished unit cost?

Of course, you don’t have to worry about studying the operating diagrams of different types of connections, but buy an already assembled version of the system. You can find such options in construction stores, but their prices are high. But this will save you from errors during assembly and calculations, because you need to know well the purpose of each part.

Example of incorrect connection

For example, the most popular Italian mixing unit for heated floors, Valtec, with a pump in Russia, will cost you about 15 thousand rubles. An equally popular American mixing unit for heated floors, Watts Isotherm, also costs between 15-16 thousand. If you want to save money, you can assemble such a unit with your own hands from individual parts.

Changing operating modes of heated floors

The thermostat is an effective solution for monitoring the water temperature in the heating circuit. This method is inexpensive and accessible to almost every owner. The boiler heats the water to 90 degrees, and water should flow to the floors at a temperature twice as low.

The desired degree can be achieved thanks to the thermostatic head:

- The supply of hot water is short-term - the water fills the pipeline, the supply ends until it cools to an acceptable temperature;

- Constant water supply with the addition of cool coolant from the return pipe.

Periodic short-term supply

With a short-term water supply, the system works in a small space - a bathroom, ceramic floor in the toilet, shower room and other places. At the supply point there is a valve with two strokes, a remote-type floor sensor and a thermal head.

As soon as the circuit is filled with coolant, the sensor is triggered and the flow is blocked by the valve. After some time, the screed will cool down, the valve will open again and hot water will fill the system. This circuit is economical and can replace the mixer unit.

For heated floors, special thermal heads from the RTL series have been developed, without an external sensor. They are installed on the return line to maintain the set water temperature without depending on the heating of the floors. By installing this model of thermostat, the automation changes the threshold heat values (no more than 40 degrees Celsius).

The installation feature is installation in an exclusively horizontal position. Experts from Moscow do not recommend setting the water level in the floors lower than the temperature in the room.

Periodic short-term injections of water into the circuit allow you to maintain stable movement along the coolant circuit without overheating the system.

Constant coolant supply

A constant supply of water requires the installation of a three-way valve in the system, complemented by a floor sensor and a thermal head. Using a tee, a connection is made from the return to the third stroke of the mixing unit. The direct water supply must always be open, so the valve must be installed professionally and correctly.

Experts recommend installing the thermal head on a three-way valve using a locking type axle box. When the sensor heats up, the valve stem moves and a gap is formed inside. This gap receives cool water from the return line.

This sequence of work allows the coolant to stably enter the circuit, while the temperature remains within acceptable limits. Due to the continuity of the flow, the floor covering quickly heats up to 28 degrees Celsius and remains comfortable for the owner, and the circuit does not overheat.

Pipes and screed will last longer due to the absence of excessively high temperatures. The addition of cold coolant is important for heating large rooms where a comfortable temperature is needed.

Nuances of choosing a device

The following guidelines are general when selecting a suitable three-way valve:

- Reputable manufacturers are preferred. Often on the market you can find low-quality shut-off valves from unknown companies.

- Copper or brass products have greater wear resistance.

- Manual control is more reliable, but less functional.

The key point is the technical parameters of the system in which it is supposed to be installed. The following characteristics are taken into account: pressure level, the highest temperature of the coolant at the point of installation of the device, the permissible pressure drop, the volume of water passing through the valve.

Only a valve with the correct capacity will work well. To do this, you need to compare the performance of your plumbing system with the throughput coefficient of the device. It is mandatory indicated on each model.

For rooms of limited space, such as a bathroom, it is irrational to choose an expensive valve with a thermomixer.

Large areas with heated floors require a device with automatic temperature control. The guideline for selection should also be the product’s compliance with GOST 12894-2005 .

The cost can be very different, it all depends on the manufacturer.

In country houses with a solid fuel boiler installed, the heating circuit is not very complicated. A three-way valve of a simplified design is quite suitable here.

It operates autonomously and does not have a thermal head, sensor, or even a rod. The thermostatic element that controls its operation is set to a specific temperature and is located in the housing.

Large areas

Installing heated floors as the main type of heating involves installing full-fledged mixing equipment that is capable of dividing the flows into two - heated floors and central heating. Here, three-way thermostatic valves with full flow into the system are required.

Experts recommend installing one common circuit where the working fluid is pumped by a pump. At the entrance to the heated floor there is a mixing valve. It is controlled by a special temperature regulator. The mixing valve is installed between the bypass and return. A sensor at the top of the valve regulates the set temperature.

If the temperature rises, the mixing valve closes the return flow. Further circulation of the working fluid occurs in the coolants of the heated floor.

Source

A number of optional elements

Additionally, the mixing unit diagram includes several more parts.

Without them it is impossible to assemble a complete set of equipment.

- Collector. This is a comb necessary for the normal functioning of the feed/return. Since there may be some restrictions arising from hydraulic resistance inside the pipeline, the length of the circuit cannot be more than 120 meters. For a large room, several circuits are arranged.

- Thermal head. The element is necessary to separate the circuit flow adjustment and ball valves. The latter will be required to perform an independent shutdown of part of the heating system.

- Automatic air vent. It is mounted on the supply and return manifold, which eliminates airing of the system and disruption of coolant circulation.

- Reset. Both collectors are drained through it.

It is necessary to pay attention to the fact that the vent located inside the manifold cabinet must be higher than the level of the heated floor contour located inside the screed or finishing.

It is impossible to completely drain the system, and therefore, if in winter it is necessary to stop heating, regardless of the reason, then antifreeze must be used as a coolant.