A double-circuit boiler gives a certain independence from central heating and allows you to always have hot water in the house. Although in general, double-circuit models are somewhat more expensive than single-circuit ones, their purchase can be more profitable, since it also allows you to replace the boiler. Which is the best wall-mounted double-circuit gas boiler to buy for your home? We will tell you what important criteria you should pay attention to when choosing and give a rating of double-circuit wall-mounted gas boilers in 2022.

What are turbocharged gas boilers?

A turbocharged gas boiler is a unit responsible for heat supply, which is additionally equipped with a forced air exchange system. Due to this feature, it does not require the construction of a full-fledged smoke shaft, since communication with the external environment occurs through a coaxial chimney.

A coaxial chimney is a continuous structure (usually included with the boiler), consisting of pipes of different diameters, nested one inside the other. Oxygen is taken in through the external channel (large pipe), and waste combustion products are discharged through the central channel (smaller pipe).

Since turbo boilers do not need high-quality ventilation of the room itself, they can be installed both in private houses and in city apartments.

The main and, perhaps, the only significant disadvantage is that due to the presence of a turbine and more complex automation, they are extremely energy dependent.

Design and principle of operation

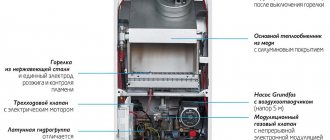

The basic structure of a turbo boiler is not much different from its predecessor, but the presence of auxiliary components makes some changes to its design.

The air necessary to maintain combustion comes from the street directly into the closed combustion chamber. Since it is isolated from the living space and directly connected only to the coaxial chimney, this completely eliminates any influence of exhaust gases on the internal microclimate.

Design of a floor-mounted turbocharged model.

A fan (turbine) removes smoke outside the house without the use of exhaust fans, creating excess pressure (turbocharging).

The rotation speed of the turbine fan is adjusted automatically, so even when the gas pressure in the line decreases, the composition of the gas-air mixture remains optimal. When changing power, the speed is instantly selected to provide the required amount of air and proper traction. In this way, the best conditions for burner operation are maintained, allowing the greatest amount of energy to be obtained from the fuel.

How to choose a room thermostat and save up to 30% per month on heating

Aspirated or turbocharged: which is better?

A traditional atmospheric boiler has an open combustion chamber: air for gas combustion is taken from the room. This means that the spent oxygen must be completely replaced with new oxygen. This requires supply and exhaust ventilation.

Without organizing good supply and exhaust ventilation, normal operation of an atmospheric gas boiler is impossible. Firstly, the fuel will not be able to burn completely and, as a result, the coolant will lose some amount of heat, and secondly, life-threatening carbon monoxide (CO) - carbon monoxide - will form in the room.

Therefore, for small buildings, where it is problematic to select a ventilated boiler room with a vertical chimney separate from the living area, it is better to choose a turbocharged boiler. And for gas heat supply of small retail spaces, offices and standard high-rise buildings, it is generally the only option.

Rules for smoke removal in turbocharged gas units

Exhaust gases from turbocharged gas boilers must be removed only through a coaxial chimney. To install it correctly, the following requirements must be met:

- the pipe should be located horizontally with a slight slope towards the street; if the boiler is a condensing boiler, then the slope should be towards the unit so that the condensate can drain into the condensate receiver;

- the chimney should be installed in accordance with the instructions supplied with the device;

- the pipe is placed 1.5 m above the combustion chamber;

- protection is placed on the head of the pipe to prevent debris and insects from entering it;

- the maximum length of the horizontal section of the chimney is 3 m, but some manufacturers make a 5 m chimney;

- the distance from the pipe to window and door openings must be at least 0.5 m; to the window above the chimney – 1 m;

- in a wooden house, a gap of 5 cm should be left between the pipe and the wall; it is filled with basalt wool;

- You cannot arrange more than 2 rotary bends.

Some manufacturers equip their gas boilers with a coaxial chimney.

If this is not provided, then it is better to choose a pipe from the same manufacturer as the heating device. The suitable diameter of the coaxial chimney for a specific model of turbocharged unit is indicated in the instructions. The pipe design must have a closing hole to allow it to be cleaned from soot and a condensate collector leading into the sewer. Note! In exceptional cases, if the chimney cannot be brought out horizontally, the chimney is installed vertically in compliance with technical requirements.

Reviews of household models with forced air exchange: advantages and disadvantages

According to reviews from owners of turbocharged gas boilers, the following pros and cons can be identified:

| Advantages | Flaws |

| safety - the tightness of the closed combustion chamber virtually eliminates the risk of smoke entering the room | high cost - prices for wall-mounted models are higher by 20-30%, for floor-mounted ones - by 20-50%, but you can eliminate the cost of building a full-fledged chimney |

| free placement - air intake from the street allows you to install the boiler in very small rooms (of course, meeting the requirements) | constant noise - the active operation of all turbo boilers is inevitably accompanied by a monotonous sound of fan rotation, its volume depends on the model, as well as the presence of a sound insulation layer in the boiler |

| simple installation of the chimney - to output the coaxial pipe, just make a hole (Ø 110) in the outer wall of the house | Volatility dependence - any problems with voltage (interruptions, non-compliance with the norm) cause the fan to stop |

| low fuel consumption - efficiency is achieved due to automation, which controls the turbine rotation speed |

Difficulties with energy supply can be easily avoided by connecting a voltage stabilizer and a backup power source to the turbocharged boiler - an electric generator (gasoline, diesel) and an uninterruptible power supply (UPS). However, it must be taken into account that this will lead to additional material investments.

Possible malfunctions of turbocharged units

Most breakdowns of double-circuit gas boilers are caused by installation errors or improper operation. Many people complain about the gas unit fading. Most often this is caused by the following reasons:

- Poor draft - occurs due to non-compliance with the rules for installing the chimney: exceeding the permissible vertical and horizontal sections or lack of slope.

- Voltage instability in the electrical network causes malfunctions in the sensitive automation, which gives a signal to stop burning.

- Failure of the draft or combustion sensor results in the device turning off.

For the proper operation of a turbocharged unit, good draft is very important, since its lack can lead not only to burner extinguishing, but also to the occurrence of reverse draft. This will cause carbon monoxide to enter the room, which is very dangerous. You can improve traction in the following ways:

- install a deflector that increases traction by 1.5 times;

- equip the chimney head with a wind protection.

If the situation has not changed for the better, then the coaxial pipe must be removed and remade in accordance with technical requirements.

Turbocharged double-circuit gas heating boilers depend on electricity supply, so in regions where power outages occur frequently, it is better not to use them. To extend the service life of a volatile unit, you should purchase and install a voltage stabilizer.

Find out here which double-circuit gas boiler is suitable for heating an apartment?

Boiler for a double-circuit gas boiler - built-in, indirect or electric

Review of double-circuit gas boilers with a power of 20 kW

How to choose a turbocharged gas boiler for heating a private home

Wall or floor

Wall-mounted models fit perfectly into the kitchen interior or can be completely hidden in a closet.

- floor-mounted ones are more versatile and durable, since the design is unlimited in weight; they often have durable cast iron heat exchangers installed.;

- mounted (wall-mounted) - compact and lightweight, medium and low power (10–50 kW) boiler units, often having greater efficiency than floor-standing models. However, due to weight requirements, they use less corrosion-resistant steel and copper heat exchangers.

In addition, wall-mounted boilers contain all the necessary heating system modules in one housing (expansion tank, circulation pump, safety valve, air vent, etc.), which not only simplifies, but also makes installation cheaper. Floor-standing models are rarely equipped with all the necessary modules.

Single-circuit or double-circuit

The functionality of a turbo boiler is determined by the number of circuits:

- single-circuit - its capabilities are limited exclusively to heating;

- double-circuit - along with heating, it heats water for domestic needs.

A double-circuit boiler is a combination of a boiler and a flow-through heater, i.e. heating of the room stops while hot water is supplied. It is worth clarifying that, contrary to popular belief, the coolant does not have time to cool down during downtime, so the temperature in the home remains unchanged.

Of course, the cost of the double-circuit option is 10–30% higher, but it is still more profitable than organizing hot water supply in any other way, for example, using a boiler and a single-circuit boiler. And if necessary, one of the circuits can be turned off - for example, in the summer, when there is no need to heat the home.

Heat exchanger type and material

A copper heat exchanger is the most optimal option for a wall-mounted model.

The heat exchanger material affects the durability of the boiler:

- cast iron (service life 25–30 years or more) is the most heat- and corrosion-resistant metal, but fragile and heavy, therefore it is used only in floor-standing models;

- copper (service life 12–17 years) is a very light and thermally conductive metal (it heats up and cools down quickly), is slightly susceptible to corrosion, but can burn out.

- steel (service life 10–15 years) - metal tolerates transportation well, because it is not sensitive to physical impact, lightweight and inexpensive to produce, but is prone to rust, which leads to leakage over the years.

Double-circuit boilers are also divided according to the type of heat exchanger: separate (one for each circuit) and dual - bithermic (the hot water circuit passes through the main heat exchanger). The latter option is cheaper, but it is less reliable, because the scale formed in it is almost impossible to clean, and it is clogging with scale that often becomes the cause of premature failure.

Efficiency

Despite the fact that the “pure” efficiency of the atmospheric (90–92%) and turbo boiler (92–95%) is almost the same, the second will have higher gas consumption efficiency.

The point is in using a coaxial chimney: when cold air from the street enters its external cavity, it begins to heat up even before entering the combustion chamber from the heat of the smoke (100–130 °C), which exits through the internal cavity of the same pipe. Therefore, less resources are spent on further heating. It’s also worth adding more efficient control of air flow and draft, which also affects gas consumption.

Minimum required power

You can calculate the required power of a turbo boiler using a simple formula: where 1* kW of energy is consumed per 10 m2 of heated area.

* heat loss of an average residential property with ceilings up to 2.7 m from central Russia.

For example, for a standard house in the Moscow region with a masonry of 2 bricks and a ceiling height of 2.7 m, with an area of 120 m2, the minimum suitable power of a turbo boiler will be Q = 120 ÷ 10 × 1 = 12 kW.

We recommend setting aside a margin of 15–20% of this value so as not to operate the unit at the limit, so for the same object Q≈14–15 kW.

Also, if we consider a two-circuit model, then we will have to add at least 15–20% for the use of hot water supply, so in total it will turn out that Q≈16–17 kW. It is also important not to overdo it with power, otherwise the boiler will “clock” too often (turn on and off), which will reduce its resource.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

The principle of operation of a turbocharged boiler

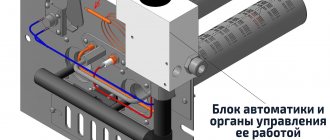

The name “turbocharged” means that the boiler has a turbine, that is, a fan that supplies air, supports combustion and removes combustion products. The design assumes a closed combustion type and a smoke removal system with several turns.

When fuel burns, a certain amount of heated gases are released. To increase efficiency through increased heat transfer, the design provides for the passage of these gases through channels, where they give off their heat, increasing efficiency. In this way, it is possible to reduce the temperature of the exhaust gases to 100-120°C. To understand how a turbocharged gas boiler works, you need to understand how equipment with a closed combustion type works.

Such units are connected to a coaxial chimney or to a “pipe-in-pipe” system: the inner pipe is used to remove gases, and the interpipe space is used to supply outside air. In equipment of this type, air circulation and smoke removal occurs using a fan, the intensity of which depends on the gas pressure. It is connected to automation.

When the gas pressure changes in the system, the automation sends a signal to change the rotation speed. However, it is worth understanding that the system is characterized by noise and, in order to reduce its level, at the beginning of the boiler operation it is necessary to set the minimum mode. Controlling the turbine operating mode makes it possible to regulate the degree of heating.

The best known manufacturers and models: characteristics and prices

BAXI ECO-4s 24F

The Italian double-circuit turbo boiler with a power of 24.0 kW was designed taking into account the specifics of Russian conditions, so it is adapted to work with low gas pressure, power outages and other unstable indicators. It also has one of the best efficiency in its price segment - 92.9%, gas consumption - 2.54 m3/h. The primary heat exchanger is made of copper.

The owners note almost silent operation; after using it for more than 5 years, there were no serious service complaints.

Manufacturer: BAXI (BAKSI), Italy.

Vaillant turboTEC pro VUW 242/5-3

Double-circuit model from the reference German brand with a power of 24 kW. It is particularly reliable and durable due to excellent build quality, the use of high-tech alloys and the best materials. Efficiency 91%, maximum gas flow 2.80 m3/h. It also features a copper primary heat exchanger, a modulating burner, functional automation with many safety systems and a pleasant, stylish design.

Manufacturer: Vaillant (Vailant), Germany (assembled in Slovakia).

Viessmann Vitopend 100-W A1HB001

One of the best gas turbocharged boilers for heating a private home and another reference German model with a capacity of 24 kW. Like the previous Vaillant turboTEC, it is highly reliable and durable, while the boiler is absolutely not demanding on the quality of the coolant and the pressure in the gas line. Efficiency – 91%, maximum gas flow – no more than 2.77 m3/h.

A serious advantage is the presence of a programmer that allows you to set the boiler operation settings for the next day or week, for example, setting the temperature to 15°C during working hours when the owners are not at home, which will significantly reduce operating costs.

The only common problem is the boiler turning off due to icing of the chimney at frosts below -17-18°C. The solution is to monitor the condition of the chimney and promptly remove ice, insulate its outer part or install an anti-icing structure.

Manufacturer: Viessmann (Wisman), Germany.

Buderus Logamax U072-24

Wall-mounted turbocharged gas boiler with a power of 24.0 kW. In fact, this is another reference German model, but with Russian localization, which made it possible to significantly reduce its cost and distinguish it from analogues. Efficiency – 92%, maximum fuel consumption – 2.8 m3/h. The boiler is also equipped with a copper primary heat exchanger and a modulated burner.

The only drawback is the lower Russian build quality, which is not typical for other German and Italian models.

Manufacturer: Buderus (Buderus), Germany-Russia.

Navien GA 23KN

A floor-standing double-circuit turbo boiler with a power of 23.0 kW has a modest gas consumption of 2.24 m3/h. It is equipped with unique protection against voltage surges: with a difference of ± 30%, the SMPS chip on the microprocessor is activated, which allows you to continue working without the risk of damaging the electronics. At the same time, the boiler is equipped with a modulating burner, a programmer, and a room thermostat and remote control are already included in the factory configuration.

Notable disadvantages are the steel heat exchanger, mediocre build quality, and noisy operation relative to the above models.

Manufacturer: NAVIEN (NAVIEN), South Korea (often with Russian assembly).

Turbocharged or naturally aspirated?

When the buyer is faced with the choice of which boiler is better to choose: turbocharged or atmospheric, all the features of their design and operation should be considered. The main difference is that in an atmospheric boiler the fuel combustion process occurs in an open manner with natural air exchange, which is why such equipment is often called convection. Such boilers are connected to a standard chimney, and the air for the combustion process is taken from the boiler room.

When using atmospheric boilers, there is an increased gas consumption and strict installation requirements regulated by SNiP. Also, atmospheric equipment must not be used in multi-story buildings and during installation the housing must not be covered with decor. In a turbocharged boiler the combustion chamber is closed. Forced air exchange and removal of flue gases using a turbine are used. During operation, air from the combustion chamber is not used during fuel combustion.

Therefore, the regulations allow the installation of such equipment in small rooms, decorating the housing, close to the meter. Turbocharged gas boilers are connected to a coaxial chimney, which serves both for the supply of outside air and for the removal of combustion products.

Therefore, the main difference compared to atmospheric boilers is forced air exchange and smoke removal.

Prices: summary table

Comparative rating of popular turbocharged gas boilers:

| Unit model | Efficiency, % | power, kWt | DHW, l/min. | Flow, m3/h | price, rub. |

| BAXI ECO-4s 24F | 92,9 | 24 | 13,7 | 2,54 | 43 500 |

| Vaillant turboTEC pro VUW 242/5-3 | 91 | 24 | 11,5 | 2,80 | 76 000 |

| Viessmann Vitopend 100-WA1HB001 | 91 | 24 | — | 2,77 | 51 000 |

| Buderus Logamax U072-24 | 92 | 24 | — | 2,80 | 37 500 |

| Navien GA 23KN | 91,5 | 23 | 13 | 2,24 | 40 500 |

Installation features

The presence of a coaxial chimney determines some differences in the installation of turbocharged gas boilers and atmospheric ones. In addition, the installation technology is influenced by the type of unit design - floor or wall.

After installing the boiler on the floor or mounting it on the wall, it is connected to the heating circuit main and to the gas pipeline. The next step is connection to the power supply network. In this case, it is necessary to fulfill two conditions - the use of a voltage stabilizer and grounding of the unit housing.

Next, you can begin installing the coaxial chimney. All structural elements must be factory-made and connected to each other without the slightest gap; however, it is not allowed to join pipes inside walls or ceilings.

As a rule, gas boiler manufacturers recommend that installation work be carried out only by qualified specialists. Such devices include, for example, the Vaillant Turbo TEK Pro gas boiler, the instructions for which warn that the unit must be installed by a specialist certified by the manufacturer, otherwise the Vaillant warranty will become invalid.

Important! According to fire safety requirements, the openings through which chimneys are discharged should be sealed with fire-resistant material.

There are several options for laying the exhaust pipe: horizontally, vertically or at an angle. Most often it is mounted horizontally through the wall of the house. When installing a chimney horizontally, it is necessary to ensure that it slopes slightly towards the street to allow the condensate generated during operation of the gas unit to drain out. You can read about what a condensing gas boiler is, as well as its advantages, by following the link.

If it is not possible to lay the chimney horizontally, it is installed vertically and led out through the roof. In this case, care should also be taken to remove condensate during operation of the boiler.

The best manufacturers of turbocharged boilers

The most popular and high-quality equipment is produced by German companies. Italian and French companies follow. A number of Russian enterprises have mastered the production of turbocharged boilers, and their quality is approaching the level of world brands.

The first in the quality rating is the products of the following companies: Buderus, Bosch Gas, Protherm, Vaillant . Slightly inferior to them: Baxi, Neva Lux, Arderia .

Next come slightly inferior Korean brands: Navien, Daewoo, Kiturami, Hydrosta .

Wall-mounted turbo boilers

Photo: idroclimaterm.it

Wall-mounted turbocharged boilers are very common, as they are compact, have a beautiful design and are easy to install.

Wall-mounted boilers have the following features:

- simple installation and connection;

- fast heating. Despite the fact that water is heated using a flow method, it occurs instantly;

- weather-dependent automation, burner with modulation capability.

The most popular are double-circuit turbocharged boilers, since single-circuit boilers are convenient for use only for heating non-residential buildings.

Floor-standing turbocharged boilers

Floor-standing turbo boilers generally have high power and are reliable in operation.

When choosing a floor option, you should analyze the following characteristics:

- heat exchanger material (cast iron or steel). Cast iron is more reliable and durable (up to 35 years), but steel is cheaper;

- number of circuits: can be single-circuit or double-circuit. Some models have a built-in tank for preparing hot water. If there is no need for DHW, then you can use a single-circuit floor-standing boiler, which copes well with heating large areas, since there is no energy consumption for DHW.

The disadvantage of floor-mounted turbocharged boilers is their size. This is important when placing it in a small area. The advantage is reliability; all components and parts of the boiler are made of durable materials due to the absence of weight restrictions. Such boilers last about 5 years longer than wall-mounted ones.