Incorrect operation of a gas boiler is a sign of equipment malfunction. This fact should not be ignored. Especially if there is a popping noise when you turn it on. There are several reasons why this phenomenon occurs. It is not always possible to solve the problem yourself. Therefore, it is worth understanding why the gas boiler slams loudly when turned on and how to act in such a situation.

We recommend reading: Why a gas boiler does not work, the main causes of malfunctions.

How does a boiler work?

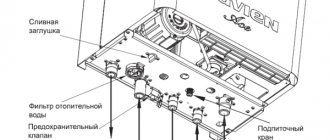

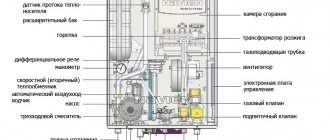

To understand the situation more clearly, you need to understand the principle of operation of the boiler. Double-circuit gas wall-mounted boilers such as Baksi or Ariston consist of several components. In the gas part, the incoming fuel is burned, the water part ensures the supply of heated water from the heat exchangers to the heating system, and the smoke removal part is responsible for removing combustion products outside the home.

Depending on the user settings, temperature sensors adjust the water heating mode. A sensor on the return pipeline turns off the boiler, depending on the achievement of the required temperature set for the return. However, the system pump does not stop running until the heat exchanger temperature drops.

This is provided to prevent the water from boiling in it. As soon as the coolant cools down to the maximum level, the electronics will send a signal to turn on water pumping and the gas valve. The whole process will start again. When you open the tap in the mixer in a double-circuit boiler, a flow sensor reacts, which informs the electronics about the need to switch the three-way valve to the mode of heating water for DHW.

When the hot water tap is turned off, it returns to heating mode. Some manufacturers provide heating for both heat exchangers during periodic switching.

What to do if the pump gets hot and whistles

Such sounds often occur after air enters the heating line; when the circuit is filled with liquid, such excesses are difficult to avoid.

Therefore, after checking the integrity of connections and pipes, specialists bleed air from each radiator in a closed system in order not only to ensure the most uniform heating of the premises in the building, but also to protect the circulation unit from breakdowns and pump whistling due to air locks.

To carry out the manipulations, it is necessary to provide for the installation of Mayevsky taps, thanks to which you can quickly get rid of the airiness of the system. Automatic devices are widely used to remove excess air from the pipeline; this happens autonomously, without human intervention, which allows you to be confident in the productivity of the device.

The boiler does not heat water for heating

So, let's look at the main reasons why a gas boiler does not heat water for the heating system and what to do about it:

- airlock. It is necessary to inspect the heating system for the presence of air in the radiators. To eliminate this problem, you need to install an air vent. Its operating principle is similar to that of an expansion tank, but it is capable of maintaining pressure in the system. Using an air vent, you need to bleed air from the system. It is important to inspect the valve itself for mechanical blockages - scale may be present there;

- corrosion in radiators. Clogging of heating devices can be determined by draining water from the system. If the water flows dirty, then you need to flush the system until visually clean water appears;

- connection errors. Hot water may not flow if the diameter of the pipes is not as specified in the project or instructions. It is necessary to check the compliance of the pipeline, the correct connection and the quality of installation of shut-off valves;

- insufficient pressure in the network. You should try adding water to the heating system, as there may not be enough pressure to trigger the automatic ignition of the burner;

- presence of scale in the heat exchanger. The first sign is prolonged heating of the coolant and heating of the batteries. It is necessary to get rid of sediments and carry out boiler water treatment. To do this, you need to disassemble the boiler and remove the heat exchanger assembly.

Before doing this, you need to shut off the flow of gas and water to the device. Then flexible connectors from the pump are connected to the heat exchanger and it is washed with a composition containing a special cleaning agent, which can be purchased over the counter. After which the parts are washed with water.

Some manufacturers allow the use of antifreeze instead of water in the heating system. This substance can be used in the following boilers: “Baxi”, “Vaillant”, “Proterm”, “Beretta”, “Korea Star”. However, it should be understood that each manufacturer recommends using its own antifreeze;

- filter clogging. If the filter screens are clogged with mechanical debris, the radiators may also have poor heating. Therefore, the filter should be checked and cleaned regularly by rinsing with water. If clogging occurs too often, then such a part must be replaced;

- incorrect setting. First of all, if there is weak or no heating, you need to check the settings of the control unit. The temperature may be set insufficiently and the gas does not heat the water;

- malfunctions of pumping equipment. If the pump power is not enough to ensure good circulation, it may turn off if it overheats. This can happen when the DHW circuit is turned on;

- incorrectly selected heating devices. If the system has radiators with unsuitable heat transfer and design parameters, this can also lead to low heating;

- incorrect slope of pipelines. Most often this problem occurs in systems with natural circulation. Regulatory documentation specifies that the slope of pipes should be 10 mm per meter of pipe. If these requirements are not met, circulation may be disrupted and, as a result, there may be no heating due to low coolant flow.

Why does the circulation pump heat up in the heating system?

Separate equipment is responsible for forcibly pumping the coolant, which does not always work correctly. The question of why the circulation pump is heating up increasingly arises among owners of private houses and apartments with individual heating.

There may be several reasons for the occurrence of such a problem; I will analyze the most common excesses. But first, you need to pay attention to the principle of operation of the unit, what standards for temperature increases exist, and what to do first when a problem is detected.

Thanks to a detailed description of 7 cases that cause a problem in the heating network, any owner will be able to quickly find and eliminate the reason why the pump is heating up; I will consider them separately.

The boiler does not heat water for hot water supply

In addition to the lack of heating of the heating system, it happens that the gas boiler does not heat the hot water supply circuit.

After all, scale has a structure that limits the passage of coolant and also takes away its heat. This is due to the thermal conductivity of salt deposits - it is much lower than the thermal conductivity of the metal from which the heat exchanger is made. Therefore, the boiler does not heat hot water well.

It is also possible that a piece has come away from the salt deposit, blocking the flow completely, which leads to a complete stop in the supply of hot water.

Structurally, the sensor is a paddle device through which water flows, which is the condition for its operation, because it sends a signal about the presence of a flow to the electronics, which, in turn, starts heating the water again. It happens that the sensor gets clogged, but it can be cleared of the blockage without removing it.

The device has the shape of a cylinder and is located near the circulation pump. To start cleaning, open and close the tap near the sensor. If this does not help, then it should be unfastened and removed, cleaned by hand and reinstalled. If this does not help, then the sensor is most likely faulty and needs to be replaced.

It is designed to shut off the heating system when the hot water tap on the mixer is opened. If the valve does not work, the boiler does not switch to heating water for DHW from heating water for heating. The first reason for its failure may be clogging with corrosion products, which needs to be removed.

If this does not help, the valve should be replaced. The hose system and filter may also become dirty. This problem is barely noticeable on the heating circuit, but on the hot water supply circuit it will be more noticeable. These elements need to be cleaned.

Design and modification solutions of modern gas boilers are aimed at uninterrupted and efficient operation. Ariston boilers, popular in Russia, are no exception. But sometimes failures occur when the unit ceases to properly perform its main function - heating water to provide hot water supply and heating the room. To understand what is the cause of the malfunction, why the Ariston boiler does not heat hot water, you need to understand how the system works.

Other Common Causes of Popping

The reasons described are among the most common. But there are situations in which turning on a gas boiler is also accompanied by an unpleasant, loud noise. They occur less frequently, but are still recommended to be taken into account. Among them:

- The ignition retarder has failed. It looks like a metal ball and is necessary to block part of the bypass channel in the water regulator. Its position is determined by the adjusting screw. It is not recommended to repair this fault yourself;

- problems with the electrode. This part is present in models with automatic ignition. If the electrode is clogged, it needs to be cleaned. Otherwise, when the water is opened, a pop will be heard;

- Malfunction of the microswitch located in the water regulator. This element is necessary to signal the unit that the water has been turned on. Then the flame is lit. If the microswitch is constantly exposed to water, it begins to oxidize. This leads to the block no longer clearly perceiving the commands sent;

- use of low-quality equipment. Such gas boilers use poor parts that quickly fail and settings are lost;

- There was a fuel leak inside the device. If the popping noise occurs after the boiler has not been used for 7-8 hours, the cause may be an internal gas leak. It accumulates in the chimney and inside the equipment housing. As a result, a pop is heard when starting work.

Work principles

Gas boilers, as a rule, have two circuits - heating and water heating. Double-circuit devices are a combination of several blocks responsible for a certain functionality of the system. Thus, the gas block is responsible for igniting and burning the burner, which allows the heat-conducting liquid to heat up, the water unit supplies water and ensures the necessary pressure in the line, the smoke exhaust unit releases combustion products into the environment, the control unit controls the operation of all boiler systems.

When the unit is started, water is pumped into the system using a pump, passing through the heat exchanger pipes. As soon as the liquid has entered the water unit, the gas supply valve opens and the burner is ignited. The process of heating the heat exchanger body occurs evenly and is controlled by temperature sensors.

Recommendations for operation and repair

- To ensure that the equipment operates for a long time and productively, you can install a voltage stabilizer, filters (gas and water), a magnetic or polyphosphate water converter, etc.

- The gas boiler must be installed strictly in accordance with the requirements specified in the passport.

- To eliminate the causes of malfunctions, you must carefully study the instructions and act according to them.

Gas boilers from the Navien company are the ideal combination of price and quality.

The main problems are why the boiler does not heat water

More often, boiler problems are detected during the heating season, when both circuits of the device are operating. There are two main problems that owners of wall-mounted gas boilers such as Ariston face:

- all boiler systems are working, the device turns on, but heats the water poorly or does not heat at all;

- the boiler does not start and, as a result, no hot water is supplied.

Each of these problems has its own causes and solutions. To troubleshoot problems, you need to figure out what caused them and what caused them.

Before finding out the reasons for the malfunction of the unit, you should look at the operating manual, read the instructions and check that the settings and connections of the device are correct.

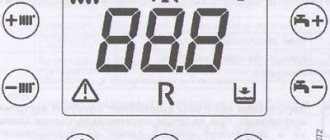

Note! Modern gas boilers are equipped with a diagnostic system that detects faults and displays an error code on the display. The instructions for the unit will help you decipher the codes.

If all requirements and conditions are met, the most common causes of malfunctions should be considered:

- Blockage. Experts say that using unfiltered working fluid increases the risk of clogging the heat exchanger pipes. The resulting scale reduces its thermal conductivity, which causes the unit to operate with excessive energy consumption. In this case, the optimal temperature regime is not achieved even with continuous operation of the device. Due to limescale deposited inside the heat exchanger pipes, the metal is subject to corrosive changes, which can lead to its rupture.

- Faulty pump. The circulation of the coolant may be stopped due to the accumulation of air, the so-called air lock in the pump. The second cause of a pump malfunction may be a rotor that is jammed. A circulation pump that stops functioning can lead to overheating of the gas boiler.

- The flow sensor is stuck. Inside the boiler there is a sensor in the form of a turbine, resembling a small fan. When the turbine rotates inside the sensor, an electrical pulse is generated due to the fluid flow, which is supplied to the control unit. This way the electrical system understands that it needs to warm up the coolant.

- The three-way valve is stuck. Such a malfunction will not allow you to switch the water supply from heating to DHW. Valve stoppage can occur due to blockage, either in the part itself or in the gas hose or filter.

- Insufficient pressure. If the volume of liquid in the system does not create the required pressure, the water supply valve does not open, which leads to burner ignition failure.

What kind of breakdowns can occur in a Navien gas boiler?

Most often, consumers choose a Navien double-circuit gas boiler; its faults are displayed on the display. Many users on the forums are interested in what error codes mean and how to fix problems.

As practice shows, the occurrence of malfunctions is mainly associated with improper installation and operation of units, as well as with voltage surges and the use of low-quality coolant.

Navien floor-standing gas boilers - pros, cons and model range

Floor-standing single-circuit gas heating boilers - what is important to pay attention to

The manufacturer has provided the following fault codes for Navien gas boilers:

- 01E – system overheating;

- 02E – lack of coolant or the flow sensor circuit is broken;

- 03E – no flame signal;

- 04E – short circuit of the flame sensor circuit or false message about the presence of fire;

- 05E – temperature sensor circuit connection failure;

- 06E – temperature sensor circuit short circuit;

- 07E – connection failure of the DHW temperature sensor;

- 08E – short circuit of the DHW sensor;

- 09E – malfunction of the coaxial chimney fan;

- 10E – failures in the combustion product removal system;

- 13E – short circuit of the heating system flow sensor;

- 27E – malfunction of the APS sensor circuit;

- 15E – malfunction of the control board.

If some error codes appear, only a service center specialist will help solve the problem. However, you can try to fix certain problems yourself without involving a technician.

Possible nuances

Today there are many gas wall-mounted boilers from various manufacturers on the market. The principle of operation of the units for all models is essentially the same, but each brand has its own nuances that may be related to the causes of malfunctions and, as a result, poor water heating.

- "Ariston" is an Italian brand that is distinguished by its reliability. The brand’s boilers are adapted to domestic utilities and operating conditions. The most common cause of malfunctions is hard water, which contributes to the formation of blockages in the heat exchanger and circulation pump.

- "Navien" - Korean autonomous gas boilers. They are easy to use and effective. A special feature of the modification is the presence of two heat exchangers and the absence of a control panel on the body. The reason why the Navien boiler does not heat hot water well may be a stop in the operation of the equipment. This is due to the air pressure sensor, which, in the presence of reverse draft in the smoke exhaust unit, sends a signal to the control board, which causes the gas supply valve to the burner to close.

- "Vailant." German quality is fully reflected in the units under this brand. Since the device is of European origin, its heat exchangers most often suffer, becoming clogged due to the poor quality of the conductive heat fluid.

- “Baksi” is another representative of Italian manufacturers of autonomous heating equipment. He has simple and reliable boilers. The main reason why the Baksi does not heat the water, as noted by specialists servicing such units, is a manufacturing defect, which is sometimes found in this model line - a South Korean manufacturer. He provided a certain algorithm for controlling heating equipment. Incorrect settings may be the answer to the question of why the boiler stopped heating water.

- Proterm is a subsidiary of the German company. When operating these boilers, you need to monitor the quality of the heat-conducting fluid and use cleaning filters to prevent clogging of the heat exchanger.

- “Buderus” is another “German” in the domestic market of autonomous heating equipment, which has proven itself on the positive side. Like all Europeans, malfunctions can be caused by the formation of limescale inside the heat exchange system, as well as clogging of the working fluid flow sensor.