What could be the reason for airing in your heating system in a private home? Let's look at a number of them and, perhaps, in this article you will find a description of your problem and thereby be able to solve it.

Possible reasons for the formation of air in a closed heating system:

- — chemical reactions in the heating system during which gas is released (here we will not go into detail about which gases): Temperature processes in the boiler;

- Chemical decomposition of water into hydrogen and oxygen (including electrolytic processes).

- Depressurization of the system (mainly the expansion tank);

Coarse filter

As mentioned above, one of the reasons that there is no coolant circulation may be the accumulation of debris in the pipeline.

To completely avoid this, again, we don’t save a penny, but install a coarse filter in front of each device: Using a filter, catching dirt is easier than correcting the consequences of a clogged pipeline or boiler heat exchangers.

Conclusion! We place coarse filters in front of each heating system device (pump, boiler, etc.) and in front of each plumbing fixture. We do NOT save pennies to “buy” problems. There are arrows stamped on the filter housing indicating the direction of movement of the coolant or water in the water supply...

The filter needs to be cleaned regularly. And this is very simple to do: close the valves before and after the filter - unscrew the plug (1) on the filter - remove and rinse the mesh under the tap - put it in place and tighten the plug. All. Not like changing pipes

These are the simple “body movements” you need to perform in order to never complain that there is no circulation in the heating system. Good luck.

The heating system must ensure uniform heating of all rooms. If the temperature in radiators or risers drops, this is often caused by a circulation problem. For efficient operation of the heating network and comfortable climatic conditions in housing, there must be free circulation of coolant through the main line. This should be taken into account at the design stage. Why there is no coolant circulation in the riser and main and what needs to be done, you should know thoroughly in order to promptly eliminate this problem in the future.

Consequences of cold return

Circuit for heating return

Sometimes, with an incorrectly designed design, the return flow in the heating system is cold. As practice shows, the fact that the room does not receive enough heat with a cold return is half the trouble. The fact is that at different supply and return temperatures, condensation may form on the walls of the boiler, which, when interacting with carbon dioxide released during fuel combustion, forms acid. It can also damage the boiler much ahead of time.

To avoid this, it is necessary to carefully consider the design of the heating system, special attention must be paid to such a nuance as the return temperature. Or include additional devices in the system, for example, a circulation pump or boiler, which will compensate for the loss of warm water

Radiator connection options

Now we can more than confidently say that when designing a heating system, the supply and return must be perfectly thought out and configured. If the design is incorrect, more than 50% of the heat can be lost.

There are three options for inserting a radiator into the heating system:

- Diagonal.

- Lateral.

- Bottom.

The diagonal system gives the highest efficiency coefficient, and is therefore more practical and efficient.

The diagram shows a diagonal inset

How to regulate the temperature in the heating system?

In order to regulate the temperature of the radiator and reduce the difference between the supply and return temperatures, you can use a heating system temperature controller.

When installing this device, do not forget about the jumper, which must be located in front of the heating device.

Rules of operation and maintenance

In order not to encounter situations in which the circulation pump installed in the heating system will require repair, it is necessary to strictly follow the operating rules for such equipment, which are as follows.

If there is no water in the pipeline, the circulation pump cannot be started. The amount of water pressure generated must be within the characteristics specified in the technical data sheet of the circulation pump

If the device produces a reduced or, conversely, increased water pressure, this can lead to its rapid wear and, accordingly, failure. During the period when the heating system is not in use, the pump must be turned on for circulation at least once a month for a quarter of an hour, which will prevent oxidation and blocking of its moving parts. It is very important to ensure that the water temperature in the heating system does not exceed 65°. In water heated to a higher temperature, sediment begins to actively fall out, which, interacting with the moving parts of the hydraulic machine, contributes to their active wear and, accordingly, failure of the entire device.

Periodic checking of the circulation pump will significantly reduce the likelihood of its failure during the heating season

Checking the circulation pump for correct operation includes actions such as:

- turning on the hydraulic machine to operating mode and checking the level of noise and vibration it creates;

- checking the pressure (pressure level) of the coolant created in the discharge pipe (as mentioned above, the liquid pressure must be within the values given in the technical data sheet);

- control of the degree of engine heating, which should not be too high;

- checking the presence of lubricant on the threaded connecting elements of the pump and applying it if it is missing;

- checking the presence and correct grounding of the hydraulic machine body;

- checking for leaks both on the pump body and in the places where it is connected to the pipeline (if there are leaks in such places, it is necessary to tighten the threaded connections and check the integrity of the installed gaskets);

- inspecting the terminal box and checking that the wire is fixed in it (in addition, it is necessary to check whether moisture is getting into the terminal box, which is unacceptable).

The main reason for the rapid wear of friction bearings in pumps is considered to be increased contamination of the coolant.

What to do if there are cold radiators in the apartment

So, you measured your temperature according to all the rules and it turned out to be below normal. If the cold snap in the apartment continues for more than 16 hours, then your course of action as the level of authorities increases:

- Call (or come in person) to the management company, housing construction cooperative , or other organization that services your home and report poor heating. Inspectors are required to appear within two days and take measurements.

- The next authority is the heat supplier . Write a statement addressed to your boss.

- Housing inspection - make a complaint describing the problem, indicate that you contacted previous authorities and the issue was not resolved.

- Rospotrebnadzor - similar to the previous paragraph.

Attention! Measurements are taken twice, with an interval of 10 minutes , the thermometer is located one and a half meters from the floor and one meter from the external wall.

As a rule, by the time Rospotrebnadzor contacts Rospotrebnadzor, enough officials have already been notified of the problem and there is a high probability of its resolution within the next month . There is no result - go with a statement to the prosecutor's office and then to court . In the application, indicate the temperature below normal, the date of measurement, attach the measurement results and copies of appeals to previous authorities with their responses.

Poor quality equipment

Due to the wide range of heating boilers and the variety of models and manufacturers, the buyer can easily make a mistake in choosing the right unit. Therefore, it is necessary to focus on the approved project. All parts and elements of equipment must meet its requirements.

It is according to the plan that a certain type of radiators with a suitable number of sections in them is purchased. Shut-off valves, adjusting elements and connecting units must be mutually compatible.

Most often, problems arise due to insufficient circulation of coolant through the pipes

. Special pumps can enhance the movement of water, but they must be chosen carefully, otherwise the devices will become a source of hum and noise. Additionally, old iron pipes are replaced with modern products made of metal-plastic or polypropylene. This will avoid some problems in certain heating systems.

Plastic pipelines are easy to install and connect to the boiler, but it is better to entrust this work to a specialist. After all, not all types of plastic are suitable for use in heating equipment; some models cannot withstand high temperatures and burst under their influence.

Unbalancing and installation

Another reason why water does not circulate in the heating system is improperly carried out imbalance during renovation or redevelopment of the apartment. This is affected by the uncontrolled installation of new radiators and heated floors.

The radiators on some floors continue to function normally, while on others they will remain cold because no coolant is supplied to them. Although the craftsmen can easily balance the distribution of water across all risers, in several apartments the system will not work.

If some residents removed the thermostats when replacing heating equipment, then heat will not flow into their neighbors’ homes. To fix this problem, you need to eliminate the thermostats in all apartments. You can increase the heat supply if you follow the example and also replace all radiators. Bimetallic or aluminum batteries fit harmoniously into modern heating systems. You must first obtain permission to replace devices, since you cannot do this yourself.

In a private house, batteries located closer to the boiler heat up more than others. To restore the balance, you need to turn off the control valves and limit the access of the coolant to nearby radiators. But sometimes the new battery does not heat up. If the entire system worked normally before its installation, then the problem lies in improper installation. When welding several polypropylene pipes, the master overheated the product, which caused its internal diameter to decrease. A specialist must redo all the work free of charge. All structural elements must be securely and efficiently fastened.

Preventing heating problems

Preventative work should be performed in the summer. It is better to combine them with major or current repairs. For the heating system to work properly, you need to:

- analyze the heating operation in the previous winter, find weak points;

- check the operation of shut-off valves, repair or replace faulty ones;

- if Mayevsky taps or valves for supplying coolant to heating devices are missing, they should be installed;

- check the slopes of the supply pipes, eliminate violations, if this is not possible, install Mayevsky taps in problem areas;

- flush or replace radiators that did not heat up enough during the previous heating season.

Prepare your heating system for operation in the summer and the likelihood of failures will be greatly reduced.

Example of heating system calculation

As a rule, a simplified calculation is performed based on such parameters as the volume of the room, the level of its insulation, the flow rate of the coolant and the temperature difference in the inlet and outlet pipelines.

The diameter of the heating pipe with forced circulation is determined in the following sequence:

the total amount of heat that needs to be supplied to the room is determined (thermal power, kW), you can also rely on tabular data;

Thermal power value depending on the temperature difference and pump power

Having set the speed of water movement, the optimal D is determined.

Calculation of thermal power

As an example, a standard room with dimensions of 4.8x5.0x3.0m will be used. The heating circuit is with forced circulation; it is necessary to calculate the diameters of the heating pipes for distribution throughout the apartment. The basic calculation formula looks like this:

The following notations are used in the formula:

- V is the volume of the room. In the example, it is equal to 3.8∙4.0∙3.0 = 45.6m 3 ;

- Δt is the difference between the temperature outside and inside. In the example, 53ᵒС is taken;

Minimum temperatures by month for some cities

K is a special coefficient that determines the degree of insulation of the building. In general, its value ranges from 0.6-0.9 (effective thermal insulation is used, the floor and roof are insulated, at least double-glazed windows are installed) to 3-4 (buildings without thermal insulation, for example, change houses). In the example, an intermediate option is used - the apartment has standard thermal insulation (K = 1.0 - 1.9), K = 1.1 is accepted.

The total thermal power should be 45.6∙53∙1.1/860 = 3.09 kW.

You can use tabular data.

Table for calculating heat flow

Diameter determination

The diameter of the heating pipes is determined by the formula

Where notations are used:

- Δt – difference in coolant temperatures in the supply and discharge pipelines. Considering that water is supplied at a temperature of about 90-95ᵒС, and it has time to cool down to 65-70ᵒС, the temperature difference can be taken equal to 20ᵒС;

- v is the speed of water movement. It is undesirable for it to exceed 1.5 m/s, and the minimum acceptable threshold is 0.25 m/s. It is recommended to stay at an intermediate speed value of 0.8 - 1.3 m/s.

Note! An incorrect choice of pipe diameter for heating can lead to a drop in speed below the minimum threshold, which in turn will cause the formation of air locks. As a result, work efficiency will become zero.

The value of Din in the example will be √354∙(0.86∙3.09/20)/1.3 = 36.18 mm

If you pay attention to the standard sizes, for example, of a PP pipeline, you will see that there is simply no such Din. In this case, simply select the closest diameter of propylene pipes for heating

In this example, you can choose PN25 with a diameter of 33.2 mm, this will lead to a slight increase in the coolant flow rate, but it will still remain within acceptable limits.

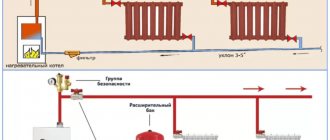

Features of heating systems with natural circulation

Their main difference is that they do not use a circulation pump to create pressure. The liquid moves by gravity, after heating it is forced upward, then passes through the radiators, cools and returns to the boiler.

The diagram shows the principle of circulation pressure

Compared to systems with forced circulation, the diameter of pipes for heating with natural circulation must be larger. The basis of the calculation in this case is that the circulation pressure exceeds friction losses and local resistance.

Example of wiring with natural circulation

In order not to calculate the value of the circulation pressure each time, there are special tables compiled for different temperature differences. For example, if the length of the pipeline from the boiler to the radiator is 4.0 m, and the temperature difference is 20°C (70°C in the outlet and 90°C in the supply), then the circulation pressure will be 488 Pa. Based on this, the coolant speed is selected by changing D.

When performing calculations yourself, a verification calculation is also required. That is, the calculations are carried out in the reverse order, the purpose of the check is to determine whether friction losses and local resistance do not exceed the circulation pressure.

Design, types and principle of operation of circulation pumps

Without knowing the structure of the circulation pump, you will not only be able to repair such a hydraulic machine if the need arises, but also carry out its regular maintenance. The design of circulation pumps consists of:

- body made of stainless steel or non-ferrous alloys;

- an electric motor whose shaft is connected to the rotor;

- The rotor itself, on which the wheel with blades is installed, is the impeller (its blades, which are in constant contact with the pumped medium, can be made of metal or polymer materials).

Circulation pump design

The circulation pump operates, regardless of its design, according to the following principle.

- After applying electric current, the drive motor shaft begins to rotate the rotor on which the impeller is mounted.

- The coolant liquid entering the internal part of the pump through the suction pipe is thrown away by the impeller and centrifugal force to the walls of the working chamber.

- The liquid, which is affected by centrifugal force, is pushed into the discharge pipe.

As mentioned above, depending on the design features, the heating circulation pump can be of different types. Thus, devices with a rotor are distinguished:

- "wet";

- "dry".

In private homes, “wet” type circulation pumps are most often used.

For circulation pumps of the first type, which are used primarily to equip household heating systems, the rotor is constantly in a liquid medium. This contributes not only to the lubrication of moving elements, but also to their effective cooling. The main advantages of this type of equipment include:

- low noise level during operation, since the water in which all the moving elements of such a device are located perfectly absorbs vibrations;

- ease of installation (such pumps simply cut into the pipeline), maintenance and repair.

Meanwhile, pumps with a “wet” rotor, if we talk about their disadvantages, are characterized by not very high efficiency, can only be installed in a horizontal position and are very critical of the lack of liquid in the heating system.

Pumps with a dry rotor are installed in separate boiler rooms and are used in systems that heat large areas

The drive motor of pumps with a dry rotor is placed in a separate unit. Rotation from the electric motor shaft is transmitted to the impeller through a special coupling. Unlike devices with a “wet” rotor, pumps of this type are characterized by a higher efficiency (up to 80%), but also a more complex design, which somewhat complicates their maintenance and repair procedures. Circulation pumps with a dry rotor are cut into the pipeline and their housing is attached to the wall, for which a special console is used.

Advantages and disadvantages

The open heating system has not yet lost its relevance, and recently it has even experienced a rebirth, and there are reasons for this. Many homeowners are concerned about the energy independence of their communications, and the open tank scheme allows this to be achieved. She has other advantages:

- Filling an open heating system and bleeding air is easier than in a closed one. There is no need to monitor the maximum pressure, and when filling, the air leaves the pipelines very quickly through the open expansion tank. All that remains is to ventilate the radiators;

- it’s easier to refill: again, pressure control is not required, and water can be added to the container even with a bucket;

- the operation of the system does not depend on the presence of leaks: here the operating pressure is very low, so as long as there is water in the heating network, it will function properly.

As usual, there were some drawbacks, due to which such systems began to be gradually replaced by closed-type circuits with a membrane expansion tank. Due to the direct contact of the coolant with atmospheric air, two processes occur in the container at once: natural evaporation of hot water and its saturation with oxygen. This leads to the following requirements:

- you need to monitor the water level in the tank and replenish it on time;

- Do not fill the heating network with antifreeze, which releases harmful substances when evaporated.

Oxygen saturation of the coolant leads to a decrease in the service life of steel parts of the boiler. For the above reasons, the open system has not been used in apartment buildings for a long time, although in the 60-70s of the Soviet era such practice took place in low-rise residential buildings. It is also undesirable to operate it with high-temperature heat sources when the coolant is close to the boiling point. The fact is that with increased pressure in a closed network, this threshold increases, and there is nowhere for water to evaporate. In an open system, the amount of water will quickly decrease, freeing up the entire volume of the expansion tank for air.

Basic physical parameters of a natural circulation heating system

Circulation pressure Рc is a physical quantity determined by the difference in the heights of the centers of the boiler and the lowest heating device (radiator).

The greater the height difference (h) and the difference in densities of heated (ρ g) and cooled (ρ o) liquids in the system, the better and more stable the coolant circulation will be.

R c =h(ρ o -ρ g)=m(kg/m 3 -kg/m 3)=kg/m 2 =mm.water column.

Let’s “look” for the reason for the appearance of circulation pressure in a heating system with natural circulation in the “wild” of the laws of physics.

If we assume that the temperature of the coolant in the heating system “jumps” between the centers of the devices (boiler and radiators), that is, the upper part of the system contains hotter water than the lower part of the system.

Density (ρ g)(ρ g).

We cut off (mentally) the upper part on the circuit diagram and... What do we see? A familiar picture from school - two communicating vessels located at different levels. And this will lead to the fact that liquid from a higher point, under the influence of gravitational force, will flow to a lower one.

Due to the fact that the heating system is a closed circuit, the water does not splash out, but simply strives to equalize its level, which leads to the heated water being pushed upward and to its further “independent gravitational” path through the heating system.

The conclusion is this! The fundamental indicator of the circulation pressure is the difference in the installation heights of the boiler and the last (lowest) radiator in the system. Therefore, in heating systems of private houses, boilers are located in basements whenever possible, observing a maximum height of 3 m.

In apartment versions, they try to “deepen” the boilers to the floor slab, accordingly “fireproofing” the “nest” where the boiler is placed in the floor.

According to the formula given above, the difference in the densities of cold and hot water in the system also has a significant influence on the circulation pressure.

A heating system with natural circulation is a self-regulating system, that is, for example, when the heating temperature of the coolant increases naturally (see formula), the circulation pressure and, accordingly, water flow increases.

At low temperatures in a heated room, the difference in water densities is large and the circulation pressure is quite large. When the room is heated, the coolant no longer cools down as much in the radiators, and the difference in the densities of the heated and cooled coolant decreases. Accordingly, the circulation pressure decreases, reducing the “consumption” of water.

Is the air in the room cool? For example, someone opened the doors to the street. The density difference increased again, increasing the water pressure.

Reason 2. The system power was not calculated

It is generally accepted that the average heat loss in a home is 100 W per square meter. But often in some rooms they can significantly exceed this value. This is why the warm floor does not work at the proper level.

How to fix it?

First, calculate the heat loss of each room. The Internet is full of ready-made calculators. Compare the heat loss figure with those rooms where your heated floor does not work. Next, try adjusting the contours of the heated floor on the collector with priority to those places where the heated floor does not heat.

You do everything through experimentation. Do not hurry. Remember that the inertia of the floor is 2-3 hours.

In extreme cases, you will have to upgrade your heating system.

Pipelines: reasons for low heating

Determining air pockets in batteries using a thermal imager

Failures in the heating mode are typical for a two-pipe heating system. In this case, the supply line that distributes the coolant to the radiators does not heat. Identification of the “problem” area can be done by measuring the temperature on the surface of the pipes or a thermal imager.

Natural circulation

Pipe slope for heating with natural circulation

What could cause such problems? If the heating does not heat well, the slope of the line may not be observed. This only applies to natural circulation systems. According to the standards, the slope of the pipes should be 10 mm per 1 m.p. In addition, the direction is taken into account - from the accelerating riser to the radiators. For the return pipe, the slope must be towards the boiler.

At the first stage, it is necessary to measure this indicator using a building level. If it meets the standard, but the heating radiator does not heat, there is a possibility of air pockets forming. In this case, an integrated approach is recommended, which includes the following steps:

- Measuring the angle of inclination. If necessary, change it to the required value;

- Flushing pipes to remove limescale;

- Filling the system with coolant with open Mayevsky taps on the radiators.

This technique will eliminate the low heat transfer rate of the heating system.

Forced coolant circulation

Operating principle of the air vent

For a system with forced movement of water in pipes, the formation of air locks can be avoided by using an air vent installed at the top of the system. In part, it performs the functions of an open expansion tank, but it does not reduce the pressure in the pipes to a critical level. Its absence is an indirect cause of poor heating of the radiator.

The specificity of closed heating systems is that it is not necessary to comply with the installation level of the pipes. However, when the critical heating level of the coolant is exceeded, steam is released, which is the main cause of air locks. Since air has a lower density than water, it will concentrate in the upper region of the pipeline sections. If heating radiators in a closed system do not heat well, the reason may be a decrease in the volume of coolant in the pipes due to air resistance.

What needs to be done in this case? First of all, check the functionality of the air vents. If the valve is idle for a long time, it may become covered with limescale, which makes it impossible to open it under air pressure.

In addition to this factor, it is necessary to take into account the excess of hydraulic resistance in the system. This is why the heating battery does not heat if the initial calculation is incorrect. Therefore, before you begin installing a new system or upgrading an old one, you should perform the calculation of the operational and technical parameters:

- Selection of pipes of the appropriate diameter - the larger it is, the lower the hydrodynamic resistance. However, this increases the volume of water;

- The likelihood that a two-pipe heating system will not heat is significantly less than that of a single-pipe one. Therefore, it is preferable to install radiators with parallel connections;

- Heating of the heating circulation pump occurs due to incorrectly selected power. It directly depends on the calculated hydrodynamic parameters.

The video shows the main reasons for poor radiator heating for a single-pipe heating system:

Reason 6. Weak pump

It is also possible that the heated floor does not heat due to an incorrectly selected pump. Such a pump cannot properly “push” the circuits and therefore your underfloor heating does not heat up.

Dear, I have a question about heating a private house connected to central heating.

Prehistory. A house for 4 owners, there are two pipes for each half from the central riser. The direct and return pipes are 34″ in size. The pipes go into the house to the collectors. Input manifold with 4 taps, + direct output to the neighbor. From 2 taps there is a distribution for heating, from 2 taps to heated floors, one floor to the bathtub, the second heated floor in the hallway.

Return from all pipes to the collector without taps. The photo shows the collector below behind the cold water pipe.

The pipes in our quarter of the house were replaced with 20″ metal-plastic, a 16″ heated floor was laid in the bathroom and hallway, pipes were laid to the heated floor and radiators through a manifold.

The problem is that water does not circulate in the system, because, as I understand it, there is pressure both in the inlet pipe and in the return pipe. And the resistance of the general system does not provide the necessary pressure to push through the return.

One of the ways to warm up was to connect the faucet to the treatment and drain the water into the sewer until the pipes warmed up.

Tell me, would it help to install a circulation pump in the return line, or something similar to a check valve? Thank you!

UPD. I added the connection diagram, if you can call this art that way =)

Recommendations for disassembling the circulation pump

Before disassembling the circulation pump, if the need arises (for example, during repairs), you must disconnect it from the power supply and remove it from the pipeline by unscrewing all fastening threaded elements.

After the pump has been removed from the heating system, you can begin to disassemble it:

- The cover is removed and secured to the pump body using special bolts.

- After removing the cover, the impeller is removed from the inside of the pump.

After this, access to all internal parts of the pump will be provided; they can be inspected, cleaned or replaced with new ones, if necessary.

Two-story house

In two-story country houses, it is recommended to use a closed heating system with a circulation pump. The list of necessary equipment here includes: a boiler, an expansion tank, a piping system, as well as the required number of heating radiators.

Copper pipes are connected to each other using special silver-based solder. The downside of this material is its high price, but it is distinguished by high quality and reliability. Metal pipes also transfer heat well, but they are often destroyed by corrosion.

Two-pipe heating system for a two-story house with natural circulation and top wiring

In two-story buildings, three types of wiring can be used: collector, two-pipe or single-pipe. When connecting heating devices using a single-pipe scheme, it is quite difficult to regulate the temperature in the rooms, because the maximum amount of heat will reach the first radiators from the boiler, while the last radiators will heat up much less than the others.

A two-pipe heating system is considered a more suitable option for a two-story country house. Here, two pipes are connected to each of the heating devices: hot water from the boiler flows through one of them, and the liquid that gives off heat flows into the other. The coolant temperature in the main supply line will be the same.

Advantages and disadvantages

So, the pump installed in the system provides it with a large number of advantages:

- For such a system, it makes no difference which pipes and with what diameter will be installed in it.

- In this case, you can use inexpensive pipes with a smaller diameter, which will save money.

- The absence of temperature differences increases the service life of system components.

- It is possible to regulate the temperature in the system itself or in individual rooms of the house.

Of course, there are also disadvantages:

- Firstly, the pump operates from an electric current network, and this, although small, is an expense. In addition, when the power goes out, the pump also stops.

- Secondly, there is a slight noise from the operation of the pumping unit. It is practically inaudible, but it is still present.

Air jams

The cause of cold batteries is usually air, which does not allow water to flow freely.

An air lock forms for several reasons.

:

Oxygen bubbles accumulate in one of the radiators or at the highest point of the heating system. Because of this, the bottom half of the radiators will be hot and the second half cold. Gurgling sounds also occur when the equipment operates. In multi-storey buildings in the highest apartments, boilers completely stop working.

In older apartment buildings, many of the pipes have long since expired. Therefore, they can cause accidents and reduce heat levels

. Microelements contained in the coolant are deposited inside the pipelines. They impede normal water circulation. The correct solution would be to replace the products, but this is not always possible.

Layers of scale form on the inner surface of the boiler, which reduces the pressure in the system. This problem is caused by the use of hard water, saturated with minerals and salts. Special reagents must be added to the equipment to soften the quality of the coolant.

When pipes are corroded or improperly connected, leaks occur. If it is in a visible area, it is easy to seal the hole with sealants. It is more difficult to deal with a problem hidden in the wall or floor. In this case, you will have to cut off the entire branch, fix the problem and install a new section. In addition to sealants, you can use special parts to clamp the pipeline, corresponding to its diameter. If it is not possible to purchase such devices, then it is enough to make a clamp. The leak area is covered with a piece of soft rubber and secured tightly with wire.

If a leak is detected at the radiator or at its junction with the pipe, wrap the hole with a strip of fabric, after soaking it in moisture-resistant construction glue. Sometimes cold welding is used. To avoid such problems, before the start of the heating season, inspect the entire system for damage. It is imperative to start the boiler and check the quality and reliability of its operation.

How to protect the pump from malfunction

It is advisable to always maintain the required volume of coolant water in the pipes. Otherwise, the pump will wear out, both in case of excess water volume and in case of insufficient water volume.

To be on the safe side and avoid breakdowns of fairly expensive pumping equipment, it is recommended to adhere to some basic rules for operating equipment of this type:

- Do not allow the pump to turn on without coolant in the closed circuit. That is, if there is no water in the heating system pipes, then you should not “torture” the pump. This will cause your equipment to break down quickly.

- It is advisable to always maintain the required volume of coolant water in the pipes. Otherwise, the pump will wear out, both in case of excess water volume and in case of insufficient water volume. For example, if a pump can distill an amount of water from 5 to 105 liters, then the need to work with volumes from 3 to 103 liters will greatly wear out the working components of the unit, which will lead to its failure.

- In case of prolonged downtime of the pump (during the low heating season), it is necessary to run the unit in the operating position for at least 15 minutes once a month. This will avoid oxidation of all movable elements of the pump unit.

- Try not to exceed the coolant temperature above 65 degrees Celsius. A higher rate will negatively affect the working and movable parts of the structure.

- In this case, check the pump housing for leaks more often. If there is even the slightest leak somewhere, you should immediately identify the malfunction and carry out maintenance on the pump.

What it is

If a system with forced circulation requires a pressure difference created by a circulation pump or provided by a connection to the heating main, then the picture is different. Natural circulation heating uses a simple physical effect - the expansion of a liquid when heated.

If we ignore the technical details, the principle of operation is as follows:

- The boiler heats a certain volume of water. So, of course, it expands and, due to its lower density, is forced upward by a colder mass of coolant.

- Having risen to the top point of the heating system, the water, gradually cooling, describes a circle by gravity through the heating system and returns to the boiler. At the same time, it gives off heat to the heating devices and by the time it reaches the heat exchanger again, it has a higher density than at the beginning. Then the cycle repeats.

Useful: of course, nothing prevents you from including a circulation pump in the circuit. In normal mode, it will provide faster circulation of water and uniform heating, and in the absence of electricity, the heating system will operate with natural circulation.

Pump operation in a natural circulation system.

The photo shows how the problem of interaction between the pump and the natural circulation system was solved. When the pump is running, the check valve is activated, and all the water flows through the pump. Once you turn it off, the valve opens and water circulates through the thicker pipe due to thermal expansion.

Possible breakdowns and ways to eliminate them

So, if something goes wrong with your circulation pump and it refuses to work, then we’ll try to repair the unit ourselves.

If the pump makes a hum, but the impeller does not rotate

The reasons may be the following:

- Presence of a foreign object in the impeller area;

- The rotor shaft has oxidized due to long-term downtime of the unit;

- Loss of power supply to the mechanism terminals.

In the first case, you need to carefully remove the pump from the heating system and unscrew the housing in the area of the impeller. If a foreign object is found, remove it and rotate the shaft by hand. When assembling the pump in the reverse order, it is necessary to install a reliable filter on the pipe.

If there is oxidation, then clean it well, lubricate all movable elements of the working unit and reassemble the pump in the reverse order.

If there is a problem with the quality of the power supply, then you will have to check the voltage using a tester. First, completely replace the cable in all sections of the cable and if a break or fault is detected. Then, if the cable is OK, check the voltage at the terminals. If the tester shows infinity, a short circuit has occurred. If it shows less voltage, it means that the winding has broken. In both cases, the terminals are replaced.

If the unit shows no signs of life at all

This can happen if there is no voltage in the network. Using a tester, check the voltage and, if necessary, correct the problem.

By the way, it is recommended to protect the pump from surges in the network by installing a reliable stabilizer. This move will also protect the pump from the combustion of a fuse, which fails as a result of constant pressure drops in the network.

If the pump starts but then stops

The reasons may be:

- Presence of scale between the moving elements of the unit;

- Incorrect pump connection at the terminals.

In the first case, you will have to disassemble the pump and check it for scale. If detected, limescale deposits are removed and all joints between the rotor and stator are lubricated.

If there is no scale, then check the tightness of the fuse on the unit. You should remove it and thoroughly clean all the clamps. Here it is also worth checking that all wires in the terminal box are connected correctly in phases.

If the pump makes a loud noise when turned on

The reason for this is the presence of air in a closed circuit. It is necessary to release all air masses from the pipes, and install a special unit in the upper part of the pipeline to prevent the formation of air locks.

Another reason could be wear on the impeller bearing. In this case, you need to disassemble the unit housing, check the bearing and, if necessary, replace it.

If the pump is noisy and vibrates

Most likely, the issue is insufficient pressure in the system. It is necessary to add water to the pipes or increase the pressure in the area of the pump inlet.

If the pressure is still low

Here it is worth checking the direction of rotation of the working unit in the pump body. If the wheel does not spin correctly, then an error was probably made when connecting the device to the terminals in phases when using a three-phase network.

Another reason for a decrease in pressure may be too high a viscosity of the coolant. Here the impeller experiences a lot of resistance and does not cope with the assigned tasks. You will have to check the condition of the mesh filter and clean it if necessary. It would also be useful to check the cross-section of the inlet and outlet pipes and, if necessary, set the correct operating parameters of the pump.

Reason 1. Lack of thermal insulation

The most common reason why a heated floor does not cope with the functions assigned to it is that you simply forgot to install the thermal insulation properly, or did not install it at all. Often, a regular polyethylene foam backing is used as thermal insulation. And the substrate is simply not intended for thermal insulation of heated floors. Instead, you need to use polystyrene foam 5-10 cm thick.

How to fix it?

Keep one thing in mind. You will already have to overpay for heated floors. But perhaps the situation will be corrected by a higher temperature supply to the heated floor and the use of more powerful heating equipment. But don't overdo it. The maximum temperature should not exceed 70 degrees. And it shouldn't be permanent. Otherwise, the pipe will quickly become unusable.

Pressure in the central heating system: GOST

Let's consider what pressure in the heating system of a multi-story building is set according to GOST.

Pressure is divided into:

- Working.

- Crimping.

Operating is the stable most comfortable indicator at which the system operates most of the time.

Pressure testing is an increased load that is created for a short time at the beginning of the heating season, when the heating is just started and its performance is checked.

- Static.

- Dynamic.

Static is created by a column of water under the influence of gravity.

And the higher the liquid was raised, the greater this indicator.

Dynamic is the excess pressure created by pumps.

In multi-storey buildings, water for radiators is first supplied to the upper floors using powerful pumping equipment. Of course, the flow of water acquires a certain speed and rises under pressure. And the higher the building, the greater the pressure needed to supply coolant to the top.

Standard for a 9-story building: 0.5 – 0.7 Pa (5 – 7 Atm).

Taller buildings: 0.7 – 1 Pa (7 – 10 Atm).

The difference in indicators between the first and last floors should not exceed 10%.

The crimping pressure should not exceed the working pressure by more than 20%.

Practice shows that the supply is usually 6 Atm., and the return is about 4 Atm. But many factors can influence this indicator.

What is the difference between heating supply and return

Heating was invented to keep buildings warm and to ensure uniform heating of the room. At the same time, the design that provides heat should be convenient to operate and repair. A heating system is a set of parts and equipment used to heat a room. It consists:

- A source that creates heat.

- Pipe lines (supply and return).

- Heating elements.

Heat is distributed from the starting point of its creation to the heating block using a coolant. This could be: water, air, steam, antifreeze, etc. The most commonly used coolant fluids are water systems. They are practical, since all kinds of fuel are used to create heat, and they are also able to solve the problem of heating various buildings, because there are actually many heating schemes, varying in properties and cost. They also have high operational safety, productivity and optimal use of all equipment as a whole. But no matter how complex the heating systems may be, they are united by the same operating principle.

Briefly about return and flow in the heating system

The water heating system, using a supply from the boiler, supplies heated coolant to the radiators, which are located inside the building. This makes it possible to distribute heat throughout the house. Then the coolant, that is, water or antifreeze, having passed through all available radiators, loses its temperature and is supplied back for heating. The most simple heating structure consists of a heater, two lines, an expansion tank and a set of radiators. The conduit through which heated water from the heater moves to the batteries is called the supply. And the water conduit, which is located at the bottom of the radiators, where the water loses its original temperature and returns back, will be called return. Since water expands when heated, the system provides a special tank. It solves two problems: a supply of water to saturate the system; accepts excess water, which is obtained during expansion. Water, as a heat carrier, is directed from the boiler to the radiators and back. Its flow is ensured by a pump, or natural circulation.

Supply and return are present in one and two pipe heating systems. But in the first there is no clear distribution into the supply and return pipes, and the entire pipe line is conditionally divided in half. The column that leaves the boiler is called the supply, and the column that comes out from the last radiator is called the return. In a single-pipe line, heated water from the boiler flows sequentially from one battery to another, losing its temperature. Therefore, at the very end the batteries will be the coldest. This is the main and probably the only disadvantage of such a system.

But the single-pipe version will have more advantages: lower costs for purchasing materials are required compared to a 2-pipe; the diagram looks more attractive. It is easier to hide the pipe, and you can also lay pipes under doorways. The two-pipe system is more efficient - two fittings are installed in parallel into the system (supply and return).

This system is considered more optimal by experts. After all, its work revolves around supplying hot water through one pipe, and cooled water is discharged in the opposite direction through another pipe. In this case, the radiators are connected in parallel, which ensures uniform heating. Which of them establishes the approach must be individual, taking into account many different parameters.

There are only a few general tips to follow:

- The entire line must be completely filled with water; air is a hindrance; if the pipes are airy, the heating quality is poor.

- It is necessary to maintain a sufficiently high fluid circulation rate.

- The difference in supply and return temperatures should be about 30 degrees.

What is the difference between heating flow and return?

And so, let’s summarize the differences between supply and return in heating:

- Supply – coolant that flows through water pipes from a heat source. This could be an individual boiler or central heating of the house.

- Return water is water that, having passed through all the heating radiators, goes back to the heat source. Therefore, at the input of the system there is supply, and at the output there is return.

- It also differs in temperature. The feed is hotter than the return.

- Installation method. The water conduit that is attached to the top of the battery is the supply; the one that connects to the bottom is the return line.

How does the water heating system of a private house work?

The main equipment for heating installation is the boiler. It is necessary to transfer thermal energy, which is released during the combustion of fuel, to the coolant moving through the pipes.

Depending on the type of boiler, the following can be used as fuel:

- natural gas;

- firewood;

- coal;

- peat.

Heating schemes using electricity as a heat source have been developed and are successfully used. But this method is expensive, although it is the safest.

Expansion tank operation

The pressure stabilization device has a membrane that separates the working space from the air. The function of an expansion tank in a heating system is to receive excess coolant, which is formed due to expansion during heating, and release it back into the system during cooling.

When heated, water expands, and the pressure in all pipes and heating devices increases, and the excess volume flows into the tank. In this case, the membrane stretches and the volume of air decreases, that is, it compresses. At the same time, the pressure in the system increases.

As the temperature of the coolant decreases, its volume in the system drops, the pressure decreases, and thus the water that was previously taken into the tank is pushed out of it by compressed air.

Heating indoor air

Pipes are routed to radiators in various ways

The room is heated thanks to radiators installed in each room. Depending on the material used, they can be steel, aluminum, cast iron and bimetallic. Bimetal batteries have excellent heat dissipation and excellent appearance.

Water flows into heating devices through a branched pipe system. To ensure uniform and rapid movement of the coolant, as well as operating pressure in the heating system, a circulation pump is used. There are also systems with gravity flow of water.

Important elements are drain taps, release valves, shut-off valves and pressure gauges.

Causes of noise

The reasons why water gurgles in heating pipes are the following factors:

- Installation errors. Different diameters of the heating circuit, a large number of line turns, incorrectly selected or installed shut-off valves, air vents often cause humming or knocking.

- Poorly secured fittings , pipelines or close proximity (contact) of pipes can cause noise as a result of its vibrations. The main method of eliminating the problem is to rework the incorrectly installed section of the pipeline, securely fixing the pipes and fittings.

- Leaks. Whistling or hissing noise in the heating system of both an apartment building and an individual building is often caused by coolant leaks. Liquid usually leaks from pipeline joints, leaky gaskets of shut-off and control valves - ball valves, air vents, thermostats. The malfunction can be easily detected by the sound and the appearance of puddles; the simplest method of eliminating it is to use overhead clamps on the pipes and replace the gaskets, winding sealing flax fibers, FUM tapes at the joints and in the fittings.

- Airing. The increased air content in the coolant and plugs during its passage cause various types of sounds of flowing water during the process of bleeding air from the heating circuit.

- Damage to fittings and electric pump. Malfunctions in shut-off ball valves in the form of weakening of their fasteners, wear of the shut-off sphere can cause a decrease in the cross-section of the passage channel and the corresponding appearance of noise. Similar sounds occur when the impeller of the circulation pump does not rotate.

- Presence of scale or foreign deposits in the passage channel . When scale forms in the boiler or on the internal walls of metal pipelines, a knocking sound often occurs due to the temperature difference between the pipe material and the coolant.

Heating schemes

Water heating

With forced circulation of the coolant there are two types - one-pipe and two-pipe. The difference between them is quite significant. Here, not only the pipe layout differs, but also their number, as well as the set of shut-off, control and control valves.

Single pipe heating system

Here we also need to consider two options, because there is a horizontal and vertical scheme.

The first option is very simple. All heating radiators are inserted into the network circuit in series. That is, the coolant flows from one device to another, followed by a return circuit to the boiler. Each device is equipped with Mayevsky taps, through which air is removed from the system, as well as taps or valves, with which you can cut off part of the system or one small section. A pump installed in such a scheme will be very relevant.

There is one point here that needs special attention. This scheme for a multi-storey building is used in a variation, when each floor has its own separate branch from the riser

The vertical diagram is simplified. In it, the riser rises above the last floor, where the pipe is lowered to the upper floor and distributed among the radiators in a horizontal pattern from device to device. Next, the pipe is lowered to the floor below, where the horizontal routing is repeated. And so on until the first floor. Now you understand that the radiators on the first floor will always be cooled.

Two-pipe heating system

Drawing of a two-pipe heating system

This scheme also contains two types of wiring - horizontal and vertical. In turn, the horizontal diagram is divided into:

- Dead end;

- Along the way;

- Collector.

What are the differences between these three schemes?

The first is the simplest, but it is very difficult to control the temperature. Each radiator has its own circuit, and the further the radiator is from the boiler, the longer this circuit is.

In the second scheme, these circuits are the same, which makes it easy to regulate the process. But this increases the length of the pipeline itself.

But the third scheme is the most effective, because each radiator has its own separate pipeline, and coolant is supplied through it. In this case, uniformity of heat is ensured. There is only one drawback - large material costs for purchasing a large amount of materials and considerable labor costs for installation work.

The vertical circuit is also divided into two types - with lower wiring and with upper wiring. The first option has a distinctive structural element - the coolant supply riser passes through all floors and on the top it enters the radiator, from which the return flows. Through this pipe, water flows to the lower floor, where it also goes directly to the radiator. And so on until the boiler. That is, in any room you will have two pipes.

More options for forced heating schemes

The second option is completely different. Here the riser rises vertically from the boiler to the attic, where pipes are routed to each radiator on the upper floor. And from them a pipe goes down to the lower floor. This return flows to the lower floor radiator as a coolant supply. That is, in each room you will always have one pipe connecting radiators on different floors.

As you can see, heating systems have different designs. When choosing any of them, you need to decide one very important question - how much money is allocated for installing heating in your home.

Battery sounds like clicking sounds

What else causes batteries to make noise, making clicking sounds and how to remove them at home? Usually the problem manifests itself when heating radiators warm up or cool down. The reason is uneven heating/cooling, as the metal expands and contracts accordingly.

To eliminate clicks and get rid of the causes of noise, try placing something between the brackets and batteries - rubber spacers up to 2-3 mm thick are enough. In the case of inexpensive bimetallic radiators, similar sounds arise due to their internal design. Their structure differs from other batteries, since two types of metals are used at once. When they do not fit well together, the expansion causes clicking and knocking noises.

If the problem cannot be fixed on your own, it is better to turn to professionals to avoid trouble. San Remo company technicians will find out and eliminate the cause of noise in batteries inexpensively and in a short time. And if necessary, they will install a heating radiator with high quality.

By clicking the “We’ll call you back” button, I accept the terms of the Personal Data Privacy Policy and give my consent to the processing of my personal data.

Selecting a circulation pump

Circulation pump

To choose the right pump, you need to take into account only two of its qualities. It should be:

- Energy saving.

- Simple and reliable to use.

Indicators such as power and pressure are determined by the size of the house itself. Eg:

- House area is 250 square meters - choose a pump with a capacity of 3.5 cubic meters per hour and a pressure of 0.4 atmospheres.

- Area 250-350 cubic meters - power 4.5 cubic meters per hour, pressure - 0.6 atm.

- Area 350-800 cubic meters - power 11 cubic meters per hour, pressure - 0.8 atm.

Of course, it is difficult to say exactly which pump is best to use for a particular home. Here you will have to make a calculation that can only be performed by a specialist. After all, for this it is necessary to take into account many factors. This must include:

- The diameter of the pipes and the material from which they are made.

- Length of the entire system.

- The number of radiators, shut-off valves and other devices, as well as their type.

- The type of fuel the boiler will operate on.

Glandless circulation pump for all water heating systems

As you can see, it is very difficult to take into account all the factors and make a calculation on your own; only a specialist can do this.

And one last thing. Often on forums you can hear complaints from private developers that there is no circulation in the heating system. What to do?

There can only be one reason - air pockets inside. To remove them, it is necessary to install Mayevsky taps on each radiator. This is an effective means of combating air that remains inside the system after it is filled with water. So you need to splurge and buy these devices.

By the way, currently such taps are produced with automatic air release. An excellent option in which there is no need to control the formation of air pockets.

In water heating systems, it is not uncommon for a problem to arise that leads to a deterioration in water circulation within the circuit. The problem has a specific name - airing in the heating system. The uninterrupted operation of water heating is based on the principles of circulation of hot water (coolant) inside the circuit and heat transfer through radiators that heat the rooms. Air in the system leads to the appearance of air pockets and, as a result, to the ineffective functioning of the entire system due to reduced heat transfer.

To begin solving the problem, it is necessary to establish the reasons for the appearance of air: natural or artificial. A natural reason is airing of the system due to the ability of heated water to release air. The higher the temperature of the coolant, the more air bubbles are released. According to physical laws, the accumulation of bubbles occurs in the upper part of the circuit, since air is lighter than water.

The remaining reasons are considered artificial. It is difficult to give a complete list, but the main reasons are considered to be the following:

- insufficient pressure in the system;

- installation errors of the heating circuit (for example, incorrect pipe slope);

- errors when putting the system into operation (for example, filling the circuit with water too quickly);

- high concentration of air in the water used;

- incorrect operation of the shut-off equipment (possibly loose connections of individual elements);

- clogged pipelines;

- consequences of repair and maintenance work;

- corrosion on metal surfaces of circuit elements;

- incorrect operation of air vents or their absence.

Deaeration of a centralized system

In apartment buildings and the private sector, central heating is designed with air collectors. They are located at the top point. When the heating system is aired, just open the tap. When an air lock forms, opening the air collector allows air to rise through the pipes. Thus, the entire system is filled with water, and there are no plugs left.

In apartments, to ventilate the system you just need to open the tap

In an apartment or house, you can remove the blockage by bleeding the air in the place where it formed. For this purpose, batteries are equipped with taps. It must be borne in mind that it is unacceptable to install plumbing elements. Special valves called air vents are used . If the owner of the premises installs a water tap instead of an air vent and accidentally drains a certain amount of coolant from the system, he will have to pay a fine.

The vent is opened using a special key or a regular screwdriver. Extreme care must be taken, but even if everything is done correctly, it is possible that not only air will come out of the radiator, but water will also leak out.

How to eliminate uneven heat transfer

Not all problems can be solved on your own. Poor heat transfer from the radiator may be a consequence of non-compliance with the slopes, indicating gross violations in the installation of the heating system. In this case, you will have to invite a specialist in heating systems.

Some heating problems can be fixed on your own.

- Air locks - air in the heating system is an inevitable consequence of filling pipes and radiators with coolant. A characteristic sign of the problem is that the radiator is warm at the bottom and cold at the top. If the section heats up unevenly, you can try to bleed air from the system using the Mayevsky valve. Some owners initially install an automatic air release valve.

Preventive measures

We figured out why air appears in the heating system and how to deal with this negative fact. It remains to be seen whether there are preventive measures that help avoid such problems. It turns out yes:

- when installing a heating system, it is necessary to provide for the installation of special devices that automatically remove air;

- Before adding water to the heating system, you should bleed the air;

- During operation, you should monitor the operation of the entire system by observing the readings of pressure gauges and from time to time monitoring the pressure in the pipes. In addition, it is recommended to monitor the level of coolant in the expansion tank, conduct a visual inspection of pipes and radiators, and check the uniformity of heat distribution along the circuit;

- The system should be periodically pumped to remove all blockages.

The implementation of this set of measures will extend the operational period of the entire heating network.

Reducing clearance in old heating pipes

In old “Khrushchev” buildings, problems in the heating system are obvious and predictable. There, the service life of the pipelines has long expired, and therefore they cause not only a decrease in heat, but also accidents. Over many decades, the pipes become so clogged with sediment that they are unable to provide normal circulation. The decision must be drastic - replace all the pipes.

In addition, a decrease in pressure in the system is caused by the formation of scale on the heat exchanger of the heating boiler. Using too hard water leads to such consequences. To prevent a similar problem with heating devices, special water softening agents are added to the system.

Pump design elements

In order for the operation of the circulation pump to be problem-free, it is necessary to regularly check the condition of the equipment. A preventive inspection will help identify negative factors that can lead to serious breakdowns in the future. Their timely elimination will allow you to avoid force majeure situations and complex repair procedures.

A standard inspection includes a few simple steps:

- checking the tightness of connections. It is necessary to carefully inspect all fittings with which the pump is attached to the heating system. Some types of connecting elements may become loose over time and must be tightened. In addition, problems may arise with the destruction of the thread or seal - in this case, you need to unscrew the fitting, cut additional turns or wind a new layer of FUM tape, and then reassemble the element;

- adding lubricant. There are bearings inside the device that must be well lubricated. Otherwise, they will work worse, which will lead to overheating of the device;

- cleaning the filter. The mesh element gradually becomes clogged with dirt, even if you use a very high-quality coolant. Therefore, it is necessary to promptly remove rust and scale particles stuck in the filter.

Actually, this is a basic set of actions that need to be performed for prevention. In addition, you should follow some rules for operating the circulation pump:

- Avoid dry running. The pump should only be turned on if the required amount of coolant is present in the heating system. Equipment running “dry” will burn out very quickly, and may even drag down some other electrical appliances;

- Avoid prolonged idle time. In many regions, the heating system operates in seasonal mode - from September to May. It is clear that there is no point in launching it in thirty-degree heat. But if left idle for such a long time, some elements of the circulation pump may fail. Therefore, it must be turned on at least once a month for a quarter of an hour. Agree, it takes a little time, but it will help to avoid possible problems in the future;

- initially purchase a pump whose characteristics fully correspond to the needs of your heating system. It happens that owners, in an attempt to save money, buy a low-power device and try to use it in a system with a large volume of coolant. As a result, the device constantly works at the limit of its capabilities and, of course, fails very quickly. That is why it is important to make advance calculations of the parameters that you should focus on when purchasing. You can find information on how to do this on our portal;

- provide for overheating and “dry running” sensors. These regulators are not available on all models, but it is advisable to find and purchase a device with them. You may not immediately notice the problem on your own. For example, if there is a coolant leak in the system, then until you detect it, the pump will run idle and may simply burn out. And the sensor will react instantly, automatically turning off the equipment, and thereby preventing breakdown.

No circulation, heating failure - why

Failure in the heating system, deficiencies, imperfections, all lead to cold radiators.

If there is no coolant circulation, then the reason needs to be determined. Most often, the answer to why the heating does not work is on the surface, obvious. Let's look in order at the main causes of heating malfunctions, why water does not circulate through the pipes, and what needs to be done first.

Let's start with the simplest and most obvious reasons.

It's clogged and clogged.

Every heating system must have a coarse filter. A very small device with a fine mesh and a sump (installed downwards! or at least to the side) saves equipment, pumps, and the boiler from coolant contamination that will be present in any system. Wood shavings, broken threads, rust, water sediment…. everything is retained by the mesh in the filter.

The sedimentation tank must be periodically untwisted and the mesh cleaned.

If the circulation in the heating system of a private house is disrupted, then the first thing you need to do is check the filter, which should be installed on the return line in front of the boiler.

Air in the system, airing

Airing can occur in any closed piping system where air removal measures have not been taken. Air is always present in the coolant, including in a dissolved state, is released during pressure changes, and accumulates at the highest points. Including in the boiler.

Automatic air vents are installed at characteristic, highest points of the system, as well as on collectors and special separators - the normal circuit is equipped with a special air catching device in which air bubbles are released from the coolant.

In addition, Mayevsky valves (manual air vents) should be on each radiator, and also possibly in other elevated places.

Checking the air supply, bleeding the air, installing air vents are common actions if circulation stops and the batteries are cold.

The circulation pump does not work

In private homes, the reason why the heating system stops working is a breakdown of the electrical equipment that controlled the movement of the coolant through the pipes.

If the heating suddenly stops working, then you need to check the functionality of the circulation pump near the solid fuel boiler or the pump in the automated boiler. In addition, the same unit can be installed in each circuit, which must work properly.

Bad polypropylene pipes

Often the consumer (customer) believes that polypropylene pipes are absolutely reliable and cannot cause heating problems or cold radiators.

But polypropylene is much more insidious than old steel or metal-plastic pipelines. Each place of soldering (welding) is a potential increased resistance in the system or a cause of cessation of circulation (weakened movement of water through the batteries), due to deposits of material inside.

It is impossible to control the quality of connections from the outside; all that remains is to cut out pieces, resolder, and remake polypropylene pipes.

Poor performance of a polypropylene system is a real problem for the home installer. Good professionals don’t take on this material at all.

Bad project

It is not uncommon for poor circulation to occur where there is poor design. Typically, the batteries are not connected correctly, according to some sequential circuit, where the last battery in the circuit receives much less coolant.

Another bad design is single-pipe circuits, where it is also difficult to establish the necessary coolant circulation through each battery.

If the radiators do not heat up evenly, or there is poor coolant circulation on individual heating devices, first of all you need to consider how the connection corresponds to the classic circuits - shoulder, associated, radial. It is necessary to bring home heating to normal design standards, and then expect good circulation and uniform heating of the radiators.

Small diameter, overgrown pipes

Old steel pipes become overgrown with rust and deposits from the inside, their throughput capacity decreases significantly over time, and there is only one solution - they need to be replaced with modern ones.

But even during installation, for the sake of economy, mistakes can be made with the choice of pipeline diameter - on mains, on groups of heating devices, diameters of 16 or 20 mm can be installed. The result is noise in the pipes, excessive consumption of electricity, and insufficient coolant flow. What pipe diameters should you choose?

A complex system

A type of bad design is an incorrectly designed complex heating system consisting of many heating circuits and several boilers. Here entire circuits will not work correctly if the work of one affects the neighboring one.

As a rule, one boiler (the backup one does not count) and three circuits - boiler, radiators, heated floors with their pumps are coordinated normally, and no questions arise. But if you connect another working boiler plus a circuit (for example, heating a garage and greenhouse), then the system will become complex. It is difficult to say how the coolant will circulate in it without equalizing the pressures at the connection points.

Theoretical horseshoeing - how gravity flow works

The natural circulation of water in heating systems operates due to gravity. How does this happen:

- Take an open vessel, fill it with water and start heating it. The most primitive option is a saucepan on a gas stove.

- The temperature of the lower layer of liquid increases, the density decreases. The water becomes lighter.

- Under the influence of gravity, the upper heavier layer sinks to the bottom, displacing less dense hot water. Natural circulation of liquid begins, called convection.

Reference. The dependence of water density on temperature is not linear. The more the liquid heats up, the faster its density decreases, which is clearly visible on the graph.

Example: if you heat 1 m³ of water from 50 to 70 degrees, it will become 10.26 kg lighter (see below for a table of densities at different temperatures). If we continue heating to 90 °C, then the cube of liquid will already lose 12.47 kg, although the temperature delta remains the same - 20 °C. Conclusion: the closer the water is to the boiling point, the more active the circulation occurs.

In a similar way, the coolant circulates by gravity through the home heating network. The water heated by the boiler loses weight and is pushed upward by the cooled coolant returning from the radiators. The flow speed at a temperature difference of 20–25 °C is only 0.1…0.25 m/s versus 0.7…1 m/s in modern pumping systems.

Low speed of fluid movement through pipelines and heating devices causes the following consequences:

- The batteries have time to give off more heat, and the coolant has time to cool by 20–30 °C. In a conventional heating network with a pump and a membrane expansion tank, the temperature drops by 10–15 degrees.

- Accordingly, the boiler must produce more thermal energy after the burner starts. It is pointless to keep the generator at a temperature of 40 °C - the flow will slow down to the limit, the batteries will become cold.

- To deliver the required amount of heat to the radiators, it is necessary to increase the flow area of the pipes.

- Fittings and fittings with high hydraulic resistance can worsen or even stop gravity flow. This includes check valves, three-way valves, sharp 90° turns and pipe reductions.

- The roughness of the internal walls of pipelines does not play a big role (within reasonable limits). Low fluid speed means low frictional resistance.

- A solid fuel boiler + gravity heating system can safely operate without a heat accumulator and a mixing unit. Due to the slow flow of water, condensation does not form in the firebox.

As you can see, there are positive and negative aspects in the convection movement of the coolant. The former should be used, the latter should be minimized.

What should be the performance indicators?

In this case, the indicator is determined from several values. Due to the presence of a circulation pump and additional elements in the heating (for example, an expansion membrane tank), dynamic pressure , and static pressure determines the vertical (altitude) level of the liquid column. The summation of these two indicators gives the final operating pressure of a closed heating system.

The norm for this parameter is a value of 1.5-2 atmospheres for houses consisting of 1 or 2 floors. The increase in pressure indicator directly depends on the increase in the number of storeys.

The upper peak value sets the weakest node in the heating circuit. This is what a hot water boiler is. Its limit is 3 atmospheres.

In multi-storey buildings, radiators and pipelines that can withstand powerful water hammer are widely used. In such systems, the pressure varies in the range from 20 to 100 atmospheres.

Pre-launch maintenance in autumn

Annual inspection and maintenance events are traditionally scheduled for late summer or early fall, when the heating system is preparing for the new heating season. But even in operating mode, you can always arrange a planned shutdown, since the entire range of maintenance work and proper startup does not take much time.

When performing repair work or inspecting the internal parts of the equipment, the water is drained, so before starting the entire system is filled with a new portion of coolant. The quality of water used to “prime” the system is of key importance, especially for systems with metal pipes or aluminum radiators. Water must be softened and cleared of solid particles; in systems with a displacement of more than 400–500 liters, it is recommended to first displace dissolved oxygen from the water.

After filling the system, if it has a closed expansion tank, the standard pressure for the cold state is injected, and air is removed using Mayevsky taps and bleed valves. It is important that before draining the water, the fittings in the piping of the circulation pump located above the return line are closed - this will prevent it from airing. When the system is completely filled with water, the circulation equipment is turned on, after which the heating unit is put into operation.

When the supply and return pipes heat up, you need to immediately make sure that there is circulation; at the first stage, it is better to set the pump to maximum speed. Next, all pipelines and radiators are bypassed, the degree of their heating is checked, and adjustments are made if necessary. If individual batteries have been drained, they are filled through the lower supply pipe, bleeding the air through the Mayevsky valve, and after complete filling, the upper valve is also opened, starting circulation.