A gas boiler is a reliable heating device, and it can be installed not only in private homes.

There are models that are quite suitable for city apartments. What criteria should you pay attention to when choosing a boiler? First of all, on the number of circuits.

Single-circuit devices are used only for heating rooms.

Double-circuit ones also provide residents with hot water, although they are more expensive. The area of the heated room, the thermal power of the device and the method of installation of the heating device are also taken into account.

Those who are planning to purchase a single-circuit boiler will find our rating useful.

It includes devices that users and experts called the best in 2022 in terms of price/quality ratio. Also, when selecting models, official test data from Rostest were taken into account.

Rating of the TOP 20 best single-circuit gas boilers of 2022

| Place | Name | Price |

| TOP 3 best single-circuit gas boilers in price/quality ratio for 2022 | ||

| 1 | Protherm Panther 25 KTO (2015) 25 kW | Find out the price |

| 2 | BAXI ECO Four 1.24 F 24 kW | Find out the price |

| 3 | Lemax Premium-30N 30 kW | Find out the price |

| TOP 3 best wall-mounted single-circuit gas boilers | ||

| 1 | Vaillant turboTEC plus VU 242/5-5 24 kW | Find out the price |

| 2 | BAXI LUNA-3 COMFORT 1.240 Fi 25 kW | Find out the price |

| 3 | Bosch Gaz 6000 W WBN 6000-18 H 18 kW | Find out the price |

| TOP 3 best floor-standing single-circuit gas boilers | ||

| 1 | Lemax Premium-25 25 kW | Find out the price |

| 2 | Lemax Leader-35 35 kW | Find out the price |

| 3 | Lemax Leader-16 16 kW | Find out the price |

| TOP 3 best single-circuit gas boilers with indirect heating boiler | ||

| 1 | BAXI ECO Four 1.24 24 kW | Find out the price |

| 2 | Buderus Logamax U072-24 24 kW | Find out the price |

| 3 | BAXI SLIM 1.400 iN (without smoke hood) 40 kW | Find out the price |

| TOP 2 best condensing single-circuit gas boilers | ||

| 1 | Protherm Lynx condensing 30 MKO 30 kW | Find out the price |

| 2 | Buderus Logamax plus GB172-35 i 34.9 kW | Find out the price |

| TOP 2 best single-circuit gas boilers for 24 kW | ||

| 1 | Vaillant atmoTEC plus VU 240/5-5 24 kW | Find out the price |

| 2 | BAXI ECO Four 1.24 24 kW | Find out the price |

| TOP 2 best single-circuit parapet gas boilers | ||

| 1 | Lemax Patriot-20 20 kW | Find out the price |

| 2 | Lemax Patriot-16 16 kW | Find out the price |

| TOP 2 best closed-type single-circuit gas boilers | ||

| 1 | Vaillant turboTEC plus VU 282/5-5 28.9 kW | Find out the price |

| 2 | BAXI ECO Four 1.14 F 14 kW | Find out the price |

Most popular manufacturers

European companies are leaders in the manufacture of single-circuit boilers.

These include:

- Viessmann . A German company known for the high quality and durability of its products;

- Vaillant. Also a German company, well known to Russian users. Produces several series of boilers adapted to difficult Russian operating conditions;

- Baxi. One of the leaders of Italian heating engineering;

- Ariston. Another representative of the Italian industry. Famous for quality and affordable prices;

- Bosch. A transnational German concern that produces a huge number of technical devices, including single-circuit gas boilers;

- Protherm. Slovak company offering a wide selection of high-quality gas boilers;

- Navien. This is a company from South Korea. It is famous for its high quality and affordable prices for all boiler models.

The above list cannot be considered complete. These manufacturers are only the most well-known on the Russian market.

How to choose a single-circuit gas boiler?

Choosing a single-circuit boiler is quite easy if you know the basic selection parameters.

If the user has clearly decided to buy a single-circuit device, all that remains is to decide on the dimensions of the boiler and the type of installation.

If you need to heat a large room, you usually buy a floor-standing model. For small homes, a compact wall-mounted unit will suffice.

You should also pay attention to the type of combustion chamber.

Boilers with an open combustion chamber are cheaper, but they are more difficult to install, since you will have to make a hole in the wall next to the device to install a chimney.

Boilers with closed combustion chambers are more convenient, and they can be installed even in apartments of multi-storey buildings.

Specifications

When choosing a model of the system in question, the technical characteristics must correspond to the level of expected comfort and the amount of heat and hot water used. Since they will vary greatly depending on the area of the room and the activity of using the system. Because some owners visit private houses only for a short period of time, while others live in them permanently.

The number of people living and the presence of pets also greatly influences. Because, in any case, the more people live, the more hot water is used. Therefore, when choosing a model, it is necessary to take into account all the characteristics of the heated object in order to choose the best option.

TOP 3 best single-circuit gas boilers with indirect heating boiler

Single-circuit gas boilers with indirect heating boilers are universal devices that can not only heat a room, but also provide residents with hot water.

BAXI ECO Four 1.24 24 kW

The wall-mounted gas boiler is designed for installation in domestic and industrial premises with an area of up to 240 square meters .

An indirect heating boiler can be connected to the device, so this model is suitable not only for heating, but also for organizing hot water supply.

The design of the device involves connection to a main pipeline with natural gas, but, if necessary, it can be converted to liquefied gas, but for this the user will have to separately purchase a set of nozzles.

The device has two heat exchangers: a primary one made of copper and a secondary one made of stainless steel. Both materials are resistant to corrosion and ensure stable temperature maintenance at the user-specified level.

The device is also equipped with all the necessary functions for safe operation: protection against overheating and freezing, gas control and automatic fault diagnosis.

Specifications:

- weight 30 kg;

- height 730 mm;

- expansion tank volume 6 l.

pros

intuitive electronic control panel;

can operate on different types of fuel (natural and liquefied gas);

affordable cost;

works relatively quietly;

Compact dimensions make installation easy.

Minuses

The kit does not include jets for liquefied gas;

Many users complain of a loud knocking noise when igniting.

Buderus Logamax U072-24 24 kW

A reliable and functional gas boiler is designed for wall mounting .

The design of the device is specially adapted for operation in the Russian climate. The boiler itself perfectly withstands unstable pressure in the gas main and voltage fluctuations in the electrical network, while simultaneously providing stable heating of the room.

Additionally, the device has a simple and intuitive control system using an electronic panel with a display . With its help, the user can configure basic performance indicators by pressing a few buttons.

Another advantage of the device is that when an independent boiler is connected, the boiler can also be used for hot water supply, and its power is sufficient for high-quality heating of rooms up to 250 square meters.

The heat exchanger is made of copper, is resistant to corrosion and heats up well.

The combustion chamber is a closed type, so this model is suitable not only for private houses, but also for apartments in high-rise buildings.

Specifications:

- weight 30 kg;

- height 700 mm;

- expansion tank volume 6 l.

pros

completely safe to use due to gas control and a reliable safety valve;

there is protection against overheating and freezing;

adequate cost;

stylish attractive design;

excellent build quality.

Minuses

if the boiler fails, repairs will be expensive;

imperfect firmware causes failures in electronic control.

BAXI SLIM 1.400 iN (without smoke hood) 40 kW

A distinctive feature of this boiler is that, despite the floor installation, it has very compact dimensions .

Thanks to this, the device is perfect for heating large residential and industrial premises, but does not take up much space.

The device has a reliable and wear-resistant cast iron heat exchanger.

The combustion chamber is open type, so the device can only be used in private homes. Since this type of combustion chamber involves connection to a chimney, installation of the device should only be carried out by a specialist.

In terms of control, users have no complaints about the boiler.

At the top of the case (front) there is a convenient electronic panel.

It is covered with a translucent lid, and several buttons and two rotary controls allow you to quickly set the necessary heating parameters. Installing the boiler involves installing a smoke hood, but it is not included in the kit, so the user will have to buy it separately.

Specifications:

- weight 150 kg;

- height 850 mm;

- maximum thermal power 40 kW.

pros

durable and high-quality cast iron heat exchanger;

convenient electronic control panel with display;

high thermal power allows the device to be used for heating large rooms;

can operate on different types of gas (natural and liquefied);

There is automatic fault diagnosis.

Minuses

no built-in expansion tank;

impressive weight.

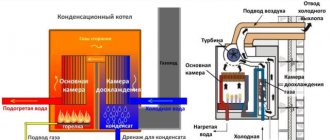

Principle of operation

Gas single-circuit boilers with an indirect boiler operate according to two main connection schemes. The principle of operation of the first is as follows:

- The three-way valve dominates here. A pump is installed directly into the outlet of the gas boiler, which provides circulation and creates pressure. The next step is to install a three-way valve, which is connected to the boiler thermostat. When heating tap water or other coolant, its flow is directed to the heating system, with priority for the hot fluid entering the boiler coil. This happens with the help of an additional, second pump. And it turns out that in this case the hot water supply and the heating system are connected in parallel, and they can form two circuits, precisely in this closed chain. And after the boiler, an additional pump is installed, which helps regulate the operation of the thermostat. The principle of starting and stopping the process is also regulated by a thermostat, namely, when the heating is strong, the fuel supply is forced to shut off, when the coolant cools down, the fuel is passed through again, and the burner is automatically ignited.

- If there is no double circuit and priority is not given to heating hot water, the boiler is mounted in a common system, installed in a convenient location, and water is heated along with all radiators.

You might be interested >> How to properly clean a heat exchanger from scale

Which company should you choose?

Since a gas boiler is an expensive device that is purchased for a long time, it is better to give preference to appliances from well-known brands.

Companies that specialize in the production of heating equipment provide a guarantee for their devices, and use high-quality materials and modern technologies for their manufacture. In 2022, as an analysis of user reviews showed, boilers from Protherm, Vaillant, Lemax, Baxi and Bosch were recognized as the best. It is these devices that are included in this rating.

Installation features

Installation of wall-mounted boilers is carried out in a certain sequence. Installation is carried out on a solid, ideally load-bearing (outer) wall. This is an important point, since models with a closed burner use a coaxial chimney (pipe-in-pipe design) that is vented outside.

As a rule, the delivery set includes a special template according to which the wall is marked. Mark the attachment points and the center of the hole for the chimney.

The hole is made with a diamond crown using special guides that feed the cutting tool onto the wall. While drilling, it is recommended to water the crown, otherwise there will be a huge amount of dust and it will become impossible to work.

After making the hole, the chimney is led into it. It is a double pipe. Air is supplied through the outer one, and smoke is exhausted through the inner one. All gaps are sealed with insulating material and the installation of the boiler itself begins.

The unit is fixed with special fasteners included in the delivery set. Connect the gas supply pipe, water make-up pipe, forward and return lines of the heating circuit. All connections must be made carefully and carefully so as not to mix up any pipelines.

The last step will be to connect the boiler to the power supply, fill it with water, supply gas and test switch it on. All detected deficiencies are immediately eliminated.

Expert opinion

Torsunov Pavel Maksimovich

Installation, configuration and first start-up must be performed by service center employees. This is a condition of the warranty agreement. If installation and connection are performed independently, the warranty agreement may be considered terminated. In addition, independent connection of gas equipment is prohibited by current rules, so it is necessary to invite specialists.

Wall-mounted or floor-standing unit?

Single-circuit models are divided into two types:

- floor

- wall-mounted

Wall-mounted options are always compact, small in size and extremely convenient in location. Due to their small dimensions, they are easy to install on the wall - the main thing is that it is strong and load-bearing. And since such a boiler is located on the wall, it significantly saves useful living space. Moreover, it does not require the installation of a foundation or any additional devices, which are often required for the second type - floor-standing units. The power spectrum of wall-mounted options usually reaches a maximum of 35 kilowatts, which is optimal for heating houses and other spaces with a total area of about 300 square meters.

Floor-standing options are always large in size and take up a lot of space. It is strongly recommended to allocate a special room for such units - a mini boiler room. This could be a basement, or a utility room, such as a cellar, closet or pantry. The difficulty in this matter is the piping - when choosing a separate room, you should take into account the possibility of connecting all the required elements of the heating system to it.

At the same time, due to their large weight, such boilers require either the preparation of a special foundation that would take the weight of the apparatus, or a very strong floor and ceiling. It is important to take into account the weight of the unit and relate it to the strength capabilities of the floor and ceilings. Despite the described inconveniences, floor-standing gas units are also in demand, since their power can exceed 35 kilowatts and heat residential buildings with an area of 300 square meters or more.

What to drown with

Gas boiler systems are classified according to the type of fuel used. Yes, gas may vary, and not every gas is suitable for use with a particular model. The vast majority of boiler units operate on natural, ordinary gas, which is supplied through gas pipelines - mains. Despite the almost ubiquitous distribution of gas in Russia, not all regions or places in the country are gasified and have similar pipelines for supplying fuel to home heat-generating equipment.

In cases where there is no public gas main near a country house, you can choose a single-circuit water-heating boiler model, which is designed for operation on liquefied gas - that is, with a conventional gas cylinder.

Today, modern manufacturers already offer universal models that can operate effectively on both natural and liquefied gas fuels. Changing the types of fuel for operation is carried out by replacing the burner of one type with another.

Electrical connection diagram

The combined version of the tank, equipped with a heating element, must be connected to the house electrical network, taking into account the transition to summer mode, in which the main coil will no longer receive heat from the boiler. We suggest using a universal circuit that includes a pump control module via a thermostat.

The colors of the wires shown in the figure correspond to the generally accepted classification: blue - neutral, brown - phase, yellow-green - ground, and so on

The circuit involves a second safety thermostat, which is activated when the sanitary water overheats. The indicator lamp signals that the heating element is turned on.

Differences between devices according to ignition method

According to the method of ignition of gas fuel, single-circuit types of boiler units are divided into:

- electro addicts

- piezo electric

Boiler devices, which are electrically dependent, “produce” a spark to ignite gas fuel using electrodes. The spark created between these electrodes provokes the burner to turn on. This ignition method is considered the safest. Devices of the second type are equipped with a piezoelectric element, which acts as an igniter for igniting the burner.

Device

With any type of external heat energy source, the boiler operates the same way, with rare exceptions. And even private innovations of individual companies, protected by patent law, do not change the essence of a long-established scheme. A portion of the heat carrier received from any source flows through a coil built into the storage tank. Circulation is maintained by a pump. Upon close contact with the tubes or reservoir, where the initially colder water is located, it heats up.

Since even one joule of heat, needlessly radiated outward, has an extremely negative effect on the operation of the system, it must be equipped with thermal protection. Polyurethane or polystyrene is usually chosen as a heat-impermeable material. The supply of new doses of cold water naturally occurs from the general water supply system. Each new portion passes through specially designed pipes. As soon as the movement cycle in the coil is completed, the coolant enters the heating system of the house - a very special pipe is provided for this.

Then certain differences begin: although most boilers are designed to supply cold water through the bottom, there are also those in which it enters through the top. In such a design, the liquid must first pass completely through the system to the lowest point. There are noticeably fewer variations in the output of the heated coolant; in almost 100% of cases it is discharged from above. It is difficult to find a reason why one should do otherwise. After all, the upper location allows you to supply hot water for as long as possible, as long as there is at least a small portion of it in the container.

In order for the coil to occupy as much space as possible within the housing, it is usually made in the shape of a spiral. When the coolant passes several cycles through this pipe, the temperature becomes equal to the heating of the liquid in the boiler itself. At the command of a special relay, the special circuit that powers the pump stops. When the coolant subsequently cools to the set value, the relay gives another command - close the circuit - and heating resumes. The advantages of such a device are quite well known. All these points must be taken into account before work begins.