Operating principle of a long-burning boiler

Solid fuel boilers appeared relatively long ago, but all of them, regardless of model and manufacturer, had one significant drawback.

Fuel had to be constantly added as it burned. It was ineffective and not economical. This situation continued exactly until 2000, until the Stropuva company found a way to eliminate this problem. It is to engineer Edmuntas Štropaitis that we owe the invention of the long-burning boiler. Today, this is the most practical and functional device for heating a private home or cottage, the performance level of which reaches 70 and sometimes 100%. But, unlike classic pyrolysis boilers, which are also characterized by good efficiency, such units can maintain heat for 7 days with just one batch of fuel!

What are its main technical features and what makes this device so economical and effective?

Long-burning boiler design

The operating principle of a long-burning solid fuel boiler is similar to pyrolysis units. The main heat is generated not from the combustion of wood or coal, but from the gasification of solid fuel. The combustion process takes place in a closed space, from where wood gas is released through a special telescopic pipe.

After this, the gas is directed into the heater nozzle, where diffusion (mixing) occurs with secondary air pumped by the fan. Thus, a continuous process will occur until the coals or firewood are completely burned. In this case, the combustion temperature sometimes reaches 1200 degrees.

Internal structure of a long-burning boiler

The effectiveness of this principle lies precisely in the fact that solid fuel is consumed very slowly, as needed, which significantly increases the efficiency of such a heating device. But not only high performance is the advantage of this design.

As a rule, the whole point of long-lasting combustion is that not the entire load of coal or firewood burns out at the same time, but only the top layer. Due to the fact that air is supplied from above and not from below, fuel burnout occurs gradually, in its upper layer.

Long burning principle

When this layer burns out, the air supply is turned on, and exactly as much as is needed to burn the top layer. This ensures such a burning duration and the ability to control the process.

It should be said that this version of the heating device is acceptable exclusively as a heating system. If you need to think about a water heating system for domestic needs, then you should look for other options.

If the option is selected specifically for heating a large house, then such a device is an excellent alternative to electric and gas appliances.

Ways to save coal

Coal consumption is high during the heating season, so home owners want to reduce it. There are several ways to help you save some money:

- Insulate the windows and prevent cold air from entering through other cracks. Thanks to this, the room will be warm if the boiler operates in moderate mode.

- Providing quality heating throughout your home also saves fuel by keeping rooms at the optimal temperature.

- It is allowed to reseed combustion residues that are regularly removed from the ash pan. They often contain lumps of coal that can be re-loaded into the firebox. However, it is necessary to carefully sort out the waste, since those that are unsuitable for combustion will worsen the process and reduce the efficiency of the new portion of fuel.

- During the combustion process, it is necessary to control the air supply. If the draft is too strong, the coal burns out faster, so refilling is required. At the same time, the house does not become warmer, since a significant part of the heat is lost due to increased draft.

- Insulate the windows and prevent cold air from entering through other cracks. Thanks to this, the room will be warm if the boiler operates in moderate mode.

- Providing quality heating throughout your home also saves fuel by keeping rooms at the optimal temperature.

- It is allowed to reseed combustion residues that are regularly removed from the ash pan. They often contain lumps of coal that can be re-loaded into the firebox. However, it is necessary to carefully sort out the waste, since those that are unsuitable for combustion will worsen the process and reduce the efficiency of the new portion of fuel.

- During the combustion process, it is necessary to control the air supply. If the draft is too strong, the coal burns out faster, so refilling is required. At the same time, the house does not become warmer, since a significant part of the heat is lost due to increased draft.

Some people remove the damper altogether, mistakenly assuming that this will help warm up the room faster. As a result, the coal burns instantly, but there is no heat in the house. If none of the methods help reduce the amount of fuel used and the rooms are still cool, it is recommended to re-check all windows and doors, and also ensure that there is no possibility of cold air entering through openings in the floors. Quite often they are invisible under the baseboards and do not allow achieving optimal temperature conditions.

3eeb01feaa154e4bff8a36d63e994dd7.jpeWhat are modern boilers equipped with?

Most models of domestic and foreign manufacturers are equipped with thermal insulation, which helps reduce heat loss. In such boilers, a control unit equipped with a fan often replaces an automatic draft regulator.

To adjust the combustion intensity, you can select an automatic or manual air supply regulator to the combustion chamber. Low-power boilers with manual adjustment are convenient to use because they allow you to adjust the draft in accordance with the selected temperature regime.

Double-circuit solid fuel boilers are also in great demand, performing two functions simultaneously: heating the premises of the house and providing its residents with hot water. When choosing a device, it is worth determining for yourself whether it will be the main or auxiliary element of the system.

Scheme: operation of a solid fuel boiler

If you focus on the cost of a solid fuel boiler, then it is better to give preference to units from foreign manufacturers in the middle price segment. The only significant difference from expensive analogues will be the absence of complex electronics.

Its main task is to control the combustion process taking into account the temperature of the interior and exterior air, thereby simplifying the operation of the unit.

Rating of combined boilers

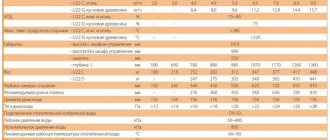

A large number of different models sometimes causes difficulty in choosing even for specialists, not to mention ordinary buyers, so we publish the top 5 models. For clarity, let's summarize the data in a table.

Table 1. The best models of 2018-2019

| Model | Fuel types | Description | power, kWt | Efficiency,% | Weight, kg |

| ZOTA MIX-20 | Coal, firewood, gas, diesel fuel electricity | A model from a Russian manufacturer that consumes basic types of fuel without problems. Withstands short-term pressure increases up to 4 atm (working 3 atm). The material of the heating elements is a seamless stainless steel tube. Their operation is controlled by an external control panel. The device is also equipped with a draft regulator and a thermomanometer, which increases the efficiency of the combustion process. To protect against heat loss, the water jacket is insulated. Wear resistance of the outer casing is achieved thanks to powder paint coating. | 3-9 | 80 | 140 |

| KARAKAN 16TPEV 3 | Firewood, gas, electricity | The dual-circuit model of the Russian manufacturer is especially popular among rural residents, because It is equipped with a wide hob on which you can cook food for yourself and your livestock. The unit can easily heat an area of up to 160 sq.m., this applies not only to residential, but also to industrial premises, incl. greenhouse or garage. The depth of the steel firebox is 0.56 m. The “water jacket” prevents the metal from overheating or burning out, which makes the device’s service life long. | 9 | 75 | 120 |

| Teplodar Cupper PRO 22 | Firewood, coal, gas, pellets | The domestic model can easily heat rooms up to 220 sq.m. When using firewood or coal, the unit acquires the features of a long-burning boiler, since on one tab the operating period is 8 and 10 hours, respectively. Another plus is the spacious firebox, which can accommodate firewood up to 600 mm long. | 6 | 80 | 115 |

| Kiturami KRM 30R | Firewood, briquettes, coal, diesel. | The double-circuit boiler from South Korea is equipped with several combustion chambers and electronic control. Capable of heating a room up to 350 sq.m. The heat exchangers are made of alloy steel, so you should not increase the pressure too much. | 35 | 85-92 | 170 |

| Protherm Bison 40 NL | Gas, diesel, fuel oil | The double-circuit model from Slovakia is capable of heating areas up to 400 sq.m. The control is carried out using a microprocessor, and the electronic display clearly shows the operating parameters of the boiler at any given time. | 38 | 89 | 148 |

Appearance of the Protherm Bizon 40 NL boiler

The best known manufacturers and models with prices

The Russian market for climate control equipment is saturated with coal-fired boilers, both domestic and Western-made. Moreover, Russian modifications have the best price-quality ratio.

Boiler Protherm Beaver 20 DLO

However, at present, the most functional ones with automatic operation are coal units from European companies.

For example, the following models became popular models of coal boilers with a 200 m2 area, according to buyers, in 2022:

- ZOTA “Master” 20, price as of 01/01/2020 - 31,889 rubles.

- Protherm “Beaver” 20 DLO, price as of 01/01/2020. — 38,440 rub.

- Bosch “Solid” 2000 B SFU 12, price as of 01/01/2020 - 51,430 rubles.

- Stropuva S15U, price as of 01/01/2020 - 39,789 rubles.

- Buderus “Logano” S181-15 E, price as of 01/01/2020 - 258,800 rubles.

- Teplodar "Kupper" OK 20, cost as of 01/01/2020 - 28,340 rubles.

- Thermocraft "Uragan" Prof 22, cost as of 01/01/2020 - 34,650 rubles.

Operating principle of the equipment

The working process is based on the combustion of fuel in the corresponding chamber

It is important to note that different materials can be used as fuel. For example, for a combination boiler, wood and coal are not the only energy sources

Such models can accept briquettes, pellets, husks and shavings. But for this it is necessary that the design of the chamber be oriented towards working with other types of solid fuel.

Regardless of the type of raw material consumed, the firebox releases thermal energy, which can be directly converted into hot air flows, or go into a heat exchanger to heat water. If a coal-fired boiler is used, the combustion process will be long and the thermal energy potential will be high. In contrast, low-density dry firewood or briquettes with chips burn quickly, leaving little heat but a lot of ash and ash.

What coal to choose for the fire?

What is coal? This is a product of plant origin, which contains carbons and non-flammable impurities. It is they who form ash and slag-like substances after burning. The ratio of the two components is different everywhere. It is this, as well as the “age” of natural fuel, that determines the grade of coal. Experts distinguish several varieties.

The “youngest” type of coal is lingite. It has a rather loose structure. If you pick up a lump of lingite, it will quickly crumble and lose its shape. This type of coal is most often used in thermal power plants, but lingite is not suitable for heating a home.

In addition to lingite, brown coal, hard coal, and anthracite are also mined - the most ancient carbon deposits. All varieties have different humidity levels. In brown coal, for example, humidity is 50%; in anthracite its threshold does not exceed 7%. Therefore, anthracite has the highest specific heat. Its indicators are 9 thousand kcal/kg. Coal has a lower figure - 5.5 kcal/kg. The brown variety has a specific heat of only 3 kcal/kg. Considering all this, it is easy to understand what type of fuel to purchase for heating the house.

Automatic boilers

Long-burning automatic coal boilers offered on the modern market are designed on the principle of pellet installations. Their feature is the presence of a burner device and a bunker for loading fuel reserves. The design of the heat exchange part of the units repeats the design of their traditional “brothers”; a fire tube heat exchanger or other multi-pass design is used to transfer heat.

The main feature is the retort type burner. It consists of a bowl - a retort, a feed auger with a gearbox and an electric motor, and a fan for forcing air. Coal from the hopper will fall into the receiving hole of the feed auger, which moves it into the bowl. The latter has side slots for the flow of air pumped by the fan.

Such a coal-fired boiler is fully automated, from the electric ignition operation to the control of combustion intensity. The operating time of the unit is not limited by the fuel supply, which can be replenished by pouring it into the bunker on the move. Only the frequency of maintenance and cleaning requires stopping the boiler once a week.

A prominent representative of this type of heater is an automatic coal boiler of the Heiztechnik brand, equipped, in addition to the main components, with a circuit for supplying hot water, a circulation pump and a programmable controller with the ability to connect external thermostats. The controller controls the operation of the burner and can stop it at any time, which is a significant advantage for solid fuel units. Another plus is the ability to quickly install a grate, remove the burner and continue working with traditional direct combustion of fuel in the firebox. The efficiency of the unit is declared by the manufacturer at 88%.

The disadvantages of a coal boiler with a screw burner are its high cost and demands on the quality of fuel. The Heiztechnik manufacturer's requirements are as follows:

- fraction size – no higher than 25 mm;

- humidity – up to 10%;

- dust content in fuel – no more than 20%;

- coal for automatic boilers - medium-coking, type 31 or 32, not higher.

How to melt correctly

The algorithm of actions looks like this:

- It is required to place sheets of dry paper at the bottom of the firebox. Then, a small layer of wood chips, logs, preferably fruit varieties. To speed up the combustion, it is necessary to arrange them in a pyramid.

- Set the paper on fire. Then close the door, but leave the ventilation hole open. Due to which you can regulate the rate of combustion of firewood. Moreover, depending on the volume of oxygen, the fuel will burn faster or slower.

- After complete combustion of the wood, you need to place a layer of small coal, up to 15 cm, on the resulting pile of ash.

- When it burns sufficiently, you can pour a larger mineral on top in the form of a pillow. The height can reach 60 cm. Before doing this, be sure to move the hot stones apart so that the coal does not bake.

If you use fuel of insufficient quality, coking may occur. Therefore, if you are not sure of the quality of the purchased raw material, put it in the form of a sandwich, mixing it with firewood. Several layers of logs, successively mixed with stone, make it possible to sufficiently warm up the installation and release heat into the premises.

Advantages of boilers of this type

As mentioned above, a modern coal-fired boiler has much in common with a classic Russian stove. But if a hot brick fireplace directly heats the air in the house, a coal boiler heats water, which then circulates through the radiator system of the heated room.

In all other respects, solid fuel boilers for heating a private house embodied the versatility of their original Russian predecessor. For example, they are unpretentious in the choice of combustible material and allow you to charge firewood, briquettes, pellets, sawdust, paper waste, rags, which in itself is a good idea for recycling combustible waste.

On the other hand, of course, operating a boiler using “frozen” fuel requires more control: you will have to monitor instrument readings and replenish the tank more often. And since such raw materials burn unevenly, temperature changes are possible in the radiator system. Not to mention the fact that garbage that is not used as fuel leaves carbon deposits and soot that need to be cleaned.

Therefore, despite the abundance of waste fuel, prudent (read lazy) owners acquire a large supply of long-burning coal. Using such a heat source, the stove can operate for several days without requiring additional maintenance, cleaning or even refueling.

Unlike a Russian stove, which requires compliance with a certain kindling technology, a coal boiler is extremely easy to use - just open the firebox and throw coal inside

This operation requires a minimum of precautions; the installation and operation features of a coal boiler mean that all potentially dangerous processes are controlled automatically

Another advantage of a coal boiler is its high efficiency, and the use of modern energy-saving technologies has doubled the productivity of new solid fuel boilers compared to old-style coal stoves.

Of course, for a city dweller, spoiled by centralized heating and water supply, the need to load the tank from time to time may seem tedious, but only at first glance. Almost all modern coal-fired boilers make the most of a single load, and temperature control is carried out by sensor systems and air supply devices.

Due to their high efficiency and safety, coal fuel boilers are successfully used for heating cottages and summer houses, residential buildings and offices. But, of course, coal equipment finds ideal use in private residential construction, where its surface can also be used to heat food.

Installation Features

A separate room is allocated for the installation of coal equipment. The room must have good ventilation and a well-built chimney. For the boiler itself, it is often necessary to make an additional reinforced base, since the weight of the device can exceed 300 kg.

The floor must be covered with non-combustible material. The simplest options are concrete pouring or steel sheets laid on top of the existing coating. A similar material is also used for wall decoration. When installing the boiler, you need to choose a place to store coal.

Criteria for selecting long-burning solid fuel boilers

We have already become familiar with the general classification of solid fuel boilers. It's time to consider the criteria by which owners of private houses determine the optimal options for units for installing heating systems. After reading the following sections, you will learn how to choose the right long-burning solid fuel boiler for your home.

Type of fuel

First of all, you must decide what fuel will be used for heating. Based on what type of fuel is more convenient to buy and import. If you have harvested wood, it would be wise to purchase a wood-burning boiler. Owners of cottages where there are no trees can recommend heating with pellets. Coal boilers are suitable for those who have the opportunity to order high-quality fuel on favorable terms. Sawdust heating systems are typically used to heat wood processing facilities.

Boiler power

To determine the required power of the heating system, you need to make simple mathematical calculations. Calculate the total volume of the premises you are going to heat. The resulting figure will help you find a model with the appropriate parameters in a wide range of long-burning solid fuel boilers. Keep in mind: you should always provide a power reserve so that during severe winter frosts the house does not become cold.

Device weight

When choosing a long-burning solid fuel boiler for heating a private home, the mass parameter is taken into account only if the owner intends to mount the purchased unit on the wall. According to state standards established by the Russian gas service, this installation method is allowed for heating boilers with a volume of less than 100 liters

Loading chamber volume

This parameter characterizes the ratio of the volume of fuel supplied to the power of the heating unit. The more fuel that fits in the loading chamber, the less often you will have to replenish the supply of firewood/coal/pellets. For steel boilers, the ratio of these values is 1.6-2.6 l/kW. Cast iron heating units consume fuel in smaller quantities - 1.1-1.4 l/kW.

The total volume of the loading chamber will help you roughly estimate the capabilities of the boiler. In any case, you will not be able to fill it 100%. The usable volume of the loading chamber is much more important. This value reflects the actual amount of fuel that you can load into the combustion chamber. To determine it, you need to know the principle of combustion of the selected boiler and the method of loading fuel (top or front).

Boiler efficiency

One of the most important parameters for any long-term combustion solid fuel heating unit. The figure expressing the efficiency of the boiler characterizes that part of the generated thermal energy that is actually spent on heating the home. By choosing a unit with a high efficiency, you can reduce power requirements. Low efficiency means waste of heat, so you will have to add more fuel to maintain an acceptable temperature in your home.

Materials for making the case

Manufacturers produce heating units in housings made of various materials.

Steel

Solid fuel boilers in a steel casing.

Inexpensive options are made from thin sheets. High-quality boilers are made of heat-resistant or high-carbon metal 4 mm thick. The advantages of boilers in a steel casing include:

- withstand temperature and pressure fluctuations;

- ease of transportation and installation;

- maintainability - cracks are treated with a welding machine.

The disadvantages of the devices are the risks of heat exchanger corrosion, thinning and burning of the walls, and the inability to increase power.

Cast iron

The body is made of cast iron, the service life of which is more than 25 years.

The boiler in the cast iron body is made on the basis of cast plates connected by bolting. The joints of the parts are treated with heat-resistant sealant. Thanks to the design, sections can be added to increase power. The advantages of boiler systems include:

- corrosion resistance;

- long-term operation - about 50 years;

- heat capacity due to the properties of cast iron and a small heat exchanger;

- maintainability - just replace or add a section.

The disadvantages of a cast iron body are cracking during temperature fluctuations, low efficiency and a one-pass heat exchanger.

Pyrolysis systems

Scientists have long noticed that the combustion of any solid fuel releases carbon dioxide, which can be used as additional fuel. This process is called pyrolysis. When wood burns, quite a lot of such gas is released. That’s why wood-burning pyrolysis boilers have become so widespread.

The operating principle of such devices is quite simple. Fuel is placed in the first combustion chamber. With little air supply, the firewood smolders and releases pyrolysis gas. which enters the second chamber. Here the gas is burned and heats the coolant of the home heating system.

This device can significantly increase the efficiency of a wood-burning boiler. The efficiency of such devices reaches 90% and higher. In addition, long-burning pyrolysis boilers have other advantages, namely:

- the fuel burns almost completely. There is no need to constantly remove numerous combustion products;

- The boiler operating time on one charge increases. It is enough to “throw” firewood into the firebox once every 15 hours;

- fuel consumption is significantly reduced, which entails savings on heating the house;

- The devices are environmentally friendly. During the combustion of pyrolysis gas, no harmful substances are released into the atmosphere. When they burn, carbon dioxide and water vapor are produced;

- it becomes possible to completely control the combustion temperature;

- Long-burning pyrolysis wood boilers are unpretentious in maintenance.

But, despite all its advantages, pyrolysis equipment is not without its disadvantages. Among them are the following:

- Pyrolysis boilers are quite expensive equipment. For many families, it may simply not be affordable. But such devices will allow you to save on heating your home, which offsets the cost of purchasing equipment;

- boilers are heavy and have impressive dimensions due to their complex structure;

- quite demanding on fuel quality. The firewood must be dry, the efficiency of the device depends on this;

- the need for a constant supply of electricity. The device contains blower fans that require electricity.

The high cost of long-burning pyrolysis heating boilers significantly reduces their popularity. But many craftsmen make such devices themselves. Schemes and drawings can be easily found on the Internet.

Fuel briquettes

In its composition, this type of fuel is similar to pellets, but looks somewhat different: briquettes are larger and can be not only cylindrical, but also of any other regular shape. The starting raw materials are the same wood chips, sawdust, and shavings. Organic residues of plant crops grown in agriculture are also widely used.

Some types of fuel briquettes are made exclusively from dry pine needles. Perhaps this is the only option for their useful use

Fuel briquettes have the same advantages and disadvantages as pellets. The main difference still comes from the size: briquettes are not suitable for automatic loading, so they are placed in the firebox manually. Products with an aesthetic appearance have gained popularity among owners of fireplaces and decorative stoves due to the almost complete absence of smoke during combustion.

Fuel briquettes are produced in various standards:

Pini-kay

Although the company with a similar name has already closed, the introduced technology is thriving. The briquettes are dark in color and have a hexagonal shape with a central channel. Pressure during molding – up to 1100 bar + exposure to high temperature. Best characteristics and high price.

RUF

Popularly known as “bricks”. These briquettes are indeed made in the form of small parallelepipeds. Formed at pressures up to 300 bar.

Cylindrical shape

Sometimes with a longitudinal hole. Working pressure – up to 600 bar.