Lemax gas boilers are in greatest demand and are the most common among domestic manufacturers. Almost all models have an excellent efficiency of 90% (the rest - 87%), have one of the lowest gas consumption rates in the class of budget Russian boilers, and a simple and trouble-free design. There are both volatile and non-volatile models on sale, single-circuit and double-circuit, floor- and wall-mounted, with steel and cast-iron heat exchangers.

The cost of all models is within the market average and slightly higher - from 13 thousand rubles for the simplest models.

In the article we will look at the best models of wall-mounted and floor-standing gas boilers Lemax, how they behave in practice, what advantages and, most importantly, disadvantages are noted by the owners, as well as what malfunctions may arise during the operation of boiler units in real conditions.

About the manufacturer

The Lemax trademark belongs to Lemax LLC (TIN 6154001478), registered in 1992 in Taganrog, the manufacturer’s address has remained unchanged to this day. The main activity is the production of gas heating boilers, but the company also produces water heaters and heating radiators. Products are distributed both through official dealers and through regular partner stores.

In addition to a large sales structure (due to demand, the brand is represented in almost all stores), the service structure is also developed, there is a hotline and a sufficient number of competent specialists in almost all regions of Russia.

The photo shows the Lemax Wise model.

In practice, boilers under the Lemax brand have really proven themselves to be reliable and trouble-free, having some of the best technical characteristics on the domestic boiler market. Often in private homes you can find models from 2005-2010 that are still working. The closest analogue is the Siberia model, which sparks debate about which of these two brands is more reliable and has a better price-quality ratio.

Review of Siberia gas boilers Some of the most reliable among domestic models

However, Lemax is the leader in demand, which can be explained by their well-known features. Gas consumption indicators are among the best among domestic models, for example, the maximum gas consumption of the most famous model Lemax Premium-10 with a power of 10 kW is 1.2 m3/hour, for Lemax Leader-16 with a power of 16 kW - 1.9 m3/hour. I would especially like to note the excellent build quality, which is not typical for domestic manufacturers: the gaps are even and minimal, everything is perfectly assembled and fixed, connections and bends do not rust even after 4-6 years of operation.

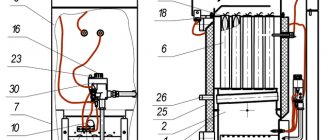

The device using the example of the Lemax Leader model.

The boiler design is standard for most domestic models: the famous Italian EuroSit automatic system and Polidoro burners. This design means that there is simply nothing to break in it. Steel heat exchangers are made of high-quality steel, which until today does not raise questions, but its thickness is only 2 mm versus 3-4 mm for analogues. Reliable and time-tested, but the fact remains a fact.

A more noticeable disadvantage is the high demands on connection, installation and configuration. Installation of Lemax boilers is somewhat more complicated than its analogues and requires certain competencies. It would not be worth focusing attention on this if it were not for the fairly frequent cases of incompetence of employees of Gorgaz, Oblgaz, etc., who make mistakes in organizing the wiring of boilers, which can lead to problems with the startup and operation of the automation (it may be necessary to replace the damaged wiring with factory).

Boilers are also demanding when it comes to the initial adjustment of the burner: if the gas pressure is too strong, frightening pops are possible when igniting; if the gas pressure is too low, there will be problems with igniting the main burner. It is especially important to comply with the requirements for the chimney: if there is insufficient draft, the draft sensor is triggered and the boiler goes out. Also, the boiler goes out even at the slightest reverse draft. However, this phenomenon is typical for all atmospheric structures that are not protected from backdraft and is only possible if there are errors in the design of the chimney.

Otherwise, the main rule is to carefully comply with all requirements, carry out installation and commissioning work correctly. According to reviews from owners and installation practice, all well-tuned boilers, regardless of the model, operate without problems for 10 years or more.

INSTALLATION EXAMPLES

- boiler;

- circulation pump ;

- expansion tank;

- heating radiators;

- automatic air release;

- relief safety valve;

- skimmer;

- tap for filling and draining the heating system.

- boiler;

- expansion tank;

- Radiator;

- ball valve for turning off the heating in the summer;

- tap for draining and filling the system;

- cold water tap for hot water supply;

- hot water outlet;

- winter-summer ball valve;

- bugle;

- relief safety valve.

Owner reviews of Lemax gas boilers: advantages and disadvantages

| Advantages | Flaws |

| High technical characteristics (efficiency, gas consumption, DHW performance) | High requirements for installation and commissioning, chimney |

| Simple, well-known design that ensures reliability | Some buyers note the models are somewhat “expensive” |

| With proper installation and commissioning, there are practically no cases of serious malfunctions in the first 8-10 years of operation | Some owners complain about claps and somewhat noisy operation |

| Availability of non-volatile models, availability of even more durable cast iron models | Sometimes they note more noticeable sizes of both floor and wall-mounted models |

| Availability of dual-circuit models | The boiler room must be kept clean and the boiler must be cleaned regularly, otherwise clogging and problems with starting or ignition may occur. |

| Excellent build quality, comparable to many European-made analogues | |

| Developed service structure, availability of competent specialists in almost all regions, availability of spare parts |

What are the installation requirements?

Standard requirements have been established for the installation of a Lemax double-circuit gas boiler. It is necessary to comply with the usual provisions for heating units, the presence of connection points to the water supply, gas mains, and the presence of a chimney.

Important. Installation should be carried out by qualified specialists who have experience working with gas equipment; amateur activities are not allowed here.

A prerequisite is the installation of all components and parts provided by the manufacturer (and specified in the manual): expansion tank, shut-off valves, flaps, and sensors. The base for the equipment must be stable and solid, preventing subsidence and distortions of the boiler, especially its displacement. When choosing the installation location, you should take into account the possibility of servicing the unit and its parts, so that, if necessary, it is convenient to dismantle the burner block or sectional heat exchanger.

Regarding the chimney, there are several options: solid, brick, or assembled from separate sections of the pipe. The latter option is very popular (and recommended by companies specializing in the production of gas exhaust systems), and it is also easy and quick to install.

The best and most famous models: characteristics and prices

Floor-standing

Premium

A non-volatile boiler unit with a steel heat exchanger, this is one of the most successful and popular models among the entire Lemax line of heating boilers. The series is represented by models with a power of 7.5; 10; 12.5; 16; 20; 25; thirty; 35; 40; 50; 60; 70; 80; 90; 100 kW. There are also double-circuit boilers; they come with the prefix “B”, for example Lemax Premium-16V, and cost an average of 5 thousand rubles. more expensive than a single-circuit analogue.

The model is characterized by excellent efficiency - 90% and low gas consumption, for example, the maximum figure for the 10 kW version is 1.2 m3/hour, for the 16 kW version - 1.9 m3/hour. It is known among experts as a win-win and hassle-free option, which is recommended in the top three options for budget floor-mounted aspirated air conditioners.

One of the disadvantages is the rather thin (2 mm) steel of the heat exchanger, although due to its high quality, in practice boilers last a standard 10-14 years. Otherwise, the boiler has all the previously described disadvantages that are also characteristic of other Lemax models: demands on the initial setting and chimney, maintaining cleanliness, large dimensions, the burner flame goes out if there is a backdraft in the chimney (despite the presence of protection against blowing out).

Please note that the maximum permissible operating pressure is only 1 bar, so it is not recommended to use the model in closed systems, where the operating pressure is usually 1.5-2 bar.

Leader

Still the same non-volatile model, but with a cast iron, much more durable, corrosion-resistant heat exchanger (service life from 25-30 years). They are distinguished by a higher operating pressure - 4 bar, have the same efficiency of 90% and the same fuel consumption indicators. The model is presented exclusively in single-circuit versions with a power of 16, 25, 40, 50 kW. Models with the “N” prefix are equipped with an updated, more advanced version of the EuroSit automation – 820 NOVA SIT, in which the thermostat now has a temperature designation, and it is possible to connect external control (for example, a room thermostat).

How to choose a room thermostat and save up to 30% per month on heating

The disadvantage is that the build quality is not as excellent as in the case of other models, namely the quality of fastening and fixing elements. It is also worth noting the relatively high price, for which some more advanced European analogues can already be considered.

Wise

One of the best Lemax gas boilers for heating a private home. It is an energy-dependent aspirated unit with a cast iron heat exchanger, characterized by a modulated burner and the presence of automatic ignition.

Despite the same maximum gas consumption figures, the model is known for its truly low consumption; in practice, the 16 kW version is often in the range of 0.9-1.2 m3/hour. This is achieved thanks to energy-dependent functional automation and a modulating burner, capable of maintaining the most optimal fuel combustion mode - continuous combustion at minimum power.

Unlike any other boilers of the brand, Wise is well adapted to both power fluctuations and gas pressure differences, which makes it easier to set up. It is possible to connect external control and organize weather-dependent operation. This is the only model that is devoid of almost all of the characteristic disadvantages described earlier. The only significant drawback is the high price, comparable even to the most reliable and functional Japanese and Italian gas floor-standing boilers. Available in 16, 25, 35, 40 and 50 kW versions.

Wall mounted

Prime-V

Mounted double-circuit convection boiler with a closed combustion chamber. Available in versions with heating capacity 10, 12, 14, 16, 18, 20, 24, 26, 28, 32 kW.

A special feature of the model is its design, consisting entirely of foreign European components. The primary (main) heat exchanger is copper, the burner has the ability to modulate the flame, the combustion chamber is a closed type, the presence of a layer of heat and sound insulation - all this made it possible to achieve one of the best efficiency indicators for standard convection boilers - 92.5%, which, of course, is positive also affected gas consumption. For example, a model with a power of 18 kW has a maximum gas consumption of 2.04 m3/hour, which is less than many European models.

The main disadvantage of Prime-V is its cost, comparable to the same European and Japanese models. In fact, the direct competitor is the most widespread, efficient, proven and problem-free Italian BAXI ECO-4s, which has almost the same design with a copper heat exchanger and flame modulation, absolutely the same functionality and a slightly larger set of safety systems. However, it is slightly inferior in terms of gas consumption, hot water temperature and adaptability to voltage drops in the electrical network and gas pressure drops.

Having lost the main competitive advantage of domestic models - price, Prime-V directly competes with the best foreign models, which makes the choice in terms of price-quality ratio not so clear.

Parapet

Patriot

One of the most common and successful parapet energy-independent gas boilers. It has a good efficiency of 87% for parapet models and low gas consumption, for example, 1.2 m3/hour for a 10 kW model. Available in versions with a capacity of 6; 7.5; 10; 12.5; 16; 20 kW. The design provides only a steel heat exchanger made of the same 2 mm steel, Italian EuroSit automatics. Despite the combustion chamber being a closed type, the device remains as simple, understandable and reliable as possible.

The only noticeable drawback is the problem inherent in almost all parapet models with the flame being blown out by the wind, after which you have to manually start the boiler. This happens much more often than in the case of traditional gas boilers. Therefore, the choice of a parapet boiler is generally controversial, despite the fact that Lemax Patriot is one of the best of them. In our opinion, installing a parapet model is justified in garages, utility rooms, small apartments or houses for temporary residence.

Is it worth considering a parapet gas boiler for heating a house or apartment?

Why does the device go out?

There may be several reasons for the burner to go out:

- Stopping the gas supply. Turn off the boiler and wait until the supply is restored.

- Unstable or absent voltage in the power supply network (for volatile Lemax boilers).

- Failure or activation of the traction sensor. We need to check whether it is there and whether the chimney is clogged. Sometimes cleaning the sensor contacts helps.

- The thermocouple contacts have oxidized and do not close. It should be cleaned with fine-grained sandpaper.

- Reverse, insufficient or excessive draft. The draft sensor responds to all situations by turning off the burner.

Problems with traction are most common in non-volatile installations, where the stability of the unit’s operation depends on it.

If the draft is too weak, the sensor turns off the burner due to the possibility of smoke in the room.

Excessive draft is dangerous due to the possibility of the flame on the burner exploding, which will provoke the supply of gas into the room with unpredictable consequences. Therefore, an increase in draft against the set value is also an emergency event, leading to the boiler stopping.

Official website: where to view all models and operating instructions

A snapshot of the official website of Lemax Russia.

In Russia, the official website of the manufacturer is located at https://lemax-kotel.ru/.

By going to the “Catalogue” menu section, you can see all available models and their descriptions, detailed technical specifications. Under each model there is a “Documents” tab, where you can find an electronic copy of the operating instructions (aka boiler passport), which describes in detail all the features of the device, installation requirements and connection diagrams, the algorithm for turning on and adjusting the operation, maintenance features, there are clear schematic images.

Which boiler model is ultimately better to choose?

The optimal, most popular and, perhaps, one of the best on the market in terms of price-quality ratio is the non-volatile floor-standing Lemax Premium with a steel heat exchanger. For this price you can get a boiler unit with excellent characteristics, build quality, reliability, but with the most basic functionality, large dimensions, installation and commissioning requirements, and a service life of 10-15 years (2-year warranty).

However, if the budget is not so limited, we recommend choosing cast iron models: the non-volatile Lemax Leader or the volatile Lemax Wise. The first is almost the same, but cast iron “Premium”, and Wise is a functional, durable, but expensive model.

Wall-mounted models can be considered if space saving or a closed type of combustion chamber with a coaxial (side) chimney is required. However, we recommend paying attention to foreign wall-mounted convection boilers of similar cost.

The main thing in choosing is to determine the required boiler power. For an average house in the climatic zone of the Moscow region, with a masonry of 2 bricks and a ceiling height of 2.7 m, the minimum required power of heating equipment is calculated from a simple rule: 1 kW for every 10 m2 of area. We also recommend a reserve of 15-20% (25-30% for dual-circuit models).

For example, having the above-described house with an area of 150 m2, the minimum required power is 150/10 * 1.2 (20% reserve) = 18 kW.

If the house is well insulated (for example, polystyrene foam 10 cm thick) or is located in the extreme southern point of a country with a warm climate, the result can be adjusted downward by 5-30%.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Device

The main design element of the Lemax Premium 16 boiler should be considered a gas burner. It is surrounded by a heat exchanger, forming a water jacket around it.

This increases the efficiency of coolant preparation and increases the internal volume of the heat exchanger, which is important for dual-circuit models . DHW preparation is carried out inside a copper coil located inside the heat exchanger, so its size is significant.

The specified gas supply mode is ensured using an Italian-made gas valve, and smoke is discharged through an opening in the upper part of the combustion chamber. The chimney is connected to a corresponding hole in the top of the boiler.

The connections for connecting the heating circuit are located on the rear side. Gas supply adjustment and burner ignition are located inside the front part of the boiler; to gain access, you need to remove the front panel .

How to turn on and light: brief instructions

Designation of boiler control elements.

If on volatile models with electronic controls, starting the boiler is intuitive and consists of pressing several buttons, then on budget non-volatile models with EuroSit automation this is a more complex algorithm:

- Before lighting the boiler, make sure that the gas supply valve is open, check the draft in the combustion chamber, for example with a match.

- Set the mechanical thermostat (rotator) to the “Off-0” position, and then counterclockwise all the way to the “⭐” position.

- Press and hold the magnetic valve button (the start button in the center of the thermostat) for 30 seconds, then press the piezo ignition button near the thermostat once without releasing the start button. At this moment the pilot burner should light up; if this does not happen, repeat the steps. If the wick burns steadily, continue to hold the trigger button for 30-60 seconds, after which you can gradually release it.

- Rotate the thermostat to set the desired power level (1 – minimum temperature, 2 – maximum temperature).

The appearance of the controls may vary slightly depending on the automation (630 EuroSit, 710 MiniSit or 820 NovaSit). The detailed algorithm is always described in the operating instructions.

How to completely turn off the boiler

- Turn the thermostat to the “⭐” position. The main burner should turn off, but the pilot burner (wick) will burn.

- To completely turn off the gas supply, turn the thermostat knob to the “Off-0” position, and then do not forget to turn off the gas supply valve.

Automation systems

Modern gas boilers are equipped with two types of automation:

Working

Controls the operation of the boiler (controls power or switches it on/off) in order to maintain the temperature of the coolant or air in the room at a user-specified level (depending on where the temperature sensor is installed).

The most “advanced” is weather-dependent automation, which takes into account the outside temperature and therefore adjusts the boiler operating mode in a more timely manner.

At the same time, the system controller constantly “learns”, remembering how the temperature in the room changes at certain boiler heating outputs and outside temperatures.

Security automation

- traction;

- coolant overheating;

- flame on the burner.

If the boiler has an igniter, then a thermocouple is also connected to the valve, which blocks it when the igniter goes out.

Other sensors block the gas supply in case of emergency situations - deterioration of draft, overheating of the coolant or extinguishment of the flame on the main burner.

Known malfunctions of Lemax boilers

Serious service complaints for Lemax boilers are rare. However, as with any other equipment, breakdowns are possible, the most common of which are a thermocouple that converts thermal energy, a weak electric current sufficient for the operation of the automation, as well as a draft sensor necessary to control draft and emergency stop of the boiler in its absence .

It is worth noting that often the thermocouple does not necessarily need to be replaced. If its contacts have oxidized, you need to carefully clean it with sandpaper and check the operation again. Otherwise, the service life of boilers is limited only by the life of the heat exchanger.

Now let's look at the most common questions that are usually not related to a malfunction (click to expand the answer):

+ Why does the main burner go out?

There can be many reasons, we have already listed all of them in one of the previous articles. Usually the cause is low gas pressure, clogging, weak draft, but most often the cause is reverse draft, when the burner flame blows out during strong gusts of wind. This happens due to errors in the design of the chimney: its overall height and height relative to the roof ridge are insufficient, and the lack of a protective deflector on the headband.

+ The boiler does not turn on, the wick or main burner does not light

If you checked the draft, it is there, there are no backdraft phenomena, most likely the problem is a clogged ignition nozzle. It is necessary to disassemble the boiler, removing the burner module and carefully clean the igniter first (blow it out, pierce the clogged hole with wire), and then the burner. Be careful not to allow even the slightest scratches or deformations; before disassembling, always photograph the position of all components. If there is no spark when igniting, the piezo ignition is faulty, but first you should try to carefully clean all contacts with sandpaper.

How to clean a gas boiler yourself: detailed instructions

Features of operation

Installation, connection, startup, configuration and maintenance must comply with the manufacturer's requirements. Each model comes with detailed instructions for the user to follow. To avoid problems, it is recommended to follow the operating rules:

- Before lighting the wick, the room is ventilated. The firebox is ventilated for 5–10 minutes. The knob that controls the burner must be closed.

- Checking traction: Apply a thin strip of paper to the holes located at the bottom of the front panel. If there is traction, the strips will be pulled into the holes. If there is no draft, lighting the gas burner is strictly prohibited.

- If the draft is sufficient, light the paper tourniquet by pressing the valve button. The flagellum is brought to the wick. When the fire becomes steady, the button is released.

- Smoothly open the control knob and make sure that the fire from the wick lights on the main burner.

- The air supply to the main burner is regulated by appropriate regulators; air must be supplied in the amount necessary to establish a stable blue-blue flame.

- While the equipment is operating, it would be a good idea for the user to periodically monitor the gas and traction. The fuel must burn without leaving soot. The color of the flame is blue-blue. Combustion should not be accompanied by hissing or popping noises.

Why does the boiler go out?

Causes of burner extinguishing and troubleshooting:

Ice build-up on the boiler head

They must be removed extremely carefully; you cannot rush - you can damage the system. Ice frozen inside, on the walls of the tip, blocks the access of air, and the flame goes out.

Defrosting is carried out slowly by removing the head of the device. Then it is brought indoors to allow the ice to thaw. While defrosting is in progress, the equipment can operate without the removed part. The pressure in the gas line has dropped. The gas distribution network or gas meter may be faulty. If the meter is broken, gas does not flow in the required volume - a problem is indicated by sounds that are not characteristic of the meter. The cause of a drop in pressure can also be a breakdown of temperature sensors or a violation of the tightness of connections. When the pressure drops, the automation signals a problem - the system turns off. You may smell gas. To solve the problem, you need to check the tightness of the connections using a damp sponge and soap foam. If there is a leak, bubbles will appear. We urgently need to call the gas workers.

How to remove soot

To clean the boiler from soot, you will need a set of tools:

- a metal brush or brush for cleaning surfaces;

- another brush needs to be purchased to clean the chimney - made of metal or plastic;

- scraper;

- steel cable;

- brush holder;

- hooks

Sequence of work:

- Shut off the fuel supply.

- Remove the door, thermocouple, nozzle, and burner tube.

- Remove the top panel.

- Remove thermal insulation.

- Remove the chimney.

- Clean the heat exchanger with a wire brush.

- To clean the heat exchanger channels you will need a vacuum cleaner.

- Clean the walls of the boiler with a brush and wipe with a rag.

- Clean the chimney with a brush. If it is too long, a steel cable may be needed.

When cleaning is completed, the device components are assembled in the reverse order.

Service

Maintenance requirements are quite simple, typical of all gas boilers.

- Annually inspect all connections and components of the heating system, the boiler itself, and light cleaning of the burner module.

- Every 2-4 years it is advisable to mechanically clean the heat exchanger; a feature of Lemax boilers is a removable top panel, which makes the task easier.

- Every 4-7 years we recommend cleaning the boiler heat exchanger to remove scale.

All points can be completed either independently or with the involvement of specialists (which, of course, is more effective and safer).

Connecting a room thermostat

A room thermostat is a convenient and useful device that allows you to regulate the temperature of the air, not the coolant, in the heating system. The default sensor monitors the outlet temperature of the heating agent.

This does not give a correct picture of the state of the microclimate in the room. For example, when the outside temperature rises, the room becomes hot.

But the sensor cannot track this, and the extract air temperature is within the limits specified by the mode, so from the point of view of the system, everything goes fine, in accordance with the boiler settings.

If a room thermostat is used, the burner will turn off much earlier, which will improve the microclimate in the room and significantly reduce gas consumption.

To connect the room thermostat, you need to set the boiler's own element to the maximum temperature.

It will only work as a limiter when overheating. The external unit is connected at one end to the automation unit, and at the other to the boiler thermostat. By default, a jumper is installed between the contacts, which must be removed and the thermostat connected.

Prices: summary table

| Model | Heat exchanger material | Available power, kW | Efficiency, % | Cost, rub. |

| Floor-standing | ||||

| Premium | steel | 7,5; 10; 12,5; 16; 20; 25; 30; 35; 40; 50; 60; 70; 80; 90; 100 | 90 | 23 700-95 000 |

| Leader | cast iron | 16, 25, 40, 50 | 90 | 60 500-70 000 |

| Wise | cast iron | 16, 25, 35, 40 and 50 | 90 | 57 000-81 300 |

| Clever | steel | 20, 30, 40, 55 | 90 | 32 000-75 000 |

| AOGV "Gazovik" | steel | 6; 8; 11,6; 13,5; 15,5; 23,2; 29 | 86 | 13 800-24 000 |

| Wall mounted | ||||

| Prime-V | copper | 10, 12, 14, 16, 18, 20, 24, 26, 28, 32 | 92,5 | 31 500-40 000 |

| Prime-C (condensing) | steel | 24 | 108 | 46 800 |

| Parapet | ||||

| Patriot | steel | 6; 7,5; 10; 12,5; 16; 20 | 87 | 21 900-25 000 |