The undoubted advantage of autonomous space heating systems over network resources is the ability to create a full-fledged heating circuit without reference to centralized mains.

Independence appears, there is no dependence on the tariffs and needs of resource suppliers.

All possible faults are located right here, inside the existing system, which allows you to quickly localize and eliminate detected problems.

Most of the problems that arise are related to the design of boilers, since the units are in a state of continuous operation, their main elements are subject to severe loads and significant wear.

Let's look at possible errors and malfunctions using the example of Baxi boilers, products of a well-known Italian company in Europe.

Malfunctions of Baksi gas boilers and their repair

The operation of any system is subject to many specific loads that arise both during normal operation and as a result of emerging malfunctions or failures of one or another element.

Among the many possible malfunctions, the most characteristic malfunctions that occur more often than others can always be identified.

For Baksi boilers, these include the following problems::

- Starting the gas burner is difficult or impossible.

- The boiler cannot be started.

- Characteristic popping sounds inside the combustion chamber.

- Installation overheating.

- The coolant temperature is too low.

- Extraneous sounds and noises heard during operation of the unit.

- Failure of any sensor.

The causes of the most common problems have been studied quite well, which allows us to list them with a high degree of confidence:

- Moisture (condensation) gets on the control board or other parts of the boiler.

- Low quality coolant (excessive hardness, formation of lime deposits).

- A drop or surge in gas pressure in the network.

- Voltage drop in the network, incorrect connection of the phase wire.

- Errors made during installation or commissioning.

In addition to the listed reasons, which occur most often, other, less common factors can affect the operation of the boiler.

For example, it is possible that one or another component of the system may fail, mechanical failure of parts, or destruction of the weakest elements of the system . Most of these situations are detected automatically and are the task of the self-diagnosis system.

Damage to the Venturi device

This malfunction most likely occurs on boilers from other manufacturers and boilers, but I think it is necessary to describe it too. Since the plastic tubes themselves are located near the gas burner, there is a possibility of exposure to high temperatures.

This mainly happens due to the presence of other malfunctions, for example, a primary heat exchanger clogged with scale or prolonged operation of the boiler at maximum power. The tubes of the device simply melt, and any, even the slightest, deformation leads to the entire system not working correctly and the unit stopping.

If the information from this article was useful and helped you, you can share it with your friends using the social buttons below.

Almost everything described above can also be viewed in the video, which describes error e 03 in detail:

How to run self-diagnosis

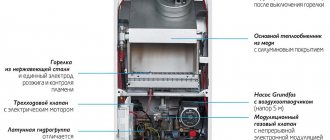

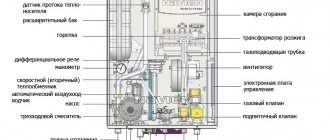

A special launch of self-diagnosis of the Baxi boiler is impossible, since this system turns on immediately with the unit and operates in continuous mode. The system is formed by a network of sensors located in all main components of the boiler.

They constantly monitor the situation and give a signal immediately if any failures or failures of any element occur . It is sent to the control board, which reacts to changes in sensor readings by generating an error code displayed on the boiler display and blocks the operation of the device until the problem is resolved.

IMPORTANT!

The presence of a self-diagnosis system is a great advantage of the equipment, since it makes it possible to avoid serious accidents, allowing you to protect an expensive installation from destruction or failure. The owner of the installation is spared the need to constantly check the condition of the boiler; smart and advanced automation does everything for him .

BAXI error E 03. Condensation in tubes

Another option for the occurrence of error E03 on the boiler is

is condensate, which under certain conditions can accumulate in the tube. It can either get on the relay itself, or simply affect the amount of vacuum and prevent the relay from operating.

Boilers of a later production date are equipped with either special extensions to collect condensate or insulated tubes to prevent its formation. If you see drops of liquid, you can remove the tube and blow it out.

Basic error codes and their interpretation

The list of standard errors that are displayed on the display in the form of an alphanumeric code is quite large.

For convenience, we present it in the form of a table:

| Error code | Decoding (problematic element) |

| E00 | Control board fault |

| E01 | Flame sensor failure |

| E02 | Overheat thermostat |

| E03 | Draft sensor on pneumatic relay or thermostat |

| E04 | Combustion mode control electrode |

| E05 | Exhaust temperature sensor |

| E06 | DHW temperature sensor |

| E09 | Control board fault |

| E10 | Pressure switch or pump operation sensor (pressostat) |

| E12 - 13 | Hydraulic pressure switch |

| E21 | Damage to control board elements |

| E22 | Low supply voltage |

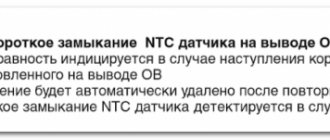

| E25 - 26 | Coolant temperature sensor |

| E31 | There is no connection between the control board and the remote control |

| E32 | DHW and OB temperature sensors |

| E35 | Flame sensor |

| E40 - 41 | Combustion product pressure sensor (draft presence sensor) |

| E42 | Flame sensor |

| E97, 98, 99 | Malfunction of the electronic control board |

The appearance of a particular code is not always able to tell an unprepared person anything. A list of errors with explanations is available in the user manual, which should be kept at hand to quickly determine the causes or source of the malfunction.

NOTE!

Eliminating errors can be done independently, but in most cases the participation of a specialist from the service center is required. It is especially important to involve it during the warranty period.

E98 baksi. Expensive board replacement?

We believe that there is no need to rush to buy a new board. An error found by the self-diagnosis system indicates that the malfunction is not emergency and most likely the board can be repaired by replacing the faulty component.

In any case, to identify a malfunction, you will need to diagnose the board itself, and to carry out subsequent repairs, you will need special equipment and appropriate qualifications, diagrams, and spare parts.

We have all the necessary equipment and spare parts for repairing electronic boards; the accumulated experience allows us to quickly carry out repairs, and this is especially true in cases where a board malfunction occurred during the heating season. Remanufactured boards are available for the most common BAXI boiler models (mainfour, ecofour). In our catalog you can see prices for baxi boards.

Other errors 97 and 99 can occur for the same reasons, but the likelihood of damage to board components is small and they are less common.

Elimination

Let's look at possible problems and what needs to be done to fix them:

E 00

This error indicates a problem with the control board. The issue can only be resolved by the service center employees, since there can be many reasons and possible consequences of the intervention.

E 01

No ignition (no flame). The reason may be either a lack of gas in the line or a failure of the ignition system.

The solution to the problem is step-by-step - first checking the presence of gas, then examining the condition of the gas equipment, checking the ignition system, etc. This error occurs most often, since there can be quite a few reasons for its occurrence.

Solving the problem on your own is not recommended; it is better to invite a specialist.

E 03

The cause may equally be a clogged chimney and a lack of contact between the fan and the control board.

It is recommended to examine both positions and carry out work on both the chimney and the contact group of the fan (pressostat).

E 05 - 06

A failure in the operation of these sensors indicates a failure of either the elements themselves or a failure of contact with the control board.

First of all, you need to check the temperature of the extract air and hot water supply to determine whether the sensor readings are generally true.

Then contacts with the control board should be restored. If a positive result cannot be achieved, the sensors need to be replaced .

E 10

A drop in water pressure indicates leaks. It is necessary to inspect the heating circuit and check the boiler drain valve.

If no problems are found in them, you should check the sensor contacts . If necessary, it is changed.

E 25

A sharp increase in the temperature of the OM indicates a lack of circulation. The most likely reason for this is airing of the heating circuit elements. The solution to the problem will be to bleed air from the system . If this does not help, the sensor must be replaced.

E 35

The signal about the appearance of a parasitic flame indicates either a short circuit of the sensor contacts due to the appearance of drops of water (condensation) on the board, a breakdown through a layer of soot, or other similar situations.

The solution to the problem will be to clean the board, install high-quality grounding and additional insulation on the contact group of the sensor.

E 98 - 99

This error indicates a failure of the control board for unknown reasons. The solution to the problem must be entrusted to a specialist; correcting the situation on your own is unacceptable.

How pressure drops in the boiler

A drop in pressure in the boiler can be caused by a single reason - a coolant leak.

If recharging the system does not have a long-term effect, it means there is a leak somewhere in the circuit. Alternatively, there is a malfunction of the drain valve through which water goes into the sewer.

The solution to the issue will be to restore the tightness of pipelines, radiators and system connections.

In addition, it is necessary to inspect the drain valve, heat exchanger, three-way valve and other boiler elements involved in the movement of the heating agent.

Why doesn't the device restart?

Failure to restart usually indicates the presence of air in the system or internal elements of the boiler.

The solution to the issue may be to bleed air from the circulation pump, which is done by loosening the central screw of the device . The air will hiss out, and when water comes out, you need to tighten the screw again until the coolant stops escaping. After this, restart the boiler.

Doesn't light up right away

The cause of delayed ignition may be incorrect information supplied by the extract air or DHW temperature sensor.

If it gives a signal about the high temperature of these liquids, the command to ignite the burner will not work.

You can check the correct operation of the sensor by disconnecting the contacts from the control board.

If after this ignition occurs as expected, then the reason is in the sensor. If the situation has not changed, the search for a solution should be carried out in the ignition equipment itself. Alternatively, condensation may accumulate in the air sensor tubes. They need to be blown out, after which the burner will start in normal mode.

Error e03. Checking chimneys.

First of all, it is necessary to carry out a visual inspection of the chimneys. It happens that the head of a coaxial chimney at the outlet can be equipped with a fine mesh to prevent the entry of large objects. In winter, when conditions are created for the formation of frost and this mesh is covered with frost so that air intake completely stops.

The rules clearly stipulate how chimney pipes should be installed for different building options. Incorrect installation of chimneys (for example, lack of slope or too long pipe sections) can lead to boiler shutdown under certain weather conditions.

The formation of ice or icicles is not a rare occurrence; ideally, when designing the boiler installation site, even the wind rose of a particular region should be taken into account.

If we are talking about the summer period, then the reason for the “narrowing” of chimneys may be spiders making webs or birds making nests. Here, I think everything is clear.

Carefully inspect the intake pipe and the air outlet pipe, if there are no obstacles there, you can proceed to consider the following possible causes of error e03 baxi.

Valve clicks

Gas valve clicks can be observed for various reasons - from a weak contact on the relay, to a difference in gas pressure in the main line and the boiler valve system. In each case, solving the problem requires its own actions.

Restore the gas valve relay contact group, adjust the minimum and maximum gas pressure, check the inlet reducer setting. All this work must be carried out by specialists from the service center; it is extremely dangerous to interfere with the operation of gas equipment on your own .