The kitchen is a common area where the whole family spends a lot of time. It is important that it is comfortable and cozy, and that the atmosphere is conducive to friendly conversations.

Today, you won’t surprise anyone with warm floors; they are installed in the bathroom, residential and even domestic premises. But many people have a question: do you need a heated floor in the kitchen and how to make it?

In the article we will talk about the types of heated floors, which of them are most suitable for the kitchen, and will dwell in more detail on how to install it yourself.

Advantages of heated floors

Controversy over the installation of underfloor heating systems has not stopped since they were invented.

The advantages that are obvious:

- It becomes possible to take off your slippers and warm socks and walk barefoot on the tiles or laminate flooring in the kitchen area, which is very comfortable. This is especially true in the kitchen.

- Cold air layers are removed. After all, as you know, warm air from standard radiators goes up, the floors and the surface above them remain cold. By heating the floor this problem is solved.

- In the kitchen area there is often a need to ventilate the room, which leads to a rapid cooling of the temperature in this area. Warm floors will help quickly compensate for heat loss.

- It is very convenient to install a heating system on the floor surface on balconies and loggias, where laying paths and carpets is not advisable.

- A person feels more comfortable when his feet are warm and his head area is at a lower temperature. Underfloor heating technologies make it possible to achieve this.

What can be said against this system? Many argue that it is expensive, others say that heat-saving double-glazed windows on modern windows and radiators are sufficient to save heat.

To decide which heated floor to choose for the kitchen, they take into account the conditions in the room, whether it is a private house or an apartment, individual or central heating, the heat-saving characteristics of the building and many other parameters.

Advantages and disadvantages

Having decided to install a heated floor in the kitchen, you need to know all the advantages and disadvantages of this heating system.

Advantages of this heating:

- uniform heating of the room;

- the surface dries quickly after washing;

- there are no complicated settings and it is possible to regulate the temperature level;

- long service life - up to 40 years.

Among the disadvantages:

- difficulties when installing a heating system - dismantling of the floor covering is required;

- increased room temperature can lead to faster spoilage of food;

- high cost of equipment;

- When using electrical structures, energy consumption increases.

Types of heated floors

Various types of heated floors have been developed. The most common are water and electric. Water ones are connected to the main heating circuit, which operates in the room. That is, there is no need to install a source of thermal energy separately. If we talk about savings during operation, then this is the best option.

The water system also has disadvantages:

- They can only be installed in private households. You can’t do this in an apartment; the law doesn’t allow it. When connected to a central system, the heating level of the coolant is automatically reduced, since the power of heating boilers is designed for a certain volume, which was laid down during the construction of an apartment building. That is, it will become colder in your neighbors’ apartments. It is not possible to obtain permission to connect. Violation of the law entails heavy fines and dismantling of the system.

- Since high pressure is created in the pipes, there is a risk of leaks. And this entails expensive repairs, not only of the water circuit itself, but also of the entire floor covering. If the water circuit on the second floor breaks down, the ceiling below will also suffer. That is, the risk of repair costs exceeds the savings in operating costs.

With the electric heating method, heating cables are installed under the finished floor, in a concrete screed. Its thickness is from 3 to 5 cm.

Among the disadvantages of cable floors are long-term installation, expensive operation, that is, increased energy consumption. Installing a thermostatic unit partially solves this problem.

The undoubted advantages are high heat transfer (efficiency is close to 100 percent), the ability to install both in an apartment and in a house.

Installation of mats

Cable mats are a mesh on which a conductor is fastened with a snake. Carbon rods are connected on both sides by wire. Mats are produced in rolls. They are rolled out on the floor surface.

If it is necessary to lay 2 tapes, then the mats are rotated, but the cable or rods are not cut. It is not recommended to damage the integrity of heating elements. Cut the mesh or wire that holds the rods or cable.

The cable on the mesh remains unchanged. An additional connection is used to connect to the thermostat. Carbon tapes must be connected to each other in a parallel circuit. To do this, use the UKC connection kit.

The conductor from the first mat is connected to the thermostat. Cover the mats with a 4-5 cm screed or tile adhesive. In this case, the floor is covered immediately.

What are electric floors?

Heating elements for electric floors come in different types:

- film;

- rod;

- cable

Heating methods can be convection or using infrared rays.

Film ones are very easy to install; they are hidden under the final coating. No concrete screed is needed. This significantly reduces the time required for installation. This insulation system is installed under parquet, linoleum or laminate.

On a note. It is not recommended to lay film heated floors under tiles or carpet. When using wooden finishing coatings, you will need to control the heating temperature - no more than 28 degrees.

Film floors can be of different designs:

- Bimetallic, two-layer: aluminum and alloys based on copper.

- Carbon film heated floors. They contain copper, carbon and lavsan elements. The film is produced in rolls that can be cut to a suitable area.

- Infrared type of floors. Their peculiarity is that they do not heat the air, but the surrounding objects, which, in turn, give off heat to the room. This is a very energy-efficient heat source.

- Rod ones, which consist of carbon heating elements. They are mounted in a thin cement screed or under a tile adhesive. Such a system can be laid under tiles, porcelain tiles, carpet or laminate.

- Cable - come in the form of sections or bays. Consist of single-core or double-core cables.

Choosing a color

The choice of material for the kitchen is influenced by many factors, including the design of the premises and its colors. If the interior is decorated in a discreet black and white palette in the style of minimalism, then finishing the floor with tiles is the best choice. The staggered installation method looks stylish and expensive.

If there is a ton of white furniture, then a dark floor will help maintain the contrast. The right choice will help to visually expand the space and hide visible imperfections.

Checkerboard finish

Combined coverings look interesting - they are more suitable for a large kitchen. This technique is often used by designers for zoning purposes. It is preferable to lay tiles and linoleum in the work area, and laminate, cork, and parquet in the dining area.

There are many options and combinations, it all depends on taste and imagination.

How to make electric floors in the kitchen area

Installation of electric heated floors in the kitchen begins with calculating the surface area that needs to be heated. They make a drawing of the kitchen and mark the places where furniture and large household appliances will be installed. If objects have high legs, they are not taken into account. The usable area is taken as the difference between the total area and closed overall furniture.

The length of the heating system is calculated by multiplying the calculated area by the specific power of the heated floor.

This indicator has the following standard values:

- no more than 120 watts per square meter if heated floors are installed as an auxiliary heating source in a house or apartment;

- no more than 150 watts per square meter when the warm floor acts as the main heating source.

Be sure to prepare the surface: dismantle the old floor coverings and level the rough.

Electrical cable installation steps:

- Prepare a place for the thermostat. Use a hammer drill to make a hole in the wall for the thermostat. From it downwards they make a groove for cables - electrical power, for the sensor. A corrugated pipe is placed in it so that the blind end of the corrugation ends approximately 6 cm from the wall. The groove is sealed with gypsum mixture.

- After the rough surface has been carefully leveled, a reflective foil heat insulator should be laid on it, the foil should be at the top. The joints are glued with tape.

- In order to fix the heating sections, you need to attach the mounting tape to the heat insulator using dowels.

- The cable should be laid evenly, avoiding sharp bends and breaks.

- The floors are then poured with concrete. Layer thickness from 30 to 50 mm.

As the concrete screed dries, it is moistened from time to time to make it stronger. After the concrete has completely hardened, the floor surface is finished.

Choosing coverage

Practical coverings in the kitchen are simply indispensable for a modern person. They must meet the following requirements:

- Hygiene - easy to clean from dirt, grease, and easy to withstand the effects of aggressive household chemicals.

- Moisture resistance. The forge in the entire house is the second room in terms of humidity after the bathroom, where the floor surface is actively influenced by water.

- Wear resistance - the floor must be resistant to abrasion, durable and reliable.

- Impact resistance. Preference should be given to a coating that can withstand falling heavy objects without damage.

These requirements do not apply to every coating. But in addition to this, it should suit the overall interior of the room, look aesthetically pleasing, and be recommended for use with heated floors. It is better to study the characteristics of the finish in advance to make the right choice.

Tile

This is the optimal choice of covering for the kitchen when planning additional heating installation. Ceramic tiles retain their environmental friendliness even with strong heating. It also does not collapse or crack with repeated heating and cooling, it has maximum moisture resistance, and is easy to clean.

Tile

But a high heating rate is not always good for your feet.

You need to choose the material wisely. For example, where there is not a lot of load on the floor, thinner tile coverings are also suitable. This will allow for better heating.

When selecting a specific type of material, attention should be paid to the following criteria:

- Hardness - it is measured on the ten-step Mohs scale. For an apartment, an indicator of 5–6 is suitable.

- Water absorption. In a room with high humidity, the water absorption of the tiles should not exceed 3 - 6%.

- Wear resistance. There are 5 different classes. For light loads on the floor, class 2 material is suitable, and in other situations, class 3 and 4.

- Chemical resistance. The tile itself is a durable coating, but it is especially important to pay attention to this characteristic for the kitchen.

- Porosity. When laying with heated floors, the density of the tiles should not be too low.

After laying the tiles, the floor must be checked for evenness. You can turn on the heating only after the glue has completely dried, otherwise the quality of the work will be ruined.

Self-leveling coating

Self-leveling flooring is a good choice for the kitchen. A screed is not required for its design, because it is capable of leveling itself. Minimal maintenance is required for such a surface; self-leveling floors are easy to clean and are not afraid of moisture, scratches, or impacts.

Another advantage is the ability to choose original colors, even if you want to create a 3D effect.

But such finishing is still considered a new product, so the cost is not the most affordable. The quality largely depends on the professionalism of the installer. Some do the job sloppy, as a result the floor looks uneven, and in the light of the sun every dot or swollen bubble is visible.

Before choosing this option, you need to find a reputable company that will do the job perfectly.

When installed correctly, the surface has a long service life - more than 50 years. It retains its original appearance for a long time.

Cork

As a cork covering for the kitchen, adhesive varieties are more suitable. The advantages of using them in the kitchen include:

- if it falls and hits the floor, the dishes will not break;

- It’s nice to walk barefoot;

- the material is an excellent heat insulator;

- good sound insulation;

- does not support combustion;

- does not release toxins;

- does not slip.

Cork

Despite many positive reviews and advantages, there are also disadvantages:

- high price, more laminate, linoleum;

- use of special glue and varnish for finishing;

- it is unacceptable to leave even minimal unevenness on the base under the cork surface;

- You won’t be able to lay the floor yourself without the services of professionals;

- high probability of scratches - easily damaged when rearranging furniture with metal legs, falling sharp objects or from the claws of animals.

There is an opinion that cork flooring is prohibited from being used with a heated flooring system. It is not true. You can conduct an experiment yourself, put a piece of floor on the battery. The material conducts heat well and is not prone to fire.

How to make water contours on the kitchen floor

Despite the fact that water floors are much more difficult to make, if you have construction skills, you can lay it yourself.

To install a heated floor in the kitchen with your own hands you will need:

- A water heater with enough power to heat the water in the circuit. They leave a small power reserve of 15-20 percent.

- When floors are installed over a large area, more than 120-130 square meters, an additional circulation pump will be required.

- Shut-off valves at the entrance and exit of the water floor circuits, which will be needed during repair and maintenance work of the system.

- You need to install a collector - a block that distributes the coolant among the circuits and adjusts the heating level. Control valves will allow you to adjust the coolant flow in each circuit. As a result, the heating system will warm up more evenly.

Way out

But not so long ago (the time frame is, of course, very relative, but still) humanity learned about heated floors, which became a real breakthrough in the field of construction and finishing work. Having installed such a floor, you can now go to the bathroom barefoot with much more enthusiasm, let your child play on the floor in his room and cook dinner in one pair of socks. And all this without fear of catching a cold and getting into a lot of trouble. Warm floors are so attractive and pleasant that they can even make you sit and lie on this surface if you are tired of using chairs, armchairs and sofas for this purpose.

Heating water circuit pipes

Warm floors are equipped with the following types of pipes:

- reinforced polypropylene;

- metal-plastic;

- made of cross-linked polyethylene.

On a note. Whatever material is used for the pipes, they must be marked “for heating”. Pipes have special operating requirements: temperatures up to 95 degrees and a pressure of at least 10 bar. They are 16-20 mm in diameter.

Various installation options:

- With concrete works. The pipes are laid on the prepared surface and filled with concrete. This is a labor-intensive process, difficult to install and heavy in terms of the total weight of the system.

- Option with flooring. The water circuit pipes are laid on a special flooring. For this, wooden blocks and plastic modules are used. The disadvantage is the increase in floor heating time.

We install water heating

Water pipes with coolant are mounted in long loops. The maximum length of the circuit is no more than 100 m. The geometry of pipe laying may vary. Usually it is a snake or spiral.

The pipes are connected to a common manifold, which is placed in a separate cabinet.

The pipes are filled with screed on top, unless they are already equipped with special mats. Instead of a screed, when installation is completed, the system can be covered with sheets of fiber gypsum - this is an insulator for pipes and top decorative trim.

Laying the water circuit

How to lay heated floors

Stages of laying heated floors when the contours are covered with a concrete screed:

- Determine the location for installing the collector. It is hidden in a box that is mounted on the wall. The collector is placed in such a place that the distance of the pipes to each heated room is the same. If possible, you can place it closer to the most massive heating circuits. Among the main conditions for installing the collector is its elevation above the floor surface in order to prevent air pockets.

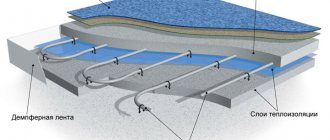

- Next, a heat-insulating layer is laid and the damper tape is secured in a circle. The insulation is placed so that the joints are covered. In case of mistakes, when the slabs could not be cut correctly and there are cracks, they are sealed with polyurethane foam. The foam that has not had time to harden will act as a good glue for the insulation layers.

- Install reinforcing mesh. When mats act as heat insulators, reinforcing mesh is not needed.

- Lay out the water circuit of the floor. There are different methods: in the form of a spiral, a loop, a snake. Maintain distances: from the pipe to the nearest wall at least 8 cm, between pipes from 10 cm to 40 cm. The pipes are attached to the reinforcing mesh using plastic clamps. It is necessary to ensure that the diameter of the pipes does not decrease at the fastening points, otherwise the contour will deform when heated. The fastening clamps are placed at a distance of one meter. Pipe turns are performed observing the minimum permissible radius.

- The laid pipes are connected to the collector. In this case, a Eurocone system or compression fittings are used. The beginning of the water floor is connected to the supply pipe of the manifold, the end pipe is connected to the return pipe. A corrugation is placed on the part of the pipe where the seam is located.

- Check the circuit. Water is supplied into it, maintaining a pressure of 6 bar. Leave for at least a day. Then inspect for leaks and deformation.

Only after making sure that the contour is made successfully can you begin to pour the concrete screed on top. In this case, water cannot be drained from the circuit; it must remain under operating pressure.

The screed takes at least four weeks to dry. Only after this period can finishing floors be made.

Wet screed device

After securing the reinforcing mesh, we move on to the screed device.

- To simplify the work, buy a ready-made dry mixture for screed (M150 or M200).

- Dilute the screed solution according to the instructions on the package;

- Start pouring from the far corner of the kitchen. To level the solution, use a long rule. To improve the quality of the screed, first install beacons on the reinforcing mesh. Level the beacons in all directions.

After the screed has dried, the beacons must be removed and the grooves from them sealed with a solution.

Screed care

A wet cement-sand screed takes 28 days to dry. For the first three days, it needs to be spilled (wetted) with water and covered with polyethylene.

The use of semi-dry screed technology with reinforcing fiber in the solution does not require spilling and covering with polyethylene. And beacons are not needed for semi-dry screed. True, you need work experience. Read a separate article about semi-dry screed in detail.

Collector unit

Before routing pipes, it is necessary to install a pipe manifold. It is selected based on the number of circuits and the desired ability to regulate heating.

Collector unit

The simplest manifolds are equipped only with shut-off valves. Regulating their operation and adjusting heating parameters is almost impossible. For these purposes, manifolds with additional control valves are selected.

Attention! The manifold must be equipped with an air vent valve and a drain pipe.

The collector is installed in a special metal cabinet, the dimensions of which are selected individually. The standard thickness is 12 cm, which allows you to “sink” it into a wall niche.

The main rules for installing a collector:

- It is prohibited to recess the manifold cabinet into load-bearing walls.

- The cabinet is positioned so that it is equidistant from all circuits. If the contours are of different lengths, the cabinet is closer to the longer one.

- The cabinet is raised above the floor level for the operation of the air exhaust system. There should be enough space under the cabinet to accommodate and bend all pipe outlets.

For details on the assembly of the collector and its operation, see the video below.