Standards

Before pressure testing, a special program is drawn up, which is approved by the engineer of the heat supply organization. It should define:

- Sequence of work.

- Personnel procedures.

In addition, it is indicated which team will perform the work and which teams are working in adjacent areas. Pressure testing of heating equipment is carried out under the supervision of the shift supervisor. In this case, all other work aimed at repairing or maintaining the pipeline must be stopped. Do not remain in the immediate vicinity of the equipment under test when the pressure rises to the maximum value. Inspection of pipes and other heating equipment should be carried out only at average values. If work is carried out in areas adjacent to the test subject, they must be fenced off and disconnected from the test equipment. If the inspection was carried out in compliance with all the above standards, an act is signed, which will be discussed below.

This document is drawn up by an authorized engineer and serves as confirmation that all work was carried out according to the rules and the tests were completed successfully. Among other things, the report indicates the parameters of the pressure testing performed and provides a conclusion on the operability of the equipment and its readiness for the heating season.

This is how pressure testing of heating systems in apartment buildings is done. Private homeowners also usually entrust this work to specialists. After all, only compliance with all required technologies during testing can guarantee uninterrupted operation of the system during the cold season.

> Forms of acts for executive documentation

Algorithm for completing documents and the procedure for drawing up an act

Organizations involved in the repair and maintenance of heating systems have an algorithm for drawing up documents and a procedure for drawing up reports that determine the procedure for flushing.

Such instructions are usually composed as follows:

- Inspection of heating equipment for cracks, chips and places where the walls of the pipeline have become thin. The pipeline is checked using increased pressure, the value of which increases by 1.25 times. Moreover, its value should not be less than 2 atmospheres. Such a check is carried out to ensure that the detected malfunction (if any) does not become a cause of disagreement between the customer and the contractor;

- After inspection, repair work is carried out to eliminate cracks, leaks, etc.

- The next step is to draw up an act containing information about the previous stage. That is, records are made about unforeseen repairs;

- After documenting the repair, a method for flushing the heating system in your home is selected. Most often, hydropneumatic washing is chosen, which is carried out using a pulp containing water and compressed air;

- The penultimate step is drawing up an estimate of the work done, the cost of which includes the cost of depreciation of equipment, fuel costs, chemicals, and also takes into account the labor of workers.

Based on all of the above, a contract for flushing the heating system is drawn up. This document, the act, stipulates the cost of services provided and the sequence of their implementation. In particular, the contract and form stipulate the responsibilities and obligations of the customer and the contractor and the timing of flushing the heating system

It is very important to include in the contract fines and sanctions for failure to complete it on time or for poor performance. These points will allow you to avoid conflicts and push the performer to perform better and more conscientious work.

These points will help avoid conflicts and push the contractor to perform higher quality and more conscientious work.

This clause is called “liability of the parties”. It is also necessary to indicate in the act for flushing the heating system in what cases, in what situation and for what reasons this contract can be terminated

At this stage, the work is just beginning, since before flushing the heating it is necessary to carefully check everything and document both the test results and organizational issues. The drawn up agreement is signed by the parties. It must be remembered that all controversial issues that arise, unresolved at the level of management of the organization carrying out the work, are resolved in court

To do this, it is extremely important to keep all documents confirming the work carried out by company representatives in your home

The final stage is the actual work of flushing the heating system; then a secondary check of the pipeline and radiators should be carried out for leaks and cracks. Then a final performance check is carried out and, after the customer evaluates the work, the heating in the house is started.

Formation of estimates for heating system maintenance

What is the difference between an estimate for repairing a heating system and a document for installation work? First of all, at significantly lower costs

However, in this case, special attention must be paid to the selection of consumables. They must be adapted to the current system. First, an analysis of future repair costs is performed

To do this, the area of the heat supply problem is determined and materials are selected to eliminate it. Unlike estimates for heating installations, consumable components cannot have a wide range. So, for chemical flushing of pipes it is necessary to use a special liquid, finding an analogue of which will be problematic.

In general, when creating an estimate for repairing a heating system, you should be guided by the following rules:

- The technical and operational parameters of the replaced components must fully correspond to the old ones that are out of order. For example, when replacing a piece of plastic pipe, you should choose the same one, made of a similar material and having the same geometric dimensions;

- In addition to the cost of new components, an estimate for their installation in heating is filled out;

- Transportation costs and services of repair specialists must be taken into account.

Often, repair estimates for the heating of a private home contain components that are purchased “in reserve.” A specialist can identify “weak” points in the heating supply and advise you to buy the most necessary components to carry out prompt repairs.

Estimate for flushing pipes and heating radiators

The heating supply must be cleaned of accumulated dirt and limescale deposits at least once every 3-4 years. This depends on the composition of the coolant and the material used to make the radiator pipes. For steel models, the frequency is less, since a corrosion layer is formed on their inner surface.

A correctly formed estimate for heating flushing directly depends on the chosen technology. When chemical cleaning occurs, most of the costs will be a special composition. For a hydraulic system, the estimate for flushing the heating must indicate the cost (rent) of the apparatus to perform this work.

Features of filling out this type of document include the following:

- The costs of analyzing the degree of contamination of the pipeline and radiators must be taken into account. Without this, the estimate for cleaning the heating will not be complete;

- After all preventive measures have been completed, the current state of the system is checked;

- The costs of disposal of contaminated liquid are taken into account. If the work is performed by a specialized company, this item is most often not indicated in the flushing estimate for the heat supply of a private house.

A separate category of work is flushing the boiler heat exchanger. Just as when filling out an estimate for installing a heating system, additional costs will include work on disassembling and assembling the heating device. It is not recommended to flush the heat exchanger using a flow method.

Features of filling out the first paragraphs of the act

The commission includes representatives:

1.company that built communications.

2. service that carried out technical supervision of the customer.

3.operating organizations.

The act should indicate the name of the organization that includes the specialist participating in the inspection, and the position of this commission member in this organization, indicating his last name and initials. Next, detailed information about the object that is subject to inspection is written down. It is necessary to write down its name without abbreviations (information can be taken from the design documents), picket numbers that are indicated at the ends of the object, the length of the pipes, their diameter, and what material they are made of, how the joints of the elements are sealed. The header of the act consists of this data.

Installation estimate for heat supply

This selection of components for the future heating system is one of the most important. In practice, problems begin at the stage of selecting the main components of the system - the boiler and radiators.

In an effort to save as much as possible, the cheapest models are purchased. However, their nominal characteristics do not correspond to the calculated ones. As a result, this leads to a significant decrease in system efficiency.

How to avoid such a situation? It is necessary to correctly calculate the costs of organizing heat supply. To do this, you will need an estimate for the installation of heating and the purchase of components. Its correct compilation is only possible if you follow these recommendations:

- Calculation of heating depending on the current parameters of the building (heat losses), type of energy carrier (gas, solid fuel, diesel, etc.). The required heating power for each room in the building is also calculated.

- Based on the data obtained, a list of equipment is compiled - heating boiler, radiators, safety group (air vent, expansion tank, thermostats) and pipelines. The type of the latter largely influences the heating installation estimate. Polymer lines can be installed independently, while steel lines are installed with the help of specialists.

- Market monitoring is carried out, as a result of which heat supply components that are optimal in cost and technical characteristics are selected.

- The cost estimates for the installation of the heating system are filled in: the cost of equipment, transportation costs and installation work.

Accepted samples of heating estimates may have different formats. The main thing is that it is convenient for the compiler to fill them out and subsequently use them as the main financial document for planning purchases.

When involving third parties (organizations) in the installation of heating, it is necessary to agree in advance on all items of the estimate in order to avoid further inconsistencies, both financially and technically.

Fire test reports

During testing for the performance and safe operation of fire equipment, several reports are drawn up:

- checking fire hydrants;

- diagnostics of internal water supply;

- checking for the safety of use and compliance with labor protection rules of fire escapes.

Fire hydrants

Testing the performance of hydrants for water loss is carried out twice a year and is often combined with checking the fire-fighting water supply system. Based on the results of the inspection, an act is drawn up and signed by the commission. Mandatory members: a representative of the fire inspection and a representative from the organization in which the inspection is taking place. Also, the commission may consist entirely of company employees.

The act states:

- general organizational information (information about the company, date and place of compilation);

- the main part describes the members of the commission and the progress of the test. Information about hydrants is presented in tabular form. The location address, diameter, pressure, water yield and affiliation of the hydrant are indicated;

- in the final part, compliance (or non-compliance) with the requirements of the hydrant condition is established.

At the end, the act is signed by authorized members of the commission.

Internal fire water supply

The act establishes the presence or absence of defects and malfunctions in the fire water supply system. The inspection is carried out by responsible employees of the enterprise. Frequency – at least twice a year; for flammable industries, inspections may be scheduled more often.

Internal fire water supply (IFP) is a complex system of pipes, sensors, and switches. Therefore, it is often checked by a labor protection or fire safety specialist, as well as by persons who are trained in fire safety.

The act is drawn up on letterhead or plain paper indicating the details. Be sure to register:

- information about the organization and participants of the inspection;

- information about the object being checked;

- inspection results;

- recommendations for eliminating defects and malfunctions, if any are found;

- signatures of responsible persons.

If additional documents are attached to the act, their list and name are indicated.

Fire escapes

Testing of firefighting equipment, including ladders and stepladders, is regulated by a special GOST. Inspections can be carried out by organizations that have received permission from the Ministry of Emergency Situations and have special equipment for this.

The test results are recorded in the test report. The documentation provides standard information about the organization and its details, information about the members of the commission. The main part provides information about the inspected objects (number of ladders and stepladders, their inventory numbers and affiliation with the structural unit), information about the results of inspections (absence or presence of defects). An instruction is given to eliminate the identified faults.

At the end, the act is signed by the members of the commission.

What is crimping

To carry out crimping, special equipment is required. Typically this is a pneumatic or hydraulic pump. The choice of equipment depends on how the tests will be carried out with water or air.

Checking the tightness of the system itself involves pumping water or air into the system under very high pressure. For cottages this is about 2 atmospheres; in apartment buildings this value is higher and depends on the operating pressure of the system. Typically, the critical pressure is 20–30% higher than the operating pressure.

If during the pressure testing process “weak” places are discovered, that is, places where the injected water or air escapes out, thereby indicating a violation of the tightness, then they must be replaced. This allows you to identify problems in a timely manner and eliminate them in a timely manner.

At the end of the procedure, a pressure test report for the heating system is drawn up.

Why and when to carry out hydraulic tests

Hydraulic testing is a type of non-destructive testing that is carried out to check the strength and tightness of pipeline systems. All operating equipment is subjected to it at different stages of operation.

In general, three cases can be identified in which tests must be carried out without fail:

regardless of the purpose of the pipeline:

- after completion of the production process for the production of equipment or parts of the pipeline system;

- after completion of pipeline installation work;

- during operation of the equipment.

Hydraulic testing is an important procedure that confirms or refutes the reliability of the operating pressure system. This is necessary to prevent accidents on highways and preserve the health of citizens.

The procedure for hydraulic testing of pipelines in extreme conditions is being carried out. The pressure under which it passes is called the test pressure. It exceeds the usual operating pressure by 1.25-1.5 times.

Features of hydraulic tests

Test pressure is supplied to the pipeline system smoothly and slowly, so as not to provoke water hammer and accidents. The pressure value is determined not by eye, but by a special formula, but in practice, as a rule, it is 25% more than the working pressure.

The water supply force is controlled on pressure gauges and measurement channels. According to SNiP, jumps in indicators are allowed, since it is possible to quickly measure the temperature of the liquid in a pipeline vessel. When filling it, be sure to monitor the accumulation of gas in different parts of the system.

This possibility should be excluded at the initial stage.

After filling the pipeline, the so-called holding time begins - a period during which the equipment under test is under increased pressure.

It is important to ensure that it is at the same level during exposure. After its completion, the pressure is minimized to operating condition.

Personnel operating it must wait in a safe place, as testing the system's functionality can be explosive. After the process is completed, the results obtained are assessed in accordance with SNiP. The pipeline is inspected for metal explosions and deformations.

How flushing and hydrotesting are carried out

Flushing heating systems is carried out in several ways:

- chemical - when chemical reagents, such as alkali, acid and anti-corrosion compounds, are added to the water to more effectively remove dirt and rust;

- hydropneumatic - when air and water under high pressure are supplied to the circuit using a compressor;

- hydraulic - regular washing with running water;

- through water hammer - this effect is achieved by connecting a special device that provides super-powerful water pressure.

Equipment for work

To clean the pipes, a pump with a hydropneumatic nozzle is required.

In-place flushing of engineering heating systems with chemical reagents is carried out using an eliminator with manual or automatic reverse. There are imported and Russian samples on the market, differing in pumping volume, type of reverse and other functions. The work is carried out using a washing reagent. Then the action of washing with the neutralizing solution is stopped. Electrical devices create excess pressure and force the chemical solution through.

For hydropneumatic cleaning, you need a pneumatic pump capable of reaching a pressure of up to 6 atm. and higher.

A hand pump is a cuvette with a plunger pump located on the side and a drive handle. Shut-off valves cut off water after heating is filled, others are used to drain the coolant from the device. The plunger pump raises the pressure to 60 bar. The disadvantage when used in private homes is that it takes many hours of work and requires a lot of muscular energy.

Professional washers use automatic devices. They set a pressure limit, upon reaching which the automation turns off the unit. Professional models maintain a pressure of 40-100 bar. Industrial pressure testing stations produce up to 1000 atmospheres.

The essence and types of crimping

Nowadays heating is most often carried out by a “water circuit” system. At the same time, heated water circulates through the works, imparting its thermal energy to the premises. Leaks are unacceptable; the pipeline must be completely sealed for normal operation. Pressure testing specifically creates a larger volume in the pipe than normal.

When this is done using air, it is called pneumatic pressing.

When using water, then hydropressing. The latter method is considered safer and therefore more popular. For this reason, an example of hydropressing is provided as a form.

When testing, it is recommended not to exceed the pressure inside the pipe more than 15 MPa. If we are talking about raising pressure with water, then there are limitations. The maximum possible pressure should not exceed the normal operating pressure by more than 30%.

In multi-storey buildings they resort to pneumatic pressure testing if the pipes are very old and there is a risk of flooding. But then there is a level of risk and all residents must be notified of the tests being carried out.

The work process is simple, but multi-stage. The algorithm looks like this:

- The necessary materials and equipment are being prepared.

- Draining the liquid that was previously in the heating system.

- Uploading a new one.

- Create the highest possible test pressure.

- Taking control measurements after 10 minutes.

- Flushing, adjusting the heating system to normal pressure levels inside.

- Documentation of work performed, generation of reports and acts.

But this is how the list of procedures looks only if there are no “thin spots” in the heating system and, accordingly, the tightness in it is not broken. If the pressure drops quickly and does not hold, then the system needs repair work. In such a situation, the specialist performs the necessary actions (replacing the pipe, sealing connections, cleaning, etc.), and then begins crimping from the very beginning. Only a heating system that has passed the test is allowed into the heating season.

Important nuance! Pressure testing should be carried out after cleaning and flushing the pipes. Otherwise, salt and other deposits inside them can mask possible external damage and breakthroughs.

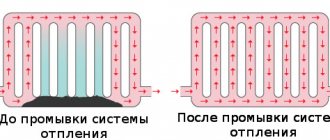

If there are deposits of about 1 cm on the inner surface, then this reduces the overall heat transfer and efficiency by 15 percent or more of the overall indicators. To document the cleaning, a special report is also drawn up.

Hydraulic test parameters

When checking the quality of a pipeline, it is necessary to determine the indicators of the following work parameters:

- Pressure.

- Temperatures.

- Holding time.

The lower limit of the test pressure is calculated using the following formula: Ph = KhP

. The upper limit should not exceed the sum of the total membrane and bending stresses, which will reach 1.7 Th. The formula is deciphered as follows:

- P – design pressure, the parameters of which are provided by the manufacturer, or operating pressure if tests are carried out after installation;

- Th – rated voltage that is allowed at test temperature Th;

- T – permissible stress at design temperature T;

- Kh is a conditional coefficient that takes different values for different objects. When checking pipelines, it is equal to 1.25.

The water temperature should not fall below 5˚C and not rise above 40˚C. The only exceptions are those cases when the temperature of the hydraulic component is indicated in the technical conditions of the object under study. Be that as it may, the air temperature during the test should not fall below the same 5˚C.

The holding time must be specified in the design documentation for the facility. It should not be less than 5 minutes. If exact parameters are not provided, then the holding time is calculated based on the thickness of the pipeline walls. For example, with a thickness of up to 50 mm, a pressure test lasts at least 10 minutes, with a thickness over 100 mm - at least 30 minutes.

Testing of fire hydrants and water supply lines

A hydrant is equipment responsible for quickly eliminating fire ignitions, so it must always be in working condition. The main task of fire hydrants is to provide the optimal amount of water to fight a fire at its initial stage.

How to properly fill out a heating system flushing report

- How is joint work with a contractor organized?

- The procedure for drawing up a report for cleaning the system

- Conclusion

If, due to various circumstances, you have decided to hire a specialized company to clean the heating system of a private house or the risers of your entrance, then you will need to draw up a number of documents in accordance with the law. The completion of the work must be completed by a correctly drawn up heating system flushing report. From our article you will learn useful information about all these formalities.

How is joint work with a contractor organized?

In addition to the final act, indicating high-quality work performed, you will need to draw up and sign a number of other documents together with the contractor. All papers drawn up in accordance with the law will give you the opportunity to make claims to the contractor in the event of poor-quality washing or in the event of material damage in the form of damage to system elements. This will also allow you to defend your rights in court.

Let’s imagine the sequence of actions of the contractor, in which you will also take part:

initial visual inspection by representatives of the organization;

- choosing a washing method and agreeing it with you;

- submit for review and signing an estimate that reflects the types of work and materials used, as well as the contract price;

- enter into a contract;

- then the heating system of the residential building itself is flushed;

- acts are drawn up for hidden work (if any);

- testing (pressure testing) of the pipeline network is carried out, which is confirmed by the relevant document;

- a report of the washing performed is drawn up, which you must endorse if there are no complaints against the contractor.

Note. The official document indicating hidden work must be accompanied by photographic evidence of the fact that these operations were performed.

Home > Document

| Document information |

| Date added: |

| Size: |

| Available download formats: |

Acting Director of AF JSC TPP A.M. Kamshekin

ON HYDROPNEUMATIC FLUSHING OF CENTRAL HEATING SYSTEMS OF BUILDINGS FOR ALL PURPOSE

Flushing the system is necessary after repairs, installation, and also after the end of the heating season to remove sludge and dirt.

The most effective is the hydropneumatic method of flushing - bubbling water with compressed air to create a violent movement of the environment in the system.

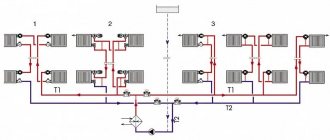

To eliminate the possibility of contamination of an already washed area, washing is carried out in the following sequence.

To flush heating systems, the following fittings must be installed at the inlet (see Appendix 1):

for connecting the compressed air pipeline from the compressor DN 32mm (18),

for connecting a cold water pipeline DN 50mm (19),

for drainage of drained water DN 50mm (20).

To ensure the possibility of removing large contaminants from pipes, the diameter of the drain pipes should be taken from the following ratios:

If there is a drainage device in the chamber, flushing water is discharged directly into the drain, and if there is no drainage, into the nearest storm drain or into the chamber, from where it is pumped out.

Legislative regulation on heat supply cleaning

Flushing and pressure testing of heating systems is regulated by regulations and is included in the register of mandatory operations for the operation of heating structures. The regulation is enshrined in current legal acts on the filing of appeals and complaints in the event of failure of management organizations to fulfill their duties.

Decree of the Russian Government No. 354

Decree number 354 specifies the annual cleaning of home heating circuits in the form of flushing. The procedure is also carried out after the installation of communications, major repairs and routine repairs, expressed by the replacement of pipelines.

In the case of an open system, disinfection is carried out. The purpose of the treatment is to remove dirt, silt, scale and lime deposits from the inner walls of the pipes.

The operation is performed using the following available methods:

- hydraulic;

- hydropneumatic;

- chemical

Membranes and nozzles of hydraulic elevators are removed during this period. Recuperators and regenerators are cleaned mechanically or chemically. It is prohibited to use media supply lines that have not been cleaned and disinfected. After the operation, the structure is filled with water.

Decree of the State Construction Committee No. 170

Resolution of the Russian Federal Construction Authority No. 170 (current version 2022) covers issues of proper operation of the heating structure. The regulations indicate a summer inspection of shut-off valves, flushing of building blocks, and elimination of permanent and temporary blockages.

If the apartment batteries do not warm up, they undergo a hydropneumatic procedure. Section V reminds us of the annual processing of the thermal configuration after the end of the heating period, and in case of replacement of elements of open circuits, they are disinfected.

The communications are flushed with a volume of cold water that exceeds the required consumption of the hot resource at least 3-5 times, until it is completely clarified.

However, employees of management structures often carry out processing, justifying their behavior by the fact that the decree of the Federal Agency is intradepartmental and cannot be implemented. Although Art. number 2.6 talks about the preparation of housing stock for winter by its owner and local government institutions.

Watch the video: “Flushing heating systems using the hydro-pneumatic ram method.”

Decree No. 290 on flushing and cleaning heating

Order No. 290 of the Russian government provides a list of services and work that must be performed to maintain the serviceability of residential multi-story buildings.

The second chapter indicates that work is being carried out to preserve heat consumption:

- hydraulic tests of communications stability;

- flushing heating radiators, adjusting heat supply units with preliminary commissioning of furnaces;

- releasing air pockets from the structure;

- washing of networks to wash away scale-corrosion deposits;

- processing of heat exchange devices.

The Resolution does not give a clear indication of the frequency of their conduct, but makes a footnote to the order of the State Construction Committee. Timing procedures must adhere to the legislation of the country, but flushing can be carried out by decision of a meeting of apartment owners.

GOST P 56501-2015

7 facts about heating radiators.

State standard number P56501-2015 (with amendments and additions in 2022) also stipulates the conditions for processing networks. His article No. 5 talks about organizing seasonal training. Shortly before the end of the coolant supply, the contractor draws up and coordinates his actions with heating or another resource-supplying structure a plan for carrying out restoration measures - flushing, pressure testing, preservation of communications.

The contractor fulfills the conditions according to the agreed schedule, after which the acts are drawn up. The first is a legal entity that provides economic services to a multi-storey building. Before the end of winter, the housing office must draw up a list of preventative and repair work, including cleaning heat consumption units. It is carried out after stopping the supply of coolant or blocks or elements that have passed diagnostics.

Flushing the heating systems of an apartment building is carried out using the methods specified in the operating regulations. The liquid pressure used in the structures is no more than the working one, and the air pressure is no more than 0.60 MPa. The water supply speed rises above the calculated rate by half a meter per second or more. After complete clarification of the washing liquid at the outlet of the unit, the cleaning is completed. GOST P 56501-2015 prohibits leaving the circuit empty.

Construction norms SNiP 3.05.03-85 (new edition 2022) also prescribe systematic treatment of heat consumption circuits.

Referring to the listed government acts, apartment owners have the right to demand that housing companies periodically flush communications.

Stages of testing

Activities consist of preparation, direct testing and analysis of indicators obtained as a result of tests.

- The first stage is preparation. During this period, the initial data on the network is clarified and recorded, after which the measurement program is developed and agreed upon. At this stage, preparatory actions are also underway to create testing conditions. This includes: Before starting the process, you need to check whether all work on welding, installation, installation of gaskets in connections, and tightening of these connections has been completed.

- You also need to check whether all the equipment is in order, the presence and functionality of the air drain valves.

- Connecting the hydraulic press to the water supply and to the pressure pipe pipeline. Checking the correct connections.

- Disconnecting the pipeline section where the test will be carried out from equipment that has not yet been fully installed or is already in use.

- Installation of necessary instruments for testing.

The second stage is to conduct a test under appropriate conditions. Tests must be carried out in compliance with all requirements regarding ambient temperature conditions. In case of violation, this may lead to inaccuracy of the received data. The necessary conditions:

- The ambient temperature during events must be above zero.

- The temperature of the water used in the test should be from +5 to +40.

- Providing observation platforms for above-ground heating systems.

- Smooth increase in pressure. It should be approximately 40% higher than nominal. To increase it, the use of compressed air is prohibited.

- The test section of the pipeline must be maintained under test pressure for at least 15 minutes.

- Upon completion, the entire site must be carefully inspected and if defects are found, the measures necessary to eliminate them must be taken.

And the last stage is to analyze the results obtained and compile a table indicating all the parameters. If deviations from the norm are detected, measures are taken to eliminate them, such as:

- Cleaning and flushing of the pipeline.

- Pipeline relocation.

- In case of serious problems, repairs and elimination of detected defects are carried out.

Upon completion of measures to eliminate the causes of deviations, the tests must be carried out again.