Impeccable compliance with standard requirements and practical recommendations during the calculation and construction of a boiler room for a cottage is a guarantee that the heating system in it will work flawlessly, and “living” heat will never leave your home.

Home boiler room: design

The design of modern boiler rooms used in private households may differ. Their features depend on the type of fuel consumed and the type of premises used. According to the method of location, the following types of boiler rooms should be distinguished:

- Built-in. The built-in boiler room is located directly inside the household. The location of the boiler room in a private house is quite convenient, but it is not suitable for every type of heating boiler. Thus, boilers that create a lot of noise (with a forced-air burner) are best used in isolated boiler rooms;

- Attached. They are located in an isolated room located in a special extension to the cottage;

- Freestanding. A separate boiler room for a private house is almost always located in close proximity to the house. It communicates with the main housing through various utilities (heating mains, gas pipelines, water supply and electrical wires).

A separate boiler room for a private home is a universal solution that allows you to install heating boilers of any design indoors, capable of operating on various types of fuel.

In rare cases, a boiler room is installed in the attic of a residential building. But this is the exception rather than the rule.

Alex720517 FORUMHOUSE user

I came to the conclusion that a free-standing boiler room, by all indicators and common sense, is better than a built-in one. Although its construction will cost more. Examples of boiler rooms separate from the house known to me show that heat loss during transfer is minimal (from the boiler room to the wall of the house - 5 meters) when using polypropylene pipes with insulation in a plastic sewer pipe. I’m generally silent about safety. Gas is gas. They don't joke with him. When using a separate facility, there are no boilers, boiler, tank or auxiliary equipment in the house. There is no noise, no unpleasant smell, space is freed up, etc. etc. There seem to be only advantages (except for the rise in price).

Yes, for boiler houses with high power (which can vary from 200 to 500 kW) and a large amount of equipment, it is better to make a separate room. It is convenient, safe and modern. Don't be afraid of the costs associated with building an additional house, as well as possible heat losses. It is worth building a separate boiler room; in this option you will always get more advantages than disadvantages.

If the project is not so cumbersome, then you can limit yourself to an extension to the house or even place the “stoker” in a separate room inside a residential building.

Here's what our user thinks about it.

Car Enthusiast FORUMHOUSE User

It makes sense to use a separate room if there is a large amount of equipment. For small boilers placed on the wall, it is better to install the boiler in the house. By the way, heat losses on the heating main can be quite significant - 20 kWh. On a winter day that’s 3 cubic meters of gas.

Where to place a boiler room in a private house - in the basement of a house, in a garage, in an extension or a special room - is up to you, but you should always plan its space correctly.

How to equip a boiler in private homes, photo.

Where to build a boiler room in a private house is up to you. But if the room could fit all the necessary equipment and there was enough space left for its maintenance, then the layout was done correctly. But we will return to this issue later.

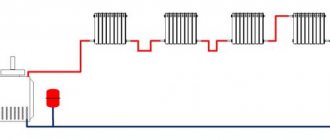

Open and closed heating circuits

Typical boiler room circuits are divided into “open” and “closed”. An open circuit is cheaper to install, but operating costs are significantly higher. In a closed system, the coolant is heated directly in the system, and the pump circulates it.

The main difference between these systems is that in an open system, the coolant in the expansion tank comes into contact with air. This means that some of the heat is lost.

The closed circuit (the most common) is labor-intensive to install, but due to its tightness, heat loss tends to zero.

Instructions for piping the boiler

Having completed the process of installing the equipment with a heat generating unit in the basement and having received a complete heating system, it is necessary to wire the boiler. In this case, it is necessary to calculate that the location of the boiler is lower than the level of the installed heating radiators and below the floor. This is very, very important when constructing systems with gravitational circulation. Then you can move on to the important stage .

- First of all, we connect the heating pipe to the outlet section of the pipe. You need to know that their diameters must be similar;

- Before you begin work on the installation process of the collector, you must very carefully learn the marks on its body , in order to avoid confusion with direct supply and “return”. The boiler has a 1.25 hole, and a 1 inch hole is intended for connecting the pipeline. All other unused outputs must be closed with plugs;

- In accordance with the instructions, the supply pipe must have a device that ensures the safety of low-temperature circuits. These, in particular, include “warm” floors. To do this, a three-way water tap is installed. With its help, you can implement temperature regulation when connecting other consumers;

- The circulation equipment of the pump is located in the return circuit. During installation, it is connected to the manifold and distribution valve;

- At the final stage of work, instruments are installed , thanks to which pressure and temperature are monitored. In addition to them, there is a pass-through filter, taps for balancing and draining. Along with them, the process of installing check and air valves is done;

- Boiler piping actions for boiler installations with a wide variety of equipment may have different orders.

Where to place the boiler room

First of all, you need to remember:

More than two boilers cannot be installed in one room (regardless of its size).

All construction and finishing materials must be fire-resistant and comply with fire standards.

The walls can only be brick or concrete blocks, plastered or tiled. Floor covering - concrete or metal.

Adequate ventilation, especially for gas boiler rooms in the house, and a chimney are required. The air must be renewed at least three times an hour. There must be a window and a door facing the street.

The dimensions of the combustion chamber vary depending on the size of the installed equipment and imply the availability of free space for maintenance.

A complete list of requirements for boiler rooms in a private house in 2018 can be found in SNiP II-35-76.

Finishing materials

When choosing products for boiler room cladding, it is important to ensure sufficient fire resistance, since there is a high probability of ignition. Safety standards and functionality are the main conditions from which it is necessary to build. Be sure to treat all wooden surfaces with a special compound before covering them with any material.

Walls

When considering the question of how to decorate the walls in a boiler room, they take into account the type of base and location of the room. For isolated buildings, you need to select materials that can withstand temperature changes without significant deformation. In addition, resistance to heat and behavior in the event of a possible fire in the room are also important. In the event of a fire, the flames must be contained within the premises for at least an hour.

Tiles in the boiler room Source stroy-podskazka.ru

Traditionally, plasterboard is used for finishing in boiler rooms, but recently several analogues have appeared. For example, acid-fiber sheets, which have a set of unique characteristics, are popular. This material is distinguished by its safety and environmental friendliness, since it does not contain asbestos or harmful compounds. Consequently, when the room is heated, there is no release of toxic substances that affect the health of the owners. Other advantages of the product include excellent strength, resistance to high temperatures and their sudden changes, the ability to bend easily and withstand exposure to liquids.

After fixing the sheets to the surface, they begin the second stage of finishing work - applying a layer of plaster. This substance will provide additional protection against ignition, and also minimize the negative effect of external factors.

To plaster the walls of a boiler room, it is important to purchase special products designed for use in flammable conditions. The substance has a grayish tint, so many owners decide to paint the room after applying it. To give walls any color, ordinary water-based paint is suitable, while the bottom layer will retain its properties and continue to provide reliable protection from flames.

The process of applying plaster Source stroy-podskazka.ru

What you can’t do without in a boiler room

Actually, the boiler itself, in which the coolant is heated. For large houses, you will need to install a collector that distributes coolant between separate groups of heating devices.

An expansion tank (tank), a water heater, a supply pipeline and shut-off valves that regulate the parameters of the heating system are also required.

Don't forget about automation to control the functioning of the system. Of course, the automation unit costs extra money, but these costs will quickly pay off.

Any heating system includes two interconnected systems - a chimney (removes exhaust gases) and ventilation (an influx of fresh air, which increases fuel combustion).

Preliminary processing

The heating system is installed on a flat surface, so first of all you should make it so using one of the following methods:

- For an ideal result, you can choose a wet screed; it allows you to efficiently level any surface. But there is also a disadvantage to using it - the long drying process, which lasts about a month. To correct old screed, it is recommended to use self-leveling mixtures.

Wet screed Source stroy-podskazka.ru

- If you need to carry out work in an accelerated mode, a semi-dry screed, which is a wet material, will help. After application, it needs to be leveled, since the mixture itself does not have this ability.

Semi-dry screed Source stroy-podskazka.ru

- One of the most modern methods is dry screed. It is done using expanded clay, with sheets of plasterboard and plywood laid on top.

Dry type screed Source stroy-podskazka.ru

Gas boiler houses

Increased requirements apply to gas boiler houses (instruction MDS 41-2.2000 and SNiP II-35-76), and gas boilers are subject to mandatory certification.

Remember that obtaining permits will require strict compliance with all regulations and standards. For example, the presence of a gas detector in the room.

Boilers less than 30 kW can be placed in the kitchen provided:

- have good ventilation in case of gas leaks. At the same time, the kitchen window area is at least 0.5 sq.m., and the width of the doorway is from 0.8 sq.m.,

- kitchen walls should be made of fireproof materials,

- The minimum room area is 6 sq.m. with ceilings higher than 2.5 m.

Solid fuel boilers - tips for choosing the best models and ideas for using boilers for heating (110 photos and videos)Screen for a heating radiator - a review of the best ideas and recommendations from designers for selecting screens for a heating system

- Chimneys for gas boilers - main types and step-by-step instructions for do-it-yourself installation (video + 100 photos)

For powerful gas boilers (exceeding 30 kW), you will have to allocate a separate building.

Arrangement of premises for heating boilers

Each type of heat supply equipment has its own operational features . Thanks to this, the room will be arranged differently depending on the selected settings. The photographs make it possible to see what a room for a heat-generating installation should be like, the equipment in which does not stop working on different fuels. We will talk about the main features in the room further.

- Gas boiler . Its use in a boiler installation carries the risk of the installation exploding. Due to this, during the work, the owner of the building must approve the project for the installation of a gas-powered unit in a personal home with the appropriate services. There should be no exposed electrical contacts in the room that has been selected for its location. All wiring must be hidden in metal pipes. Lighting fixtures located in the room must be covered with shades. Nowadays, many companies recommend purchasing a gas heat-generating unit as a kit. By paying cash, the owner receives all the equipment that is necessary and materials that ensure the reliability of its operation;

- Liquid fuel boiler . It is necessary to place a boiler next to the tank with the possibility of free access to it for refueling. In most cases, its volume is 3-4 tons. Its capacity is calculated according to the volume of use during one season. Productive ventilation must be arranged in the room itself. You can find out how to create it from the manuals that are available on many special sites. The photographs attached to them will help you understand how to do this correctly. Also, the heat-generating installation in the room must have a high level of sound insulation, since installations operating on liquid fuel make loud noise during operation;

- solid fuel heat-generating installation in a private home involves the installation of a chimney that should exit above the roof. Among other things, a sheet of steel must be laid on the floor directly in front of the firebox. The equipment itself must be placed at a certain distance from the walls. This will give good maintenance;

- Electric heating boilers . There are no properties during their installation process. However, when installing this equipment in a personal home, safety regulations must be followed;

- Combined heat generating units . They combine all of the above, depending on the types of fuel used.

Solid fuel boiler room

According to building codes, there should be no solid fuel boilers in living rooms and kitchens. The extension should be correctly placed next to a blank wall, as shown in the photo of a boiler room in a private house. For high fuel power, independent buildings are built.

Components of an effective solid fuel heating scheme:

- corresponding heat generator,

- boiler piping, including a circulation pump, three-way valve, safety group,

- chimney,

- storage water heater,

- automation unit,

- fire extinguishing complex.

Coal, peat or firewood are solid fuels. In the case of coal, it is important to remember that coal dust in high concentrations is explosive. Therefore, it is important to protect the electrical wiring.

Ventilation system

For proper functioning of gas heating units, a trouble-free air flow is required. It should be enough to both maintain combustion and remove gases.

To ensure good air exchange, a low-power device in a dilapidated building is mainly sufficient for natural ventilation of the room for the combustion chamber. Air enters here from cracks in windows, door openings, and also with the help of other non-densities.

If the boiler installation has sealed door and window openings, then it is hardly possible to do without additional ventilation.

Liquid fuel boiler houses

Installing such a boiler room in a house is much simpler than installing gas or solid fuel analogues. Such furnaces are placed both inside and outside the house.

High noise and specific smell usually exclude the placement of such a furnace in the kitchen. A reasonable solution would be to allocate a separate room with good sound insulation.

Double-circuit gas boiler: the best models, recommendations for choosing and installing a boiler with your own hands (105 photos)- What does an inverter air conditioner mean: difference, myths

- Benefits of Drip Irrigation

An absolute plus is that no permits or approvals are required. All that is needed is free access for transport with fuel, as well as regular refueling of the boiler.

Regulations

You should immediately decide on the regulatory framework. Until mid-2003, SNiP standards No. 2.04.08-87 were in force. On July 1, 2003, SNiP 42-01-2002 came into force. All requirements and standards for installing boiler rooms in a private home must be taken from this document.

It is advisable to know the standards, although the design of a boiler room in a private house should be drawn up by a specialized organization. This way you can decide on the possibility and impossibility of installing this or that heating equipment, as well as what work you have to do in order to adjust the existing or under construction premises to the standards. For every difficulty or controversial issue, it is worth going to the design department of the gas supply organization and talking with them. There are a lot of nuances associated with the features of each house, which can only be solved by being tied to the house plan or its design.

Summing up

The legislative framework changes frequently, so already at the preliminary stage of designing a combustion chamber it is important to study all current standards and regulations. When planning to install a powerful furnace, it is wise to contact specialized organizations.

Believe me, saving on the work of professionals often leads to a significant overpayment during operation, as well as extremely unpleasant and dangerous consequences for the life and health of your household. Even if the boiler room is small, be sure to consult with specialists.

Boiler room equipment

Uninterrupted operation of the boiler room, and naturally the provision of hot water and heat to the home, is impossible without a whole set of specialized devices and communication components. The necessary components of the system include:

- The boiler is the main heat generator. It is here that the coolant is heated, which is subsequently supplied to a storage electric water heater and radiators. Based on the source of heat energy, boilers are divided into five types: electric, gas, solid fuel, liquid fuel and combined.

- Electric storage water heater – tank-water heater. In the middle of the container there is a tube through which the hot coolant moves - it transfers heat to the water in the electric storage water heater, thus heating it to the desired temperature.

- Distribution manifold - pump, hydraulic distributor and comb. This unit ensures the distribution and uninterrupted circulation of the coolant throughout all elements of the working system.

- Diaphragm tank - expansion tank: compensates for the increase in pressure during the heating of the working coolant.

- Safety devices - Mayevsky valve, safety valves, a device for determining the pressure value: protect the system from excess air and excess pressure.

- Automation – various types of electronic devices that are intended for coordinated control of all elements of the heating and water supply system.

- Flue outlet - exhaust pipe: removes gaseous, liquid and solid substances of working fuel into the environment. There is no urgent need for a smoke exhaust only, for example, if an electric boiler is in operation in the boiler room.

- A set of shut-off valves necessary for timely shutting off the movement of the heat carrier in the event of dangerous situations.

Photo of boiler rooms in a private house

Preparatory work

Installation of equipment requires a level base. Therefore, first of all you will need to level the floor. There are many ways, the choice depends on the design and material of the building, as well as on the desired speed of work:

- A traditional wet screed allows you to get a perfectly flat base, but it dries within 28 days. If the screed has already been poured, it can be leveled with construction self-leveling compounds.

To level the walls, use plaster, plasterboard or CSP boards.

Little tricks

The decoration of the boiler room can be original and stylish. Brightly colored porcelain tiles combined with designer items and accessories will perfectly fit into the interior of your home. A matte surface interspersed with veins will add volume.

Cleaning will not be difficult. On a light surface, dust is not visible at all.

Doors are installed in two places. One is connected to the house, the second to the street. The entrance is equipped with additional structures. Fire-resistant metal sheet will strengthen the fire barrier. An estimated time of 60 minutes is enough to block the fire and call the fire department.

It is better to take classic, compact, no-frills lamps. Regular lamps will also work. Keep a small flashlight in a visible place in case of a power outage.

Don't get carried away with decoration. After all, the boiler room belongs to the utility rooms. The main boiler here is what you need to think about. Therefore, curb your appetites and direct your creative energy to other objects.

General information

Despite the wide range of fuels, the use of solid fuel boilers remains the best option for rural areas, where in most cases there is no gasification.

Of course, you can use electricity, but in this case heating will cost much more. True, many people prefer traditional Russian stoves to boilers. However, this option is only suitable for relatively small houses. If the housing is large and has several floors, then you cannot do without a boiler.

It should be borne in mind that wooden houses are more demanding in terms of fire safety. Therefore, the arrangement of a boiler room requires a special approach and compliance with certain rules, which we will read below.

The walls of the boiler room must be lined with non-combustible material

How to paint the floor on the veranda at the dacha with your own hands

Painting your porch is an excellent option for protecting your flooring. Paint protects the floor from damage and corrosion. Various materials can be painted:

- wood - boards, MDF, decking boards;

- concrete.

How to paint the floor on the veranda at the dacha, except with acrylic paint

For painting the wooden floor of an open veranda, the most optimal are acrylic, alkyd, nitro-enamel and oil paints. For good wood, you can also use stain or varnish. Before painting the veranda boards, the floor must be cleaned of remnants of the previous paint, if any, and sanded.

It is better to paint concrete floors with epoxy, acrylic paint or polyurethane enamel. Epoxy paint is not exactly painted on - it is rather “rolled” across the floor with a special spatula until an even layer is formed. It does not wear off over time and gives a very bright color.

How to paint the floor on the veranda at the dacha? Choose acrylic paint and polyurethane enamel. They are applied with a regular brush or roller. Before painting, it is better to clean the surface from dust and prime it, which will ensure better adhesion of the paint.