Protherm gas boilers are high-quality, but relatively inexpensive heating installations for the mass consumer.

In this case, the pricing policy does not in any way reflect the capabilities or functionality of the equipment, since almost all the parts are used from the flagship of European heating engineering - Vaillant, a subsidiary of which is Protherm[/anchor].

Slovak boilers are intended for sale in Russia, so they immediately adapt to specific technological conditions - work in difficult climatic conditions (with increased loads), with changes in water or gas pressure, power supply.

In order to promptly notify the user of any deviations that have occurred, a self-diagnosis system has been developed.

Let's take a closer look at this issue.

Basic errors and malfunctions in Protherm gas boilers

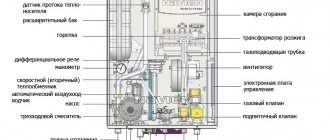

All possible problems are constantly monitored by self-diagnosis system sensors. This is a group of thermistors and other elements that are triggered when the specified operating mode changes.

The signal from the sensor passes to the electronic control board, which immediately gives an alert on the display. An alphanumeric code appears, such as F 01 or F 28 .

Each combination indicates a particular error, i.e. failure or failure of the corresponding unit unit.

IMPORTANT!

A complete list of errors, quite long, is outlined in the instructions, which are recommended to be kept on hand to quickly identify the problem node.

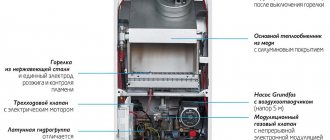

The operation of a gas boiler is entirely based on the use of a burner. This is the main and most critical component of the device, since it is the burner that performs the main task and is the source of maximum danger.

This determines the degree of control over its operation by the boiler automation . In addition, the condition of the heating circuit (presence and pressure of water) and the smoke removal system are subject to increased attention.

The Protherm boiler self-monitoring system includes several dozen items in its list, most of which determine the condition of gas equipment and smoke exhaust systems as areas of increased danger. However, less important elements are not left unattended.

Causes of breakdowns

The causes of breakdowns can be established even before the boiler starts operating.

These are: errors in the design and calculations for the selection of additional devices (not included in the boiler configuration), switching elements, determination of the type and cross-section of the required installation wires. The causes of breakdowns in the future may be:

- Poor quality, incorrect installation and connection of the device with deviations from installation requirements.

- Violation of the basic rules for using the equipment specified in the instructions.

- Failure to comply with the requirements for carrying out routine, preventive and periodic work and inspections.

- The presence of a manufacturing defect, which is discovered both during the warranty period and after its completion.

- All components and assemblies have a certain service life, and the reason for their failure is natural wear and tear.

- In heating element boilers, the heating elements themselves may fail due to low water quality and the formation of salts and scale on their surface.

- Failure of most components and assemblies due to large voltage surges exceeding all permissible standards. These tolerances are specified in the operational documentation.

For ion boilers, water compliance with the required standards is of great importance.

How to run self-diagnosis

The self-diagnosis system operates in constant mode. The start-up occurs simultaneously with the start of the boiler, and the system can only be stopped when the unit is stopped. Therefore, no special actions are required to enable self-diagnosis .

There is no need for special contact with the system; if a problem occurs, it will immediately report it, and if no notifications are received, it means that the boiler is operating normally and no problem points have been detected.

All main codes and their decoding

Let's look at the main error codes for Protherm boilers:

| Code | Decoding |

| F00 | Exhaust pressure loss |

| F01 | The flame on the burner went out |

| F02 | Heating temperature sensor failure |

| F03 | Boiler overheating |

| F04 | DHW sensor failure |

| F05 | Other problems |

| F06-07 | Traction sensor failure |

| F08 | Gas valve failure |

| F09 | Hood grounding break |

| F10 | Malfunction or short circuit of the forward temperature sensor |

| F11 | Malfunction or short circuit of the return temperature sensor |

| F12-13 | Malfunction or short circuit of the DHW boiler temperature sensor |

| F14 | Collector sensor short circuit |

| F15 | Smoke sensor short circuit |

| F16 | Short circuit of traction sensor |

| F18 | Boiler grounding short circuit |

| F19 | Exhaust sensor short circuit |

| F20 | Overheating, emergency shutdown |

| F21 | Boiler shutdown due to exceeding parameters |

| F22 | Low water level |

| F23 | Large temperature difference between forward and return OB lines |

| F24 | Rapid increase in temperature |

| F25 | Excess of supply water temperature |

| F27 | Parasitic flame (signal of a non-existent flame on the burner) |

| F28 | Burner ignition failed |

| F29 | Burner flame loss |

| F35 | Failure in the flue gas exhaust system |

| F37 | Fan speed exceeds rated value |

| F81 | Circulation pump malfunction |

A complete list of codes is available in the user manual. In practice, only a few errors occur (or none at all), but there can be many possible problems.

F29.

The error appears during boiler operation and indicates loss of flame.

Recommendation: first you need to make sure that the gas line is not blocked by a tripped shut-off valve (for example, due to voltage instability) and that the pressure is normal.

Probable Causes

- Ionization sensor is dirty. It does not “see” the flame and does not provide a signal to the Proterm Gepard electronic module about stable operation of the burner. Cleaning clears the error.

- The grounding is broken. You should check the reliability of the contacts of the wires suitable for the sensor.

All other reasons causing boiler error F29 (gas fittings, control board, electrode corrosion) must be diagnosed and eliminated by a service technician. It is better for the user not to figure it out on his own.

Elimination of defects in work

Usually, the appearance of an error does not mean that the boiler is broken. It is possible that the sensor may trigger falsely in response to a power surge or for other reasons.

Therefore, the first reaction to an error is to reset it and restart the boiler. If the error appears again and again, more effective measures must be taken.

Let's look at ways to eliminate the most common errors:

- F03 . Boiler overheating. The temperature of the heating agent rose to the maximum 95°. After the temperature drops, the boiler will start automatically. If the error persists, the thermal fuse must be reset.

- F04 . Failure of the DHW sensor. Check the contacts and clean them from oxides. As a last resort, replace the sensor.

- F10-11 . Failure of the supply or return temperature sensors causes the boiler to shut down due to the inability to control the degree of heating of the system. Check the condition of the sensors, clean the contacts, and if the problem recurs, replace the faulty element.

- F20 . Overheating of the boiler can happen for various reasons. Most often, the culprit is poor circulation due to a broken pump impeller. It is also often difficult to heat water due to layers on the walls of pipelines. The sensors do not confirm that the set temperature has been reached, and the heat exchanger outside is already too hot. The solution to the problem will be flushing the heat exchanger.

- F28 . Check the presence of gas in the line. Clean the ionization electrode using fine sandpaper. Check the condition of the boiler grounding circuit. If all these measures do not give a positive result, look for the reason in the boiler’s electronic board. Most often you have to change it.

- F62 . Gas valve malfunction. The device requires maintenance, cleaning and lubrication. There may also be problems with the electronic control board.

- F75 . Problems with the pressure sensor. Check the total pressure in the system. Inspect the condition of the pump. Bleed the air in the radiators using a Mayevsky tap.

It is inappropriate to provide a complete list of problems and ways to eliminate them, since the very name of the error most often contains a hint on how to fix it. The predominant type of solution to the problem is to replace the unreliable element.

Why does the burner go out?

If the chimney is clogged, combustion products are not removed and draft disappears.

A burner is a metal part in the shape of a pipe with various nozzles, through which gas enters and is burned in air forced into a special chamber. When turned on and during operation, a mixture of carbon monoxide and carbon dioxide, as well as soot with water vapor, appears. These combustion products are discharged outside. Uniform distribution of gas is achieved through a system of nozzles; air is pumped using natural draft.

The fuel supply is shut off due to the device’s automation in the following cases:

- draft in the chimney decreases or disappears completely;

- the gas pressure in the supply line drops below normal;

- the flame of the burner itself goes out due to the impossibility of removing combustion products.

Automatic shutdown sometimes occurs due to external reasons or due to generator failure. Owners of non-volatile devices of simple design are less likely to encounter such problems. Modern wall-mounted boilers with a closed combustion chamber often turn off the fuel supply themselves in a number of situations. This happens when the flow sensor is triggered due to a stop in the movement of the coolant in the heating system, the air supply decreases or stops completely.

Power surges and power outages in the home network can also cause problems with the boiler

If the unit has become worse at heating or does not work in one of the modes, you need to pay attention to such signals

To prevent the boiler from turning off during operation or at the wrong time, the device must be inspected more often for malfunctions. It is better to entrust this work to a specialist who can identify even complex problems at an early stage.

How to turn it on

The boiler is started by pressing the round “main switch” button to the right of the display.

Power supply to all boiler systems begins. Usually the boiler is in standby mode, i.e. There is no preparation of coolant and hot water. The display shows the current state of the device, so the user can immediately determine what the boiler automation is currently doing.

To start the process, you need to set the temperature of the heating agent or hot water supply, after which the burner will start and the coolant will begin heating.

These actions will be accompanied by characteristic sounds of pump operation, water movement, and burner startup.

The boiler is stopped by simply pressing the main switch.

Doesn't start

There may be several reasons why the boiler does not light. The simplest one is that the power cable is not connected correctly.

Protherm boilers are phase-dependent, i.e. the phase must be connected to a specific electrode.

The same requirements apply to the “zero” and “ground” electrodes. The problem can be solved simply - you need to turn the plug over in the socket, or swap the electrodes if the design of the plug does not allow you to change its position.

Other reasons for the inability to start the boiler may be:

- No voltage in the network.

- No or extremely low gas pressure.

- Failure or breakdown of automation (control board),

- Short circuit of one of the sensors that can block the device.

All these reasons can block the launch and hold the problem until it is fixed. The search must be carried out in stages, from the simplest to the more complex reasons.

NOTE!

It is not recommended to independently interfere with the state of the boiler’s electronics or automation, especially if it is under warranty. All issues should be resolved only with the participation of technicians from the service center.

Useful tips

- To avoid the occurrence of error f1 due to phase reversal, a mark must be applied to one side of the plug body (for example, with a felt-tip pen). Even after de-energizing Protherm Klom for the period of maintenance, there will be no problems with its commissioning.

- In order to ensure stable operation of the gas boiler, it is recommended to connect it to the network via a UPS. Otherwise, if the owners are absent, the house may be left without heat - there will be no one to press the R button on the Protherm Klom panel. The consequences are predictable: cold heating radiators, or even an ice plug in the circuit if part of the route is laid in an unheated room or outside the building.

On a note! The absence of a manufacturer's seal on the boiler body automatically voids the warranty. Before solving the problem that caused error f1 under the Protherm Klom casing, you need to look at the mark in the passport. Otherwise, you will have to pay for the elimination of all faults (purchase of spare parts, labor), maintenance of heating equipment from your own pocket.

Why does the pressure in the device increase?

A rise in pressure is an extremely dangerous situation, fraught with mechanical failure and even an explosion.

The liquid is incompressible; it fills the entire volume of the pipelines. If the pressure on the pressure gauge approaches 3 mbar and continues to rise, it’s time to take action.

One of the reasons is the failure of the expansion tank. When heated, the liquid expands and its volume increases by 4% .

A normally functioning expansion tank absorbs this excess interest, but if it is already full, the excess liquid simply has nowhere to go. This situation can be determined by the state of the relief valve - heating agents will constantly ooze out of it.

The main failure of the expansion tank is membrane rupture . With it, water fills the tank completely, leaving no room to accommodate the expanded liquid. The solution would be to replace the membrane or the entire expansion tank.

Another possible reason is that the supply valve is not closed or has failed. Water continues to flow into the system, increasing the pressure.

It is necessary to check the condition of the tap and turn it off or replace it. You should check the condition of all shut-off valves and clean the strainer. There may also be problems with the boiler automation, which can only be resolved with the help of a specialist from the service center.

F04.

No burner flame. The Proterm Jaguar error is caused by a lack of signal from the boiler ionization sensor.

Probable Causes

- Gas does not flow: after servicing (repair) Proterm Jaguar, the valve on the pipe remained in the “closed” position; operation of the shut-off valve on the main line; contamination of the gas filter mesh. All this is easy to check and fix.

- Poor contact, a break in the signal line disrupts the “visibility” between the ionization sensor and the Proterm Jaguar electronic module, hence the error.

- Electrode contamination. It will take a few minutes to remove carbon deposits, and a specialist is not needed.

- Incorrect sensor position. The error usually occurs after replacing it yourself.

Why does blood pressure drop?

A drop in pressure indicates a leak. It can be not only in the boiler, but also anywhere in the system - radiators, pipelines, taps, etc. Often the cause is a failed relief valve, which gradually releases water from the system into the sewer system.

The way to solve the problem is to search, detect the problematic element causing the leak, and repair or replace it.

How to connect to electricity

The electronics of gas boilers are demanding on the correct connection of the phase, zero and ground electrode.

If the contacts are reversed when connecting, the boiler will not start. Therefore, it is important to use a special plug and socket that does not allow you to connect the device in any other way. When running the cable, you need to check the correct distribution of the electrodes in the socket.

To check, use a probe screwdriver or other special devices.

Useful tips

- To avoid the occurrence of error f1 due to phase reversal, a mark must be applied to one side of the plug body (for example, with a felt-tip pen). Even after de-energizing Protherm Klom for the period of maintenance, there will be no problems with its commissioning.

- In order to ensure stable operation of the gas boiler, it is recommended to connect it to the network via a UPS. Otherwise, if the owners are absent, the house may be left without heat - there will be no one to press the R button on the Protherm Klom panel. The consequences are predictable: cold heating radiators, or even an ice plug in the circuit if part of the route is laid in an unheated room or outside the building.

On a note! The absence of a manufacturer's seal on the boiler body automatically voids the warranty. Before solving the problem that caused error f1 under the Protherm Klom casing, you need to look at the mark in the passport. Otherwise, you will have to pay for the elimination of all faults (purchase of spare parts, labor), maintenance of heating equipment from your own pocket.

Connecting a room thermostat

A room thermostat allows you to more accurately adjust the indoor microclimate . Its sensor checks the air temperature, which gives more accurate results than checking the extract air temperature, which is produced by the boiler electronics.

Using a room thermostat allows you to turn off the boiler when the set values are reached, when the device’s own sensors are not yet ready to give a command to stop heating.

The thermostat is connected to a special gap in the control board, the contacts of which are closed by default with a jumper.

To connect, turn off the boiler, open the lid and remove the jumper . Then the room thermostat is connected in the required order and a test switch is performed.

If the device operates normally, close the lid and proceed to further operation of the boiler with additional equipment. If problems are found, they are corrected immediately.

IMPORTANT!

Detailed instructions for connecting a room thermostat are available both on the device itself and in the user manual for the boiler. Under no circumstances should you act at random.

Expert advice

- Before you begin repairing the Ariston boiler, you need to press the “RESET” button (translated as reset, playback, zero) and restart the heating installation. Often this helps restore its functionality. As a rule, the occurrence of an error is caused by voltage instability - a typical case in the private sector.

- If an Ariston boiler does not have a display and its indicator lights are blinking, it is not a fact that a malfunction has occurred. This happens when the Comfort mode is turned on. The heat generator is forced to adapt to the microclimate in the room, hence its periodic switching off/on