Most of the requirements for installing a boiler are described in detail in the passport or recommendations for heating equipment. For a careful and diligent worker, it is almost impossible to make a mistake. Another thing is the installation of the heating circuit.

It is not so easy to piping a boiler with polypropylene. General recommendations, as a rule, are not enough, because you have to take into account the characteristics of the premises. And the boiler piping schemes with polypropylene differ for different types of boilers.

What is boiler piping with polypropylene

In a simplified interpretation, piping a boiler with polypropylene is considered to be a set of control devices with the distribution of heating pipes from the outlet on the boiler heat exchanger, along the circuit, through all the heated rooms of the house or apartment. The quality of the system depends on how correctly the piping scheme is chosen.

What's included in the harness:

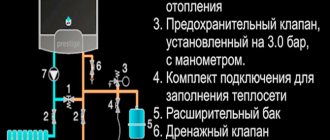

- Security group. It includes a pressure gauge, air valve, thermostat. Depending on whether the water will circulate naturally or using a pump, a flow meter and an emergency valve may be included in the group.

- Propylene pipes designed for hot water supply or heating.

- Expansion tank.

- Taps and valves that allow you to regulate the amount of hot water for a specific branch of the piping.

- Dirt filter.

It is generally accepted that the expansion tank is an attribute of all existing boiler piping schemes. But it is not so. Modern gas boilers already have a built-in compensation tank for 1.5-3 liters of water. If the boiler heats a small room, then the built-in tank will suffice.

The use of polypropylene pipes requires the installation of an emergency or steam valve. The essence of the problem is that water heated by the boiler can boil, most often at the entrance to the heating circuit. If this happens, then boiling water and steam will flow further through the pipe, it will reach a section with a tank with an air release valve, and that will be the end of it.

But before the vapor-air plug leaves the system, it will melt the polypropylene. Therefore, when piping a boiler with polypropylene, the valve is installed before water enters the pipes. This is usually a problem with solid fuel boilers, since coal and wood fireboxes have high thermal inertia. If overheating occurs, then it will not be possible to stop the process in seconds.

This is a must know valuable advice

Before purchasing a flexible hose, it is necessary to check the size of the thread at the outlet of the plate, its classification and whether it is straight or angular. If the outlet is of a direct type (directed into the wall), you must purchase a sleeve with a square at the end.

The gas hose should not be painted - this will accelerate its cracking. A more attractive look can be created by covering it with special paper or oilcloth.

It is also strictly forbidden to tightly seal gas communications with false plasterboard panels and other structures - this will make it difficult to carry out service work on individual elements.

To camouflage the gas supply system, a collapsible box is used, which can be easily dismantled if necessary. In this case, there will be constant access to all structural elements of the gas system.

It is forbidden to use unnecessary connections. Independent complication of a gas structure, according to technical regulations, may entail a fine or disconnection from gas supply

If a technician was called to connect the gas stove, it is necessary to check that the work was performed correctly: the excess tap from the tap at the lower end should be unscrewed, the flexible line should be directly connected exclusively to the tap located on the branch pipe, and its other end - only to the outlet of the gas stove.

It is also possible to use an adapter. Any additional installations are prohibited.

Types and characteristics of pipe products for heating systems

For heating systems, two types of PN25 pipes are used:

- with an internal reinforcing layer of polypropylene and fiberglass;

- with an additional inner shell of aluminum foil.

For piping a boiler with natural circulation, polypropylene reinforced with a mixture of polyethylene and fiberglass is usually used. The pressure is almost equal to atmospheric pressure, the outlet temperature usually does not exceed 80-85 ℃. Therefore, using more expensive pipes with an internal foil lining may be a waste of money.

For gas and electric boilers, the piping can be made from PN25 pipe with any type of reinforcement. Glass-reinforced polyethylene has a lower coefficient of thermal expansion. Polypropylene with aluminum foil is less deformed and sag due to heating.

When soldering with fittings, the foil has to be peeled off, so the labor intensity of assembling the boiler piping is higher.

There is no need to skimp on materials for lining heating boilers with polypropylene in a private home. Firstly, unlike hot water supply, the pipes and fittings of the heating system are constantly under load, which means the risk of leaks in the event of a defect increases sharply.

Secondly, any accident and its elimination with resoldering of polypropylene will cost much more than the benefit from conditional savings on materials. The rupture of polypropylene can cause failure of boiler equipment.

PN25 pipes with aluminum foil can be operated at temperatures up to 95 ℃, the maximum pressure should not exceed 10 atm, operating pressure - 2.5 atm. For the water injection supply line, unreinforced PN10 PPR polyethylene pipe can be used.

Popular brands

The market for floor heating units can be divided into premium, medium, economy and super-economy classes. Of course, boilers of the first type are the highest quality devices that can operate for decades, are made from the most durable materials and do not fail even in critical situations. They are generally very reliable. Their average efficiency is about 98%. Premium boilers are produced by such market titans as De Dietrich, ACV, Wolf. The best boilers are produced by German companies Vaillant, Viessmann, Buderus.

Selecting a heating boiler

Products De Dietrich

Boiler WOLF CGG-1K

Middle-class units are usually produced under European brands. They work in milder conditions and last about 15 years. However, not all types of boilers are able to withstand fluctuations, for example, in electrical networks. Manufacturer brands: Ariston, Beretta, Baxi, Electrolux, Kiturami, Protherm.

Floor-standing gas boiler Beretta Fabula 43E CAI 90

Electrolux floor-standing double-circuit boiler with atmospheric burner, cast iron heat exchanger with built-in 100 liter boiler, FSB 15 Mi/HW series

Economy class boilers have low prices and are slightly inferior in quality and reliability to middle class units. These are the brands Mayak, Alphatherm, Mora, Olympia Boiler.

Gas floor-standing boiler AlphaTherm Beta AT 20

Super-economy class are the most affordable boilers in terms of cost. They are usually produced by Ukrainian, Chinese and Russian companies. Their warranty period rarely exceeds two years, and externally the units look quite simple. Brands: ATON, Dani, Termotechnik, Vektor Lux, ATEM, Borinskoe, Vulcan, Danko, Zvezda-Strela, Kirovsky, Termolux, Mimax.

Floor-standing gas boiler Aton Atmo 16ЕВМ (double-circuit)

Vaillant turboTEC pro VUW INT 202/5-3 H

What to choose

It is believed that the choice of PN25 pipes should correspond to the cost of boiler equipment. For cheap wood burning, you can use Chinese pipes. But not the first ones that come to hand, but those that are produced in China under a license from one of the European Union countries, made from imported raw materials using original equipment. For example, the “BLUE OCEAN” brand.

To piping a double-circuit boiler with polypropylene, you can use German products from Banninger or Italian pipes from Valtec. Among the cheaper ones, we can recommend high-quality polypropylene from. They are not capricious during installation and tolerate low temperatures well. Vesbo is the best Turkish pipe for piping.

Did you choose the pipes for piping the boiler yourself?

Instructions for self-connection

Paying a gas technician for installation work is not too high, but many home craftsmen prefer to do everything themselves. This is a feasible task that requires the purchase of components and theoretical knowledge.

To connect, you will also need to prepare the following tools and buy materials:

- keys: gas No. 1, adjustable 22-24;

- a screwdriver for tightening the clamp, if required;

- sealants (Loctite 55 thread, flax, FUM - tape);

- gasket ½;

- gas sleeve;

- ball valve 1/2′;

- a brush and soap solution, which will be required to control the work.

A rag and a plastic stopper will also come in handy. The rag will be used as a temporary seal against gas leaks. The narrowed edge of the plug must be adjusted to fit the hole in the supply pipe. If during the extraction process a homemade part gets stuck, you can easily remove it with a corkscrew.

Step #1: Removing the old slab

Shutting off the crane when lowering is a primary task to ensure the safety of the work being performed. Next, you need to unscrew the locknut located on the outlet and remove the coupling. If the old slab has a coupling and locknut that were previously painted, this will significantly complicate the process of dismantling them.

Sometimes it is not possible to complete this procedure, then you will need to cut the eyeliner with a grinder.

The gas stove is dismantled after disconnecting the gas main from the conductor pipe. Difficulties that arise with unscrewing the lock nut on a metal pipe can be solved by cutting off the liner

In the process of unscrewing the squeegee located in the lowering valve, it is necessary to hold the valve itself with a key. It does not have to be removed unless you plan to replace the faucet. When they plan to delay the installation of the slab, an additional plug is installed on the lower side.

Step #2: Replace the faucet

There are situations when the wall is located very close to the tap and there is no way to dismantle it. In this case, it is necessary to bend the fastening and install a wedge between the wall and the pipeline. However, this is done in such a way that it is possible to continue doing the work.

It is necessary to prepare a piece of rag sufficient to completely block the pipe after dismantling the old tap. The next thing will be to tear it off without completely unwinding it. You will also need to prepare the selected type of seal. Do not forget to thoroughly ventilate the room during work to eliminate gas vapors.

After unscrewing the tap, the outlet from the pipe is tightly fixed with a finger and then with a wet rag. The main actions are aimed at eliminating gas escape from the pipe as much as possible. In this case, the thread on the branch should not be closed, since it will be covered with the selected sealant.

Before winding the seal, the threads on the lower end must be thoroughly cleaned. Next, its winding is carried out directly. This process ensures a reliable and airtight fixation of the new faucet, which is then tightly screwed on. The last step is to install the previously removed handle on the faucet.

Using soap foam, the tightness of the connection of the faucet and the gas pipe is checked. If the work was completed correctly, installation of the gas hose can continue.

If gas equipment is connected to the mains for the first time, you will definitely need to call a gas technician. In his presence, the equipment is checked for gas leaks when the valve is open. If the gas service worker does not find any violations, he must enter the established brand of stove into the register.

Step #3: Connecting the Flex Hose to the Stove

The external thread of the hose fitting is wrapped with a sealant. After this, it must be screwed into the tap on the branch pipe. The flexible hose is connected to the manifold at the finishing stage.

Next, the stage of test opening the tap on the lower side is mandatory to check for gas leaks. Using soap foam, the joints are treated with a brush. If foaming occurs when opening the gas tap, the work must be redone.

It is necessary to check the threads located on the manifold of the plate. Quite often it is 3/8′. In this case, you will need to install a 1/2′ adapter with a seal

When the work of replacing a gas hose is carried out in a private house where bottled gas is used, an additional replacement of the nozzle with a smaller diameter will be required. If this is not done, the burners will produce too much soot, which likes to settle on furniture and dishes in the kitchen.

Options for piping boiler equipment

When choosing a scheme, you will need to pay attention to the design of two separate parts of the heating system:

- boiler equipment safety groups;

- diagram of pipe distribution and heat delivery to the premises.

The safety group configuration depends on the type of boiler. The manufacturer of boiler equipment indicates in the product passport the minimum set of devices that ensure the operation of the unit. He even gives a recommended wiring diagram for the outlet and inlet of the heat exchanger. You just need to install the devices correctly.

You will have to plan the wiring diagram yourself, choose the type of circulation and the method of equalizing pressure throughout the heating system. For low-power boilers, leveling can be done by including bypass valves in the piping. For powerful heating systems, balancing is performed in an intermediate tank - a hydraulic collector or, in other words, a hydraulic arrow.

Forced circulation circuits

The system uses pumping of the coolant, so the heating circuit quickly and evenly warms up to operating temperature. It is best to solder the line from glass-reinforced polypropylene; it gives a relatively small elongation of the pipes, so there will be no problems with deformation of the pipelines.

For apartments and private houses with a small number of rooms, polypropylene piping is often performed using a linear single-pipe scheme. Thanks to the pump supply, hot water moves through the pipe at high speed, so all radiators are heated more or less evenly.

The batteries are connected to the circuit in series one after another. In this case, the supply from the boiler to the radiators and the gaps are made of glass-reinforced polypropylene PN25. The return can be made with a PN20 pipe.

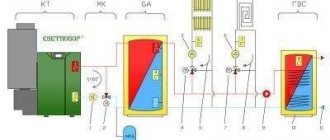

For large rooms and private houses on two floors, piping is often performed by dividing the heating system into several lines. In this case, a distribution manifold is used. The main circulation pump pumps hot water through the boiler heat exchanger and hydrocollector. Due to the high pressure and temperature, both units, supply and return pipes are made of steel.

On the other hand, dedicated hot water supply lines to radiators, heated floors or boilers are connected to the distribution manifold. This part of the harness is made of PN25 polypropylene. Each line is equipped with its own tap and circulation pump.

You can find piping options with a distribution manifold made of polypropylene or metal-plastic. Such schemes are used for heating apartments, for example, in houses for several owners with one boiler and a hot water boiler.

With natural circulation

In private houses and apartments with individual heating, old schemes without forced water circulation can be used. The boiler piping is carried out in the form of a closed loop of two pipes - direct supply and return. Batteries or tubular registers are connected between them.

The direct supply line is often made of steel pipe. The coolant temperature can reach 95-98 ℃. Therefore, polypropylene is not used for piping the boiler outlet. Hot water is directed through the top pipe and returns through a line laid at the level of the boiler heat exchanger inlet fitting. Cooled water is collected in the return, the temperature of which rarely exceeds 60 ℃, so you can install PN20 polypropylene without any problems.

The piping of a heating system with natural circulation must include an expansion tank. According to the diagram, it is installed above the boiler, on a vertical steel pipe with a height of at least 180-200 cm.

A heating system with natural circulation of coolant is also called gravity, but this is not entirely correct. It would be more correct to call it impulse.

The water in the heat exchanger is heated to a high temperature, steam appears under slight excess pressure. The steam flow pushes water up the steel pipe to the level of the expansion tank, lifting it and at the same time saturating it with microbubbles.

In this section of the piping, the microbubbles cool and turn into a liquid state, releasing additional heat and heating the water. The coolant becomes hot and heavy, so due to the difference in levels, the boiling water squeezes out colder water and returns to be heated by the boiler.

An expansion tank must be present in any heating boiler piping scheme, but with a natural circulation scheme, this device additionally ensures the pumping of hot water through the heating circuit.

Electric and diesel heat generators

Connecting a diesel fuel boiler to the radiator system is identical to piping gas-using installations. Reason: a diesel unit operates on a similar principle - an electronically controlled burner heats the heat exchanger with a flame, maintaining the set coolant temperature.

Clarification. The recommendation does not apply to heaters equipped with a homemade burner device that burns diesel and waste oil, for example, a Babington flare burner. An individual approach is needed here.

Electric boilers, in which the water is heated by heating elements, an induction core, or through the electrolysis of salts, are also connected directly to the heating. Automation located in an electrical cabinet connected to the network according to the electrical diagram provided is responsible for maintaining temperature and safety. Other connection options are shown in a separate publication on the installation of electric heating boilers.

Wall-mounted mini-boiler rooms equipped with tubular heaters are intended only for closed heating systems. To work with gravity wiring, you will need an electrode or induction unit, which is tied according to the standard scheme:

If you look at it, there is no need for a bypass here - the boiler will not work without electricity either

Criteria for choosing a wiring diagram

The selection of a suitable option begins with determining the type of circulation and the method of replenishing the circuit with water. For a private home, both natural and forced coolant circulation can be used.

If there are no problems with power outages, and the house has a central water supply, then the best option would be a gas boiler with:

- piping made of polypropylene;

- pumping coolant;

- replenishing the system with a drain from the water supply network.

Thanks to the use of a pump and the low temperature of the hot water, there is no need to cut into steel sections. It will be enough to piping polypropylene pipes. The piping of the boiler and radiators is carried out according to a two-pipe scheme.

Strapping for large apartments and houses

For buildings with a heated attic, piping can be done according to a natural circulation scheme. It will be necessary to raise the water tank to the second floor under the attic ceiling. You will need to install washers in the pipework of the upper and lower pipes, preferably taps that regulate the flow of hot water. Otherwise, it will be difficult to balance coolant flows on different floors.

In such schemes, the use of polypropylene in the boiler piping improves the quality of heating, since the internal walls of polypropylene pipes are always smoother than those of steel pipelines.

If in an apartment or house, in addition to heating, the boiler is used as a heat source for a hot water boiler, heating a bathhouse, heating a heated floor, then it is better to choose a piping scheme with a hydraulic arrow.

The same piping scheme can be used for a solid fuel boiler. The security group that controls temperature and pressure will change. It will also be necessary to replace the polypropylene with steel or copper in the area from the boiler outlet to the inlet fitting of the water gun.

Country option

In holiday villages there are always problems with electricity. Either they turn off the lights for several days, or the voltage in the network is clearly not enough for the boiler automation to work, and most importantly, it is possible to start the pump. While it is still possible to install an uninterruptible power supply unit for the combustion front control system, it is difficult to select such a device for the pump, and it is expensive.

In such conditions, wiring is done for a system with natural circulation of water, but with a bypass pump included in the circuit. On smooth propylene pipes, heating with natural circulation will work efficiently, only slightly inferior to schemes with pump supply.

Typically, a pump is needed to quickly warm up a room or remove air from the system. It is turned off at night, since the hum from the running engine can be heard even if the boiler is in the summer kitchen.

Types of gas flexible hoses

The current market offers a fairly extensive list of gas hoses. In addition to the material, you will also need to choose a manufacturer. And in this case it is better not to save. The item is bought once and for a long time. Having saved 500 rubles, you can then spend a lot on health and repairs if the pipe starts leaking gas. Therefore, let’s first look at the varieties.

Rubber-fabric

It has many advantages that allow it to be used in a gas system:

- easy installation;

- good flexibility;

- low cost;

- various sizes;

- excellent electrical insulation.

The disadvantage of such rubber parts is poor rigidity. Today, the industry produces hoses from a special material of high elasticity. Therefore, their service life can reach 10 years.

The cost of such hoses usually does not exceed $7.

Bellows metal

Professional gas fitters consider it the most suitable for gas systems. The service life of such hoses can be more than 25 years. It connects to a gas stove without any difficulty. Bellows systems can be connected to boilers and water heaters, and they are completely safe.

If you have a gas stove equipped with electric ignition in your kitchen, in order to connect the bellows device, a special insulating connection is created between it and the tap.

This type of hose bends freely and can withstand high pressure, reaching 6 atmospheres. It can withstand significant temperature changes ranging from -50 degrees to heating up to 200 degrees. The main disadvantage of a bellows hose is its cost. It is many times higher than similar gas connections.

The advantages of such bellows metal systems include:

- made of stainless steel;

- complies with GOST;

- meets all technical requirements;

- protected from any mechanical influences by a special polymer coating;

- able to withstand any mechanical impact;

- the warranty period exceeds 30 years;

- withstands voltage of 1500 Volts.

Oxygen

It can also be connected to gas stoves, but you need to take into account several very important points:

- The internal diameter must exceed 16 millimeters;

- The surface in contact with oxygen must be well cleaned of oil. Otherwise, the hose will overheat and material damage will occur.

The advantages of oxygen hoses include the following characteristics:

- withstands high pressure. It can reach 20 atmospheres;

- very simple installation;

- low cost;

- rich assortment;

- does not conduct electric current.

Nuances and piping options for different types of boilers

Most of the problems that arise in the operation of boiler equipment are associated with improper installation of the equipment in the boiler piping. Often, efficient operation is hindered by the wrong type of taps. For example, instead of ball metal ones, installers like to install cheaper models made of polypropylene.

What is the difference? Taps made of polypropylene, especially on the hot water branch, become tightly “welded” after a year, and it is impossible to turn the valve.

Gas equipment

For heating using domestic gas, two types of boilers are used, floor-mounted and wall-mounted. The first type of gas boiler is not much different from classic coal or wood-burning models. Additionally, automatic control of the gas combustion front and a chimney draft presence sensor are installed.

The piping, which should be located on the same level as the heat exchanger, must have an air release valve, a pressure sensor, and a water make-up valve.

Regardless of the model and power of the floor-standing gas boiler, an expansion tank is included in the piping. Especially if the heating circuit is built using a hydraulic arrow. In this case, the expansion tank is placed immediately at the outlet of the boiler heat exchanger.

The relatively low water temperature makes it possible to pipe the premises with polypropylene pipes. Moreover, the distribution manifold is also often assembled by soldering polypropylene tees.

For wall-mounted single- and double-circuit boilers, it is advisable to install expansion tanks, regardless of whether a compensating tank is present in the design. Moreover, a tank is placed in the harness, both on the heating line and on the hot water supply line. Experts advise embedding an air release valve into a polypropylene pipe; this is done at the highest point of the heating circuit.

When assembling the piping, the heating circuit feed line from the water supply is equipped with a dirt filter and a pressure reducer. It is believed that polypropylene, unlike steel, does not produce debris particles, but it is better to include a filter on the piping, since the make-up water may be of poor quality.

Electric heater

Unlike gas boiler equipment, an electric boiler operating in a “heating-pumping” cycle can operate in both cyclic and constant heating modes. The use of polypropylene for piping an electric heater turns out to be even more profitable than steel pipes.

Firstly, polypropylene does not conduct current, so the heating circuit is isolated from the electric heater. We are talking about pipes with fiberglass reinforcement.

Secondly, polypropylene pipelines have a lower thermal conductivity coefficient than steel ones, so less heat is lost. This means that in the bathroom, where there is a heater, a manifold and all the fittings, there will be no “tropics”, while in the rest of the rooms it will be cool.

Only the distribution manifold and the safety group installed in front of it with an air and emergency relief valve are made of metal in the piping. There should not be any other elements except the pressure gauge. If for technological reasons it is necessary to place cranes in front of the group, then after completion of the assembly work the valves are opened and the rotary handles are removed or blocked.

Installation of gas supply

Installation of the bellows gas hose is carried out in compliance with the following rules:

- it is unacceptable to hide the liner in the wall, since any leak that is not detected as soon as possible can lead to emergencies, damage to property and loss of life;

- Do not install a hose with a large number of kinks;

- condensation on the equipment will help reduce the service life of the liner.

Installation diagram:

- choosing an installation location in accordance with the recommendations given above;

Optimal connection diagram for a gas stove

- turning off the gas supply to the premises. To make a temporary shutdown, you can use the tap installed in the apartment, and if it is missing, you need to contact the management company;

Individual gas shut-off valve

- dismantle the old eyeliner (if any);

- if the supply line and tap are missing, then before connecting the equipment, it is necessary to cut a thread on the pipe and install a tap that allows you to shut off the gas supply directly in the living room. For example, to troubleshoot equipment;

- dielectric installation;

- A flexible hose is connected to the tap. As a rule, in this situation, the “nut” connection method is used;

When connecting the liner, special attention is paid to installing the sealing gasket. A connection without a gasket will not be completely sealed

To increase the tightness, you can additionally use FUM tape or other similar material.

- connecting the supply to gas equipment using an o-ring. All nuts and fittings must be fixed using an open-end wrench without unnecessary effort. Even slight overtightening can lead to damage to the seal and rapid depressurization;

Connecting the liner to the equipment

- examination. To identify a leak, you can use a soap solution and an ordinary brush (sponge). If soap bubbles appear on the surface when applying the solution, then the connection is not airtight.

Leak detection with soap emulsion

How to connect a gas stove yourself, watch the video.

If you cannot install the equipment yourself, it is recommended to contact gas service specialists. Replacing the eyeliner will cost approximately 300 - 500 rubles.

How to choose the right gas hose

It is necessary to purchase such devices only in special stores that have certificates for each product.

The gas hose braid should have a yellow mark. It is placed only on the gas hose; on the water hose, a blue-red line is placed.

All hoses come in different sizes to accommodate a wide range of connections. The most common range is one to two meters. Usually, fastening threads are made with dimensions of 1/2″–3/4″.

The ends can be equipped with two nuts. The so-called nut-nut, sometimes a nut with a fitting. This hose is called a “nut-fitting”. A nut with an internal thread is called a female; a fitting with an external thread is called a male.

Approximate cost of work

Work on connecting any water heating device to a gas boiler should be entrusted to professionals.

The cost of their services will depend on the actions required. For example, designing a boiler room costs from 300 rubles, for installation of a boiler you need to pay from 3,000 rubles, and for installing a pump group - at least 3,300 rubles. Hello to you, my reader! I dedicate this post to an interesting question that different people periodically ask me. This question sounds like this: “I heard that you can connect a storage water heater to a double-circuit boiler and not buy an indirect heating boiler. Is it true?" I will say right away that such a scheme exists. Let's figure out together why all this is needed.

Recycling

In a parallel position to the main radiator heating circuit or a small circuit in the area from the boiler to the hydraulic switch, a low-temperature circuit is installed. It contains a bypass and a three-way thermostatic valve. Thanks to the pump, water constantly circulates inside the underfloor heating pipes.

To select new portions of hot coolant from the supply pipe when the temperature inside the return pipe drops, a three-way mixer is used. It can be replaced with a simple thermostatic valve equipped with a remote capillary-type temperature sensor or an electric thermocouple. The sensor is installed in a niche on the return line of the heated floor. The valve is activated when the coolant temperature drops.