2021

| no comments

3. Press the control handle all the way and, without releasing it for 10-60 seconds, press the piezo igniter button 4 until a flame appears on the pilot burner. After igniting the pilot burner, the control handle must be held pressed for 60 seconds, then smoothly released; if the flame goes out, repeat steps 7.2-7.3., increasing the time for pressing control handle 3, no earlier than 1 minute (or after a spontaneous click inside the automation).

The Lemax Premium gas boiler deserves the buyer’s close attention. The domestic manufacturer is literally hot on the heels of famous European brands. Happy owners of a highly efficient boiler note in product reviews that with proper installation, operation and maintenance, the Lemax Premium boiler significantly reduces heating costs. cares about consumers and presents a decent selection of exceptionally high-quality heating devices. Taking into account the growing popularity of energy-efficient individual heating systems, the company’s engineering department annually offers new equipment, each time increasing its technical characteristics. The high quality of the products is primarily due to modern production. Innovative machines and mechanisms from the world's leading companies (Italian and German) took their place at the enterprise. A well-functioning quality control line for manufactured products eliminates defects at the stage of product release to the consumer.

- The traction sensor does not work;

- Flame separation occurs in drafts and strong winds;

- The chimney does not draw;

- The thermocouple does not produce the required voltage;

- Reduced gas pressure;

- Lack of oxygen.

Grounding of gas boilers

How to make grounding:

- You need to take as a basis a contour in the shape of an isosceles triangle made of 3 metal rods 3 meters long.

- The conductors need to be connected.

- Using an ohmmeter, measure the resistance inside the circuit (should be a value close to 4 ohms). If the value is higher, you can add another element to the contour.

- You need to continue until the port value is as close as possible to 4 ohms.

For grounding, rods and tubes are used, which are connected by metal strips. They are installed vertically in the ground so that the system works even in winter. It is recommended to coat metal elements with an anti-corrosion solution.

Advantages and disadvantages

The advantages of Lemax floor-standing gas boilers include:

- Simplicity, reliability and durability of the design.

- Non-volatility, increasing stability and reliability of operation.

- Ease of Management.

- Low fuel consumption.

- Relatively low price with high quality components.

- It is possible to only heat the home, or additionally prepare hot water.

There are also disadvantages:

- Ignition of Lemax boilers is quite difficult, especially if you lack the skill.

- Natural cravings are very unstable and depend on many external factors.

Disadvantages are common to all energy-independent models of gas boilers. However, they are many times compensated by undoubted advantages, so it is more correct to consider them design features.

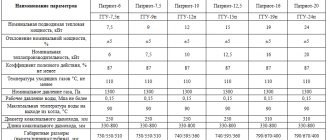

Specifications

Let's look at the table of the main technical characteristics of Lemax floor-standing boilers:

| Characteristics | Values |

| Boiler type | Gas |

| type of instalation | Floor |

| Type of fuel | Natural, optionally liquefied gas |

| Thermal power | 6-100kW |

| Efficiency | 87 -93% |

| Gas consumption | 0.38 – 2.6 m 3 /h |

| Maximum coolant temperature | 90° |

| Diameter of coaxial chimney | 250-310 mm |

| Chimney length | 330-800 mm |

| Water pressure in the system nom/max | 1.5/2 Bar |

Features of installing a floor-standing gas boiler

A gas boiler, regardless of whether it is a floor-standing or wall-mounted model, should be installed in accordance with the rules and regulations:

- installation of a floor-standing gas boiler is carried out in a separate room, which is called a furnace or boiler room, with an area of at least 4 “squares”;

- ceiling height – from 2.5 meters;

- the volume of the room should be more than 8 m³ with a heating unit power of up to 30 kW, 13.5 m³ with 31 - 60 kW and 15 m³ with 61 - 200 kW;

- It is necessary to have an opening window;

- the width of the door in the boiler room cannot be less than 80 centimeters;

- finishing of the combustion chamber must be done using non-combustible materials;

- It is unacceptable to have a false floor or false ceiling in the room;

- It is mandatory to ensure the flow of air entering through a non-closing vent, the cross-section of which is 8 cm² per 1 kW of unit power.

Other requirements include:

- compliance with the length of the horizontal section of the gas duct within the boiler room is no more than 3 meters. The rotation angles cannot be more than 3. The flue must have a vertical outlet that rises above the ridge of the roof or above the gable of a flat roof by at least one meter. When installing a chimney for a gas boiler, you should use only solid materials that are resistant to chemical and thermal influences, since combustion products form aggressive substances when cooling. Layered materials such as asbestos cement pipes can be used, but if they are located at a distance of more than 5 meters from the exhaust pipe;

- Before installing a floor-standing gas boiler, it is necessary that the boiler room is properly prepared (for more details: “Rules for installing a gas heating boiler - installation and connection instructions”). The space in front of the unit is left free. A durable fireproof metal sheet measuring 1 by 1 meter is laid on the floor under the heating unit. Asbestos cement cannot be used, since neither firefighters nor gas workers recognize it - it wears out over time, and in addition, according to sanitary standards, it is prohibited to keep materials containing asbestos in residential premises;

- in the boiler room there cannot be places like cavities where combustion products or a gas mixture dangerous to human life can accumulate. In the case where a gas appliance is planned to be used to heat a house, gas workers will definitely check the condition of the heating structure in the apartment or house. In horizontal sections, pipes should be located at a slope that does not exceed 5 millimeters per linear meter in the direction of movement of the coolant. An expansion tank and an air valve should be installed at the highest point of the heating system. The heating structure must withstand the pressure testing process under a load of 1.8 bar.

Installation of even the simplest model is not permitted in the following cases:

- if the apartment is located in an apartment building where there is no main gas duct;

- when the kitchen has a false ceiling that the residents do not want to remove, or a permanent mezzanine. If the bottom of the mezzanine is made of cardboard or wood, it is easy to dismantle it.

Installing a gas boiler in a private house - requirements, installation and use rules

How a Lemax floor-standing boiler should work

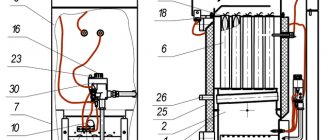

Lemax company presents a large number of models of floor equipment. For stable operation, Italian SIT automation is used.

The principle of operation of the boiler is as follows. A gas burner is built into the housing, heating the heat exchanger, with a built-in DHW and heating system coil. Coolant circulation is carried out naturally (non-volatile) or forced.

It is customary to distinguish several types of stationary equipment according to the following technical characteristics:

- Number of circuits - the Lemax steel single-circuit floor-mounted gas heating boiler works with virtually no complaints. It is non-volatile. Provides maximum performance. Used to heat the home heating system. It has low gas consumption. The Lemax floor-standing household double-circuit gas boiler operates in two modes: heating the coolant and water for hot water supply. The advantage of the model is its high efficiency (there is practically no difference in gas consumption compared to Valliant and other boilers). There are certain shortcomings associated with the operation of the secondary circuit. Mainly associated with errors made when piping the boiler. Lemax steel floor heating 2-circuit gas boilers are an economical and optimal option for a large private house.

Heat exchanger design - there are two modifications that differ in the material used in the production of the boiler. Russian non-volatile single-circuit gas heating boilers Lemax with a cast iron heat exchanger have the best technical characteristics among the entire model range of the manufacturer. The cast iron firebox is resistant to aggressive substances and overheating, thickness 4 mm. The sectional heat exchanger is manufactured at the VIADRUS plant (Czech Republic). It has anti-corrosion properties. The steel heat exchanger is sensitive to the quality of the coolant. A water treatment system is required for operation. The thickness of the steel heat exchanger is 2 mm.

Download: Lemax Clever - user manual.pdfDownload: Lemax KSG - technical data sheet.pdfDownload: Lemax Wise - user manual.pdfDownload: Lemax Leader - technical manual.pdfDownload: Lemax Premium - instructions.pdfDownload: Lemax Premium 50 60 70 80 90 100 - instructions.pdfDownload: Lemax Gazovik.pdfDownload: Lemax Premier.pdfDownload: Lemax Comfort - turbo nozzle for a gas boiler.pdf

Floor-standing versions are non-volatile. To ignite the boiler, a manual ignition system using a piezoelectric element is used. After the flame dies out, you will need to start the combustion process yourself.

How to flush heating

You can purchase various reagents in the retail chain, offered in 3 types:

The concentrate and powder must be diluted with water, following the manufacturer's instructions. As a rule, before cooking, the water is heated to 40...60 °C. The finished liquid for flushing the heating system is poured into a barrel and disposed of after use.

We will give a number of recommendations on the best way to flush heating pipes:

We do not recommend using various folk remedies for washing, in particular citric acid. Firstly, it is only effective against scale, which is found only in boiler heat exchangers. Secondly, a high concentration of the acid solution is required; with a large amount of water it cannot be achieved.

Boiler location

The regulatory framework that would regulate the installation of a solid fuel boiler in a private home has not yet been developed. However, the basic requirements for the placement of such equipment can be found in SNiP “Heating and Ventilation” and SNiP 31-02-2001 “Single-apartment buildings” (for the Russian Federation), as well as a number of other individual acts.

It is worth noting that the SNiP “Boiler Installations”, which is often mentioned on the Internet, is not designed for low-power household appliances - its requirements apply to equipment with a power of more than 360 kW, and the rules for installing gas equipment are too strict.

Based on the analysis of the available regulatory framework, which relates to the procedure for placing heating devices on wood, the following tips can be highlighted on how to install a solid fuel boiler in a house:

- Any type of solid fuel, be it wood, coal or pellets, creates a large amount of dust. In addition, during operation of the boiler, varying amounts of smoke may enter the room. In this regard, it is not recommended to install a solid fuel boiler inside the living rooms of the house. Although the regulatory framework does not directly prohibit the installation of a solid fuel boiler in the kitchen, hallway or other rooms, with the exception of the bedroom.

- The best option for placing a solid fuel boiler would be an equipped separate boiler room or one attached to a common house. You can also focus on technical rooms in the house itself, a basement, garage or hallway with good ventilation.

- Heating equipment should be located as close as possible to the outer wall in order to facilitate the work of laying out the chimney, not to create too long a horizontal section or not to lead the pipe through the ceiling.

- Any solid fuel boiler requires periodic cleaning of the heat exchanger and maintenance. Therefore, it is necessary to ensure free access to it. To do this, leave at least 1 m of space in front, and approximately 60 cm in the back and sides, but not less than 25 cm.

- It is prohibited to connect the flue duct of a solid fuel boiler to brick ventilation ducts inside the walls.

In small-sized boiler rooms, heating equipment can be placed quite close to the wall, but only on the unattended side. In this case, the gap can be at least 10 cm, and there must be a gap of at least 25 cm at the back.

How a Lemax floor-standing gas boiler should function

As already noted, floor-mounted units are in greater demand among consumers. This equipment uses Italian Sit automation, which makes the operation of the equipment more stable.

Gas boiler Lemax Patriot 16

The operating principle of the boiler unit is based on the following points. The housing contains a gas burner, which heats the heat exchanger with a built-in DHW coil and the heating system. The movement of the coolant is carried out in a natural or forced way.

Let us consider in detail the types of equipment according to a number of criteria:

- Number of circuits - the Lemax steel single-circuit gas boiler in a floor-standing version functions almost without any complaints. It depends on electrical energy and is characterized by high performance. Used for space heating. Gas consumption is very low. The Lemax floor-standing double-circuit gas boiler operates in two modes: heating the coolant and heating water for hot water supply. As its advantages, it is worth noting its high efficiency. One of the disadvantages is the insufficient quality of the secondary circuit. This is mainly due to mistakes that were made when piping the boiler. Steel floor-mounted units with two circuits are economical devices that cope well with heating large houses.

- Heat exchanger design - there are two modifications that differ in the material of manufacture. Lemax single-circuit gas boilers, the heat exchanger in which is made of cast iron, are distinguished by higher technical characteristics among all models of this manufacturer. The 4 mm thick cast iron firebox tolerates aggressive substances and is not afraid of overheating. The sectional heat exchanger is manufactured at the plant of the Czech company Viadrus. It is characterized by resistance to corrosion. The heat exchanger, made of steel, is very sensitive to the quality of the coolant. To operate, you need a water treatment system. The thickness of the steel heat exchanger is 2 mm.

Methods for cleaning the heat exchanger

Removal of scale and soot can be done mechanically or using special chemicals.

Mechanical cleaning

The cleaning process takes place using a foam sponge, a brush with soft bristles, and a mini high-pressure washer. The most effective of the listed tools, allowing you to quickly remove plaque and destroyed layers of scale, is a mini high-pressure washer.

Before cleaning, in order for the reaction to proceed efficiently, it is advisable to apply a special liquid for removing carbon deposits to the radiator plates, or treat the surface with dishwashing detergent. You can combine two methods of removing dirt and pour descaling liquid into the coil. After 30 - 40 minutes, and with the combined method after 30 - 180 minutes (depending on the type of reagent used), thoroughly rinse the elements of the flow radiator with water under pressure.

Cleaning with chemical reagents

Dry cleaning can take place at a static or dynamic pace. When using the static method, the heat exchanger is removed from the water heater and filled with the active substance:

The dynamic method of removing carbonates is carried out with special boosters. A booster is a device designed to circulate scale-active liquid both through the heating system and through its individual components. The flushing liquid used is the same as for static cleaning.

The use of H2SO4 causes premature corrosion of the metal parts of the booster.

All activities are carried out outdoors or in a well-ventilated area, using personal protective equipment (goggles, rubber gloves) and clothing that well covers parts of the body in order to prevent acid and fumes from entering the human body. To improve the catalytic reaction and reduce processing time, the contacting liquid should be 50 - 60°C.

Which boiler from the model range to choose

Consumers have a somewhat contradictory opinion about Lemax boilers: some praise them for their unpretentiousness, inexpensive maintenance and reliability, others criticize them for the occasional failures and malfunctions. The manufacturer has been manufacturing heating systems for decades - this alone deserves trust. As for problems, as the experience of service center workers shows, they occur in almost all models and depend little on the brand.

When choosing a unit, owners should consider the following conditions:

- the boiler must have a power reserve;

- 1 kW approximately corresponds to 10 m2 of heated area;

- level of heat loss in the house.

The range of heating equipment is constantly expanding, new, productive and reliable products are appearing. The obvious advantages of Lemax brand boilers include the fact that a solid repair base has been formed for them, the main “problem” areas have been identified and the restoration of faulty equipment is not a problem. Moreover, most major problems can be fixed at home, without turning to specialists for help.

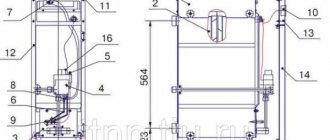

Device

The Lemax Premium 10 boiler is a metal welded container with an opening in the front part in which the combustion chamber is located. This design is used to impart greater pressure to the direct flow of hot coolant to create stable circulation.

The upper part of the structure has a pipe for connecting the chimney. The inlet and outlet pipes of the heating circuit are located at the rear of the boiler, so it cannot be installed close to the wall.

There are removable panels that are easily detached and provide access to the control handle and piezo ignition button.

Where to start the installation?

- First you need to mark the installation location on the wall or on the floor, depending on the type of boiler.

- Check whether there are enough parts and other auxiliary elements. In general, we mentally install the boiler at its future place of operation.

- View installation instructions.

IMPORTANT! Alone, you can only install a small-sized or floor-standing boiler (and even then not always). In most cases, you will need the help of one or two people.

Premises requirements

- The size of the installation room depends on the power of the boiler. The minimum area is 4 square meters, and the ceiling height is 2-2.5 meters.

- The doorway is at least 80 centimeters wide.

- Windows are a must. The minimum requirement for a 4 square room is a small window measuring 0.15 square meters.

- For every kilowatt of device power there should be 8 cubic centimeters of ventilation.

- Gas pipes must be metal, no other material is allowed.

- The diameter of the chimney should depend on the power. The minimum diameter is 13 cm, and it should not taper towards the top and should protrude above the roof surface by at least half a meter.

- There should be gas sensors in the room, and a gas stop valve on the boiler itself.

- The boiler must be equipped with a fuel flow sensor.

- In an apartment building, you can install the boiler everywhere except the basement, and in a single-apartment building it is recommended to install it in the basement.

- The boiler power supply (for autonomous boilers) and the electricity supply system must have thermal insulation and electrical insulation screens.

How to install equipment correctly

Strictly follow all the rules and regulations of SNiP 42-01-2002 “Gas distribution systems”, without deviating from them.

Any attempt to improvise or change classical technology may be noticed by inspectors.

And if this causes an accident or losses to other residents of the house, the owner faces administrative, and, in some cases, criminal penalties.

- If the boiler is wall-mounted, the floor under it must be perfectly level, since the pump pumping water can cause vibration and displacement of the boiler. If the vibration is strong, the gas pipes or water supply system may become disconnected from the boiler, leading to a gas leak or flood.

- If it is possible to make a stand for the boiler, this will secure the structure and increase the adhesion strength to the floor.

- If you install the boiler near a stove, boiler or other heating elements, then the total power of the thermal field between them will be higher than what the sensors show, since they measure this only inside the system itself. This rule is not specified in SNiP, but is often the cause of premature wear of the mechanism or failure.

Documentation

Required documents:

- A summary of the fuel consumption of a specific device. This can be done both by the workers who install the boiler and by the owner-installer himself. The technical data sheet of the device must indicate data on the consumption of electricity, gas and water. Within 14 days, a gas service employee must issue preliminary consent to install the unit.

- Installation project, which indicates all installation points and steps, communication connection diagram and chimney outlet.

- Technical specification, which specifies data on installation and communication to the boiler.

- Certificate of the device, reviewed and certified by gas workers. Certificate of standardization of the boiler.

Once the project has been approved, installation can begin. Professionals typically keep an installation protocol that outlines basic steps to protect themselves in the event of equipment failure or an accident that results in damages.

The protocol is signed by the customer (boiler owner). If you are installing it yourself, the protocol should indicate the main steps specified in the instructions for the boiler. If an accident occurs during installation or the boiler does not function properly, the protocol will serve as legal protection.

ATTENTION! In the case when the installation is carried out by specialists, and the protocol is signed by the customer, it has legal force, and if the installation is performed by the customer himself, the protocol is a regular description of the actions.

Kinds

The “Premium” line is made of first-class steel, its thickness is 0.2 cm. The grade of steel used is DC01, it fully complies with Russian, European and even North American quality standards.

The main technical characteristics are as follows:

- generated power 7.5-10 kW (for closed systems with a pressure of 1 atm);

- generated power from 12.5 to 60 kW (in systems with pressure up to 3 atm);

- a special enamel coating with anti-corrosion characteristics that works effectively when heated to 750 degrees;

- coating the heat exchanger with a reagent that blocks the action of mineral oil and salts dissolved in water;

- autonomy of use;

- unique design of the gas burner and valve;

- prevention of excessive heating and stopping traction;

- ease of cleaning;

- maximum efficiency.

Heating efficiency is increased due to increased air supply in the primary and secondary circuits, as well as thanks to a volumetric heat exchanger and long-term retention of flue gases. Hot water supply is provided in systems designed for a minimum of 12.5 kW. Conversion of equipment to liquefied gas fuel is allowed. Weight varies from 39 to 125 kg. The “Patriot” selection is made based on both gravitational and forced circulation of the coolant; connection to the electrical network is not necessary.

The “Patriotic” series is made of strong steel and is used without a chimney. The boiler must receive air from the outside. The shape of the heat exchanger is rectangle. The generated thermal energy ranges from 6 to 20 kW, the fuel burns in a completely closed compartment. To complete the burner, Italian parts produced by world-famous concerns are used.

Smoke removal is quite reliable. An inspection port is provided to monitor the main and pilot burners. The boiler casing can be easily removed, which greatly facilitates service. Smoke removal is provided by structures made of stainless steel. Company warranty – 36 months. The efficiency of the devices is 87%, the exhaust gases are heated to at least 110 degrees.

The nominal gas pressure is 1.3 kPa, and the operating pressure in the water line is limited to 0.2 MPa. Depending on the modification, the hourly gas consumption ranges from 0.38 to 1.2 cubic meters. m. All boilers in the series heat water up to 90 degrees, the size of the coaxial chimney is 25 or 31 cm in diameter, 33-80 cm in length. Connection is made through gas pipes with a cross section of 0.5 inches; Connected pipes can be 1-1.5 inches larger

The manufacturer promises that the boiler will demonstrate excellent anti-corrosion characteristics and provide decent heat output. There is no need to connect it to the electrical network. The typical power range includes 16-50 kW. Permissible operating pressure is 4 bar, efficiency is 0.91. Measures are taken against the occurrence of soot and excessive heating.

AOGV of this series is invariably equipped with a thermomanometer, which allows you to control the pressure in the system as comfortably as possible. The design, as in other models, allows you to switch to liquefied gas, and the general warranty is 3 years. Automation through Novosit components means that the thermostat is located on the front panel. All temperatures are clearly provided there, so choosing the appropriate mode is extremely simplified.

The category of floor-standing boilers includes “Gazovik”; this selection works great when receiving thermal energy from 6 to 29 kW

The Lemax single-circuit boiler can be equipped with either a cast iron heat exchanger (in the Leader and Wise collections) or a steel one - these are Premium, Gazovik, Forward. The simplicity of the design and the opportunity to save significantly will please all responsible consumers. The parapet type of boilers is represented by all Patriot modifications - these are models 6, 7.5, 10, 12.5, 16, 20. The efficiency of all these designs is 87%, they are capable of heating water up to 90 degrees. The weight of the products varies from 42 to 67 kg depending on the modification.

Gazovik

Forward

Wise

Why does the device go out?

There may be several reasons for the burner to go out:

- Stopping the gas supply. Turn off the boiler and wait until the supply is restored.

- Unstable or absent voltage in the power supply network (for volatile Lemax boilers).

- Failure or activation of the traction sensor. We need to check whether it is there and whether the chimney is clogged. Sometimes cleaning the sensor contacts helps.

- The thermocouple contacts have oxidized and do not close. It should be cleaned with fine-grained sandpaper.

- Reverse, insufficient or excessive draft. The draft sensor responds to all situations by turning off the burner.

Problems with traction are most common in non-volatile installations, where the stability of the unit’s operation depends on it.

If the draft is too weak, the sensor turns off the burner due to the possibility of smoke in the room.

Excessive draft is dangerous due to the possibility of the flame on the burner exploding, which will provoke the supply of gas into the room with unpredictable consequences. Therefore, an increase in draft against the set value is also an emergency event, leading to the boiler stopping.

When is cleaning possible?

In any case, it is inappropriate to wait until the moment when the device turns into a grimy “Cinderella”, so cleaning the gas boiler from soot is carried out at a certain time. There are three options.

The first 2 cases are not very attractive for equipment owners, since they involve expenses due to the invitation of an “alien” master. Often you can handle cleaning yourself, but almost any rule has exceptions. For example, it is better not to experiment with a condensing boiler that has a closed combustion chamber. If the owner is completely unfamiliar with such a unit, then professional help is already a necessity.

Preventative cleaning of a gas boiler from soot - flushing the heat exchanger - is a simple operation, and it is also performed quite quickly. This procedure can be carried out independently without much difficulty.

There are certain symptoms that indicate the need to clean your equipment. These include:

All these signs may not only be symptoms of a clogged unit, so other possible causes of problems should also be taken into account when diagnosing the equipment yourself.

How a Lemax floor-standing gas boiler should function

As already noted, floor-mounted units are in greater demand among consumers. This equipment uses Italian Sit automation, which makes the operation of the equipment more stable.

Gas boiler Lemax Patriot 16

The operating principle of the boiler unit is based on the following points. The housing contains a gas burner, which heats the heat exchanger with a built-in DHW coil and the heating system. The movement of the coolant is carried out in a natural or forced way.

Let us consider in detail the types of equipment according to a number of criteria:

- Number of circuits - the Lemax steel single-circuit gas boiler in a floor-standing version functions almost without any complaints. It depends on electrical energy and is characterized by high performance. Used for space heating. Gas consumption is very low. The Lemax floor-standing double-circuit gas boiler operates in two modes: heating the coolant and heating water for hot water supply. As its advantages, it is worth noting its high efficiency. One of the disadvantages is the insufficient quality of the secondary circuit. This is mainly due to mistakes that were made when piping the boiler. Steel floor-mounted units with two circuits are economical devices that cope well with heating large houses.

- Heat exchanger design - there are two modifications that differ in the material of manufacture. Lemax single-circuit gas boilers, the heat exchanger in which is made of cast iron, are distinguished by higher technical characteristics among all models of this manufacturer. The 4 mm thick cast iron firebox tolerates aggressive substances and is not afraid of overheating. The sectional heat exchanger is manufactured at the plant of the Czech company Viadrus. It is characterized by resistance to corrosion. The heat exchanger, made of steel, is very sensitive to the quality of the coolant. To operate, you need a water treatment system. The thickness of the steel heat exchanger is 2 mm.

- https://aqua-profi.com/service/montazh/montazh-i-zamena-kotlov/ustanovka-kotlov-lemaks/

- https://vdomteplo.com/otopitelnoe-oborudovanie/kotly-otopleniya/gazovye-k/ustanovit-svoimi-rukami-k.html

- https://vse-otoplenie.ru/montazh-parapetnogo-gazovogo-kotla-svoimi-rukami

- https://1popechi.ru/gaz/parapetnye-ustanovka.html

- https://mr-build.ru/newteplo/ustanovka-kotla-lemaks-patriot-svoimi-rukami.html

A little about the manufacturer

began its journey in 1992 on the shores of the Azov Sea, or more precisely in Taganrog. Against the background of a sharp change in the political situation and a real economic catastrophe, the founders of the organization managed to concentrate a close-knit group of performers capable of fulfilling any, even the most sophisticated order. As a result of many years of efforts, it was possible to ensure a stable position in the market, and in one of the most advantageous positions.

Lemax boilers are considered one of the best in terms of cost and quality. The company produces single-circuit and double-circuit systems, as well as water heating columns.

Possible faults

No matter how hard the engineers try to prevent possible problems, no matter how attentive the owners themselves are, sooner or later everyone faces failures. If Lemax Premium, for example, goes out (the main burner stops arbitrarily), we can assume the following reasons:

- weak vacuum in the smoke passage;

- gas outlet overflow;

- Incorrect thermostat setting.

First, inspect the channel through which the smoke is removed. If any dirt or blockages are found, they are removed immediately. If this does not help or nothing interfering is detected, you need to configure the regulator.

If a gas leak is detected, you should give up the idea of fixing it yourself. All restoration work may only be carried out by authorized gas service specialists.

Please note: cleaning chimneys and burners can help with excessively elongated flames that take on an orange or even red hue.

If there is no movement of water in the system, it needs to be topped up. When this measure does not help, you will have to redo the entire heating circuit. If the boiler suddenly turns off due to a temporary failure in the gas supply, the inlet valve must be closed. Then very unpleasant consequences will be excluded. If you cannot light the boiler, the problem may be related to the igniter or thermocouple. It is necessary to clean the contacts and replace the thermocouple. You also sometimes need to work on the traction sensor, connecting it not “by crimping”, but according to a more practical scheme.

Important: ignition is strictly not allowed if the fire from the igniter rushes outward, which is almost always due to a lack of draft and poses a great danger

User manual

Operation of Lemax floor-standing gas boilers comes down to igniting the burner as needed and setting the desired temperature. All other operations - replenishing the volume of water in the heating circuit, installing a chimney, connecting a boiler - are performed without interfering with the boiler design.

To ignite the burner, turn the regulator to position 1, which means switching on the operating mode. Then you need to push it all the way and hold it while pressing the piezo ignition button.

When the pilot burner lights up, the button is released, but the regulator is held for about a minute.

Periodically it is necessary to clean the internal components of the boiler from carbon deposits and soot . You also need to monitor the condition of the heat exchanger, gas valve and other components of the unit.

Periodic maintenance should be performed by specialists from the service center. It is not recommended to do this work yourself, especially if the warranty period has not yet expired.

Do-it-yourself installation of a parapet gas boiler

It is necessary to begin the installation of heating equipment by carefully studying the instructions and safety rules described in it. It must also be remembered that the commissioning of the boiler is approved by gas services. If you installed the boiler yourself, then involve specialists in consultation to complete the correct installation.

The process takes place in several stages.

Installation conditions

First, choose the optimal location for installing the boiler, in accordance with existing standards.

The equipment is installed only in premises that are classified as non-residential (kitchen, hall, utility rooms).

The outlet for the chimney pipe must be located on an external surface that is resistant to fire. In most models, it comes with a metal casing. It is attached directly around the diameter of the pipe outlet on the outer wall. If there are elements on the chimney outlet wall that can ignite when heated, then the distance to them should be at least 20-35 cm.

It is strictly forbidden to lead the chimney onto balconies and loggias, into passage arches, especially into the entrance. It must be remembered that toxic combustion products are removed.

It is prohibited to install the exhaust chimney near the supply ventilation intakes (distance from 60 cm - for low-power boilers; up to 1.5 meters - for equipment with a power of over 7 W). If the inlet ventilation and chimney are located close together, exhaust gases may enter the supply ventilation ducts.

Periodically, the chimney will need to be cleaned, so it would be more correct to place it in a place where it can be accessed, for example, under a window.

For the first floors, it is preferable to install a mounted boiler, approximately at a height of 2-2.2 meters.

Indoors, flammable surfaces must not be placed closer than 30 cm around the boiler (upholstered furniture, curtains, tulle).

There must be access to the system from all sides, at least one meter.

Boiler installation

You will need the following tools: a diamond drill for making a hole in the wall, boiler fasteners, a level, caps (shut-off valve), an adjustable wrench.

Installing a parapet boiler with your own hands requires certain practical skills. Sequencing:

- First, a hole is punched in the wall, the size of the outer diameter of the chimney. For this purpose, special diamond drills with a diameter of 240-270 mm are used.

- Then the outer contour of the coaxial pipe is installed. The chimney is installed at an angle of 4-5 mm to allow condensation to drain.

- Next, fasteners for the mounted boiler are screwed in and markings are made for the floor section.

- Install a water supply system and gas outlet.

- The internal chimney pipe is fixed.

- Install the boiler, connect the water and gas connections to it, and the heating system pipes.

The last stage will be the control launch of the boiler. It is more correct to carry it out in the presence of a specialist. Make sure that the flame is even, there is a special viewing window for this. Check to see if the gas has leaked or water has leaked at the joints.