. SECURITY MEASURES …………………………………..

NEVALUX water heaters

- Image

- Text

1

CONTENT

SECURITY MEASURES ……………………………………………………………………………………………………………………………… … 4

TECHNICAL DESCRIPTION …………………………………………………………………………………………………………………………. 6

2.1.

Purpose of the boiler…………………………………………………………………………………………………………………………………….. 6

2.2.

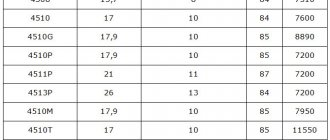

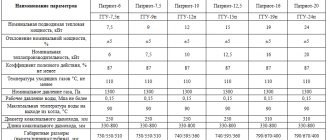

Technical specifications ………………………………………………………………………………………………………… 6

2.3.

Overall and connection dimensions………………………………………………………………………………… 7

USING THE BOILER ……………………………………………………………………………………………………………………………………… 7

3.1.

Turning on the boiler…………………………………………………………………………………………………………………….. 8

3.2.

Adjusting the coolant temperature………………………………………………………………………………………… 8

3.3.

Turning off the boiler……………………………………………………………………………………………………………………………………….. 9

BOILER MAINTENANCE ……………………………………………………………………………………………………………………. . 9

4.1.

Inspection…………………………………………………………………………………………………………………………………………… …….. 10

4.2.

Boiler care……………………………………………………………………………………………………………………………………… . 10

4.3.

Operations performed during maintenance ……………………………………………………………. 10

STORAGE RULES ……………………………………………………………………………………………………………………………………… … 10

GENERAL REQUIREMENTS ……………………………………………………………………………………………………………………………… … eleven

OPERATIONS BEFORE INSTALLATION …………………………………………………………………………………………………………………….. 11

7.1.

Heating system ……………………………………………………………………………………………………………………………………… 11

BOILER INSTALLATION ……………………………………………………………………………………………………………………………………… ………… 12

8.1.

Mounting the boiler on the wall……………………………………………………………………………………………………………. 12

8.2.

Installation of pipelines……………………………………………………………………………………………………………. 12

8.3.

Connecting the boiler to a liquefied gas cylinder ……………………………………………………………………. 13

8.4.

Connecting the boiler to the electrical network ……………………………………………………………………………………………………………. 13

CHIMNEY INSTALLATION ……………………………………………………………………………………………………………………………………………… .. 14

9.1.

Connecting the boiler to the chimney …………………………………………………………………………………………………………….. 14

10.

PUTTING THE BOILER INTO OPERATION (FIRST START-UP) ………………………………………………………………………………… 15

10.1.

Filling the heating circuit with water and pre-start checks …………………………………………………………….. 15

10.2.

Post-start inspection of the boiler……………………………………………………………………………………………………………. 17

10.3.

Additional features (options) ……………………………………………………………………………………….. 18

11.

Conversion of the boiler to a different type and pressure of gas………………………………………………………………………………………… 18

12.

DEVICE and control of the boiler operation…………………………………………………………………………………………… 19

12.1.

Boiler structure ………………………………………………………………………………………………………………… 19

12.2.

Purpose of the boiler components. ……………………………………………………………………………………………. 20

12.3.

Boiler operation……………………………………………………………………………………………………………………………………………… .. 20

13.

Troubleshooting………………………………………………………………………………………………………………. 22

14.

Delivery of the boiler to the consumer ……………………………………………………………………………………………………………………………………… …. 23

15.

Maintenance and operation check……………………………………………………………………………………………………………. 24

15.1.

Maintenance …………………………………………………………………………………………………………. 24

15.2.

Checking the operation of the boiler…………………………………………………………………………………………………………….. 25

16.

PROCEDURE OF OPERATIONS WHEN REPAIRING THE BOILER AND REPLACING COMPONENT PARTS……………………………………………………………. 26

16.1.

Removing the cladding………………………………………………………………………………………………………………………………………. 26

16.2.

Replacing the burner……………………………………………………………………………………………………………………………………… 26

16.3.

Replacing the heat exchanger……………………………………………………………………………………………………………. 26

16.4.

Replacement of the water-gas unit ……………………………………………………………………………………………………………. 26

16.5.

Replacing the water unit ………………………………………………………………………………………………………………….. 27

16.6.

Replacing the membrane of the water unit …………………………………………………………………………………………………………….. 27

16.7.

Replacing the water unit rod seal ……………………………………………………………………………………… 27

16.8.

Replacing the water assembly plate ………………………………………………………………………………………………………………… 27

16.9.

Replacing the gas unit…………………………………………………………………………………………………………………… 27

16.10.

Replacing the solenoid valve (magnetic plug) ………………………………………………………………. 27

16.11.

Replacing the thermocouple……………………………………………………………………………………………………………………. 28

16.12.

Replacing the cold water supply pipe to the heat exchanger ………………………………………………………………………………… 28

16.13.

Replacing the hot water outlet pipe from the heat exchanger………………………………………………………………. 28

16.14. Replacing the thermal relay (water overheating sensor) ……………………………………………………………………………….. 28

16.15.

Replacing the thermal relay (traction sensor) ……………………………………………………………………………………………………………. 28

16.16.

Replacing the pump………………………………………………………………………………………………………………………………………… 28

16.17.

Replacing the thermostat………………………………………………………………………………………………………………………………………. 29

16.18.

Replacing the thermomanometer……………………………………………………………………………………………………………. 29

16.19.

Replacing the safety valve………………………………………………………………………………………… 29

16.20.

Replacing the fuse…………………………………………………………………………………………………………….. 29

17.

Disposal ………………………………………………………………………………………………………………………………… …………………. 29

18.

WARRANTY …………………………………………………………………………………………………………………….. 30

19.

CERTIFICATE OF ACCEPTANCE ………………………………………………………………………………………………………………….. 31

20.

CERTIFICATE OF CONVERSION TO ANOTHER TYPE OF GAS………………………………………………………………………………….. 31

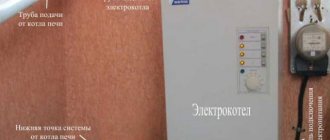

Features of installing wall-mounted gas equipment

It is worth noting that a wall-mounted double-circuit boiler is a self-sufficient system and the installation of such equipment and its connection to existing networks does not cause difficulties. In order to install and connect a gas boiler, the following components are used:

- ball valves for cutting off water lines and heating circuits;

- various surges;

- coaxial chimney that comes with the boiler.

To ensure the protection of the boiler from various impurities, it is necessary to install a number of filter elements: gas, magnetic and coarse filter. Gas wall-mounted boilers are installed in the following sequence:

- The Neva Lux boiler is installed on the wall using special strips that are included in the kit. To securely attach the mounting strips to the wall, it is best to use anchors.

- Ball valves are installed at the inlet and outlet of the boiler of the DHW and heating circuits. This will facilitate further preventive maintenance of the unit.

- Then comes the installation of all the necessary filters using suitable filters.

- After this, you can begin installing the heating circuit and DHW, or make a connection to existing pipeline systems.

All gas connections and filter installation must be carried out by gas company employees who have permission for this type of work.

Advice! It is best to install the Neva Lux boiler in the kitchen or in another room of a private house where there is a ventilation hole. This is due to the rules for using gas equipment and general safety. Also, when choosing an installation location, you should take into account the convenience of supplying communications: water and gas pipes, electrical wiring.

The simple design and reliability of Neva Lux gas boilers is confirmed by numerous consumer reviews. After proper installation, there is no need to worry about the safety of the equipment. Modern automation allows you to avoid emergency situations even in the event of emergency situations: a power outage or a drop in pressure in the gas line.

. CONTENTS OF DELIVERY …………………………………..

Page 2

- Image

- Text

2

21.

CONTENTS OF DELIVERY ……………………………………………………………………………………………………………………………. .31

22.

NOTE ABOUT BOILER INSTALLATION AND MAINTENANCE …………………… 32

Appendix I………………………………………………………………………………………………………………………………………… …………………………….. 35

Appendix II…………………………………………………………………………………………………………………………………… ……………………………. 38

Appendix III ……………………………………………………………………………………………………………………………………… ………………………….. 39

User Guide...

Page 3

- Image

- Text

User Guide

3

Dear buyer!

Thank you for choosing our product. You purchased

single-circuit wall-mounted boiler with an open combustion chamber “NEVALUX-8618”.

When purchasing a boiler, check:

completeness of delivery (see section 21, page 31) and presentation of the boiler; compliance of the type (natural or liquefied) gas you use with the type of gas,

specified in section (page 31) of this manual and on the plate on the boiler casing.

Also require the sales organization to fill out warranty repair coupons. When purchasing a boiler using a loan, a payment schedule must be drawn up with

indicating the amount to be paid. The payment schedule must be signed by the Buyer, indicating the date and deciphering the signature.

The boiler and this manual are two integral parts of what we offer.

goods. The manual contains information about the procedure for installing the boiler, the rules of its operation and maintenance, compliance with which will ensure long-term trouble-free and safe operation of the boiler. Please read the manual carefully before putting the boiler into operation, follow the instructions contained therein and store it carefully for future use.

Sincerely, OJSC GAZAPPARAT, St. Petersburg

Installation of the boiler is allowed only in non-residential premises with a temperature not lower than +5

0

C in

strict compliance with the Gasification Project, SNiP 42-01-2002 “Gas distribution systems” and SP 62.13330.2011 “Gas distribution systems. Updated edition of SNiP 42-01-2002.”

All installation work, installation, owner instruction, preventive maintenance,

Troubleshooting and repairs are carried out only by a specialized service organization.

The boiler is not intended for use by persons (including children) with reduced mental

abilities or lack of life experience.

Responsibility for the safe operation of the boiler and its maintenance in proper condition

is borne by its owner. Failure to comply with the safety measures and installation, use and maintenance rules set out in the manual can lead to boiler failure, fire, burns, gas poisoning or carbon monoxide (CO).

OJSC GAZAPPARAT is constantly working to improve its products.

products and reserves the right to make necessary changes to the boiler design. These changes may not be reflected in the instruction manual.

September 2, 2011

Most popular models

Let's look at the models of gas boilers from BaltGaz, which are in stable demand.

Neva Lux 7218

To supply heat to rooms with an area of up to 180 m², the best option is the Neva Lux 7218 boiler. The hot water supply circuit is necessary to increase comfort and provides residents with hot water. This double-circuit boiler includes a bithermic heat exchanger, thanks to which all user functions remain at a high level.

Distinctive features of the device design and technical characteristics are as follows:

- closed combustion chamber;

- the operating temperature in the heating circuit and the hot water supply circuit is between 30°C;

- Thanks to additional settings, you can switch the operation of the equipment to liquefied gas;

- The performance of the Neva Lux 7218 boiler is very high, the efficiency reaches 90%;

- Thanks to the electronic unit, the flame is continuously monitored. This is carried out both during the operation of the heating circuit and the hot water supply circuit;

- All components are European, due to which the unit has a large number of positive user reviews.

Neva Lux 8224

This unit is wall-mounted. Let's look at the design features of the device:

- high power makes it possible to use double-circuit units 8224 to supply heat to rooms with an area of up to 250 m²;

- the unique combustion chamber is water-cooled, which increases the service life of all structural elements several times;

- microprocessor software, which is present in boilers of this model, determines the maintenance of the specified temperature regime. Error - less than 1°;

- In addition, this device includes two heat exchangers: a copper one for heating; plate, made of stainless steel - for hot water supply.

More information about the types of heat exchangers for gas boilers is presented here

The control of the device in the model 8224 has been improved, a remote control option and a PC connection have appeared for diagnostics and the ability to more accurately configure the equipment.

All about the boiler remote control module can be found here

Wall-mounted gas boiler Neva Lux 8224 with a closed combustion chamber

Heating devices of this model have a digital display that displays all the information coming from the automatic self-diagnosis system.

Neva Lux 8618

The wall-mounted gas boiler Neva Lux 8618 is a single-circuit gas boiler. Compared to floor-mounted units of the same power, this model has higher productivity, the efficiency is 90%. The boiler is also characterized by reduced gas consumption.

Wall-mounted units Neva Lux 8618 have the following characteristics:

- due to its compact size, such equipment can be installed even in small rooms, they will not take up extra space;

- a large number of positive reviews indicate the reliability of the equipment. The devices are suitable for Russian conditions;

- Thanks to the built-in circulation pump, the boilers can be installed in ready-made heating systems.

In addition, to such boilers you can connect an indirect heating boiler, a forced smoke removal fan, or a room thermostat, thanks to which the equipment is highly economical.

These gas boilers can operate at a reduced pressure of 0.3 Bar.

Security measures

Page 4

- Image

- Text

User Guide

4

1. SAFETY PRECAUTIONS

For your own safety and to avoid boiler failure, strictly

prohibited:

use a faulty boiler; put the boiler into operation without an installed flue pipe or if it is faulty

chimney;

carry out gas hazardous work, all maintenance and repair work of the boiler

must only be carried out by a specialized service organization;

maintain the boiler while in a state of alcohol or drugs

intoxication;

make changes to the boiler design; touch the combustion products exhaust pipe during boiler operation, because temperature

heating of this pipe can reach 100

WITH;

use gas and water supply, as well as a heating system for grounding; touch the boiler if you are standing without shoes (or your shoes are wet) on a wet floor; maintain the boiler if it is not disconnected from the power supply and the gas supply is not shut off; make changes to the operation of security and control systems without permission and instructions from

boiler manufacturer;

damage and deform the electrical wiring elements of the boiler, even if it is switched off

power supply;

expose the boiler to atmospheric precipitation.

To avoid carbon monoxide poisoning, the room in which the boiler is installed must

have ventilation that provides air exchange of at least one volume of the room per hour.

If the boiler is idle for a long time in winter or if there is a risk of freezing

pipelines, it is necessary to drain the water from the boiler and from the heating system.

Do not store flammable or volatile substances (gasoline, solvents, etc.) in

the room in which the boiler is installed.

During normal operation of the boiler and if the gas pipeline is in good working order, there should not be any feeling in the room.

smell of gas.

IF YOU SMELL GAS:

close the gas supply valve located on the gas pipeline in front of the boiler; open windows and doors to ventilate the room, ensuring maximum air flow

fresh air;

do not use electrical appliances to avoid sparks; do not use the telephone in a gas-filled room; do not smoke or use open flames (lighters, matches, etc.); immediately call the emergency gas service by phone. 04.

Using a faulty boiler or failure to comply with the above operating rules

may lead to an explosion or fire, gas poisoning or combustion products.

The first signs of poisoning are: heaviness in the head, strong heartbeat, noise in the

ears, dizziness, general weakness. Then shortness of breath, nausea, vomiting, and impaired motor functions may appear. The victim may lose consciousness.

To provide first aid in case of gas or combustion products poisoning, you must:

take the victim to fresh air; call an ambulance; unbutton clothing that restricts breathing; give ammonia a sniff; cover warmly, but do not let you fall asleep.

First aid in case of electric shock should be provided immediately, after

capabilities at the scene of the incident, while simultaneously calling for medical assistance.

First of all, you need to free the victim from the effects of electric shock as soon as possible.

current. If it is impossible to disconnect the electrical installation from the network, then you should immediately begin to free the victim from live parts, using insulating objects.

When releasing a person from tension, you should use a rope, stick, board or

another dry object that does not conduct current.

How to buy a gas boiler and not make a mistake?

A buyer, choosing, for example, a wall-mounted gas boiler Neva Lux 8224 reviews for which may be false and written to order, must understand that they cannot be relied on. After all, it often happens that the design is ideal, the equipment is the most modern, but poor-quality assembly worsens all the advantages. For example, in 2014, reviews characterized the wall-mounted gas boiler Neva Lux 8224 as a naturally raw product, which is called “finish it with a file.”

This review appeared due to poor quality assembly, as well as due to unstable operation of the boiler due to a defect in the coaxial chimney, which was not specified in the instructions. Of course, the Neva company has now taken certain measures and eliminated shortcomings in the assembly of the product. There are practically no complaints about the Lux 8618 model and you can buy a single-circuit wall-mounted gas boiler Neva Lux, with delivery to any region, in specialized stores.

Prices for mounted gas boilers depend on their power, type, configuration and demand for the device. For example, the Neva Lux gas double-circuit wall-mounted boiler offered by many online stores, the price of which with a power of 24 kW, but with different configurations, ranges from 31,800 to 35,600 rubles.

The most expensive boiler, Nevalux 8224, is equipped with a built-in storage boiler. When choosing a boiler for heating, if you are satisfied with the gas boiler Neva Lux 8224 price, it is best to get reviews from real owners or gas equipment specialists.

User Guide...

Page 5

- Image

- Text

User Guide

5

First aid after the release of the victim depends on his condition. If he's in

consciousness, then you need to provide him with complete rest for a while, not allowing him to move until the doctor arrives.

If the victim is breathing very rarely and spasmodically, but a pulse is palpable, you should immediately

perform artificial respiration using the “mouth to mouth” or “mouth to nose” method.

If there is no breathing, immediately take the victim to a warm room with fresh

air and perform artificial respiration until the doctor arrives.

Overall and connection dimensions, Using the boiler

Page 7

- Image

- Text

User Guide

7

2.3. Overall and connection dimensions

Overall and connecting dimensions of the boiler are shown in Fig. 1 .

1 – gas regulator handle; 2 – thermostat handle; 3 – thermomanometer; 4 – viewing window; 5 – mounting holes; 6 – gas supply, thread G ½; 7 – heating circuit outlet, G 3/4 thread; 8 – heating circuit inlet, G ¾ thread; 9 – drain plug; 10 – switch button; 11 – piezo ignition button; 12 – safety valve;

Rice. 1. Overall and connection dimensions of the boiler

3. USING THE BOILER

For normal and safe operation of the boiler, the conditions of clauses 2.2.4, 2.2.9 and

2.2.18. Failure to comply with these conditions may lead to incorrect or unstable operation of the boiler or failure. The boiler heating capacity specified in clause 2.2.2 is ensured (with an accuracy of ± 5%) at the nominal gas pressure at the inlet of the operating boiler, specified in the “Acceptance Certificate” section.

Malfunctions of the gas boiler Neva Lux

The simplest single-circuit and non-volatile model Neva Lux 8618. It completely lacks electronics. A simple Neva gas boiler is very reliable.

The most common faults characteristic of this boiler are the following:

- very low level of gas pressure in the line;

- low pressure due to the presence of air in the circuit;

- burner flame goes out;

- mechanical damage to the boiler or heating circuit.

The presence of a control unit with a microprocessor in the Neva Lux 8224 model allows for self-diagnosis of faults that arise during the operation of the gas boiler. The electronics installed on the Neva Lux double-circuit gas boiler displays faults on the display in the form of an error code.

Inspection, Boiler care, Operations performed during maintenance

Storage rules

- Image

- Text

User Guide

10

4.1. Inspection

Before each start-up of the boiler, and in the case of boiler operation during the heating season, once a day,

necessary:

make sure there are no flammable objects near the boiler and chimneys; make sure there is no smell of gas in the room (if a smell of gas is detected in the room

contact the gas service);

make sure there are no water leaks in the heating system, if leaks are detected

contact a specialized service organization;

carry out an external inspection of chimneys for damage. If found

damage to chimneys, contact a specialized service organization.

4.2. Boiler care

regularly, especially before the start of the heating season, clean the system water filters

heating;

periodically remove air from the heating system (see clause 10.1, page 15); add water to the heating system to the required pressure (see clause 10.1, page 15); the boiler should be kept clean, for which it is necessary to regularly remove dust from the top

surface of the boiler, and also wipe the lining first with a damp and then with a dry cloth. In case of significant contamination, first wipe the lining with a wet cloth moistened with a neutral detergent, and then with a dry cloth. It is prohibited to use strong detergents containing abrasive particles, gasoline or other organic solvents to clean the surface of the cladding and plastic parts.

ATTENTION! do not change the water in the heating system unnecessarily, this will allow

reduce scale formation in the heat exchanger. Before the upcoming long-term downtime of the boiler in winter, it is necessary to drain the water from the heating system to avoid damage to the pipelines when it freezes.

ATTENTION! All boiler maintenance operations should be performed only after it has been

disconnecting from the network and cooling down.

4.3. Operations performed during maintenance

During maintenance the following work is performed:

1) cleaning the burner block (burner); 2) cleaning the heat exchanger from soot and cleaning (rinsing) the heat exchanger pipes from scale (if

necessary);

3) replacement of seals in gas and water systems; 4) checking the tightness of the gas and water systems of the boiler; 5) lubrication of moving joints (if necessary), it is recommended to use thick

silicone-based lubricants;

6) checking safety devices, they must work without failures; 7) the combustion product exhaust system must be checked for leaks; Checking the heating system for blockages.

7) the combustion product exhaust system must be checked for leaks; Checking the heating system for blockages.

ATTENTION! Maintenance operations associated with disassembling it

gas or water communications must be carried out only after the boiler has been completely turned off (the taps on the water and gas lines in front of the boiler must be closed, the boiler must be disconnected from the electrical network).

5. STORAGE RULES

the boiler must be stored and transported in packaging only in the position indicated on

manipulation signs.

the boiler must be stored in a closed room that guarantees protection from atmospheric and

other harmful effects at air temperatures from −50 ºС to +40 ºС and relative humidity not exceeding 98%.

when storing the boiler for more than 12 months, it is necessary to carry out preservation according to

GOST 9.014−78.

the openings of the inlet and outlet pipes must be closed with plugs or plugs.

Comments

Select → I found the instructions for my water heater here! #manualza

- Click →

I'm not stupid, I strictly follow the instructions.

Manualza!manualza.ru

Still not with us?

Review of the Neva Lux boiler range

The range of popular gas boilers produced by the Neva company includes two basic series: Lux and Turbo. In this article we will consider the most famous and popular Lux series, which is divided into two categories:

- Single-circuit gas boilers Neva Lux, designed for individual homes. The series is characterized by ease of maintenance, low cost and energy independence.

- Double-circuit wall-mounted gas boilers of the Neva Lux series are equipped with open or closed combustion chambers; the boilers include a bithermic heat exchanger. The chimney can be coaxial or classic. The series is equipped with high-precision automation. It is possible to connect two heating systems to the Neva Lux series boiler, and some models have outlets for organizing heated floors.