Gas floor-standing boilers Lemax with a steel heat exchanger

This class is represented by five categories, each of which has its own gradation in terms of unit power. Thus, you can select the heating device to suit your needs as accurately as possible. The main thing is that the pressure in the heating system does not exceed 2 atmospheres. Let's look at the categories of heaters with a steel heat exchanger in more detail:

- Lemax premium boilers;

- premium nova;

- patriot;

- gas worker;

- clever.

Lemax premium steel boilers are divided into two groups. The first is from 7.5 to 60 kW, the second is from 70 to 100 kW. The units are made of steel 2 mm thick. For greater efficiency, the heat exchanger is made in the shape of a cylinder, just like Conord boilers.

The inner surface of the heat exchanger is protected with inhibitory compounds, which prevents the deposition of scale and salts.

The heater is non-volatile and equipped with Italian SIT automatic equipment. The smoke temperature in Lemax heating boilers is at least 110 degrees. Maximum water temperature 90 degrees. The unit operates at a nominal gas pressure of 1.3 MPa.

Some improvements have been made to the Lemax heating boiler of the premium nova series. The temperature regulator is now located on the front of the housing, and it is now possible to connect a thermostat and a turbocharger for the chimney. In addition, the heater is equipped with a soft start system. The power of the units in this series ranges from 7.5 to 30 kW.

The peculiarity of the Patriot series boilers is that they have a closed combustion chamber. The unit does not need to be connected to the electrical network and does not require the installation of a full chimney. This is a parapet boiler that takes combustion air from the street through a special pipe (similar to a chimney). At both ends there are outputs for connecting to the heating system. Power varies between 6-20 kW. All models are single-circuit.

According to reviews, infrared quartz heaters for summer cottages are less reliable than carbon ones.

Read this article about how to choose a heater for your room.

The gas worker series is a classic AOGV with a power from 6 to 29 kW. Accordingly, the device is volatile, the combustion chamber is of an open type, the operation is controlled by a thermocouple. Compared to models of other series, the gas line has a slightly lower efficiency (87% versus 90%). The heaters are equipped with draft, gas and water pressure sensors. Available only in single-circuit version.

The clever series heaters have the widest functionality. An indirect heating boiler, indoor and outdoor temperature sensors, a turbocharger for the chimney, and a control unit via the Internet can be connected to the boiler. Thermal power from 20 to 55 kW. Consumes 9 W of electricity per hour.

INSTALLATION, PREPARATION FOR WORK...

Page 10

- Image

- Text

10

Premium-M V. 1.03

6.

INSTALLATION, PREPARATION FOR WORK

6.1. The volume of the room in which the boiler is installed must be at least 8 m

3

. Dis-

the distance between the boiler casing and the walls must be at least: – 150 mm at the rear; – 100 mm on the right and left; – 1000 mm at the front.

6.2. In the room in which the boiler is installed, it is necessary to provide natural

natural ventilation.

6.3. When installing the boiler to the heating network, it is necessary to lay a sheet of non-flammable material on the floor.

heat-insulating material, a sheet of iron on top, install the boiler on it.

6.4. Connections between the boiler and the heating system and the gas main must be threaded.

side ones, allowing, if necessary, to disconnect the boiler. If the boiler is installed to replace an old boiler, it is necessary to flush the pipelines and radiators of the heating system to remove rust deposits, scale and sediment. If these requirements are not met, deposit products (rust, sediment) are transferred to the boiler, which significantly complicates the circulation of the coolant and reduces the heat transfer of the boiler. In this case, claims regarding the temperature indicators of the coolant during boiler operation are not accepted by the manufacturer.

With increased heat consumption of the room (thickness of the external walls of the house, integrity of windows and doors, distribution of heating system pipes in attics, attics that are not insulated, exceeding its area or significantly exceeding the coolant capacity - the number of radiators, pipes) from the established standards, the temperature The temperature of the coolant may not reach 80 °C, which does not mean that the boiler is defective.

6.5. The coolant capacity in the heating system should not exceed: Premium 10 – 150

liters, Premium 12.5 - 180

liters, Premium 16 -

240

liters, Premium 20 -

300

liters, Premium 25 -

375

liters, Premium 30 -

450

liters, Premium 40 -

600

liters.

6.6. To properly fill and recharge the system, be sure to install a waste

safety valve 1.5-1.7 kgf/cm

2

at a distance of no more than 150 mm from the place

connecting a valve to fill the heating system.

6.7. The expansion tank is installed at the top point of the main riser, preferably

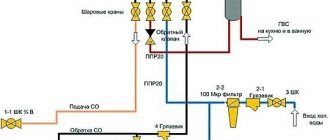

in a heated room. It is prohibited to install a valve on the signal pipe (see Fig. 2, 3).

6.8. Horizontal sections of heating system pipelines must be carried out with

a slope of at least 10 mm per 1 m towards the heating radiators and from them to the boiler. This is done to ensure free release of air when filling the system with water and eliminate the occurrence of air locks.

6.9. Pipelines, heating radiators and their connections must be sealed

clean, water leaks are not allowed.

6.10. For a closed heating system, it is necessary to install a safety system with

safety valve for a pressure of no more than 1.5-1.7 kgf/cm

2

.

6.11. The chimney device to which the boiler is connected must comply with SP42-

101-2003 “General provisions for the design and construction of gas distribution systems” (see Fig. 4).

6.12. After connecting the boiler to the gas supply system and filling it with coolant

heating system, employees of a specialized service center or local gas management must adjust and check for operation of the safety automatics and temperature control, and also check the tightness of all threaded connections on the boiler gas pipeline and up to it.

6.13. Before igniting the gas burner, check for the presence of draft according to clause 4.3. With absence

ignition of the gas burner device is prohibited.

Comments

Select → I found the instructions for my water heater here! #manualza

- Click →

Very simple guys serve in remote missile garrisons and are not afraid to write clear instructions. For example, in one instruction of the missile unit of the Siberian Military District there was the following entry: “The operator on duty is prohibited from sleeping with his head on the control panel of the missile launcher, so that drool from his open mouth does not short-circuit the electrical contacts.”

Manualza!manualza.ru

Still not with us?

Gas floor-standing boilers Lemax with cast iron heat exchanger

Heaters of this class can operate in heating systems with a pressure of up to 4 atmospheres. The wall thickness of the heat exchanger is 4 mm, which makes it very durable. Cast iron, unlike steel, is less susceptible to contamination, and its service life is much longer. There are two types of heaters in this category: leader and wise.

In a solid fuel boiler, coal is loaded through the top.

Lemax leader gas boiler, technical characteristics:

- non-volatile;

- power 16-50 kW;

- Efficiency 91%;

- overheat protection;

- traction sensor;

- maximum water temperature 80 degrees;

- nominal gas pressure 1.3 MPa.

The temperature control is located on the front part, with a pressure gauge located nearby. It is possible to connect a room thermostat. Thanks to this, you can set the required temperature in the room, which will be maintained at the same level. If necessary, you can install a fan to improve smoke removal.

Wise series boilers are connected to the electrical network, consumption is 7 W/hour. They can heat the coolant up to 90 degrees. They have an uninterruptible power supply installed, so voltage drops are not a problem for these boilers. The unit has connections for connecting an indirect heating boiler, various types of thermostats, and wireless control units. The option of switching to another type of energy carrier (liquefied gas) is also allowed.

Dear owner of the premium boiler

Page 3

- Image

- Text

Premium-M V. 1.03

3

Dear owner of the “premium” boiler!

We are grateful to you for choosing brand products

lemax

.

Now you are the happy owner of a highly efficient boiler, which

which, with proper installation, operation and maintenance, will reduce the cost of heating your home and will serve you for many years.

"lemax"

– a federal-level trade organization in the field of heating equipment

mining, provides consumers in Russia and the CIS with steel, cast iron and wall-mounted boilers, gas water heaters and other related products.

"lemax"

– leader of the Russian market of domestic gas boilers (according to independent

British expert agency BSRIA, Russian consulting agency Amico). The company has been operating on the market for more than 20 years.

"lemax"

– has its own modern production base, having

modern

plant for the production of domestic heating gas

boilers

.

"lemax"

– the only manufacturer of heating equipment in Russia

The area where the robots work is high-tech Italian and German machines. We are waiting for your feedback and suggestions on the company website

www.lemax-kotel.ru

.

Gas wall-mounted boiler Lemax

The Lemax company produces only one line of prime-v wall heaters. Each device is equipped with SIT automation made in Italy. All models in this series are dual-circuit and can operate in heating systems with a pressure of up to 3 atmospheres.

Chimney of a parapet boiler.

The boilers are equipped with a closed combustion chamber, so they require the installation of a coaxial chimney. A fan is located above the combustion chamber. Turbocharging is needed to pump in air from the street and at the same time remove smoke outside. The maximum length of a coaxial chimney can be up to 5.5 m.

Solid fuel boiler Lemax

Solid fuel heaters are available in two configurations:

- solid fuel boiler – forward series;

- potbelly stove – series heat house and heat house-S.

According to reviews, the Lemax solid fuel heating boiler is designed to operate on coal. In this case, it is possible to use firewood and even natural gas as an alternative. In the latter case, you need to order a special burner. The peculiarity of this unit is the vertical loading of fuel, the hatch is located on top. Coal can be poured directly from the bucket.

The most economical heaters for an apartment are those that are equipped with good automation and thermostats.

About kerosene heaters for summer cottages is written here.

The TT boiler is available in three capacities (13.17 and 21 kW). Heats water up to 95 degrees, works in autonomous heating systems with pressure up to 0.2 MPa. The efficiency is quite low - only 75-80% for coal and 72-77% for wood.

Potbelly stoves are made from 4 mm steel. They come with a flat top and a basket for stones. The last option is used in doubles. The thermal power of both stoves is 10 kW. Weight 65 and 80 kg. Logs up to 60 cm long can be placed in the firebox. A potbelly stove can only be heated with wood.

Autonomous heating systems based on gas boilers are widespread in European countries.

In our country they are less popular, however, the situation is changing every year. Users are actively switching to heating using imported and domestic heating installations.

The choice of boilers is very wide, which makes it possible to choose the appropriate installation for any conditions or room size.

Let's consider floor-standing gas boilers produced by the domestic company Lemax.

Lemax floor-standing gas boilers

The Lemax company was founded in 1992 in Taganrog. Gas boilers produced by this company are assembled from imported components from leading European manufacturers.

Floor-standing boilers are non-volatile, operate on natural draft and do not need to be connected to the power supply, however, they have the ability to connect water heating units and turbo nozzles to create forced draft.

Lemax floor-standing boilers are presented in a large assortment; the model range has samples with a power from 6 to 100 kW, which allows you to heat apartments or large houses.

STEEL GAS BOILER “LEMAX” WITH CLOSED COMBUSTION CHAMBER “PARIOT” SERIES

STEEL BOILER LEMAX PATRIOT 7.5 WITHOUT CHIMNEY

More details

The “LEMAX” boiler of the “PATRIOT” series is designed to work with natural and forced heating systems without connecting to the electrical network. The flueless design allows the boiler to be installed both in a house and in an apartment. In this case, combustion air is taken from outside the room. The rectangular heat exchanger is made of high-quality steel 2 mm of increased plane from the Magnitogorsk Iron and Steel Works. Thanks to the coating with anti-corrosion enamel “CERTA” (exposure temperature 750°C) and treatment with an inhibitory compound, the heat exchanger is protected from aggressive environments: salt solutions, mineral oils.

ADVANTAGES:

- Power range from 6 to 20 kW;

- Closed (sealed) combustion chamber;

- Convenience of boiler maintenance due to the use of removable cladding elements and profile equipment;

- Equipped with a gas valve from the Italian concern “SIT” and an injection microtorch burner “POLIDORO”;

- Availability of a boiler overheating protection system;

- A special smoke removal design ensures the operation of the boiler;

- The holes on the front panel of the boiler create a convection effect;

- Observation window for monitoring the combustion of the main and ignition burners;

- Coaxial smoke removal system (stainless steel available);

- 3 year warranty.

Advantages and disadvantages

The advantages of Lemax floor-standing gas boilers include:

- Simplicity, reliability and durability of the design.

- Non-volatility, increasing stability and reliability of operation.

- Ease of Management.

- Low fuel consumption.

- Relatively low price with high quality components.

- It is possible to only heat the home, or additionally prepare hot water.

There are also disadvantages:

- Ignition of Lemax boilers is quite difficult, especially if you lack the skill.

- Natural cravings are very unstable and depend on many external factors.

Disadvantages are common to all energy-independent models of gas boilers. However, they are many times compensated by undoubted advantages, so it is more correct to consider them design features.

What series and models are floor-standing

The Lemax group of floor-standing boilers includes the following series::

- Patriot . There are 6 models available with a power from 6 to 20 kW, which is optimal for apartments or small private houses. Parapet-type units are equipped with convection openings in the body, allowing the room to be heated. If such a boiler is in the kitchen, radiators will not be needed. A coaxial chimney eliminates the need for labor-intensive connections to a common house pipe.

- Premium . The series consists of single- and double-circuit models of floor-standing gas boilers with a power from 7.5 to 100 kW. There are 22 models in total. Double-circuit units have the letter B in their name. The most capacious series, allowing you to select the right boiler for any room or operating conditions. The simplicity of the design makes them very reliable and durable, and the low gas consumption contributes to the popularity of this equipment.

- Premium N. They differ from the basic Premium series by the presence of a gas valve 820 Nova Sit. The remaining features and parameters are the same as the main line models, but the power of the models is limited to 35 kW.

- Wise . These boilers are new, they appeared relatively recently. Made from ductile gray cast iron. They have 5 models with a power of 16, 25, 35, 40 and 50 kW. Single-circuit models with a sectional heat exchanger. They differ from conventional series in the need to connect to the power supply network.

- Leader . They are also a new product in the Lemax model range. Non-volatile single-circuit boilers with power from 16 to 50 kW. The cast iron sectional heat exchanger allows for high efficiency of thermal energy transfer.

STEEL GAS BOILER “LEMAX” SERIES “PREMIUM” 70-100

STEEL BOILER LEMAX PREMIUM 70 WITH AUTOMATIC NOVA 820 SIT

More details

The LEMAKS boiler is made of high-quality 3 mm steel with increased flatness from the Magnitogorsk Iron and Steel Works. Thanks to the coating with anti-corrosion heat-resistant enamel “CERTA” (exposure temperature up to 750°C) and treatment with an inhibitory compound, the heat exchanger is protected from aggressive factors: salt solutions, mineral oils.

Advantages:

- Temperature regulators are located on the front panel, which allows you to accurately select the thermal mode;

- Availability of a protection system against overheating, traction interruption and soot formation;

- Maximum efficiency due to: increasing the heat exchange area, changing the design of the turbulator for maximum retention of exhaust gases;

- It is possible to connect a room thermostat, with which you can regulate the boiler temperature relative to the indoor temperature;

- Two independently operating gas valves 820 NOVA SIT;

- The boiler does not require connection to the electrical network;

- An overpressure valve of 3 atm is installed;

- Increased primary and secondary air flow;

- 3 year warranty.

Specifications:

Specifications

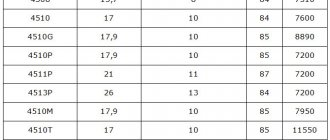

Let's look at the table of the main technical characteristics of Lemax floor-standing boilers:

| Characteristics | Values |

| Boiler type | Gas |

| type of instalation | Floor |

| Type of fuel | Natural, optionally liquefied gas |

| Thermal power | 6-100kW |

| Efficiency | 87 -93% |

| Gas consumption | 0.38 – 2.6 m 3 /h |

| Maximum coolant temperature | 90° |

| Diameter of coaxial chimney | 250-310 mm |

| Chimney length | 330-800 mm |

| Water pressure in the system nom/max | 1.5/2 Bar |

STEEL GAS BOILER “LEMAX” OF THE “PREMIUM” SERIES WITH AUTOMATION 820 NOVASIT

STEEL BOILER LEMAX PREMIUM 7.5 N WITH AUTOMATIC NOVA 820 SIT

More details

Additional benefits:

- The temperature regulator is located on the front panel of the boiler with temperature indications, which allows you to accurately select the optimal temperature regime;

- Connection of a room thermostat, with which you can regulate the boiler temperature relative to the indoor temperature;

- Work together with the Lemax turbo nozzle for forced removal of exhaust gases;

- Soft start system.

Specifications:

Device

Lemax floor-standing gas boilers have a heat exchanger in the form of a welded or cast iron container that forms a water jacket around the combustion chamber.

A gas burner is installed in its lower part, and under it there is a gas valve, control devices and connecting pipelines . The upper part of the heat exchanger has a passage for installing a chimney, which can be of a classic or coaxial design.

The connections for connecting the heating circuit for different models are located either on the sides or on the back of the boiler. There is also a hot water supply pipeline (for dual-circuit models).

The operation of the unit consists of the coolant entering the heat exchanger tank, heating and exiting independently under the influence of gravity - the density of the heated layers decreases somewhat, which helps to displace them by colder layers of liquid.

Self-circulation of the coolant is based on this effect. Hot water is heated in a copper coil installed inside the heat exchanger .

Smoke removal occurs under the influence of natural stove draft.

User manual

Operation of Lemax floor-standing gas boilers comes down to igniting the burner as needed and setting the desired temperature. All other operations - replenishing the volume of water in the heating circuit, installing a chimney, connecting a boiler - are performed without interfering with the boiler design.

To ignite the burner, turn the regulator to position 1, which means switching on the operating mode. Then you need to push it all the way and hold it while pressing the piezo ignition button.

When the pilot burner lights up, the button is released, but the regulator is held for about a minute.

Periodically it is necessary to clean the internal components of the boiler from carbon deposits and soot . You also need to monitor the condition of the heat exchanger, gas valve and other components of the unit.

Periodic maintenance should be performed by specialists from the service center. It is not recommended to do this work yourself, especially if the warranty period has not yet expired.