Navien boilers are modern heating equipment equipped with automation and a protection system. Sensors for detecting problems of varying levels of complexity allow the user to eliminate many minor problems on their own, without resorting to the services of a service center. The accompanying instructions contain codes that characterize a particular problem in the operation of the boiler. Based on this list, the user can easily find information on solving many problems. In this material we will analyze error 03 and tell you how to fix it.

It is important to mention that for high-quality and long-term operation of the equipment, it is necessary to adhere to the universal rules for operating high-tech devices:

- Responsible approach to equipment installation, carried out in strict accordance with the instructions.

- Using high-quality components and materials that will ensure uninterrupted operation of the equipment for a long time.

- It is important to carry out preventive maintenance of equipment (inspection and cleaning of components).

- Do not forget to check the readiness of the equipment for operation (gas supply, sensor condition, water supply).

By observing these conditions, you can avoid rapid wear of equipment and frequent breakdowns.

The Korean company strives to minimize information on user intervention in fixing problems. This is caused by the manufacturer’s concern for the safety of customers who may make mistakes in fixing a technical problem and thereby harm themselves and their loved ones.

It is important to remember that Navien boilers are complex and explosive equipment. Therefore, troubleshooting on your own must be done with the utmost care, following the clear instructions of specialists.

Design Features

Boiler structure

To attract the attention of buyers, the Korean manufacturer developed a perfect design of the gas unit, minimized the number of breakdowns and released its product at a relatively low price. One of the advantages of a gas unit is the clear and detailed instructions, which greatly simplifies setting up the selected mode.

The company adheres to the same principles in installing an electronic control system and regulating other parameters.

The versatility of a gas boiler can be judged by its operating capabilities:

- The regulation circuit with a microprocessor chip allows you to both protect and smooth out voltage surges in the power supply network. In case of changes in the current parameters, the electronic system is able to maintain a mode for the full functioning of all components of the unit, which has a positive effect on the operational life of the device. The adjustment circuit also allows you to avoid possible malfunctions due to false activation of sensors. This feature of the electronic system is of particular importance for the operation of the equipment, given the instability of the voltage in the power network and its deviations over a wide range.

- The design of the gas boiler is designed taking into account a possible drop in water pressure to 0.1 bar. This allows blocking actions and device breakdowns to be reduced to a minimum, which is ideal for its installation on the upper floors of a building.

- The Navien boiler is capable of neutralizing possible malfunctions caused by a decrease in supply pressure to 4 mbar, which is critical for the normal functioning of many modern systems equipped with electronic control.

- Thanks to the design features of the Navien gas appliance , the heating system will not freeze even when the gas supply is cut off. To prevent the emergency mode from being activated when the coolant temperature drops below 5 degrees, as well as the inability to ignite the burner, a built-in pump was provided for forced and continuous circulation of water.

- There is a double heat exchanger for separate heating of hot water and coolant, which is very convenient (you can optionally adjust the preheating of water). Easy-to-use electronics allow you to precisely set the appropriate mode.

Line diagnostics

A problem with the gas supply to the Navien boiler is expressed in a blockage of the path or low pressure. The method for searching for the “culprit” of error 03 depends on the connection diagram of the unit to the main line or tank with “blue fuel”. If the building has a gas stove, the task is simplified . You can determine if there are problems in the pipeline by igniting the burner.

It is also easy to check the pressure by turning on all of them: by the intensity of the flames and their stability, it will become clear whether it is sufficient for the normal functioning of the equipment. For gas boilers, and Navien is no exception, there is a lower response threshold. And if gas flows, but the pressure in the line is below critical, error 03 is inevitable.

For objects without a stove or with a Navien boiler connected via a separate line, the following procedure for diagnosing system elements is recommended.

Shut-off valve controls

- After the Navien boiler is taken out of operation for some period,

the gas path must be shut off , which is what most users do. But before starting up the heating installation, many people forget that the pipeline themselves was blocked. - If a shut-off valve is installed at the facility, when the voltage on the line is turned off, it is activated; cocked manually.

Solenoid shut-off valve

Counter

non-working meter also causes error 03 of the Navien boiler. It is sealed, but the user can verify its normal functioning visually. You need to try to turn on some kind of gas appliance to ensure the consumption of “blue fuel”.

Filter

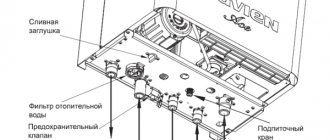

Its mesh needs regular cleaning . During operation of the Navien boiler, the cells become clogged with ice and other solid fractions deposited along the pipe. Pulling the mesh out of the glass, rinsing it and putting it back in place takes just a few minutes.

Navien boiler heating system water filter. It is necessary to systematically clean the filter, since its contamination is one of the reasons for boiler overheating and error 02

Storage tank

With an autonomous gas supply, the Navien boiler is connected to a gas holder or cylinder group. If we are not talking about maximum fuel consumption, the cause of error 03 is the gearbox. Typical faults: icing or dirt blocking the channel. In any case, solving the problem is not difficult.

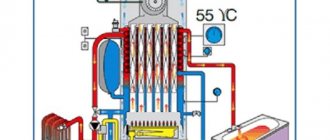

Operating principle of the Navien boiler

The operating principles of modern gas boilers are almost the same for all manufacturers, the only differences are in the configuration of the equipment and the internal arrangement of the actuators. The flow diagram of water in the boiler is shown in the figures. The Navien boiler works either to maintain the required temperature in the CO, when heated water from the first heat exchanger is pumped by a circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, and the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from the flow sensor located on the hydraulic unit with the make-up tap.

Differences between Navien Ace and Navien Delux

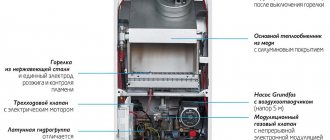

Navien Delux is a modified model that replaced Navien Ace. Navien Delux Coaxial is a series of boilers with two heat exchangers with a power from 10 to 30 kW with a closed combustion chamber and forced smoke removal using a turbine. The manufacturer notes the following features of Navien Delux:

- Frost protection system. Unlike boilers from other manufacturers, in addition to automatically turning on the burner when the temperature drops below 6 degrees, at temperatures below 10 degrees the boiler ensures continuous movement of the coolant by activating the circulation pump.

- Fan with variable speed. Navien Delux boilers are equipped with a turbine with adjustable blade rotation speed depending on the readings of a special air pressure sensor. This ensures an optimal gas-air mixture ratio and increases boiler performance.

- The heat exchanger is made of stainless steel. By using a fan with variable rotation speed and increasing combustion efficiency, it became possible to replace the copper heat exchanger with a stainless steel heat exchanger, which certainly has a significantly longer service life.

- It is also noted that the boilers are protected from the influence of mains voltage surges by a special protective chip and the ability to operate at low (up to 4 mBar) pressure of main gas and water. In other words, the manufacturer tried to make a product that is maximally adapted to the worst operating conditions.

User manual

Navien gas boilers are operated automatically, with minimal human intervention.

The owner only needs to observe the readings on the display and respond in a timely manner to the appearance of an error code.

In addition, the user determines the operating mode - summer or winter:

- Summer mode is determined only by DHW heating.

- Winter mode starts the heating system simultaneously with the supply of hot water.

The display has a button with a corresponding icon (symbol of a snowflake or sun).

If it is necessary to adjust the extract air temperature or other parameters of the heating system, the winter operating mode must be turned on. Exhaust temperature is adjusted when the radiator icon is flashing.

If it lights up steadily, the display shows the current temperature . By pressing the “radiator” button so that the icon flashes, press the “+” or “-” buttons to change the set coolant temperature.

The icon stops flashing after a while (a few seconds), and the boiler will begin to heat or cool the coolant in accordance with the instructions received.

Solving the problem with error "10"

Sometimes the Navien boiler displays error “03”, but in some cases you may notice that the display shows code “10”. This may occur due to a malfunction of the fan. The tubes may be damaged or incorrectly connected. They must go from the fan scroll to the pressure sensor. Sometimes a clogged chimney causes error “10”. However, in some cases, strong gusts of wind may cause the boiler to display the above error. Malfunctions can be eliminated by replacing or repairing the fan. The chimney should be cleaned, but check it first. The tubes from the sensor must be connected correctly; it is important to avoid kinks, if any.

Running self-test

The Navien boiler self-diagnosis system operates constantly and does not require a separate startup.

The probability of a failure of one or another node exists at any time, so the sensors send signals about the status of certain elements 24/7, never stopping.

If the sensor stops working for any reason, the corresponding error code immediately lights up on the display. This is an important function that helps maintain performance and timely troubleshooting .

Navien boiler error 02

Error 02 is caused by the heating circuit flow sensor located at the outlet of the main heat exchanger. If nothing prevents the movement of water in the CO circuit, after turning on the pump, the sensor contacts close and the signal is registered by the control unit, otherwise error 02

.

The following main reasons can be identified:

- low pressure in the heating system (to control the pressure, Navien boilers are equipped with a dial pressure gauge located on the front cover - you need to check and, if necessary, feed the system to 1.2-1.5 bar)

- failure of the flow sensor (to check, measure the resistance of the sensor before and after turning on the pump)

- no circulation in the heating circuit

- control board is faulty

Lack of circulation means that for some reason the coolant cannot move normally through the heating pipes. Obstacles can be: clogged cleaning filters, freezing of a section of the pipeline, closed taps around the perimeter of the heating system, the presence of an air lock or a malfunction of the pump.

To remove air, you can try to start the boiler in a special test mode, after first opening the air vent valve on the pump. To activate the test mode, you need to turn off the boiler and move switch No. 1 on the DIP-Switch block of the board to the ON position. We will discuss the testing of actuators in more detail in a separate article.

We recommend watching a video in which one of the users simulates error 02 on a Navien boiler:

Causes of malfunctions and their elimination

To understand how to troubleshoot a particular problem in a gas unit, you need to know the causes of malfunctions:

- Code 01E indicates an increase in the temperature in the device. This is possible due to blockage in the ducts, which caused them to narrow, or there were problems with the circulation pump.

- Code 02E indicates the presence of air, insufficient water, damage to the impeller in the circulation pump, a closed distribution valve, or the flow sensor has become unusable.

- Code 03E is displayed as a result of problems with the ionization sensor, lack of gas supply, lack of ignition, when the tap is closed, or when the boiler is not properly grounded.

- Code 05E indicates poor contact between the temperature sensor and the controller, or a short circuit in the same area.

- Code 10E is displayed on the screen if the fan fails, as well as if the sensor tubes are incorrectly connected directly to the fan. In addition, a clogged chimney or a strong gust of wind can also cause the device to malfunction.

- Code 11E , as a rule, is displayed on European-made boilers (with appropriate sensors).

- Code 13E indicates a short circuit in the heating water flow meter.

- Noise and hum may occur if the coolant is poor.

- The reason for the lack of hot water is the valve , which has become unusable. The optimal valve service life is 4 years.

How to fix:

- Error 01E: carefully inspect the impeller in the circulation pump to detect various problems; check the resistance in the pump coil itself; examine the heating system for the presence of air (bleed off excess).

- Error 02E: deflate; check the pressure and resistance in the coil; whether a short circuit has occurred; open the valve (distribution); check the resistance in the flow meter; remove the sensor housing and clean the flag.

- Error 03E: clean the flame sensor from debris (you can use fine-grained sandpaper to get rid of gray deposits on the electrode).

- Error 05E: examine the circuit from the controller to the sensor. If there are problems, the sensor should be replaced with a new one. The meter and controller connectors must first be disconnected and then connected.

- Error 10E: repair the fan or replace it; check the connections on the tubes of the measuring device; Clean the chimney of all kinds of debris.

- Error 13E: replace the sensor.

You can get rid of noise and hum by disassembling the product and cleaning the heat exchanger. If the problem cannot be solved, the part must be replaced. Inspect the taps; they should be open as much as possible. Reduce water temperature.

Equipment diagnostics

Ionization sensor

When looking for the cause of error 03 in the Navien boiler, you need to start with the measuring device. Repair practice shows that most often this is the culprit.

Possible defects

- Problems with the signal line. Error 03 Navien can be initiated by a wire break, damage to its insulation (and therefore a short circuit to the boiler body or to each other) and unreliable contact (oxidation of the lamellas, loose fitting of the plug). It’s easy to visually identify the defect and fix it yourself.

The sensor grounding wire (housing) requires special attention A feature of the Navien boiler circuit, which not everyone knows about, is the inclusion of resistance in this circuit. It happens that the resistor burns out , the line breaks, and error 03 is displayed. You can check for integrity with a multimeter: when measuring, the device should show R within 0.5 MOhm.

- Electrode contamination. You need to unscrew the fasteners, remove the assembly from the socket and clean the measuring element from carbon deposits, soot, and stuck-on dust.

Navien boiler ionization sensor

Location of the ionization sensor in the Navien boiler

Ignition transformer

In the boiler, Navien is located under the electrode assembly. Burnout (break) of the TP winding also causes error 03 to appear. Continuity testing is simple: with a multimeter with the “kOhm” mode set.

Gas valve

Error 03 is triggered by a problem with one of the 3 coils. As a rule, modulation has nothing to do with it: combustion of its winding is an exceptional case. But two shut-off valves in Navien boilers sometimes fail.

Error 03 of the Navien boiler, initiated by a problem with one of the 3 coils

Suitability test

- When the heating system is turned on, two characteristic clicks should be heard. If there is only one, then some shut-off coil is faulty.

- The windings are checked, as when testing a transformer, with a multimeter. It should show a resistance of about 5.6 kOhm.

The appearance of error 03 Navien may be caused by a malfunction of the boiler electronic board . But it is tested for functionality and repaired only in a service workshop. On your own, without experience, relevant circuits and instruments, it is better not to experiment, but to immediately turn to professionals.

Recommendations for operation and repair

- To ensure that the equipment operates for a long time and productively, you can install a voltage stabilizer, filters (gas and water), a magnetic or polyphosphate water converter, etc.

- The gas boiler must be installed strictly in accordance with the requirements specified in the passport.

- To eliminate the causes of malfunctions, you must carefully study the instructions and act according to them.

Why does blood pressure drop?

The cause of a drop in water pressure in the system can only be a leak. At the same time, it can be both in the boiler itself and outside it - in pipelines, radiators, etc.

We recommend: Double-circuit floor-standing gas boiler: specifics of device and choice

It is necessary to open the feed valve, start the boiler and carefully inspect the entire system, step by step. If no leaks are found, the boiler must be inspected. When looking for the cause, you should be guided by the rate of pressure drop.

Perhaps the water goes into the expansion tank, in which the membrane has ruptured. Another reason could be a worn safety valve. If it is connected to the sewer, the leakage will not be noticeable.

NOTE! In any case, the drop in pressure indicates that it is going somewhere. It is necessary to find the leak, otherwise it may get wet and destroy the structure of the house.

Checking the operation of the ignition electrodes

At the next stage, we will check for the presence of a spark at the ignition electrodes. Using a Phillips screwdriver, you need to unscrew the two screws that secure the electrode block in the combustion chamber. And then carefully remove the electrodes and pull them out of the boiler firebox. Let's connect the power supply and put the boiler into operation. The pump starts up, the fan turns on, we hear the gas valve closing the coils open, but ignition does not occur. No spark. I'm guessing the problem is with the ignition transformer. It requires replacement. Let's turn off the boiler and turn off its power supply.

Check if the spark plug produces a spark

Reasons for increased pressure

An increase in pressure in the boiler is primarily demonstrated by the safety valve, which begins to release excess pressure. This problem often confuses even experienced specialists.

The reason lies in the secondary heat exchanger. Hot water is heated from the already heated heating agent, receiving energy in a plate secondary heat exchanger. Both liquids exchange thermal energy without mixing with each other.

But, if a fistula occurs, allowing water from the hot water system to penetrate into the heating system, the pressure will increase and tend to balance with the higher pressure of domestic hot water.

If such a problem occurs, the secondary heat exchanger should be replaced, since repairing it is complicated and ineffective.

Extraneous noise without errors

If you also decide to purchase a Navien boiler, error “03”, the reason for which was mentioned above, may also occur to you. But sometimes the operation of the equipment is accompanied by extraneous noise, which is not normal, but the display does not show errors.

You may hear a humming sound when you turn on the hot water. This situation, admittedly, arises quite often. It is due to the fact that the heat exchanger becomes clogged; this is a consequence of using low-quality coolant. If you are faced with such a situation, then the heat exchanger needs to be replaced, but first, at least just clean it.

Power-on problems

There may be several reasons for such a malfunction.:

- There is no voltage in the network (or it has decreased too much, it has become less than 150 V).

- No gas.

- The boiler is blocked by a protection system that was activated due to a critical error (overheating above 98°).

Other reasons for failure may also occur . First of all, you should check the voltage in the network.

The boiler is capable of compensating for fluctuations of up to 30%, but with more significant changes, it simply will not start. You can solve the issue by using a separate outlet and installing a stabilizer.

If all possible causes have been checked and eliminated, but the boiler continues to be silent, you should invite a specialist . Perhaps the cause was a failure of the control unit, a breakdown, or another serious problem.

You should not attempt to resolve the issue yourself; this may cause the final destruction of the unit.

MORA boiler and EFD-503 control units

Case from practice. Several EFD-503 units came in for repair. Such blocks are installed directly on the gas fittings and are used in boilers MORA, BERETTA, PROTHERM and others. So, specifically in this modification of the block, the error reset occurs through the closure of two contacts on the block itself, and the switching is displayed on the control panel with a button. The client says I change the blocks regularly once a year. Tired of replacing it (the price of 1 unit is approximately 10 thousand, and there are two of them in the boiler), he turned to us for repairs. In fact, faults were identified and corrected on the units provided - the units were sent back. Installation result: 1 unit works, two worked for 20 seconds, went into error and no longer work.

The probability that the control unit only worked for 20 seconds after repair is very small (even more so if there are two units at once). A more suitable description of the malfunction is “phasing error” - non-compliance with the polarity of the connection. I ask - what actions does the boiler perform before the error appears? The answer is none, just a mistake and that’s all. Let me explain that the error should be reset, maybe you have a bad contact on Reset. No, about the theory of contact - we know that the blocks are faulty. Okay, send it. The client sends two blocks after repair and two additional blocks from the “faulty” collection. We first install the blocks that were repaired on the stand. Blocks are in error. We reset the error - ignition is in progress, the valve opens, the unit sees the flame - it is working! We deliberately create an error on the block, reset it again - there is ignition, the board works according to logic. We check all four blocks in the same way - everything is in error, after a reset everything works. We provide information to the client about which contacts are closed on the block to reset the error, he takes the “faulty” block from the collection and voila! - works. All questions have been resolved.

What to do if the aspirated air leaks?

For the Atmo model range with an open (atmospheric) burner, the primary heat exchanger is made of copper.

The appearance of a leak is almost always associated with its destruction. Purchasing a new heat exchanger is not an easy and expensive task, so most often the issue is solved by soldering the fistula .

To carry out repairs, you should contact a technician from the service center, since this requires a qualified specialist who can dismantle the unit, find the fistula that has arisen, solder it properly, simultaneously rinse the heat exchanger and install it in place without damage.

The work is complex and requires the participation of a trained person.

The control board is faulty

This error, which is difficult to accurately diagnose, is designated by code 15E. It is almost impossible to understand how the control board works without special education. The most correct algorithm of action in such a situation is to invite a specialist who can use testing to determine and eliminate the causes of the problem.

The place where the Navien gas boiler is repaired is chosen by the foreman: in particularly difficult cases it is necessary to transport the boiler to a service center. To avoid problems of this type, it is strongly recommended to equip the supply networks of the Navien boiler with a voltage stabilizer.

Review of less common errors

We have listed the error codes that most often bother users. But there are other symbols that indicate irregularities in the operation of Navien gas boilers and potential repairs.

11 – failure in the operating parameters of water level or pressure. This error appears on the displays of boilers with automatic make-up. To fix it, you need to turn off the system, check the operation of the water filling valve, remove any remaining water in the pump drain, reconnect the pump and restart the system. If it doesn’t help, call technical service.

12 – absence of flame. There are many reasons, and we recommend acting as for errors 03-04. First, check if the gas taps are closed, if there is power supply and if everything is in order with the grounding.

15 – problems with the control board. If it does not respond to power supply, it requires repair or replacement.

We recommend: Circulation pump for heating: types and characteristics, how to choose the right one, review of popular models and manufacturers, their pros and cons

16 – overheating of the system, and any of the components can overheat: fan motor, heat exchanger, pump motor. What you can do yourself: clean the filters and heat exchanger, change the thermostat. After a half-hour “rest”, the unit can be restarted - most likely, it will work.

17 – errors related to the DIP switch. You need to correct the control board settings and restart the boiler.

27 – failure of the pressure sensor. If there is no blockage, you need to check the serviceability of the sensor and fan, and then replace the failed part.

30 – overheating of the smoke thermostat. It is necessary to turn off the boiler, allow it to cool for 30 minutes, then restart. If it doesn’t work, check the fan and air pressure sensor, clean the chimney.

93 – the “on/off” button is broken. You should replace it yourself or call a specialist.

Many problems can be solved independently, which is why the manufacturer provides brief instructions on how to resolve emergency situations.

But if it comes to complex repairs or replacements, it is better to have the unit repaired at a service center, with a subsequent guarantee for new spare parts

If an unknown error code appears on the display of a geyser or floor-standing Navien model, you also need to contact specialists.

The boiler does not heat water

This video is the solution to your problem!

Watch to the end and you won’t need to call a specialist.

It is impossible to survive without boiler houses in the climatic zones of Russia. Moreover, this also applies to the warmest regions, Sochi, Anapa and Rostov-on-Don. Winters are still harsh and people cannot survive without heating. Therefore, it will definitely not be possible to do without heating systems and hot water. And only boiler houses can provide the city with all this. Today we will look at the reasons why the boiler does not heat the water - how to solve this problem and what to do about it......

They are very different. It all depends on the heat source. It can be either steam or water. They may vary by location. If the house itself decided to build its own boiler room, then a specially separate room in the house can be allocated for it. Or extensions are made to the house for these purposes. One of the main requirements when constructing boiler houses is good ventilation.

If the boiler operates with steam, then very high demands are placed on the quality of water purification, and then steam. Therefore, it will definitely not be possible to manage such boiler houses without a whole complex of cleaning installations. This also includes AquaShield electromagnetic softeners, which are highly valued by boiler house employees today.

If a gas boiler suddenly stops heating water, the reasons may be different, but most often when using water from a central water supply without softening units, the cause may be limescale deposits. Moreover, it is hard and difficult to remove. The table shows possible signs of the reason why the boiler stops due to scale formation.

| Reason for boiler shutdown | Signs |

| High rigidity | Heating the bottom of a gas boiler, but at the same time weak heating of the water A sharp increase in electricity or solid fuel consumption White-gray coating on the bottom of the boiler The boiler does not heat the water to a certain temperature Poor pipe capacity Increased electrical conductivity of heat |

Other reasons for boiler shutdown are simpler. A piece of scale may also get stuck in the pipe and block normal operation, and a crack in the gas boiler may also contribute to the shutdown. But in these cases there will definitely be no scale residues on the walls of the equipment. If the boiler room does not have boiler water softeners or treatment facilities installed, then the root cause will of course be water hardness. If the treatment plant is standing and the equipment has been checked recently, then most likely this is not the problem.

If the video did not help you, then try installing anti-scale filters (polyphosphate or electromagnetic) in front of the boiler. Because Hard water and scale are the root cause of malfunctions and breakdowns of gas boilers!

In any case, if there is no cleaning in the system, then you will have to urgently address this cause and solve it. For boiler houses there is a whole range of water softening devices that are suitable:

- AquaShield;

- Ultrafiltration and conditioning for steam boiler houses;

- Ion exchange for economical consumers of gas boilers

The most wasteful process of cleaning and softening will be in steam boiler rooms. There you will have to remove not just all organic and inorganic impurities. Even dissolved gases will have to be removed. Degassing is quite troublesome and costly. But the operation of the boiler depends on the quality of the steam. This is where membrane softeners work to make the water completely isolated.

Many consumers of gas boilers choose AquaShield for the simple reason that it does not require maintenance and does not require spending money on it. But its biggest advantage for boiler equipment was and remains the ability to remove old lime deposits even in the most difficult places. Usually, to eliminate such residues, the equipment needs to be unscrewed, the parts need to be soaked in aggressive acidic environments and kept there for up to two hours. But even after boiler treatment of water, it is necessary to clean the surfaces with metal brushes or cleaners. If your gas boiler does not heat the water to the required temperature, then the reason is scale deposits. The electromagnet does all this work without damaging the surface, at the molecular level.

Important nuances during repairs

When repairing a boiler, you need to know how to fill the coolant after draining. Before refilling, turn off the gas and turn off the power to the equipment. It is necessary to check the position of the distribution and shut-off valves and open them as much as possible.

The make-up tap, which is located at the bottom of the device, must be turned to the left. When the pressure gauge mark is 1.2-2 bar, close the tap. If the emergency indicator starts working, you should drain the water and repeat the procedure.

Another boiler malfunction, solution to the problem:

To ensure that the device works for a long time and properly , you can purchase a voltage stabilizer, a water and gas filter, as well as a polyphosphate or magnetic water converter.

We must not forget that installation of equipment must be carried out in accordance with the manufacturer’s requirements. Before fixing the problem, you need to familiarize yourself with the classification of problem codes and see what a specific error may mean. When making repairs, it is important to study the instructions and follow the information provided in it. Navien gas boilers are an excellent option for both a private home and a city apartment. In case of breakdowns, it is very important to diagnose and fix the problem in a timely manner. In case of serious malfunctions, it is best to entrust the work to a specialist.

Main characteristics

Korean manufacturers took care of the convenience of consumers and released an extensive range of heating systems. The equipment is highly reliable and affordable. Features of Navien gas boilers:

- The device is equipped with an adjustment circuit that avoids problems associated with voltage fluctuations in the network. This function protects the system from damage due to false triggering of sensors. This function is very useful because the voltage in the power grid is not always stable.

- The heating system is able to stabilize its operation when the supply pressure decreases to 4 bar.

- The device does not freeze even when there is no gas supply. There is a pump for forced water circulation.

- The system contains a double heat exchanger designed to heat the coolant and water. Preheating can be programmed.

- Electronics are simple and convenient.

Gas boiler Navien:

Types of equipment

The Navien company has a very wide range, including floor and wall equipment. The units can function normally even with an unstable supply of fuel and electricity. Models have a turbocharging function and are equipped with a frost protection system.

Floor equipment is ideal for country houses. It heats the room efficiently and provides it with hot water. The units are simple and compact. Condensing equipment is available. Such devices significantly reduce home heating costs.

Types of Navien boilers:

The following Navien models are very popular: Ace, produced with different power levels, for example, 16 k or 20 k, Deluxe, Prime.

The company produces both single- and double-circuit equipment.

Rules of operation and timely maintenance

When purchasing a gas unit to heat your apartment or private home, you should remember that modern devices belong to the category of complex, high-tech, full of automation and protective systems. Therefore, in order to extend the life of the boiler and prevent its premature failure, it is necessary to follow certain operating rules.

- Firstly, this is installation in accordance with established requirements, according to the scheme recommended by the manufacturer, and not based on the advice of a familiar master.

- Secondly, these are high-quality materials and components: savings at this stage threaten to develop into financial costs for boiler repairs in the future.

- Thirdly, this is a thorough check of the condition of the sensors, chimney, water/gas supply before starting the boiler. Inspection and cleaning of main components should be done regularly, and not occasionally.

The automation will tell you the probable causes of problems by displaying coded messages on the display. Experience shows that following these recommendations will help avoid possible serious breakdowns and failures, which means that owners will not have to find out what typical malfunctions the Navienace boiler has and what will be required to eliminate them.

Error code instruction

By introducing electronic circuits into the gas boiler control algorithm, manufacturers have made it easier for ordinary users to use the units at home.

Nowadays there is no need to call representatives of the service organization with which an agreement has been concluded for the supply of fuel, inspection and repair of equipment. Errors are displayed on the electronic display in the form of digital symbols, and instructions for correcting them are given in the technical manual.

Sample control panel. In modern electronic models, the display is located on the control panel, and the symbols are clearly visible even in the dark thanks to the bright LED backlighting in red, orange or blue.

Please note: for Navien boilers, information can be displayed in both digital and alphanumeric characters. This means that there is no difference between error “15” and “E15” - it carries the same information. So, let's move on to the symbols, their decoding and instructions for further actions.

Outwardly, it looks like this: the heating circuit is operating normally, and cold water suddenly starts flowing from the hot water tap. The information screen, however, displays information about heating the water to the desired temperature.