With the development of individual heating and hot water supply, more and more households have become owners of gas boilers. The modern unit is very compact, efficient, has a long service life and a self-diagnosis system. If the boiler stops producing thermal energy, an error code appears on the operating screen, which will tell the user the source of the causal failure. The factory instructions clearly describe not only possible failures, but also the actions that need to be taken to eliminate boiler errors. Users will be able to eliminate many of them on their own, and if they are associated with a violation of the integrity of working elements, they will need to be repaired or replaced; the latter is best done through a service center, especially if the unit is under warranty.

What is a gas boiler error?

During the operation of the equipment, a situation may arise when the automatic protective equipment is triggered. That is, the gas boiler detects that something is not working correctly and is blocked. To facilitate finding the cause of a malfunction, most gas boilers are equipped with a fault display system for initial diagnosis. In some cases this may be a combination of LED signals, in some cases an error code is displayed on the display, in some cases the display shows the specific cause of the malfunction (some premium boilers). The malfunction itself can be critical (emergency), or minor - requiring simple user actions. Also, in some cases, the operation of the boiler is blocked until the error is reset (for example, lack of water pressure in the boiler), and in other cases, the error must be reset by the user (for example, problems with igniting the burner).

Most often, the procedure for dealing with errors is described in the user manual, which is supplied with the gas boiler. It also indicates how the error is reset.

About Viessmann

The German manufacturer Viessmann Group specializes in the creation of heating equipment and alternative energy sources. The company has established itself as a reliable manufacturer and is represented in more than 70 countries around the world. The company has been a leader for several years and is one of the best-selling brands in the CIS and Eastern Europe, even despite serious competition from other European and Asian brands.

This time, the company presents a reliable, energy-efficient and safe wall-mounted gas boiler Viessmann Vitopend 100 A1JB. Among the main advantages are the following:

- one of the quietest and smallest options for wall-mounted water heating boilers in its segment;

- efficiency is a maximum of 91%;

- high level of comfort in creating hot water;

- constant hot water output is up to 15 liters per minute;

- electronic control method with automatic diagnostic function;

- a new chimney system prevents freezing in winter;

- Perfect for installation in rooms with limited space.

Reference! Modern German wall-mounted boilers are very popular all over the world. They have become especially relevant for the CIS countries. That is why they are made taking into account the harsh climatic characteristics of the northern regions.

How to reset a gas boiler error?

First of all, you need to read the instructions - information on how to correctly reset the error and the reason for the error is indicated there. Some errors simply cannot be reset until the problem is fixed. Example: lack of water in the boiler. Until the pressure sensor (or pressure switch) registers the required value, the error will not go away, it is useless to reset it - you need to recharge the boiler, the automation will record this and the error will disappear on its own.

Another example: the boiler failed to ignite (E01 on BAXI, F28 on Vaillant, 501 on Ariston). The process of igniting the boiler is associated with a sequence of actions. In most cases, the order is as follows: the circulation pump starts (the presence of circulation is registered by sensors), the fan starts, the presence of draft is determined, the gas valve opens and voltage is supplied to the ignition transformer - a spark hits the burner. Relatively speaking, in the presence of air, gas and sparks, the boiler will ignite. That is, the point is that the ignition process itself consists of several operations that can be controlled visually. And in this case, the boiler automation cannot determine whether the fault has been fixed or not on its own. That is, the user must first figure it out, eliminate the cause of the malfunction, and then give the command for the next startup attempt. In this case, this is what happens using the reset button.

This is a very important point to understand: if the error belongs to a category that is reset by reset, then after the reset, another ignition attempt will MUST occur, which will be accompanied by the activation of the actuators.

The second important point to understand: errors that require a reset button are not reset by turning the boiler off/on. This depends on the specific control unit! You need to study the instructions. Often control units remember a critical error and a power reset will do nothing!

Additional features

The gas wall-mounted boiler is attractive not only for its small size, high efficiency and low cost, but also for its modern appearance, thanks to which it can fit into any interior, regardless of the chosen room for installation: kitchen, toilet, bathroom, etc.

Installation is so simple that not even a specialist, but an ordinary buyer can handle it. If you are not confident in your abilities, then it is recommended to consult a specialist. The technician will assemble and install the boiler in the required location within 30 minutes.

Thanks to its low noise level, this unit is perfect not only for new apartments and houses, but also as a modernization of existing heating systems.

The error does not clear

Sometimes users and specialists who carry out diagnostics cannot reset the error and conclude that the control unit is faulty. The main reasons why the error may not be reset:

- the error cannot be reset until the fault has been eliminated (for example, lack of pressure in the boiler)

- poor contact between the reset button and the control board (often seen on Vaillant TEC boilers)

- the reset order is broken (in some cases you need to hold Reset for a certain time)

- A malfunction of the information board (display board) is rare, but possible.

At the same time, when the user’s board is changed, everything works because there is no error on it. Everything will work until the next error appears, and if the reason is not figured out, they will replace a working board every time.

From practice, we often received serviceable units for repair that simply had not cleared the error. It is often impossible to convince (especially specialists) that there is a possibility of a problem with the error reset. “We know everything, we can do everything, 20 years of experience - we checked everything, the error does not reset - the control board is faulty!”

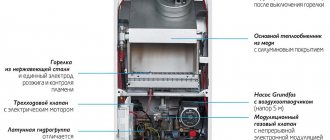

High level of comfort

A built-in plate heat exchanger is responsible for preparing water, which makes it possible to obtain hot water without a separate water heater, which will take up extra space. As soon as the first intake of hot water occurs, the boiler immediately heats the next portion so that the consumer always has access to it, without wasting time.

But even despite the classic high German quality of all design elements, sometimes minor problems can arise. You can often handle them yourself, thanks to their simple but reliable design.

MORA boiler and EFD-503 control units

Case from practice. Several EFD-503 units came in for repair. Such blocks are installed directly on the gas fittings and are used in boilers MORA, BERETTA, PROTHERM and others. So, specifically in this modification of the block, the error reset occurs through the closure of two contacts on the block itself, and the switching is displayed on the control panel with a button. The client says I change the blocks regularly once a year. Tired of replacing it (the price of 1 unit is approximately 10 thousand, and there are two of them in the boiler), he turned to us for repairs. In fact, faults were identified and corrected on the units provided - the units were sent back. Installation result: 1 unit works, two worked for 20 seconds, went into error and no longer work.

The probability that the control unit only worked for 20 seconds after repair is very small (even more so if there are two units at once). A more suitable description of the malfunction is “phasing error” - non-compliance with the polarity of the connection. I ask - what actions does the boiler perform before the error appears? The answer is none, just a mistake and that’s all. Let me explain that the error should be reset, maybe you have a bad contact on Reset. No, about the theory of contact - we know that the blocks are faulty. Okay, send it. The client sends two blocks after repair and two additional blocks from the “faulty” collection. We first install the blocks that were repaired on the stand. Blocks are in error. We reset the error - ignition is in progress, the valve opens, the unit sees the flame - it is working! We deliberately create an error on the block, reset it again - there is ignition, the board works according to logic. We check all four blocks in the same way - everything is in error, after a reset everything works. We provide information to the client about which contacts are closed on the block to reset the error, he takes the “faulty” block from the collection and voila! - works. All questions have been resolved.

And this case is not the only one. This happens often, and on different boilers.

Possible malfunctions and DIY repair methods

The house smells like gas

Do you smell gas? This shows it is leaking. Open the window and turn off the equipment. According to the instructions, you will need a household solution of soap and water, FUM tape, and a suitable adjustable wrench. Next, the solution must be distributed to all threaded connections. If bubbles appear, there is a leak in these places. After this, we turn off the gas, use a wrench to unscrew the connection and wind the FUM tape onto the external thread.

Then you need to put everything back together, reapply the solution, and connect the gas. If we managed to eliminate the leak (there is no smell of gas), we remove what is left of the solution. However, if a leak is not found, you need to turn off the valve and invite a specialist.

Fan doesn't work

You can repair the system without calling a technician if the power of the boost fan is lower than required, or there is a loud noise while it is running. First, remove the fan and disassemble its housing. If possible, you need to remove the bearings, lubricate them or replace them. It could also be a winding issue. A transformer will help correct low network voltage. If you need to repair electronics, or if your actions have not brought results, you need to call a technician.

We recommend: Why does a gas boiler go out?

The chimney of a floor-standing boiler is clogged

To resolve the issue, you will need a metal brush. Disassemble the chimney and remove dirt yourself. If the chimney is solid, it can be cleaned with prepared chemicals or devices. For the last option, call a specialist.

High temperatures

When the heat exchanger is dirty, it causes overheating of the equipment.

Turn off the boiler, gas, turn off the water. Next, remove the heat exchanger with an adjustable wrench and clean it with a brush. The hydrochloric acid solution is then poured through the pipe into the heat exchanger. Foam indicates accumulated scale. Pour the solution, repeat until the desired result. Next, after washing, you need to install the heat exchanger back, winding all threaded connections.

Self-shutdown

When it turns off, the gas boiler does not work; this may be caused by a defect in the combustion sensor or the need to clean the chimney. To solve the problem, we remove the obstacle that has arisen to the further functioning of the system.

Cleaning the boiler heat exchanger

Typically, heat exchangers are made of stainless steel (then we clean it with a wire brush) or copper (a metal sponge will do here). You need to turn off the equipment and wait until it cools down. Turn off the faucet and remove the face cap, then discard any remaining water. Next, remove the heat exchanger and clean it mechanically, then leave the heat exchanger in a solution of citric acid or vinegar (1 tablespoon per 1 liter of water), or in the prepared mixture for a couple of hours, until completely cleaned. Next, rinse and dry. Return to original position.

Electrical failures

You should have special stabilizers at home to prevent breakdowns due to power surges, especially if you have a wall-mounted unit.

We recommend: Do you need a stabilizer for a gas boiler?

Incorrect installation

In case of installation errors, it is recommended to immediately invite a specialist, since incorrect installation threatens to break all equipment.