Protherm skat error codes

| Code | Meaning | Elimination |

| F.00 | Temperature Sensor (NTC) Error |

|

| F.10 | ||

| F.13 | ||

| F.19 | ||

| F.20 | Safety shutdown: safety temperature limiter |

If the boiler turns on again, replace the safety temperature limiter.

|

| F.22 | Dry start |

|

| F.41 | Stuck relay (HDO) |

|

| F.55 | Contactor or relay stuck |

|

| F.63 | EEPROM communication failure | – Reset the product to factory settings (D.096). |

| F.73 | The water pressure sensor signal is out of the correct range (too low) |

Replace the faulty wire to the water pressure sensor.

|

| F.74 | ||

| F.85 | The water in the storage tank is frozen | When the temperature at the NTC sensor drops below 3°C and there are no pressure surges, the boiler automatically switches off. When the temperature rises above 4 °C, the boiler automatically turns on again. |

| F.86 | External water heater frozen | If the temperature in the external water heater drops below 3°C, the boiler will automatically turn off. When the temperature rises above 4°C, the boiler automatically turns on again. Note If the external water heater is not activated, the error is not displayed. |

F.10 — Short circuit of the NTC sensor at the OB output

- — a malfunction is indicated in the event of a short circuit of the NTC sensor installed at the OB output

- — the message will be automatically deleted after reconnecting the NTC sensor

- — a short circuit of the NTC sensor is detected if the voltage in its circuit is below 0.45 V

- The sensor in this case shows a deliberately incorrect value compared to that indicated in the table

RECOMMENDATIONS

- Check sensor connections

- Check sensor cables

- Check sensor resistance (replace if necessary)

Causes of breakdowns

The causes of breakdowns can be established even before the boiler starts operating. These are: errors in the design and calculations for the selection of additional devices (not included in the boiler configuration), switching elements, determination of the type and cross-section of the required installation wires.

The causes of breakdowns in the future may be:

- Poor quality, incorrect installation and connection of the device with deviations from installation requirements.

- Violation of the basic rules for using the equipment specified in the instructions.

- Failure to comply with the requirements for carrying out routine, preventive and periodic work and inspections.

- The presence of a manufacturing defect, which is discovered both during the warranty period and after its completion.

- All components and assemblies have a certain service life, and the reason for their failure is natural wear and tear.

- In heating element boilers, the heating elements themselves may fail due to low water quality and the formation of salts and scale on their surface.

- Failure of most components and assemblies due to large voltage surges exceeding all permissible standards. These tolerances are specified in the operational documentation.

For ion boilers, water compliance with the required standards is of great importance.

F.13 - Short circuit of NTC sensor of external DHW storage tank

— the fault is initiated on the boiler display in the event of a short circuit in the NTC sensor of the external DHW storage tank

— the message will be automatically deleted after reconnecting the NTC sensor

— a short circuit of the NTC sensor is detected if the voltage in its circuit is below 0.45 V

RECOMMENDATIONS

- Check sensor connections

- Check sensor cables

- Check sensor resistance (replace if necessary)

Prevention and recommendations for use

Compliance with operating rules, together with the implementation of timely preventive measures, extends the period of trouble-free operation of the unit. It is preferable to carry out preventive maintenance during the lowest load of the boiler, in the summer.

During the current heating season, it is advisable to pay attention to problems and deviations that arise during operation. In the warm season, it is recommended to replace all unstable elements and troubleshoot problems. Then carry out a preliminary launch and check the functionality of the boiler equipment and systems.

F.19 - Short circuit of outside temperature sensor

— a malfunction is indicated in the event of a short circuit of the outside temperature sensor

— the message will be automatically deleted after reconnecting the NTC sensor

— a short circuit of the NTC sensor is detected if the voltage in its circuit drops below 0.45 V

— the error is not indicated if the equithermal control function is inactive (E-)

— in this case, the boiler continues to operate in normal heating mode (without equithermal regulation)

RECOMMENDATIONS

- Check sensor connections

- Check sensor cables

- Check circuit voltage

- Check sensor resistance (replace if necessary)

How to run self-diagnosis

The self-diagnosis system operates in constant mode. The start-up occurs simultaneously with the start of the boiler, and the system can only be stopped when the unit is stopped. Therefore, no special actions are required to enable self-diagnosis .

There is no need for special contact with the system; if a problem occurs, it will immediately report it, and if no notifications are received, it means that the boiler is operating normally and no problem points have been detected.

Error f20 on the Proterm Skat boiler

— a malfunction is indicated if the emergency thermostat is activated as a result of boiler overheating

— the message will be automatically deleted after manually resetting the emergency thermostat

This emergency thermostat should be installed on the copper pipe.

This thermostat is installed in older versions of the boiler; boilers built after 2012 do not have this thermostat.

There is a thermostat on the heat exchanger

- remove the protective rubber shell from it

-in the middle you will see a small red button, press it and assemble everything in reverse order. But find the cause of overheating.

Not only press, but also identify the cause of overheating, why it happened. !!!

Lack of circulation, check the pump and air in the system. , there may be air in the heat exchanger, etc.. To check the pump, unscrew the plug to bleed the air (you can look at it visually or touch it with a screwdriver). The pump is from Wilo. If it is broken and does not rotate, replace it. To make it more economical, you can buy one head rather than the entire pump assembly

Overheating doesn't just happen.

RECOMMENDATIONS

- air in the boiler heat exchanger

- Check the heating pump (no flow through the device)

- Check the overheat thermostat

Decoding

Overheating is the factory interpretation of error f20 in the instructions for the Proterm Skat boiler. It is generated by electronics based on a signal from the emergency thermostat after operation (activation). The code is deleted without user intervention by returning the sensor to its original state (done manually). The main questions that arise from error f20 are: where is the thermostat located, how to reset it (the Reset button on the panel of the Proterm electric boiler is missing) and why the fault code appears again. Let's look at it in order.

Where is the sensor installed?

It is located above the heat exchanger of the electric Proterm, on the outlet pipe. When the temperature in the circuit reaches a value higher than the permissible value, the contacts close, an alarm signal is sent to the board, and error f20 is generated. If it happens while the Proterm boiler is running, wait until it cools down.

Heat sensor in the boiler Protherm slope

For safety reasons, disconnect the unit from the mains before performing work!

How to reset the thermostat

Protherm electric boilers do not have a self-return sensor: it is controlled manually. To solve the problem, press the button. If the causes of Proterm overheating are eliminated, error f20 will clear after starting the boiler.

Boiler thermostat Protherm slope

Advice

In Protherms released after 2012, the thermostat is installed in a hidden way, so users cannot find it. To gain access, remove the rubber cap covering the sensor. Just be careful not to let the thermal paste come out. Its deficiency reduces the sensitivity of the device, which causes incorrect operation.

What causes overheating

Error f20 is the result of insufficient coolant circulation or blocking of the heating circuit. This causes a sharp increase in temperature, triggering the emergency sensor of the Proterm boiler.

Air

It accumulates constantly even in a sealed circuit. Gas formation is a natural process in a liquid system, and the higher the temperature, the more active it occurs. The accumulation of bubbles prevents the movement of water, the speed slows down, the “plug” stops circulation, although the heating elements operate in accordance with the design power. Delete, and error f20 will not appear.

- The Proterm heat exchanger often causes code f20. The manufacturer recommends bleeding air from it after installing the boiler, although this should be done periodically. For this purpose, a valve is provided with a connected tube through which gases and liquid are diverted beyond the perimeter of the electric boiler installation into a substitute container for safety reasons.

Boiler heat exchanger Protherm slope

- Pump. An automatic valve is installed at the top of the pump. Unscrew the cap, bleed it, error f20 will go away.

Valve in an electric boiler protherm slope

Advice

Before starting the Proterm boiler after a long period of inactivity, it is recommended to manually rotate the pump shaft. This eliminates the sticking of pairs of seals, and the pump will not operate at low speeds, which leads to overheating, error f20.

- Walk through the facility: vent everywhere where provided. Including automatic valves for heating radiators, which often fail during operation in systems due to water hardness and coolant contamination.

Circulation pump failures

Incorrect operation, stopping affects the fluid flow rate, causing overheating and error f20 Proterm.

Typical problems

- No tension

. Check the integrity of power and control circuits and the reliability of contacts. Breaks cause the pump to stop, melting of the insulation - regular short circuits and malfunctions. - Pollution

. When using unprepared coolant in the heating circuit, the inside of the pump becomes clogged with tiny fractions. They are also deposited on parts: impeller, shaft. Perform partial disassembly, remove the rotor, clean it, error f20 will not appear. - Interturn closure

. The Proterm boiler pump does not reach its design capacity, circulation drops, and overheating occurs. The solution to the problem with error f20 is to replace the pump. The services of a professional are not needed - it is performed by the user. - Capacitor.

Installed on the pump housing, under the terminal box cover. Loss of capacity prevents the pump from entering mode when starting the Proterm boiler; error f20 appears. Measure “C”, if there is a discrepancy, replace it (the value is indicated on the body).

Advice

. There are other reasons for pump malfunctions: bearing destruction, blocking of the internal air removal channel, shaft curvature, impeller deformation and a number of others. It is not advisable to revive - given the low cost, buy and install a known-good pumping device.

Check additionally

- Circuit breakers

. There are two of them on the board. Professionals and users note: error f20 appears when the lower Pr (80 mA) burns out. - Coolant properties

. Applies to cases of filling the circuit with antifreeze liquid. Not all antifreezes are suitable for use in heating systems - check the characteristics. Failure to meet the manufacturer's requirements leads to overheating and error f20. - Settings options

. If there is insufficient circulation, service technicians recommend going to the Protherm boiler menu and selecting parameter d. 19, set the value = 0. The pump will switch to increased speed: if there are miscalculations in the design of the circuit, or the wrong choice of boiler, Proterm by power allows you to get rid of error f20.

Control module.

The electronics of imported equipment reacts to any violation of the electrical network parameters. In case of improper grounding, connection of the boiler, voltage instability, after a thunderstorm, loose contact, board failures are inevitable, hence the Proterm errors. Do not perform diagnostics yourself - contact a service organization. The following defects are visually detected: condensation on the board (dry), breakage of conductive paths, melting or destruction of component housings, burnt areas, dust or dirt (remove). A specific malfunction in the circuit is diagnosed on a stand simulating a Proterm electric boiler. The board changes during testing, so when calling the technician, indicate its designation (symbols of numbers and letters on the panel).

Melting of the machine

F.22 - Loss of water - insufficient water pressure in the heating system

— a malfunction is indicated if the water pressure in the heating system drops below 0.6 bar

— the message will be automatically deleted after the heating water pressure in the system increases above 0.6 bar

– as a result of adding water to the heating system

- an error message will not appear if the pressure sensor is faulty

The pressure sensor is used to determine the water pressure in the boiler (heating system). If there is a lack of heating agent in the boiler, the pressure sensor will transmit information to the boiler control board, which will give a command to stop it.

Operating principle

As the water pressure increases, the volume of the membrane carrying the magnet will increase. Opposite the magnet there is a Gall sensor, which changes the incoming voltage on the boiler control board depending on changes in the magnetic field parameters. The change in magnetic field parameters depends on the change in the distance of the Gall sensor relative to the position of the magnet. Measuring points

Pressure sensor input voltage:

Measuring points 1 and 2 = 5 V DC Reference values: Measuring points 1 and 3 At a pressure of 1 bar / 1.7 V DC At a pressure of 1.5 bar / 2 V DC At a pressure of 2 bar / 2.3 V DC

RECOMMENDATIONS

- Water pressure too low 0.3 Bar. When filling the boiler with water, in this case it is not necessary to press the RESET button.

- Water pressure sensor malfunction. Replace.

- Check for leaks in the boiler and heating system.

- Check the serviceability of the pump. The pump may be blocked. disassemble it and check for proper operation and cleanliness.

Warranty and warranty conditions Transportation and storage of T...

Page 19

- Image

- Text

19

Warranty and warranty conditions

Transportation and storage

It is recommended to transport and store the boiler in its original factory packaging - it is necessary to limit force on the packaging, avoid impacts and, except for the moment of unpacking, do not place the boiler in a position in which it could fall out of the packaging. The boiler must be stored under appropriate standard conditions (non-aggressive and dust-free environment, temperature difference from 5 to 50 °C, air humidity up to 75%, limitation of biological influence, shock and vibration).

The warranty for an electric boiler manufactured by PROTHERM SKAT is provided if the Product Data Sheet is available and other conditions specified in the Operation Manual and Installation Manual are met (sections “Introduction”, “Installation of the boiler”).

F.41 — “Stuck” relay Proterm Skat

- — this message will appear if the boiler slowly tries to “unstick” the relay 5 times

In such cases, the LED on the boiler control panel will start flashing. The boiler will try to unlock the relay, and if unsuccessful, error message F41 will appear on the display. The boiler will operate at minimum heat. After turning it off and on again, the boiler will begin to operate in operating mode, but the LED will continue to flash on the display. Contact a specialized service organization.

- the message will disappear after turning the boiler on and off again

- the presence of a problem with a “stuck” relay after turning on the boiler again continues to indicate the blinking of the HDO LED

- the message will disappear after updating the factory settings of the boiler stored in the EEPROM memory (code d.96)

— the error image is eliminated by turning off and restarting

turning on the boiler

— when turned on again, the boiler signals that the relay is stuck

HDO LED flashing

Examination:

- When canceling the command to heat the heating water - at the end of the heating cycle of the heating agent (opening the RT circuit) or the hot water supply (the temperature of the water in the storage tank has reached the set value).

When the “programmable temperature limiter” is activated, i.e. if the set temperature is exceeded by 5 °C. Note: This function is activated when the boiler is in “standby” mode (i.e. the absence of any commands). The function starts when the detector is activated. If the boiler operates with a jumper and an external temperature sensor without heating the hot water supply, then a similar problem with the relay may remain unattended until the water temperature in the system, calculated by the equithermal control unit, exceeds 5 °C. Checking for relay sticking does not depend on the boiler operating mode. It is related to the current state of the heating function. At a time when the latter is turned off, the relay status is checked. The boiler is in this state whenever the heating elements stop working, i.e.: 1. after canceling the commands for heating the heating water and preparing the hot water supply, activating the anti-freeze protection system - heating. 2. when the programmable temperature limiter is activated - setpoint + 5 °C Note: If the detector is triggered (for example, in the event of an accidental closure of the relay contact), the function is activated (i.e., similarly as described in point 1). In addition, the function is also activated in the following cases: DHW: cases 1 and 2 may occur. AV: room thermostat - 1 and 2 AV: jumper + external temperature sensor

If the boiler does not heat the water

It does not heat the coolant due to failure of the heating element, provided that all other components and indicators are working. Repair of electric boilers is carried out as follows:

- Disconnect the device from the power supply, close the shut-off valves and drain the water from the boiler.

- Remove the housing of the electric heating boiler.

- If it is impossible to get to the heating element, other parts are dismantled.

- Unscrew the bolts that hold the heating element.

- They take out the heating element and put another one with the same characteristics in its place. At the same time, change the gasket.

- Fix the heating element with bolts.

- Install other components if they were removed.

Next, install the protective casing and check the functionality of the device.

F.74 - Short circuit (signal - +5 V) extract air pressure sensor

— this message will appear in the event of a short circuit (signal - +5 V) or open circuit of the exhaust pressure sensor

— the message will be automatically deleted after reconnecting the pressure sensor to the appropriate location

— a short circuit of the sensor with a +5 V signal is detected if the voltage rises above 4 V

RECOMMENDATIONS

- Check the sensor connector

- Check the sensor

- Press RESET of the boiler. If the error persists, replace the pressure sensor

Boiler overheating (97°C measured by heat flow sensor) (NTC2, NTC5)

- The coolant level is below critical: the pressure in the system has dropped below 1 Bar, it is necessary to increase it to the value required by the boiler 1-1.5 Bar.

Leak . It can appear in places where pipes are connected to a heat exchanger, radiators, expansion tank, or in their housings due to cracks or loose seams. The boiler itself also leaks if the heat exchanger is defective or the tightness of the joints of parts is broken. Often a leak in the boiler itself is not visible, due to the fact that the liquid that gets on the hot tubes immediately evaporates, but greenish stains will be visible if we are talking about copper. Insufficient coolant volume . The reason is simple – natural evaporation. This, although rare, is observed even in closed heating systems and is one of the likely causes of boiler error f20.

- Problems with the pump : check the pump for operability/restart the pump or at least change the speed to maximum (move the speed switch).

Cleaning the pump shaft : scale, oxidation on the rotor, clogged internal channel - can be eliminated by cleaning and rinsing under running water.

Motor winding burned out : if the pump does not show signs of life after the operations performed, then it is burned out and needs to be replaced.

- Clogging of the main filter : solid fractions and microparticles of salt deposits deposited from the circuit accumulate in it. As a result, the speed of movement of the coolant gradually decreases, as a result, conditions arise under which the boiler overheats, and the protection circuit generates error f20.

- The problem is in the main heat exchanger : the heat exchanger is clogged or a crack has appeared.

Other faults

The appearance of an error does not mean that a major overhaul of the Proterm gas boiler is required. False alarms are common, so the equipment needs to be restarted first. If the problem does not disappear, then you will need to conduct a thorough diagnosis. Some boiler error codes are more common, others less common, but in any case you should act according to the instructions, without panic.

Error 00

Code 00 indicates a breakdown of the temperature sensor. To eliminate the malfunction, you need to reboot it, carefully inspect and clean the contacts. If necessary, the temperature sensor will need to be replaced. To avoid high gas consumption, it is recommended to buy original parts.

Error a6

In Protherm heating equipment, error a6 appears when the air temperature is low at the installation site of the unit. To solve the problem, you need to heat the room by installing a reducer.

Error f05

Error f05 in a Protherm gas boiler indicates a lack of air for the normal functioning of the unit. To eliminate the breakdown, you need to clean the chimney, check the draft, and open the window in the boiler room.

Connecting a room thermostat

A room thermostat allows you to more accurately adjust the indoor microclimate . Its sensor checks the air temperature, which gives more accurate results than checking the extract air temperature, which is produced by the boiler electronics.

Using a room thermostat allows you to turn off the boiler when the set values are reached, when the device’s own sensors are not yet ready to give a command to stop heating.

The thermostat is connected to a special gap in the control board, the contacts of which are closed by default with a jumper.

To connect, turn off the boiler, open the lid and remove the jumper . Then the room thermostat is connected in the required order and a test switch is performed.

If the device operates normally, close the lid and proceed to further operation of the boiler with additional equipment. If problems are found, they are corrected immediately.

IMPORTANT!

Detailed instructions for connecting a room thermostat are available both on the device itself and in the user manual for the boiler. Under no circumstances should you act at random.

Baxi, Proterm or Navien, what else would you recommend for 100 sq. m.

If you need a cheap boiler, then of course Proterm, if you decide to invest in an expensive one, then of course Vailant (Proterm, a cheaper brand of this manufacturer). It makes sense to buy a Baxi only if they sell it to you very cheaply (there are huge discounts on them), the advantage is a good service network, but cheap models like Main For are absolute rubbish! Navn is generally a temporary cauldron for severe punishment of sinners! Everyone who was sold it goes broke during use and loses their nerve due to constant and regular breakdowns, and the customer service is reduced to telephone advice and mail-order sales of very expensive spare parts. Therefore, many people throw away Navien without waiting for the end of the first heating season. Wissmann boilers are of absolute German quality and reliability, amazing durability proven by many years of Russian operation, minus they are more expensive than all of the above.

Buderos Germany

What a difference you have - comparing Baksi with Navien... Like Opel and Zaporozhets - both drive, but how... If possible, take Baxi - excellent boilers from a good company with a very developed service network...

Share your experience

If you have experience in correcting error F20 in the Protherm Skat electric boiler, write in the comments to this article, we will try to consider your option and analyze it in detail in this or one of the following articles. You can also send photos and videos with comments and descriptions.

The original article is posted on the website

https://fixbroken.ru/oshibka-f20-kotla-proterm/

Did you like the article? Like and repost will be the best gratitude.

Pump

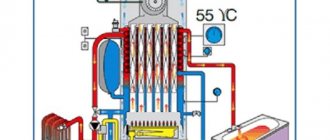

Lack of coolant circulation in the circuit triggers the temperature sensor (NTC - position 7 on the Proterm Cheetah diagram), an alarm signal to stop the boiler and error f20 on the display.

Before working on the pump, you need to check the position of the shut-off valve controls of the heating system (valves, ball valves). Accidental movement of the lever may block the channel. Coolant circulation stops and error f20 appears.

Probable Causes

How to connect to electricity

The electronics of gas boilers are demanding on the correct connection of the phase, zero and ground electrode.

If the contacts are reversed when connecting, the boiler will not start. Therefore, it is important to use a special plug and socket that does not allow you to connect the device in any other way. When running the cable, you need to check the correct distribution of the electrodes in the socket.

To check, use a probe screwdriver or other special devices.